Introduction

Please note: All measurements provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, the following adjustments can be made to the stated extrusion lengths:

- 200x200: Remove 100mm

- 400x400: Add 100mm

- 500x500: Add 200mm

-

-

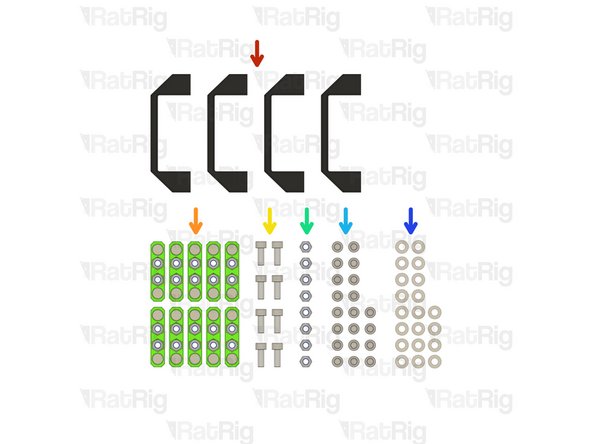

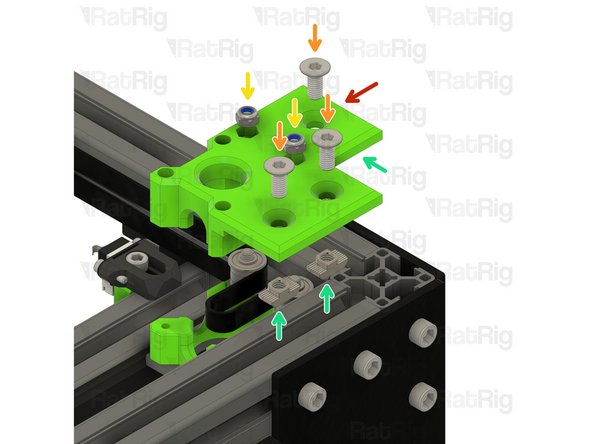

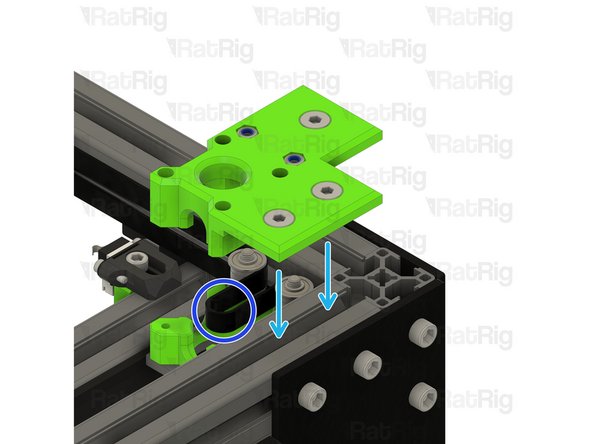

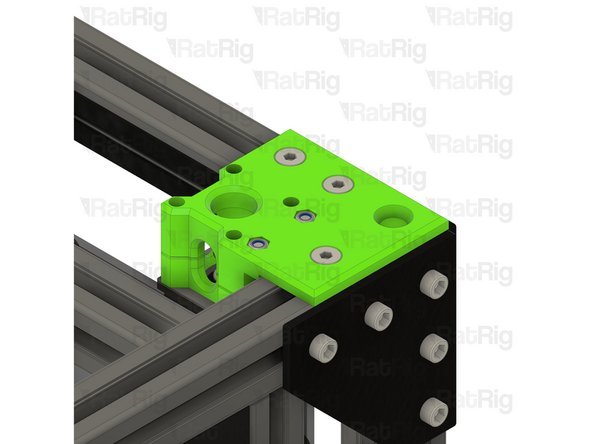

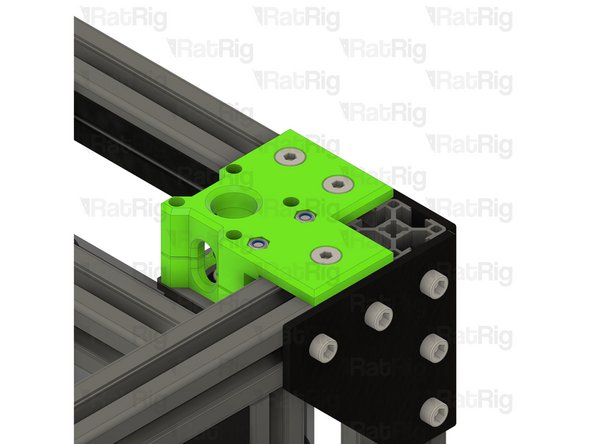

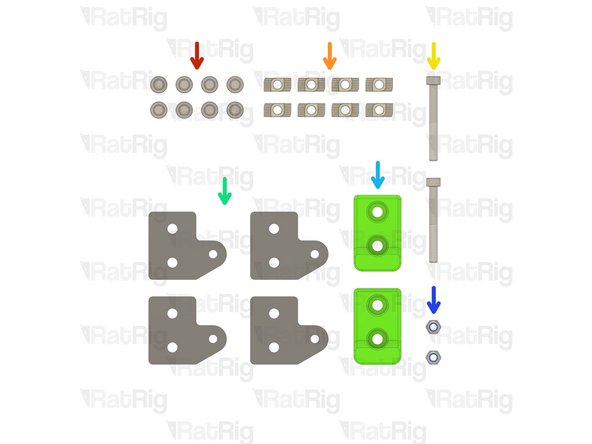

6x T-Shape Joining Plate for 3030

-

30x M6x12 Cap Head Screw

-

30x 3030 Drop-in T-Nut - M6

-

-

-

M6x12 Cap Head Screw

-

3030 Drop In T-Nut - M6

-

T-Shape Joining Plate for 3030

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Set these plates aside until Step !!

-

-

-

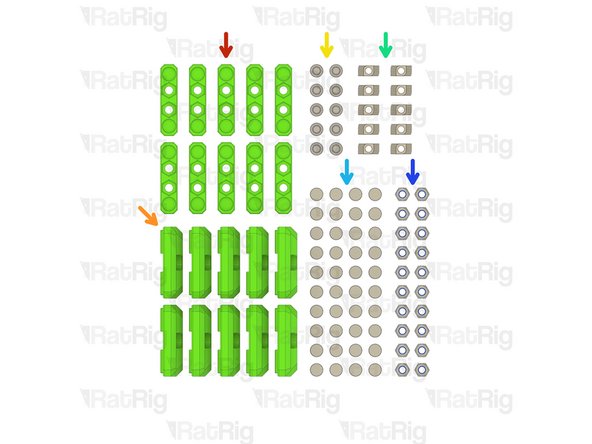

10x panel_magnet_holder printed part

-

10x panel_magnet_mount printed part

-

10x M6x12 Cap Head Screw

-

10x 3030 Drop-in T-Nut - M6

-

40x Neodymium Disc Magnet - 10x4mm

-

20x M6 Nylon Locking Hex Nut

-

-

-

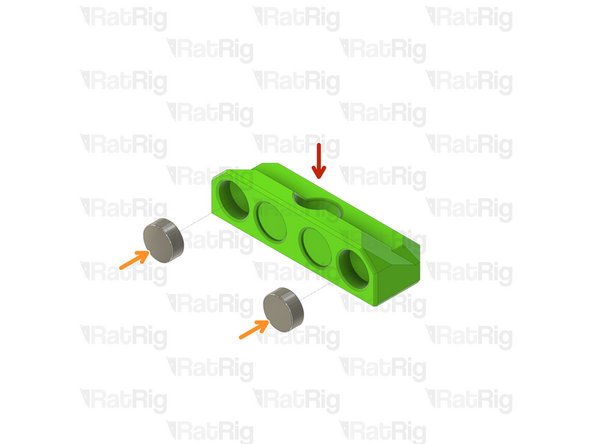

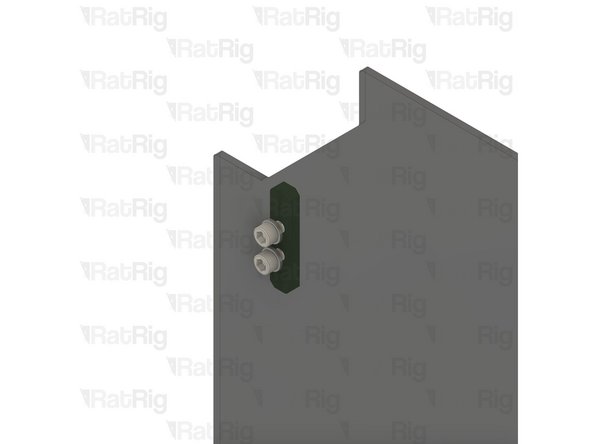

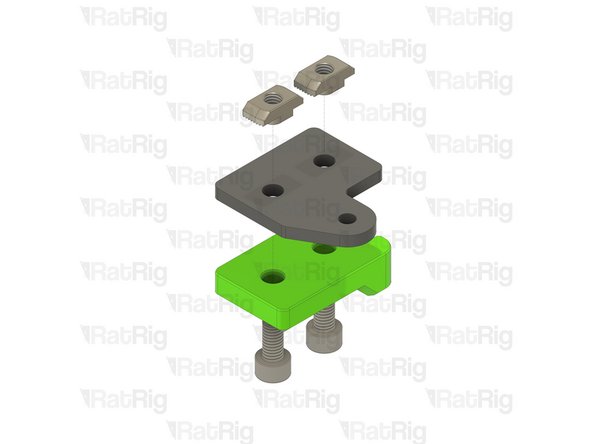

panel_magnet_mount printed part

-

Neodymium Disc Magnet - 10x4mm

-

The magnets are designed to be a tight fit into the printed part. If they are loose, or you wish to secure them further, place a few drops of cyanoacrylate glue into the printed part before adding the magnet

-

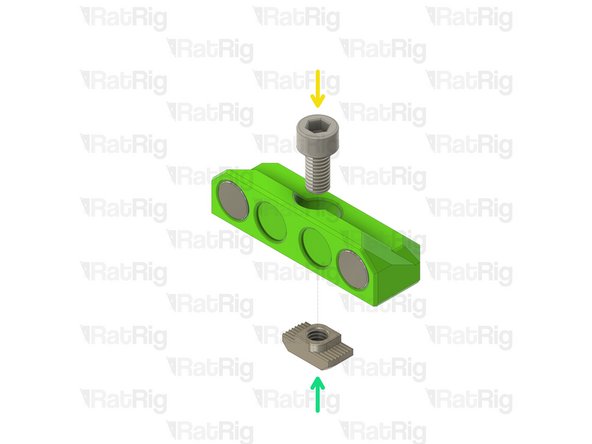

M6x12 Cap Head Screw

-

3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Set these assemblies aside until Step !!

-

-

-

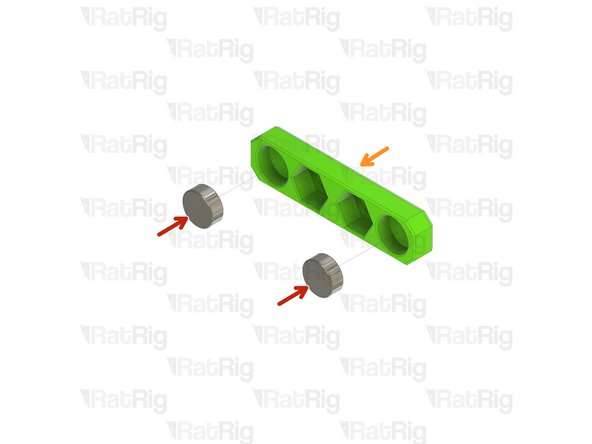

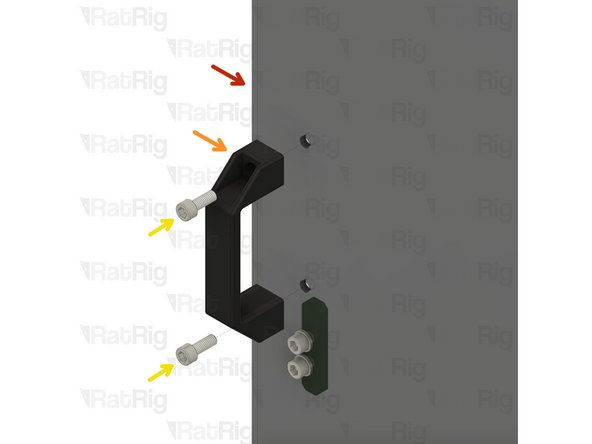

panel_magnet_holder printed part

-

Neodymium Disc Magnet - 10x4mm

-

The magnets are designed to be a tight fit into the printed part. If they are loose, or you wish to secure them further, place a few drops of cyanoacrylate glue into the printed part before adding the magnet

-

M6 Nylon Locking Hex Nut

-

Set these assemblies aside until Steps 7, 8 & 11

-

-

-

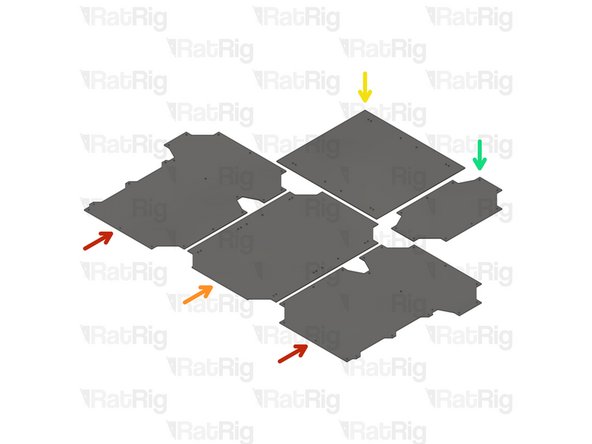

RatRig provides DXF and STEP files for you to have your own panels produced locally. These are available for download on the RatRig V-Core 3 GitHub repository

-

2x panel_enc2_side_size

-

1x panel_enc2_door_size

-

1x panel_enc2_top_size

-

1x panel_enc2_back_size

-

Use the file with the correct size for your printer (200, 300, 400 or 500)

-

-

-

4x Rat Rig nylon door handle

-

10x Panel magnet mount assemblies from Step 5

-

8x M6x16 Cap Head Screw

-

8x M6 Nylon Locking Hex Nut

-

24x M6x12 Cap Head Screw

-

24x M6 Washer

-

-

-

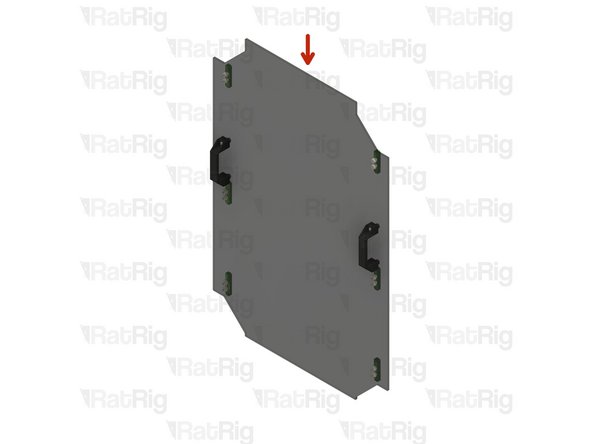

There are 6 magnet mount positions on the door (or 4 on the 200). Repeat the following for each of them

-

panel_enc2_door_size

-

M6x12 Cap Head Screw

-

M6 Washer

-

Panel magnet mount assembly from Step 5

-

Take care not to over tighten the M6x12 screw as you can damage the printed parts

-

-

-

There are 2 magnet mount positions on the door. Repeat the following for each of them

-

panel_enc2_door_size

-

Rat Rig nylon door handle

-

M6x16 Cap Head Screw

-

M6 Nylon Locking Hex Nut

-

Do not overly tighten the M6 nylon locking hex nuts when securing the handles, as this can cause the panel to warp which will prevent a good seal to the printer

-

-

-

Completed door panel assembly

-

Set the completed door assembly aside until Step !!

-

-

-

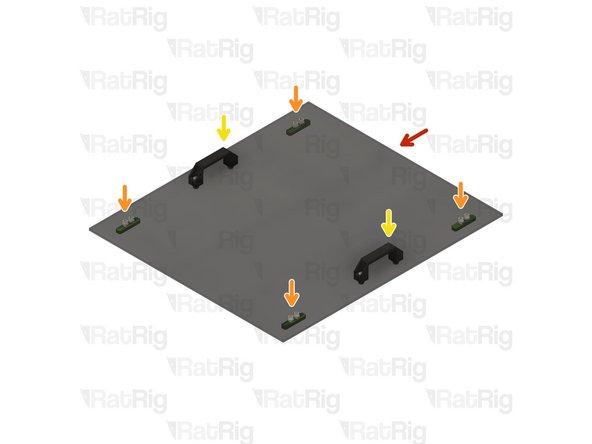

panel_enc2_top_size

-

Install four of the panel magnet mount assemblies to the top panel

-

Take care not to over tighten the M6x12 screw as you can damage the printed parts

-

Install two of the Rat Rig nylon handles to the top panel

-

Do not overly tighten the M6 nylon locking hex nuts when securing the handles, as this can cause the panel to warp which will prevent a good seal to the printer

-

Set the completed top assembly aside until Step !!

-

-

-

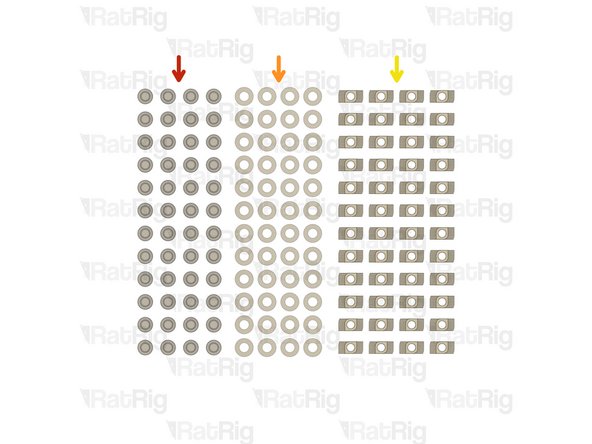

48x M6x12 Cap Head Screw

-

48x M6 Washer

-

48x 3030 Drop-in T-Nut - M6

-

-

-

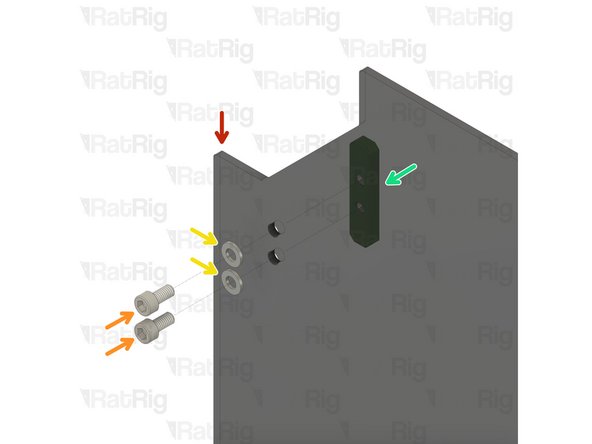

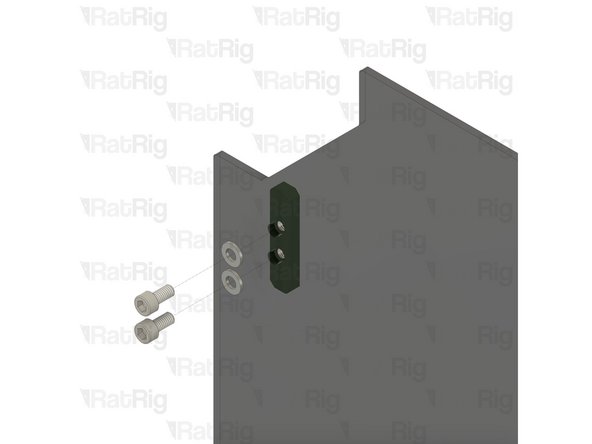

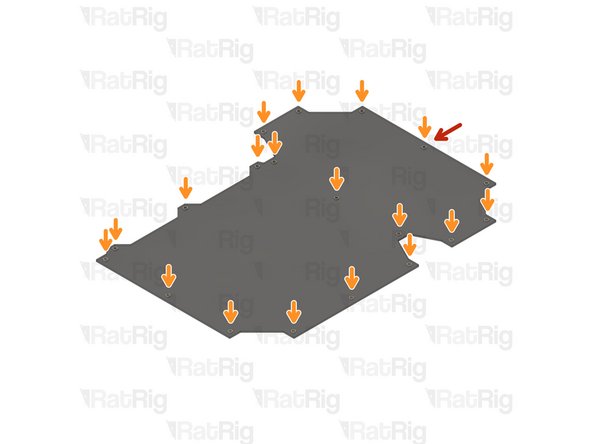

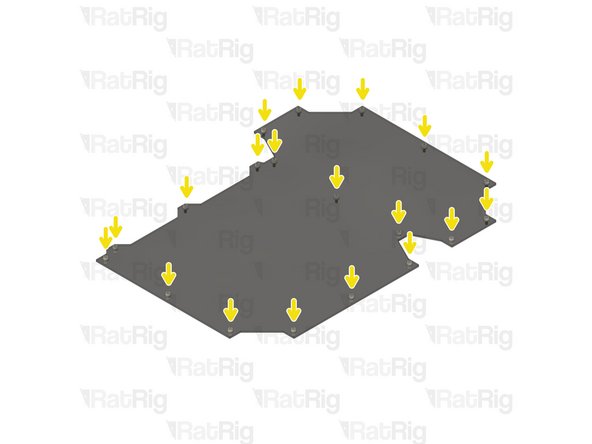

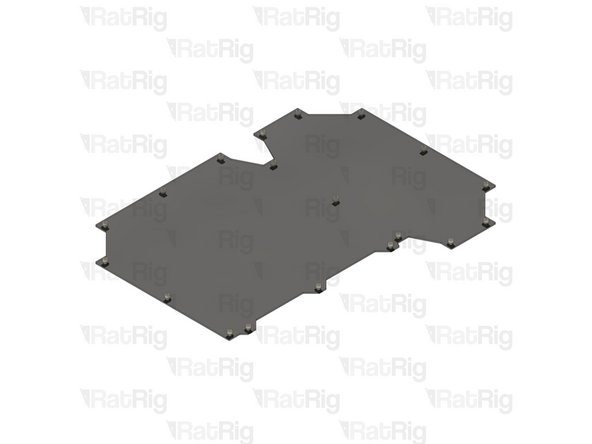

panel_enc2_side_size

-

M6 Washer

-

M6x12 Cap Head Screw

-

3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

-

-

Repeat the previous steps to install an M6x12 cap head screw, M6 washer and 3030 drop-in t-nut to each hole on the remaining panels as shown

-

Set all panels aside until Step !!

-

-

-

EVA3 toolhead assembly

-

Upper CoreXY belt tensioner

-

Lower CoreXY belt tensioner

-

Loosen both CoreXY belt tensioners as shown

-

-

-

Left CoreXY motor assembly

-

M3x35 Cap Head Screw

-

Support the NEMA17 stepper motor whilst removing the M3x35 screws

-

Remove the four M3x35 screws to release the NEMA17 motor

-

Left CoreXY NEMA17 stepper motor

-

Set the 4x M3x35 screws and NEMA17 stepper motor aside until Steps 20 & 21

-

-

-

M5x40 Cap Head Screw

-

Loosen, but do not remove, both of the M5x40 screws

-

-

-

M6x14 Countersink Screw

-

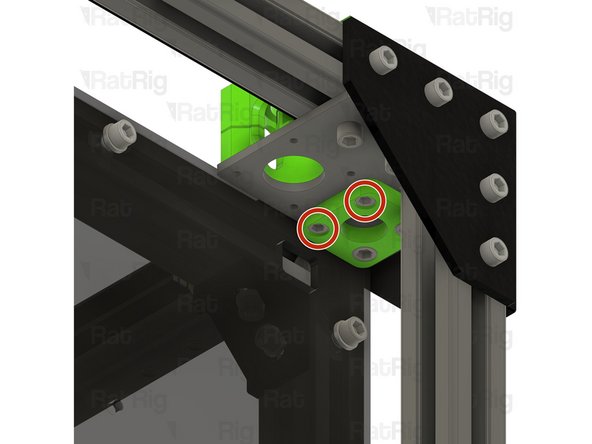

Loosen the three M6x14 screws

-

Lift the upper CoreXY motor cage assembly from the machine

-

Remove all 3 M6x14 screws, and 3030 t-nuts, from the printed part

-

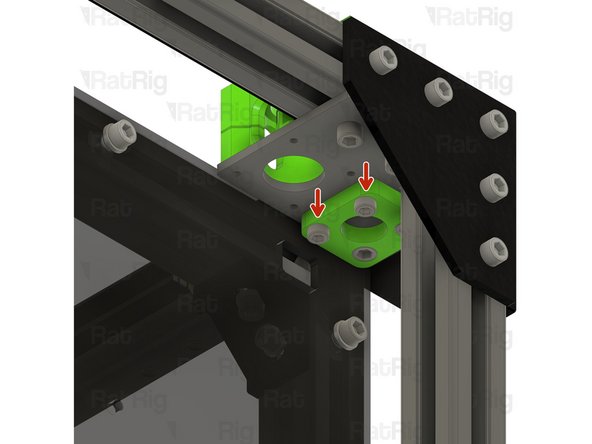

Remove the two M5 nylon locking nuts from the printed part

-

-

-

xy_motor_cage_top_left_3.1_cutout printed part

-

M6x14 Countersink Screw

-

M5 Nylon Locking Hex Nut

-

3030 Drop-in T-Nut - M6

-

Assemble the new CoreXY motor cage top as shown

-

Install the xy_motor_cage_top_left_3.1_cutout assembly onto the frame as shown

-

Make sure the belt loop remains in the position shown

-

Tighten the three marked M6x14 screws to secure the CoreXY motor cage top to the frame

-

-

-

M5x40 Cap Head Screw

-

Tighten the M5x40 screws to secure the bearing stacks into the CoreXY motor cage top

-

CoreXY NEMA17 stepper motor from Step 16

-

Position the NEMA17 motor up and into the motor cage from below,

-

-

-

Insert the M3x35 screws from Step 16 into the CoreXY motor cage as shown, and fasten them to secure the NEMA17 motor to the mount

-

-

-

Repeat Steps 16 thru 21 to replace the right side CoreXY motor cage top

-

-

-

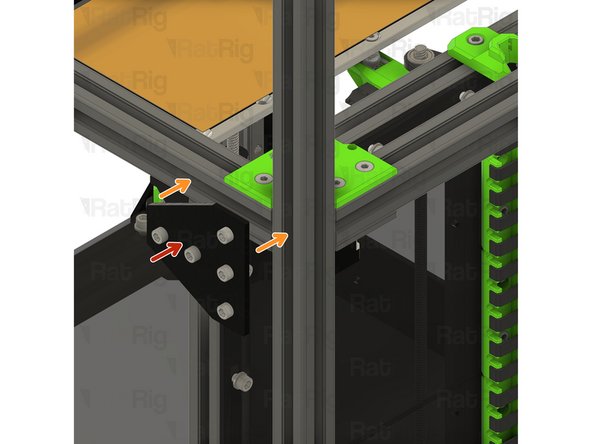

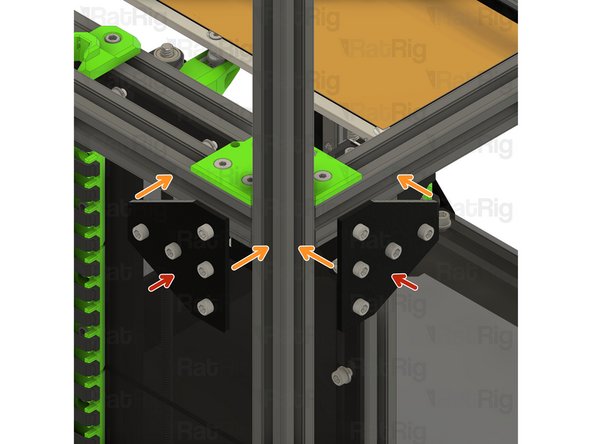

M6x12 Cap Head Screw

-

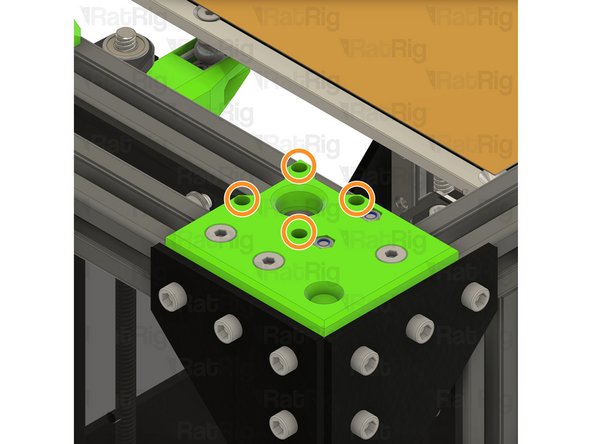

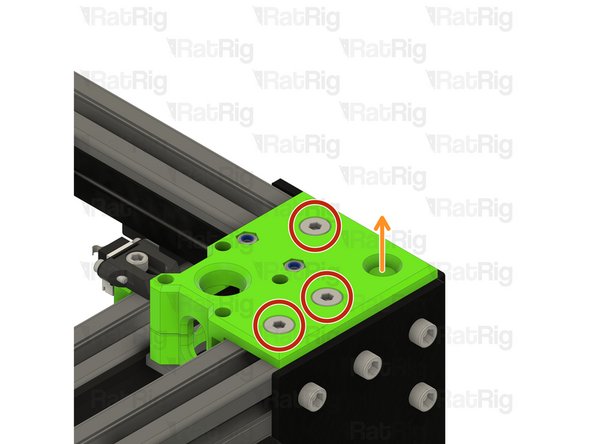

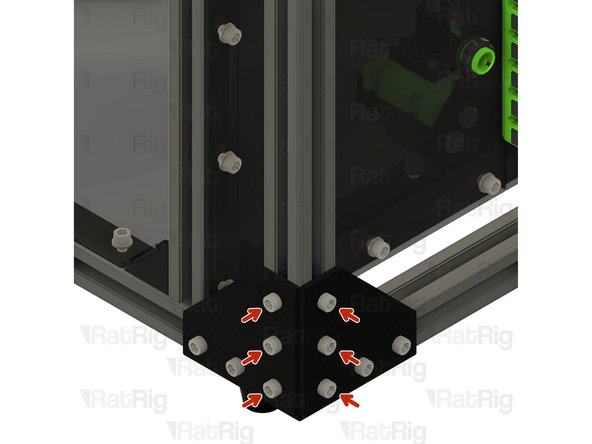

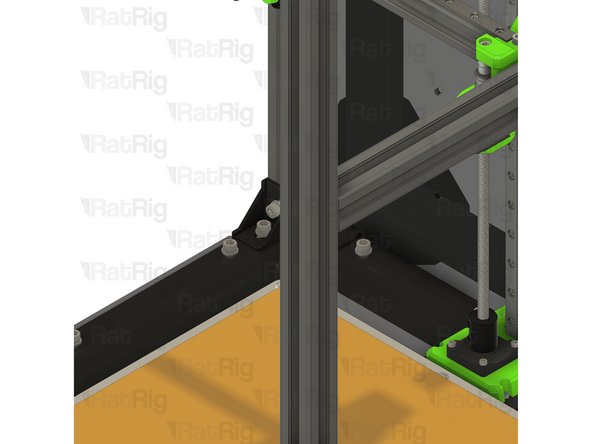

Loosen all of the M6x12 screws and remove the corner plate assembly

-

Loosen all of the M6x12 screws and remove the second corner plate assembly as well

-

Set these corner plate assemblies aside until Step !!

-

-

-

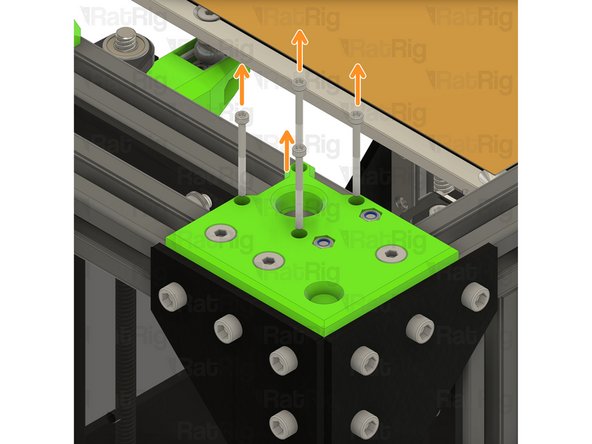

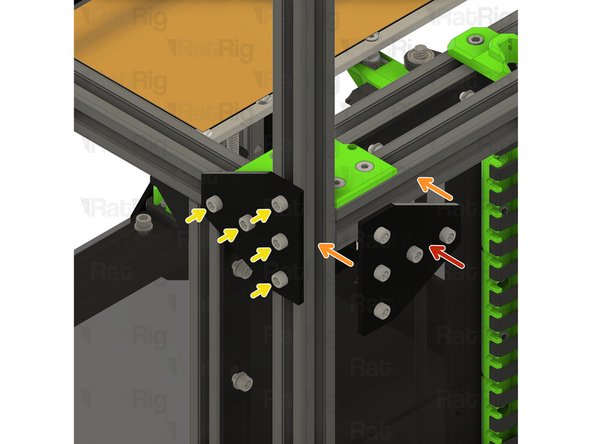

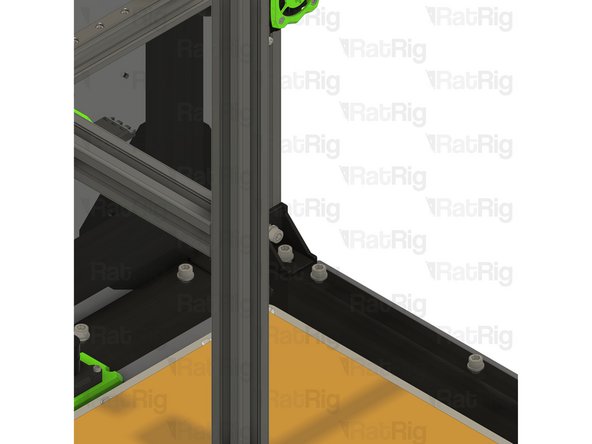

M6x12 Cap Head Screw

-

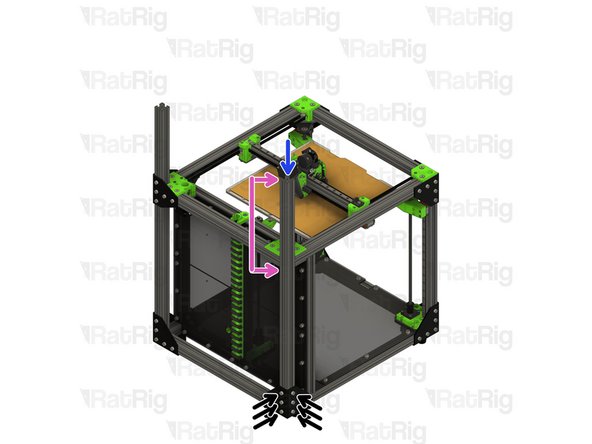

Loosen but do not remove the marked M6x12 screws

-

Rear right 3030 extrusion

-

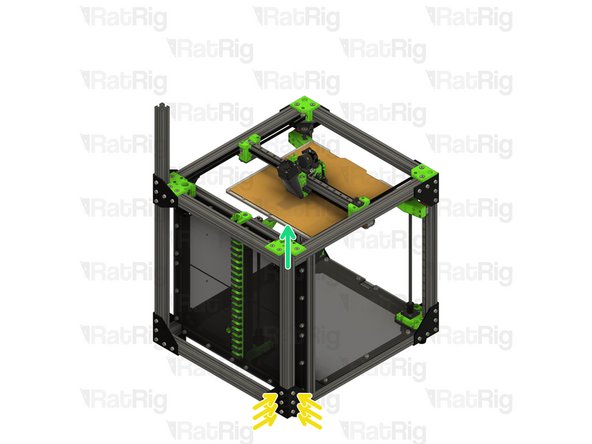

Pull the 3030 extrusion upwards to remove it from the machine frame

-

-

-

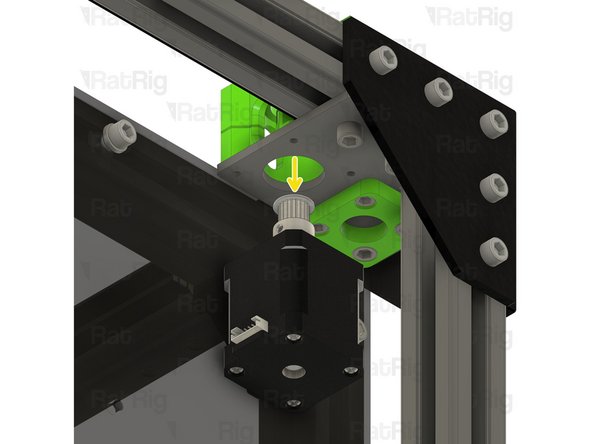

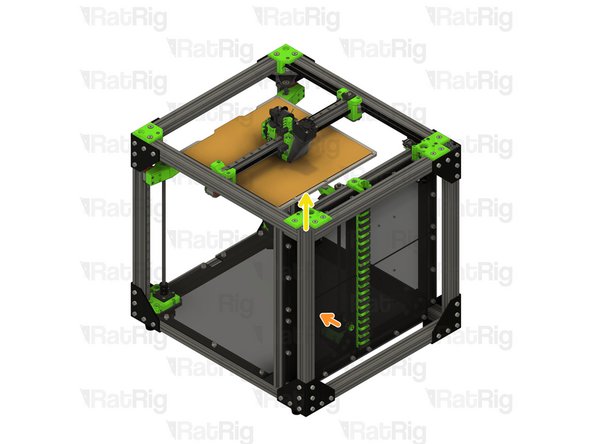

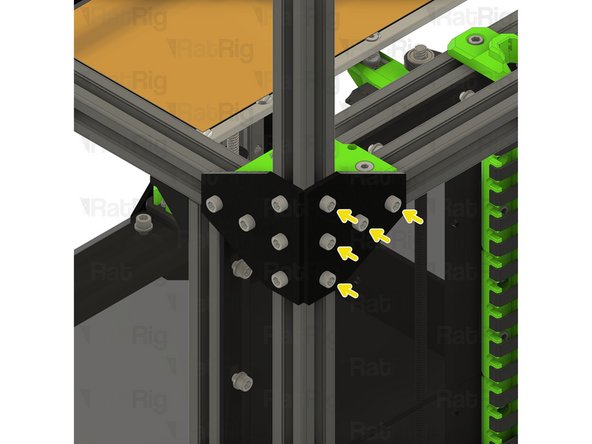

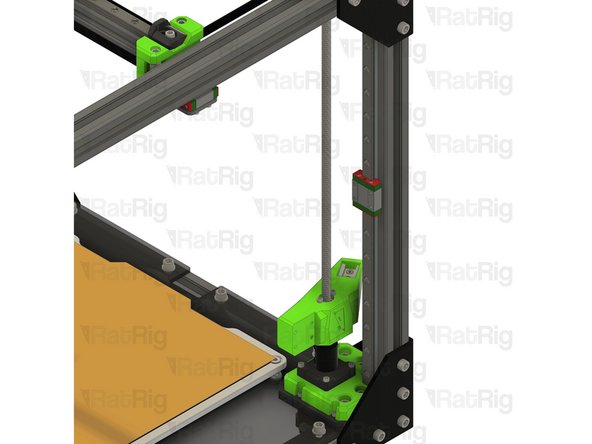

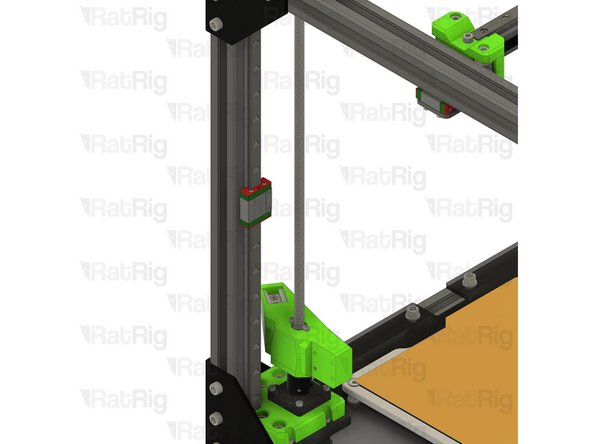

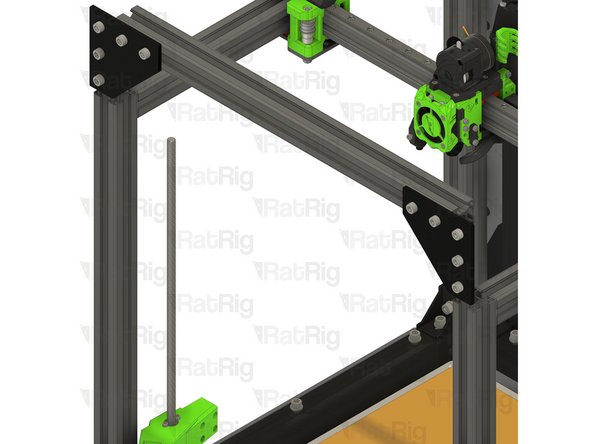

760mm 3030 Extrusion

-

Insert the 3030 extrusion into the bottom corner plate assemblies

-

You may need to rotate the 3030 t-nuts to insert the 3030 extrusion

-

Measure from the underside of the rear extrusion, to the top of the newly installed extrusion. It should measure either 230mm (for a V-Core 3 200) or 280mm (for a V-Core 300, 400 or 500)

-

Ensure the extrusion is fully inserted before continuting

-

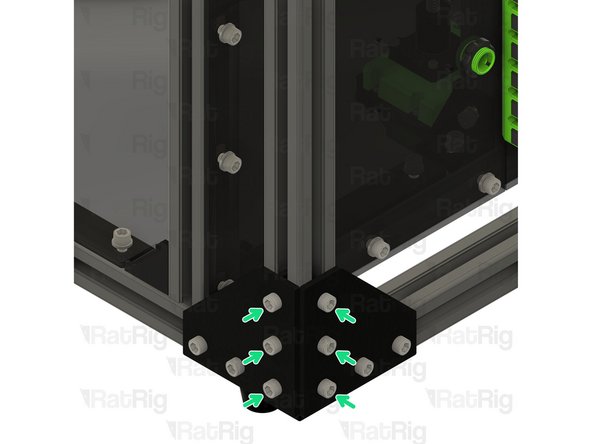

Tighten the six marked M6x12 screws to secure the 3030 extrusion to the frame

-

-

-

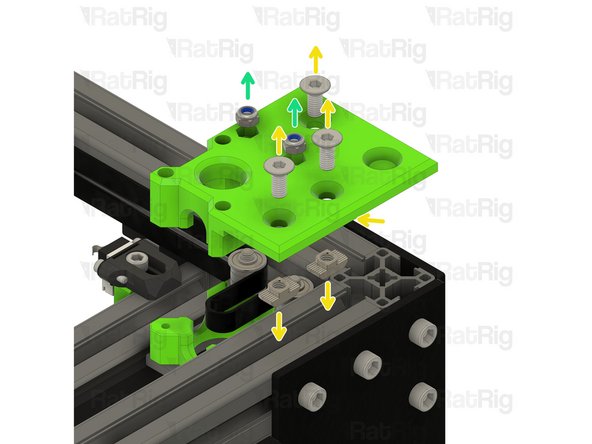

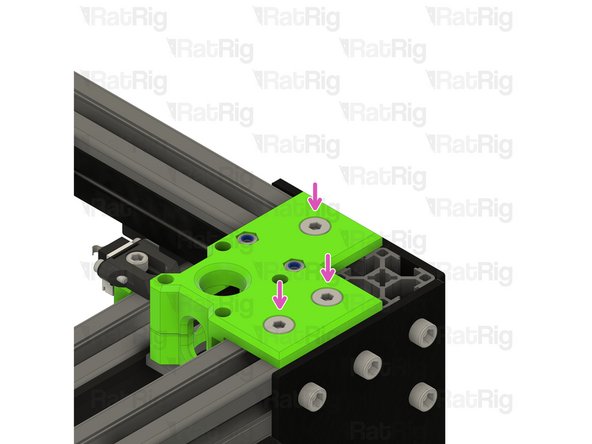

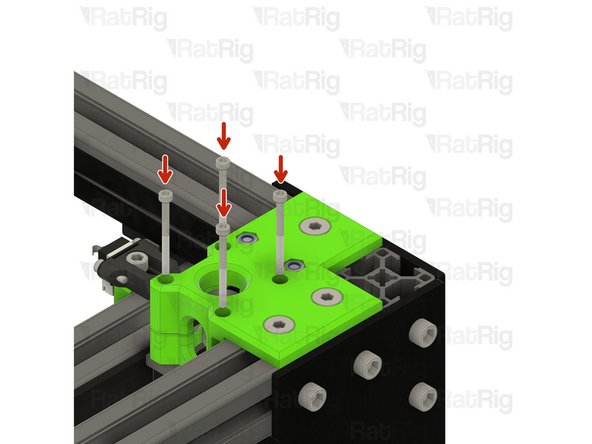

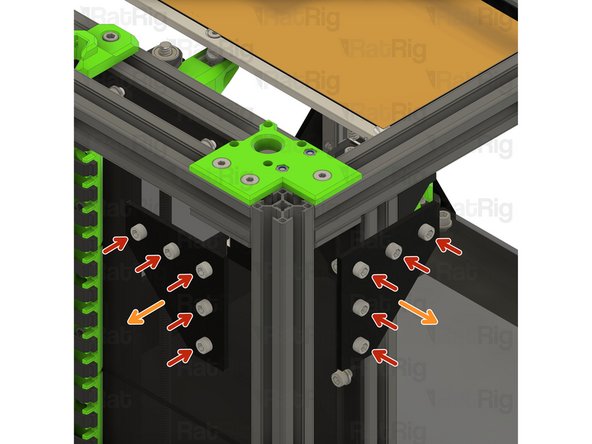

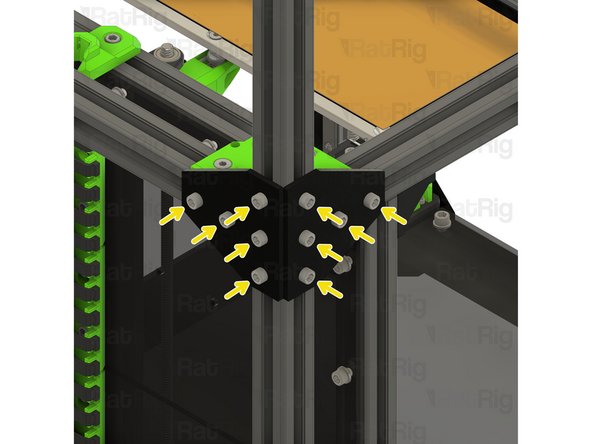

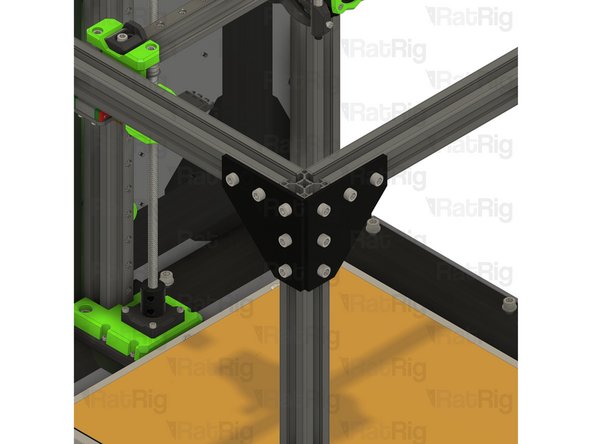

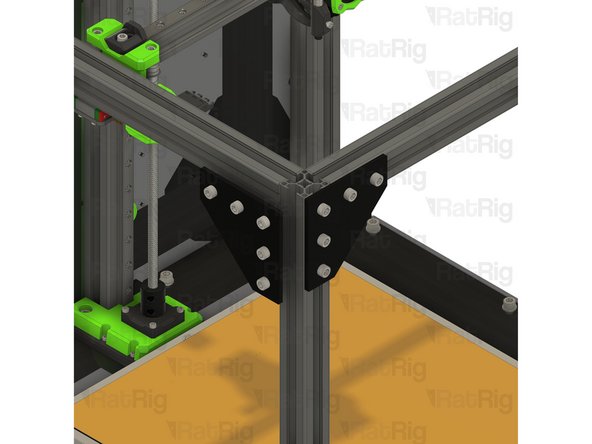

T-Shape plate assembly from Step 2

-

Position the T-shape plates as shown

-

Secure the T-shape plates to the frame by fastening the five M6x12 screws

-

-

-

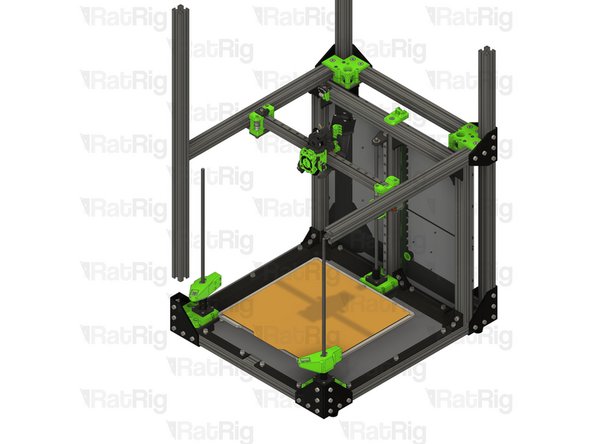

M6x12 Cap Head Screw

-

Loosen all of the M6x12 screws and remove both corner plate assemblies

-

Loosen but do not remove the marked M6x12 screws

-

Pull the rear left 3030 extrusion upwards to remove it from the machine frame

-

Insert the 760mm 3030 extrusion into the bottom corner plate assemblies

-

You may need to rotate the 3030 t-nuts to insert the 3030 extrusion

-

Measure from the underside of the rear extrusion, to the top of the newly installed extrusion. It should measure either 230mm (for a V-Core 3 200) or 280mm (for a V-Core 300, 400 or 500)

-

Tighten the six marked M6x12 screws to secure the 3030 extrusion to the frame

-

-

-

T-Shape plate assembly from Step 2

-

Position the T-shape plates as shown

-

Secure the T-shape plates to the frame by fastening the five M6x12 screws

-

-

-

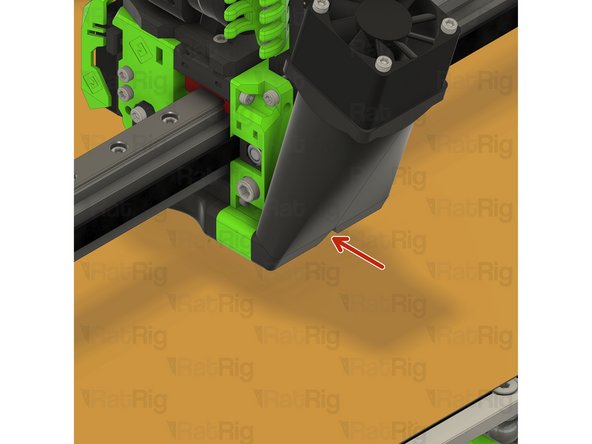

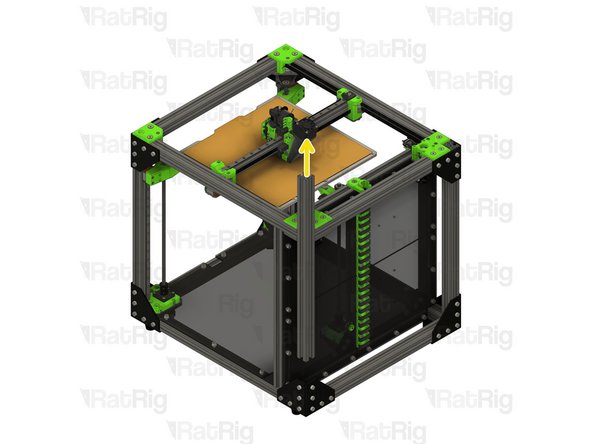

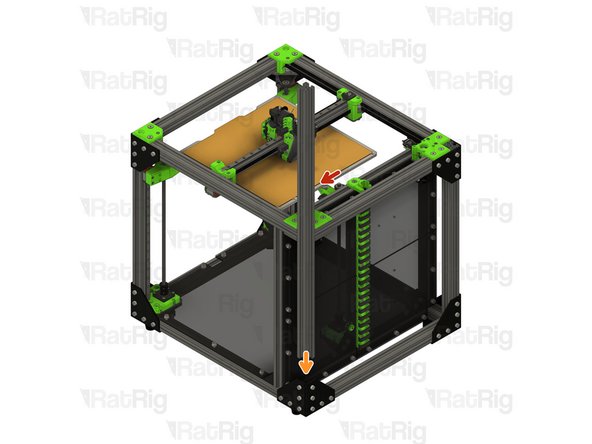

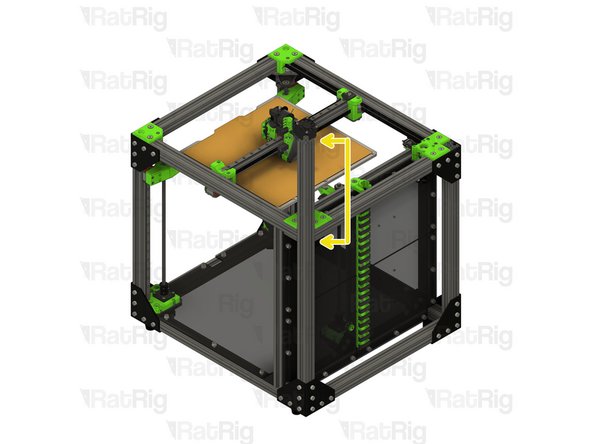

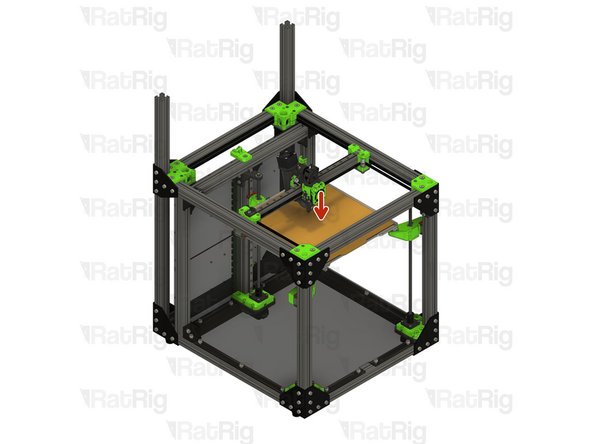

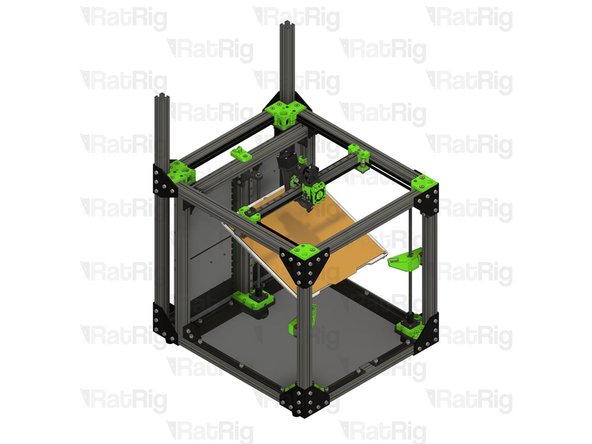

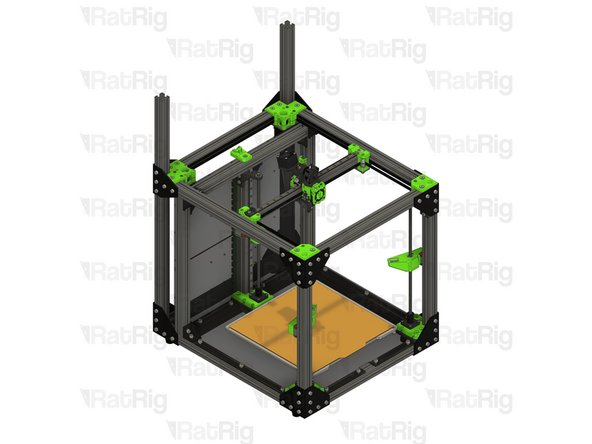

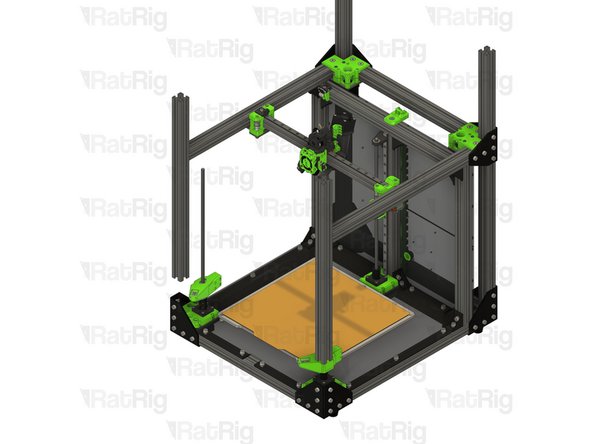

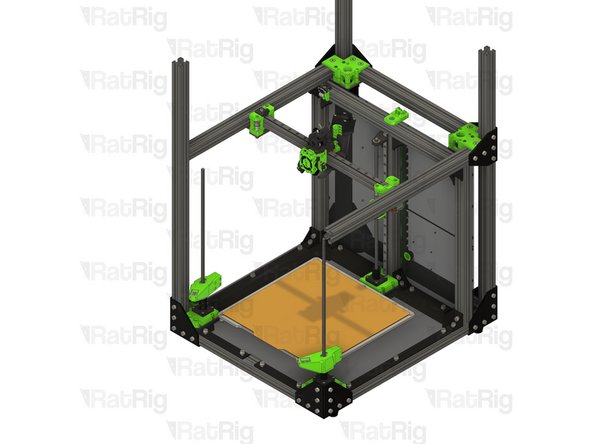

Print bed assembly

-

Lift the print bed assembly off of the bed arms and set it on the base panel (if installed), or the surface the printer sits on

-

To lower the bed arms, you can manually rotate the leadscrews counter-clockwise

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

8x M6x12 Cap Head Screw

-

8x 3030 Drop-in T-Nut - M6

-

2x M5x45 Cap Head Screw

-

4x idler_plate_enclosure_2.0 plate

-

2x y_min_bumper printed part

-

2x M5 Nylon Locking Hex Nut

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-