Introduction

It is strongly recommended to assemble the StrongHold PRO CNC using two or more people. Certain steps of the assembly require moving parts which are both large and extremely heavy.

Once fully assembled, the rough total weight of the various machine sizes are as follows:

(Note: These values exclude the weight of the spindle, spindle mounts, wiring and spoil board)

1000x1000: 90KG

1000x1500: 100KG

1500x1500: 115KG

These provided weights can be roughly split 60:40 between the machine base and the X-axis gantry.

-

-

Several of the StrongHold PRO printed parts have sacrificial layers which need to be removed prior to assembly

-

It is recommended to remove them by using a screwdriver, a hex key, or a drill, to push through the layers. This clears the holes for the screws.

-

sh_pro_x_dragchain_mount_cap printed part

-

Sacrificial layers to be cleared

-

Prepared printed part

-

-

-

The following printed parts have sacrificial layers which require clearing:

-

Z-axis transmission cover

-

X-axis drag-chain mount - upper

-

X-axis drag-chain mount - lower

-

Y-axis endstop mount

-

-

-

It is recommended to have the following tools available for assembling the StrongHold PRO CNC:

-

Allen Key / Hex Wrenches in the following sizes: 2.5mm, 3mm, 4mm, 5mm, 6mm & 10mm

-

Tape measure or calipers

-

Engineers Square

-

Open end spanners in the following sizes: 5.5mm, 7mm, 8mm, 13mm & 19mm

-

Wire cutters, wire stripper & a crimping tool

-

Circlip Pliers

-

Cross slot / philips and slotted / straight screwdrivers

-

-

-

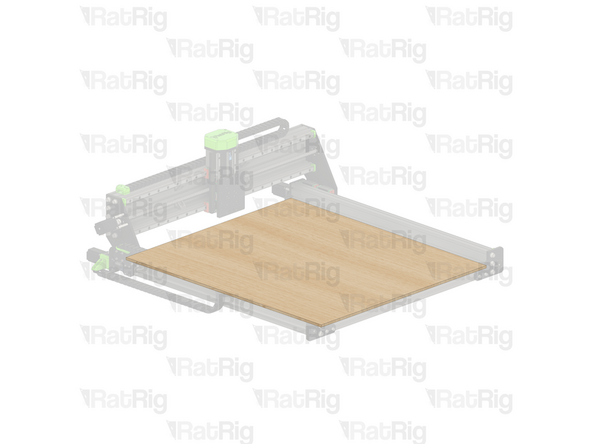

The spoil board is not provided as part of the kit, and must be sourced separately

-

The size required depends on which StrongHold PRO model is being assembled:

-

SH PRO 1000x1000: 1050x1216mm

-

SH PRO 1000x1500: 1050x1716mm

-

SH PRO 1500x1500: 1550x1716mm

-

The thickness of the spoil board will affect the maximum working height

-

It is recommended to use a spoil board which is at least 10mm thick

-

-

-

Occasionally you will need to install a hex nut into a printed part

-

The hex nut needs to be fully pulled into the printed part to ensure there are no issues with assembly or cross threading

-

This animation shows an example of how to use a cap head screw to pull a hex nut into a printed part

-

-

-

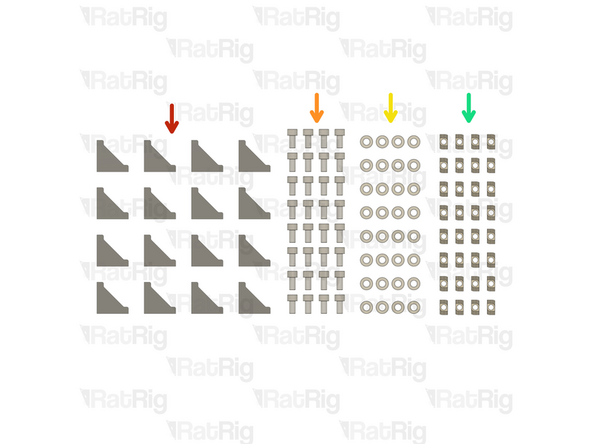

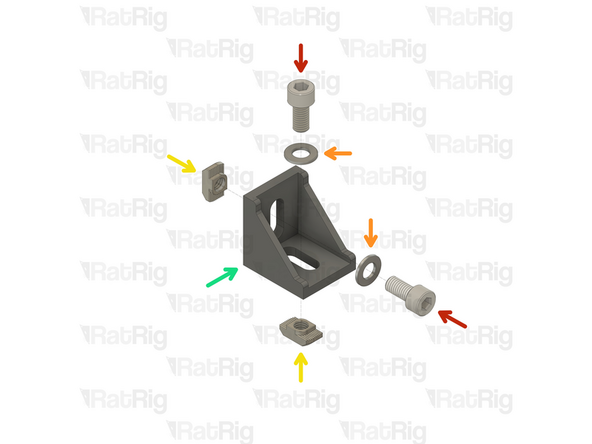

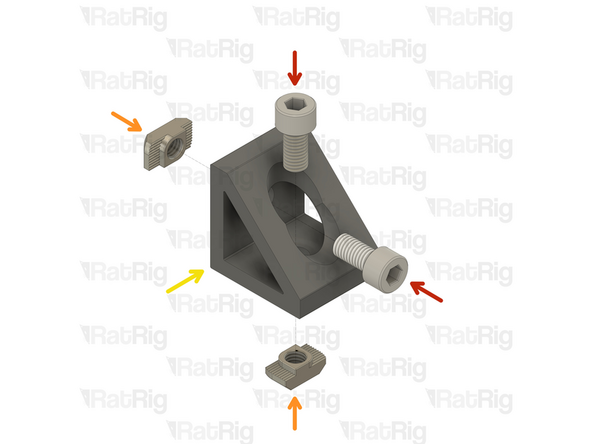

16x 4040 Cast 90 Degree Corner

-

32x M8x16 Cap Head Screw

-

32x M8 Washer

-

32x 4040 Drop-in T-Nut - M8

-

-

-

M8x16 Cap Head Screw

-

M8 Washer

-

4040 Drop-in T-Nut - M8

-

4040 Cast 90 Degree Corner

-

Loosely thread the 4040 T-Nuts on to the M8x16 screws. Do not tighten them at this point.

-

-

-

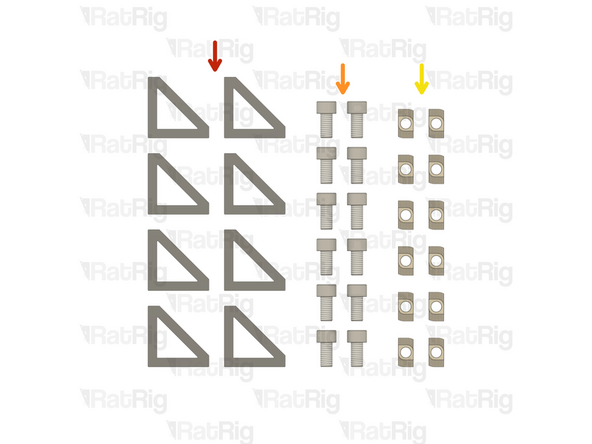

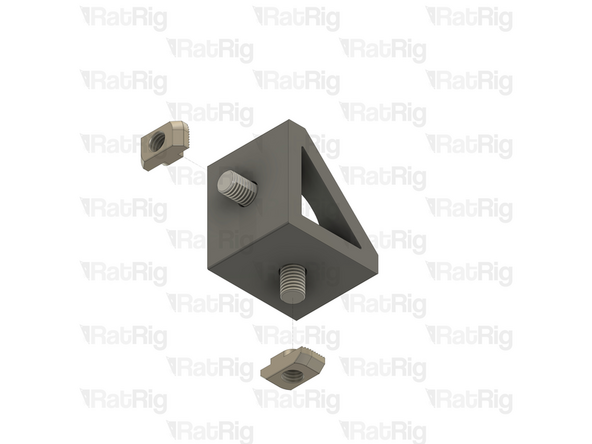

8x 4040 Extruded 90 Degree Corner

-

12x M8x16 Cap Head Screw

-

12x 4040 Drop-in T-Nut - M8

-

-

-

M8x16 Cap Head Screw

-

4040 Drop-in T-Nut - M8

-

4040 Extruded 90 Degree Corner

-

Loosely thread the 4040 T-Nuts on to the M8x16 screws. Do not tighten them at this point.

-

-

-

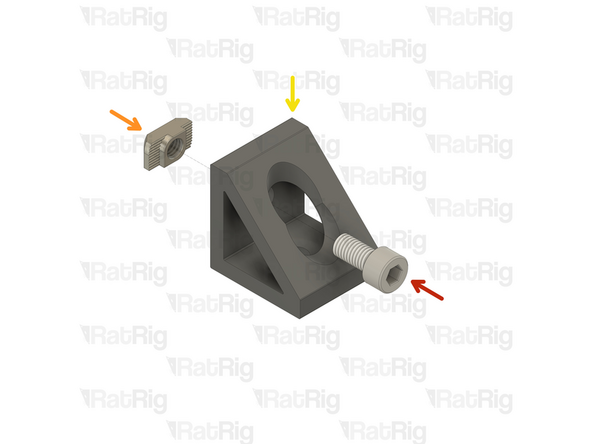

M8x16 Cap Head Screw

-

4040 Drop-in T-Nut - M8

-

4040 Extruded 90 Degree Corner

-

Loosely thread a 4040 T-Nut on to the M8x16 screw. Do not tighten it at this point.

-

Cancel: I did not complete this guide.

2 other people completed this guide.