Introduction

Please note: All measurements and component counts provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, please refer to the following list for the linear rail lengths, and required number of fasteners:

- 200x200: 2x 250mm, 3x 300mm, 56x M3x12 Screw, 56x 3030 T-Nuts

- 300x300: 2x 350mm, 3x 400mm, 76x M3x12 Screw, 76x 3030 T-Nuts

- 400x400: 2x 450mm, 3x 500mm, 96x M3x12 Screw, 96x 3030 T-Nuts

- 500x500: 2x 550mm, 3x 600mm, 116x M3x12 Screw, 116x 3030 T-Nuts

-

-

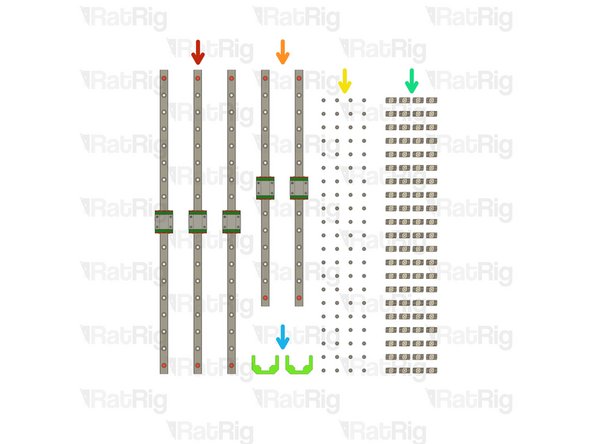

3x 400mm MGN12 Linear Rail

-

There will be a fourth rail of this length in the kit. Leave that one in its packaging until later

-

2x 350mm MGN12 Linear Rail

-

84x M3x12 Cap Head Screw

-

14x 3030 Drop-in T-Nut - M3

-

2x MGN12 3030 Alignment Tool

-

-

-

Paper Towels

-

The linear rails are supplied with a protective oil coating on them, so prepare your work surface with disposable and absorbent paper towels

-

Linear Rail

-

Carefully open one end of the linear rail packaging and remove the rail. Place the rail upon the paper towels and dispose of the packaging

-

Take a paper towel and carefully wipe the excess lubricant from the rail

-

-

-

With the rail still on the absorbent paper towels, carefully and slowly move the carriage from one end of the rail to the other

-

The carriage should move smoothly over the entire length of the rail

-

Small changes in resistance are normal, but the carriage becoming much harder to push, or binding completely are not

-

Repeat the previous test whilst applying a small amount of force downwards on the carriage

-

The carriage will likely travel more smoothly when applying a downwards force, this is normal

-

If the carriage does not move smoothly, or binds completely, refer to the Linear Rail Troubleshooting Guide

-

-

-

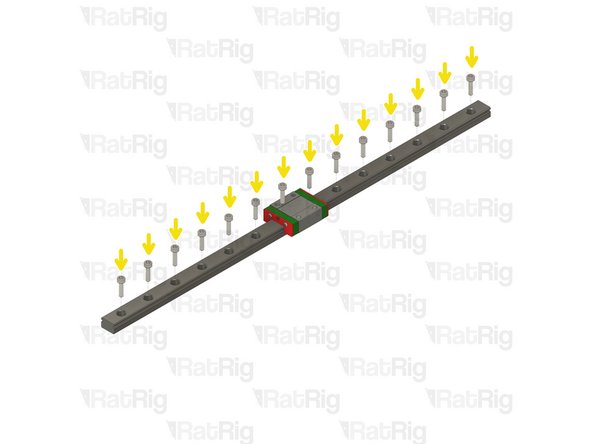

Linear Rail

-

Remove the plastic stops installed in the ends of the linear rail

-

Do not allow the linear rail carriage to leave the end of the rail

-

Insert an M3x12 screw in each of the holes on the linear rail

-

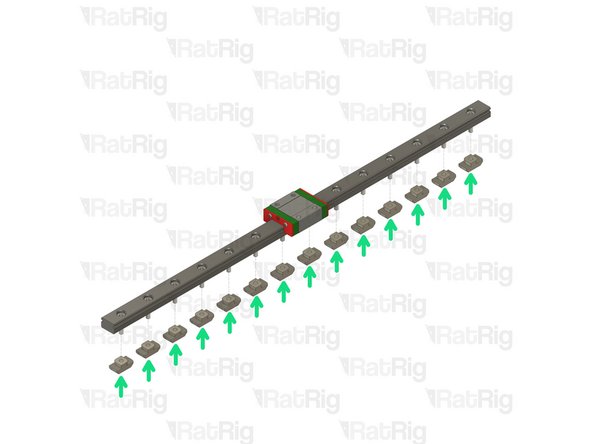

Loosely thread a 3030 T-Nut onto each of the M3x12 screws

-

Repeat these steps for the other 4 rails

-

-

-

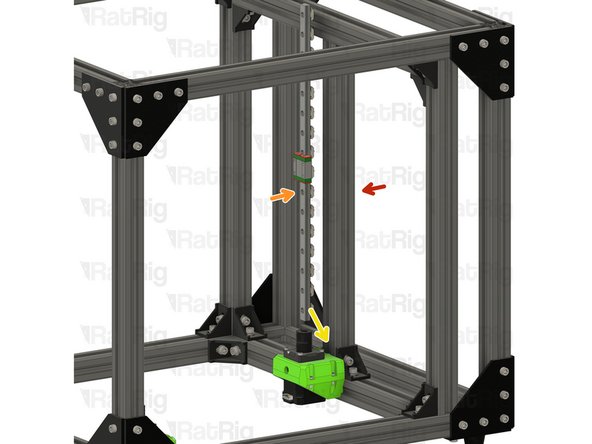

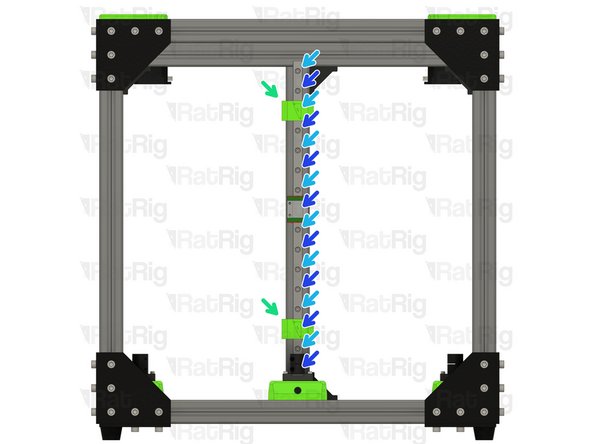

V-Core 3.1 Frame Assembly

-

400mm MGN12 Linear Rail Assembly

-

Insert the linear rail into the 3030 extrusion

-

The linear rail will rest on the lead screw motor cage

-

Install the two MGN12 3030 alignment tools as shown, this will make sure the linear rail is positioned correctly

-

Fasten the marked M3x12 screws, starting from the bottom

-

Fasten the remaining M3x12 screws, starting at the bottom

-

Remove the MGN12 3030 alignment tools

-

-

-

400mm MGN12 Linear Rail Assembly

-

Insert the linear rail into the 3030 extrusion

-

The linear rail will rest on the front lead screw motor cage

-

Install the two MGN12 3030 alignment tools as shown, this will make sure the linear rail is positioned correctly

-

Fasten the marked M3x12 screws, starting from the bottom

-

Fasten the remaining M3x12 screws, starting at the bottom

-

Remove the MGN12 3030 alignment tools

-

Repeat these steps for the linear rail on the opposite side

-

-

-

Installation of the Y-axis rails may be easier if you place the V-Core 3 frame upside down

-

350mm MGN12 Linear Rail Assembly

-

Insert the linear rail into the 3030 extrusion

-

Position the linear rail so that its end touches the 3030 cast corner bracket as shown

-

Install the two MGN12 3030 alignment tools as shown, this will make sure the linear rail is positioned correctly

-

Fasten the marked M3x12 screws, starting from one end

-

Fasten the remaining M3x12 screws

-

Remove the MGN12 3030 alignment tools and repeat these steps for the linear rail on the opposite side

-

-

-

Continue with the next guide: 04. CoreXY Idler Assemblies

-