-

-

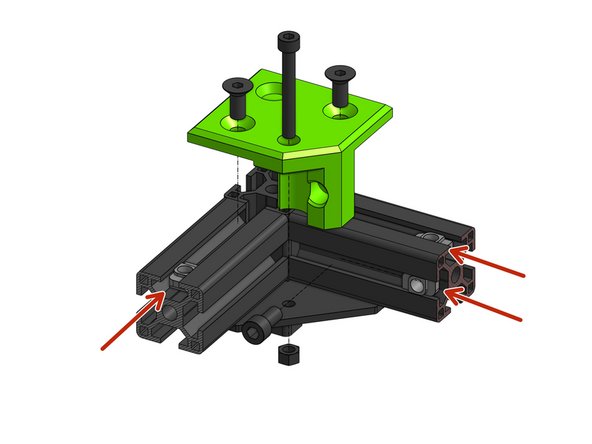

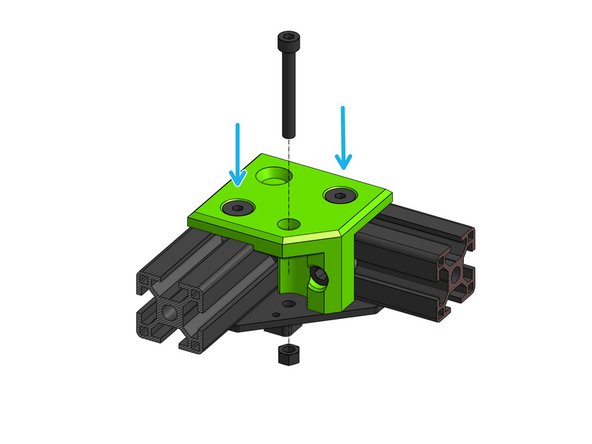

Thread the Cap Head Screws M6x12 through the idler plates. Four screws per plate

-

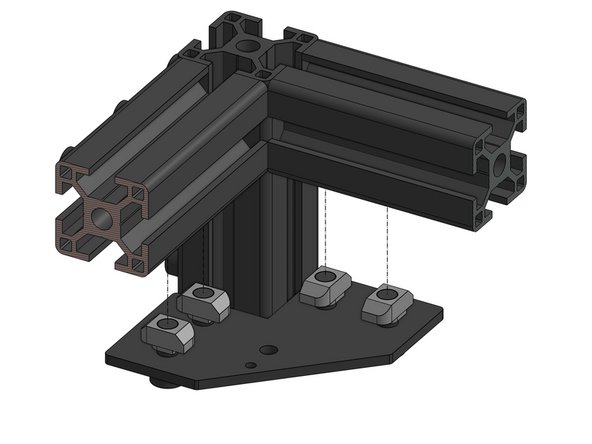

Attach the 3030 M6 T-nut to the screws. Don't tighten yet

-

-

-

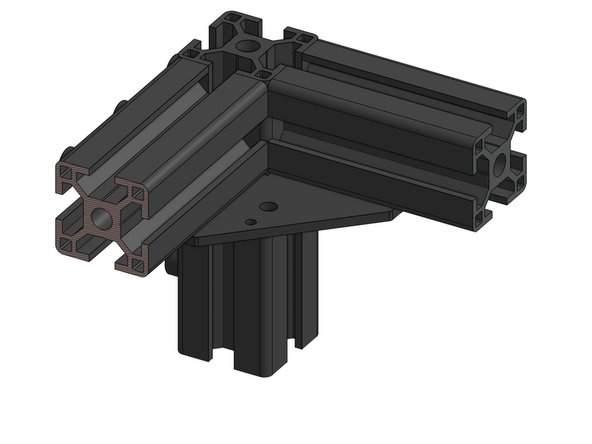

Attach the right XY Idler base to the frame. Fasten the nuts firmly

-

Repeat for the left side

-

-

-

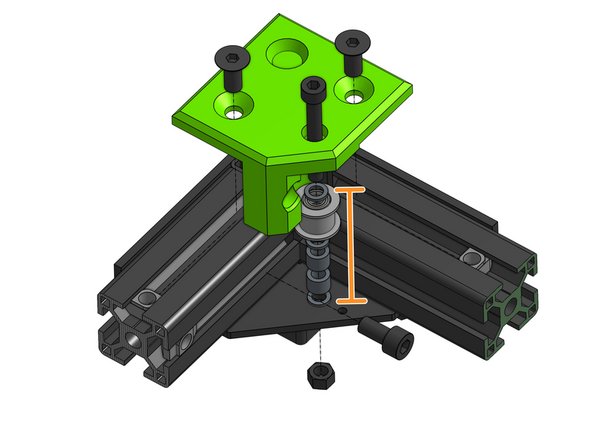

Slide the 3030 M6 T-nuts' into their place in the extrusion

-

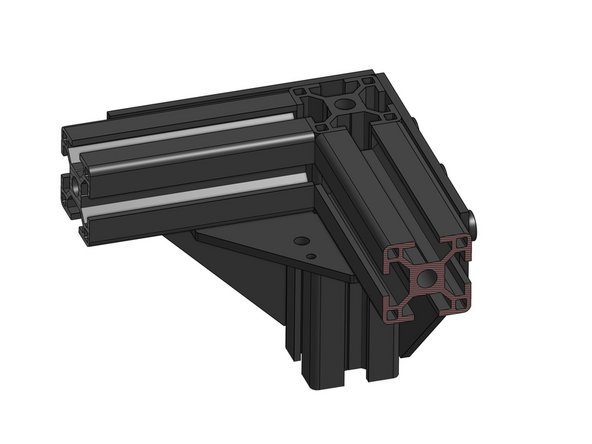

Fasten the xy_idler_right to the frame with the two Countersink Screws M6x14 and one Cap Head Screw M6x12 that goes in from the side

-

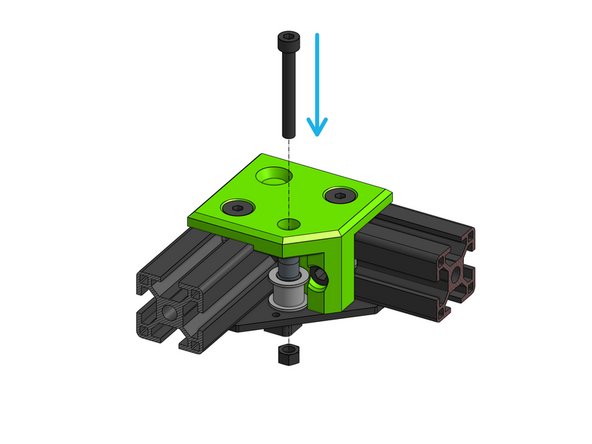

Prepare a Cap Head Screw M5x40 but do not thread it in yet.

-

-

-

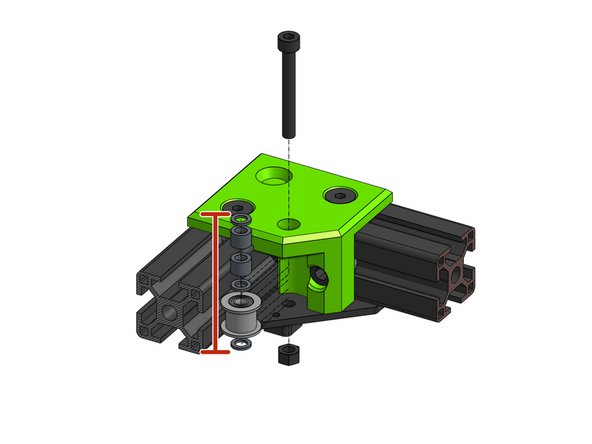

The order for the bearing stack from the bottom is: shim, idler, shim, 2x 6mm spacer, shim

-

Thread the bearing stack onto the Cap Head Screw M5x40

-

Attach the M5 nut from the bottom, do not over tighten - it should be snug but should not prevent the idler from spinning

-

-

-

Repeat the same steps for the left XY Idler assembly.

-

The only difference (aside from it being mirrored) is that the bearing stack is upside down - from the bottom it's: shim, 2x 6mm spacers, shim, idler, shim

-

-

-

This is how the XY Idler assemblies should look like looking from the back

-

Cancel: I did not complete this guide.

50 other people completed this guide.

One Comment

If you are having trouble getting the bearing stack into place, thread the bearing stack onto a thread or a thin wire, then pull the ends of the wire through the holes in the mount, from the inside out. The bearing stack will slide into place.

Tyler Suard - Resolved on Release Reply