-

-

2x lead_screw_motor_cage_front_3.1 printed part

-

2x Axial Thrust Bearing

-

2x pillow_block printed part

-

2x Rigid Lead Screw Coupler

-

2x 48mm NEMA17 Stepper Motor

-

-

-

8x M3x18 Cap Head Screw

-

8x M6x20 Cap Head Screw

-

8x 3030 Drop-in T-Nut - M6

-

8x M3 Nylon Locking Hex Nut

-

8x M3x12 Cap Head Screw

-

-

-

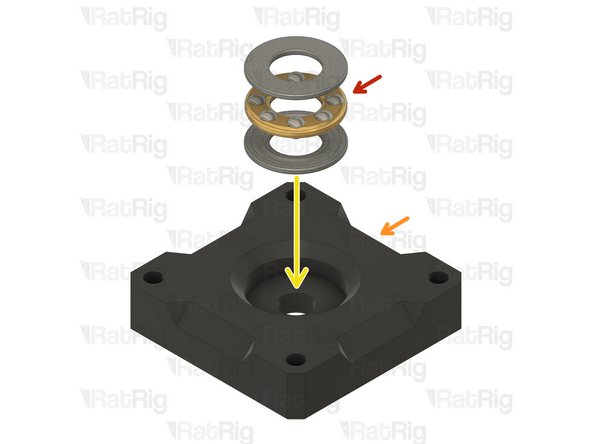

Axial Thrust Bearing

-

The axial thrust bearing has three components. Two end caps and an inner bearing assembly.

-

pillow_block printed part

-

Assemble the axial thrust bearing into the pillow_block as shown

-

Make sure that the thrust bearing is fully inserted into the printed part. The top ring of the thrust bearing should be flush with the top of the pillow_block.

-

If desired, you may add a drop of light oil to the inner bearing assembly of the thrust bearing

-

lead_screw_motor_cage_front_3.1 printed part

-

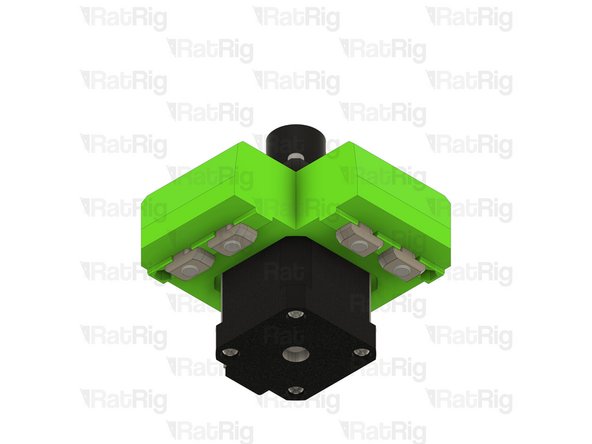

Place the pillow_block assembly atop the lead_screw_motor_cage_front_3.1 in preparation for the next step

-

-

-

pillow_block and axial thrust bearing assembly

-

lead_screw_motor_cage_front_3.1 printed part

-

M3x18 Cap Head Screw

-

48mm NEMA17 Stepper Motor

-

Insert the NEMA17 motor into the lead_screw_motor_cage printed part, as shown

-

Insert each M3x18 cap head screw through the pillow block, the lead screw motor cage, and fasten them into the NEMA17 motor

-

Take care not to over tighten the M3x18 screws as you can damage the printed parts

-

-

-

Assembly from the previous step

-

Rigid Lead Screw Coupler

-

Install the lead screw coupler on to the exposed shaft of the NEMA17 motor

-

Apply downward pressure to the top of the lead screw coupler whilst tightening the marked screw

-

Tighten the marked M3 screw to secure the lead screw coupler to the motor shaft

-

-

-

M6x20 Cap Head Screw

-

Insert each M6x20 cap head screw into the lead screw motor mount as shown

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x20 screws. Do not tighten them at this point.

-

-

-

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

Do not worry about fully seating the M3 nuts into the mount, this will be done in the next step

-

-

-

M3x12 Cap Head Screw

-

Insert each M3x12 cap head screw into the lead screw motor mount as shown

-

Slowly tighten the each screw to seat the M3 nut below

-

Take care not to over tighten the M3x12 screws as you can damage the printed part

-

These screws are used to mount the optional printed trim part when using a base panel

-

-

-

Repeat Steps 3 to 8 to assemble the right Z-axis motor mount

-

Once you have both front Z-axis motor mounts assembled as shown, proceed to the next step

-

-

-

lead_screw_motor_cage_rear_3.1 printed part

-

pillow_block printed part

-

Axial Thrust Bearing

-

48mm NEMA17 Stepper Motor

-

Rigid Lead Screw Coupler

-

-

-

4x M3x18 Cap Head Screw

-

1x M6x20 Cap Head Screw

-

3x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

4x M3x12 Cap Head Screw

-

4x M3 Nylon Locking Hex Nut

-