-

-

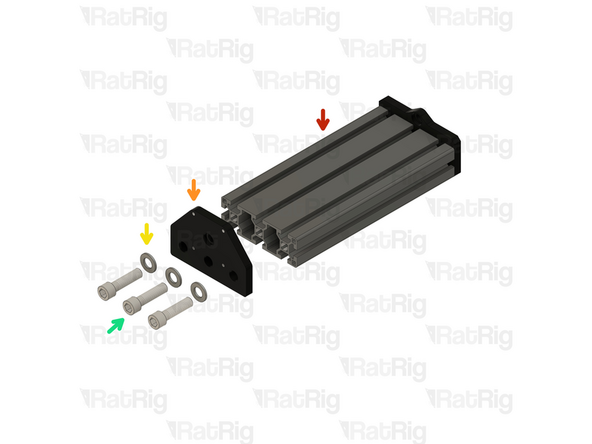

250mm 40120 Extrusion

-

Rat Rig StrongHold ONE CNC Bottom Plate

-

Rat Rig StrongHold ONE CNC TopPlate

-

3x M12x45 Cap Head Screw

-

3x M12x25 Countersunk Screw

-

3x M12 Washers

-

-

-

250mm 40120 extrusion

-

Rat Rig StrongHold ONE CNC Bottom Plate

-

3x M12x25 Countersunk Screw

-

Tighten the screws on the Bottom Z Plate

-

-

-

Assembly from previous Step

-

Rat Rig StrongHold ONE CNC Top Plate

-

3x M12 Washers

-

3x M12x45 Cap Head Screw

-

Tighten the screws on the Top Z Plate

-

-

-

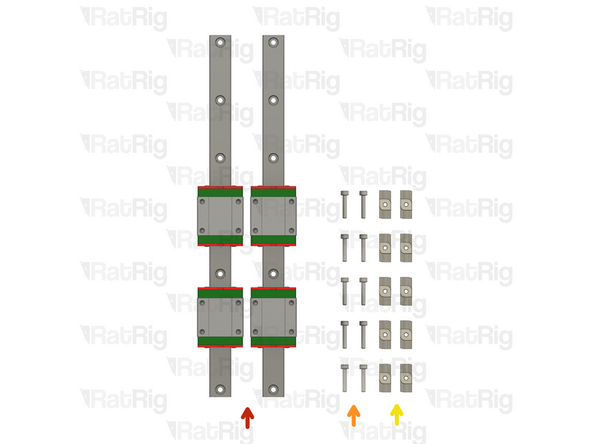

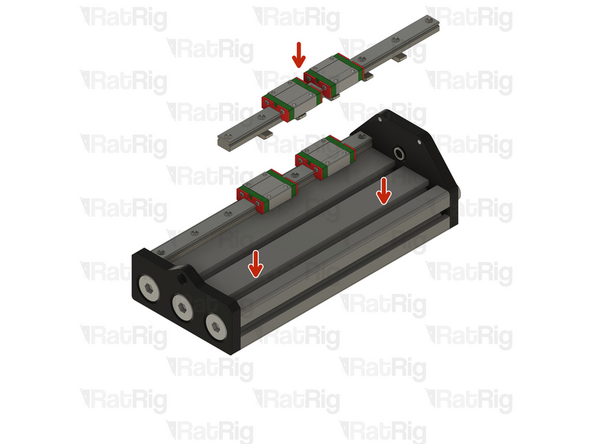

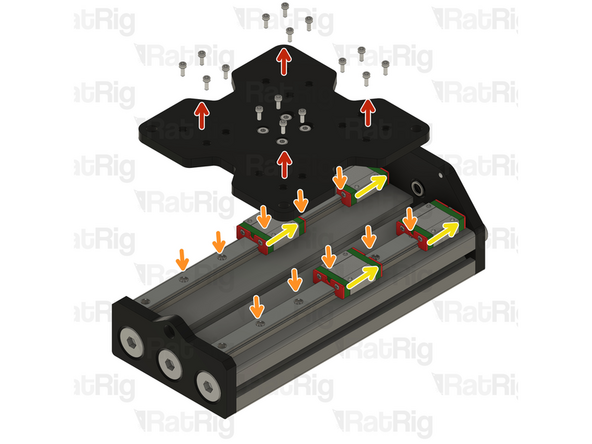

2x 250mm MGN15 Linear Rail with 2x Carriages

-

10x M3x16 Cap Head Screw

-

10x 4040 Drop-in T-Nut - M4

-

Leave the holes on the ends empty

-

Prepare the Linear Rails as detailed in Step 6 of the X-Axis Gantry Assembly Guide

-

Insert an M3x16 Cap Head Screw into each of the holes on the linear rail and loosely thread a 4040 Drop-in T-Nut

-

Repeat these instructions for the second linear rail

-

The linear rail carriages are not interchangeable. Do not try to use a carriage on a different linear rail than the one it was supplied with.

-

-

-

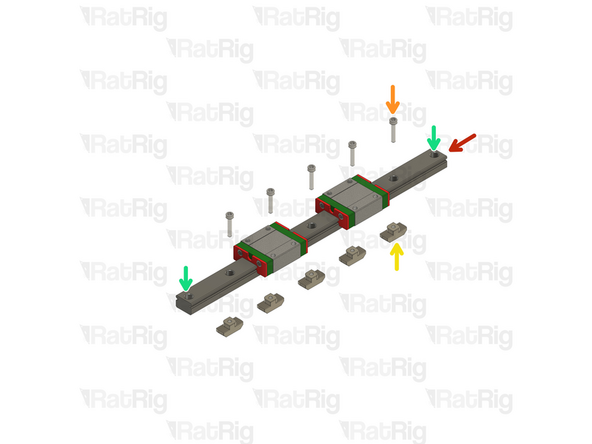

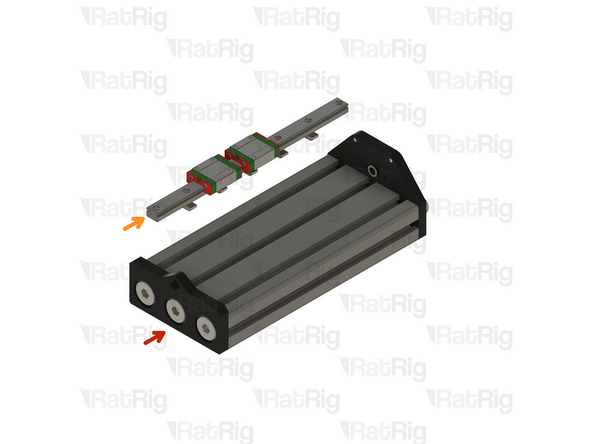

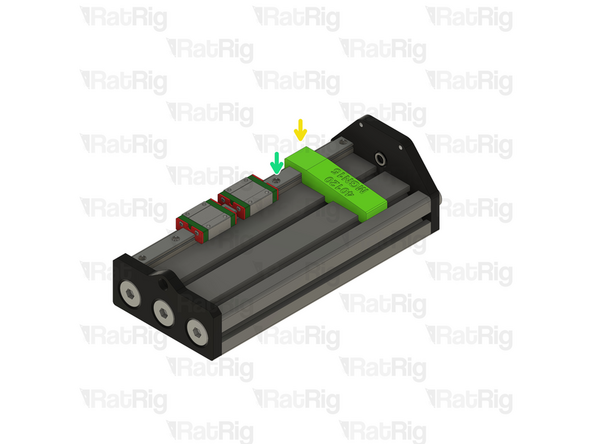

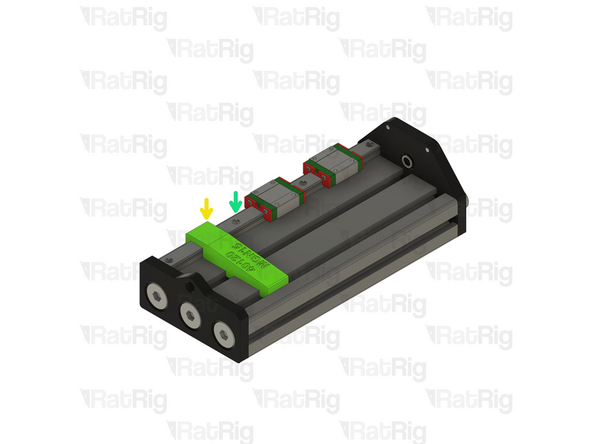

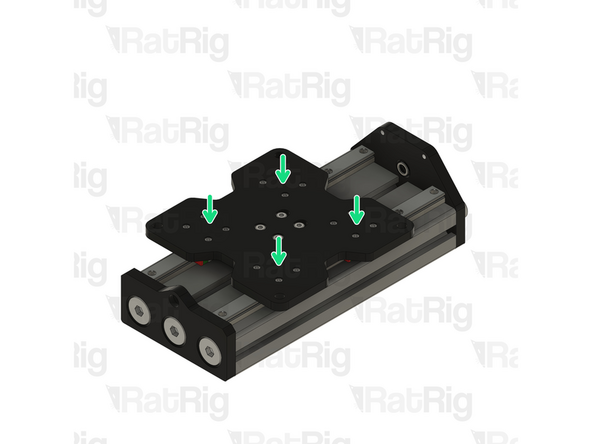

Assembly from Step 3

-

Linear Rail assembly from the previous step

-

Install the MGN15 40120 alignment tool as shown, this will make sure the linear rail is positioned correctly

-

Tighten the screw next to the alignment tool

-

Repeat the steps to tighten the screw on the other end of the rail

-

Tighten the remaining screws

-

-

-

MGN15 linear rail

-

Place the linear rail on to the 40120 extrusion as shown, do not tighten any of the screws at this point

-

-

-

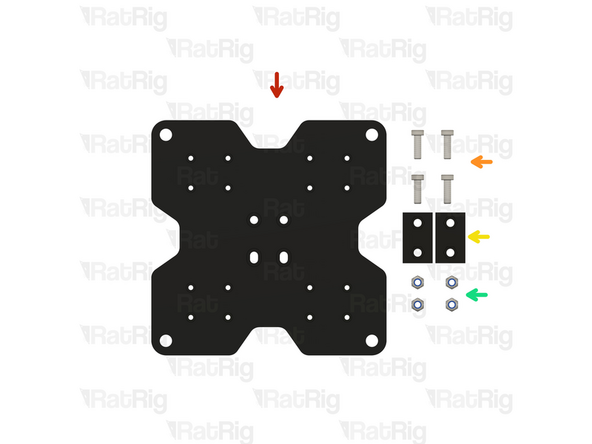

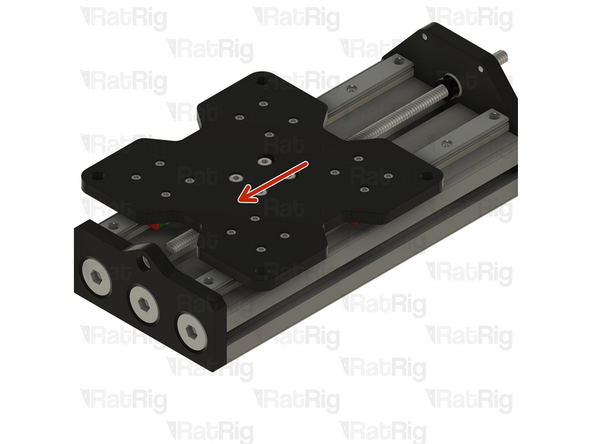

Rat Rig StrongHold ONE CNC XZ Joiner Plate

-

4x M5x16 Low Profile Cap Head Screw

-

2x Nut Block for TR8x8

-

4x M5 Nylon Locking Hex Nut

-

Repeat Steps 9 and 10 to assemble another XZ plate

-

-

-

Assembly from previous step

-

XZ Plate assembly from previous step

-

Make sure the Nut Blocks face are facing the assembly, and the threads are oriented accordingly to the linear rails

-

16x M3x8 Cap Head Screw

-

Install an M3x8 screw through each hole in the plate, and into the MGN15 linear rail carriage below, lighty tighten them

-

-

-

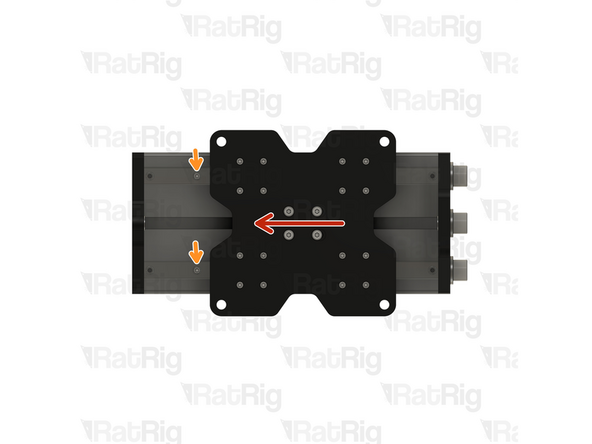

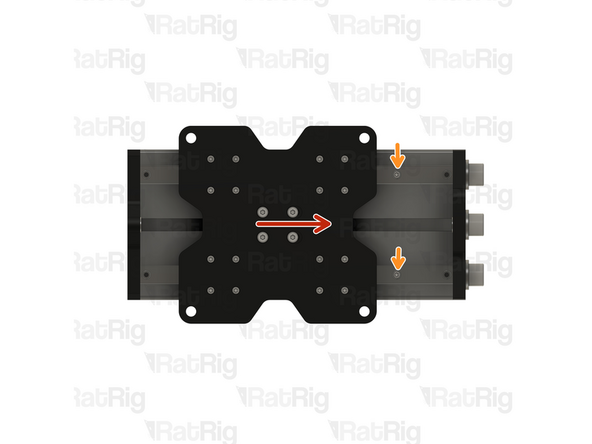

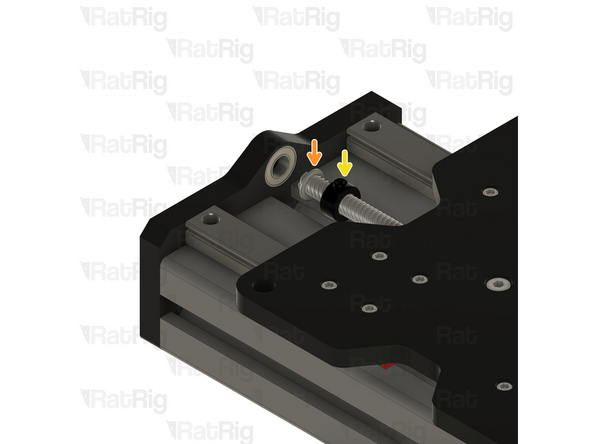

Push the XZ Plate to the one side

-

Tighten the M3x16 screw closest to the XZ plate

-

Repeat the Steps with the Plate pushed to the opposite side

-

If the Z-axis binds or becomes tight, check that the lower rail is aligned correctly. Loosening the screws securing the lower rail to the 40120 extrusion and repeat the steps above.

-

Do not overtighten the screws as it can cause the axis to bind.

-

-

-

Remove the XZ Plate

-

Tighten the remaining screws on the linear rail

-

Move the carriages to access the screws underneath them

-

Reinstall the XZ plate and tighten the screws on it

-

-

-

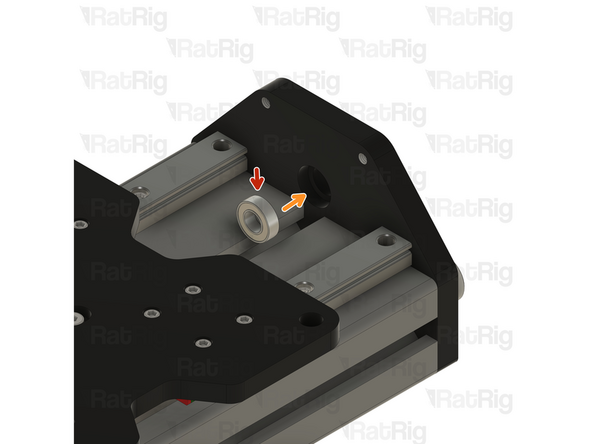

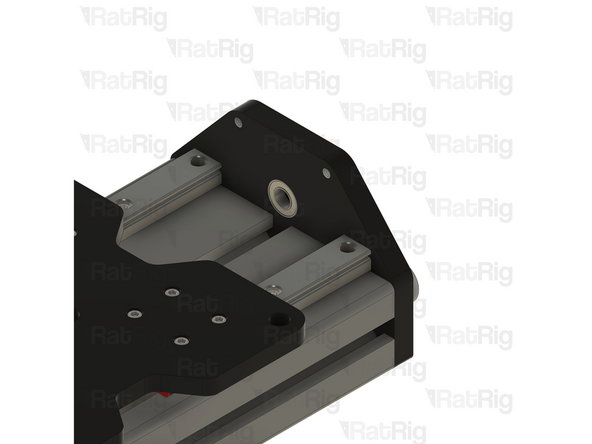

688ZZ Ball bearing

-

Push the ball bearing against the slot on the inner side of the plate.

-

-

-

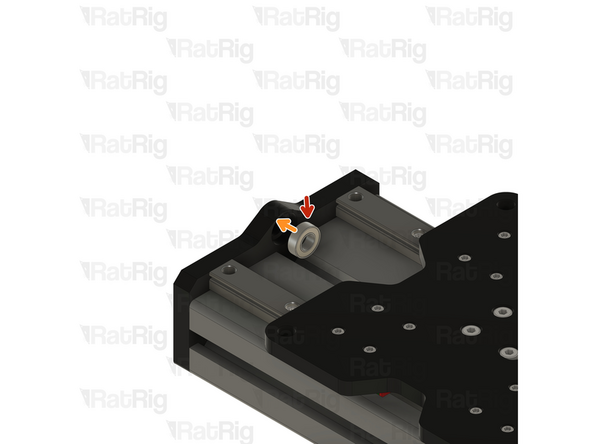

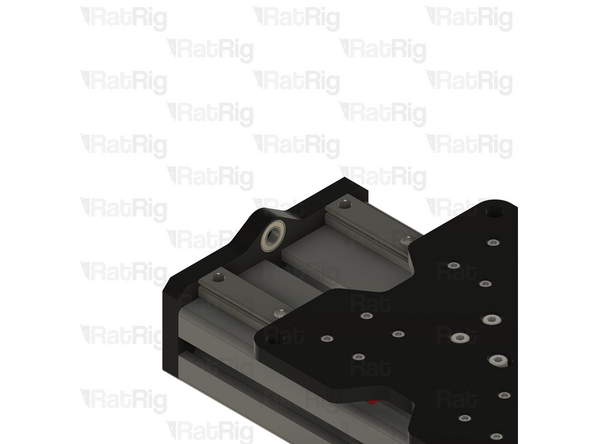

688ZZ Ball bearing

-

Push the ball bearing against the slot on the inner side of the plate.

-

-

-

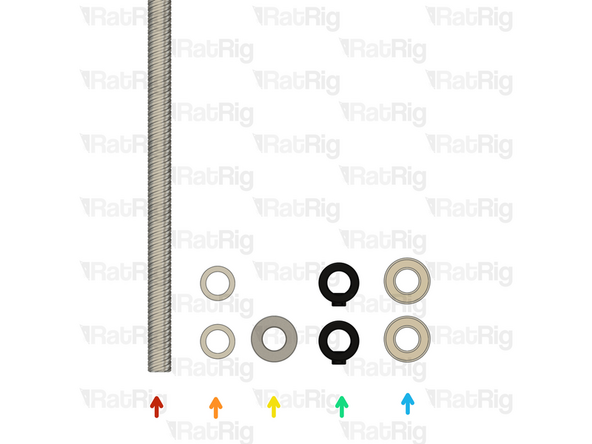

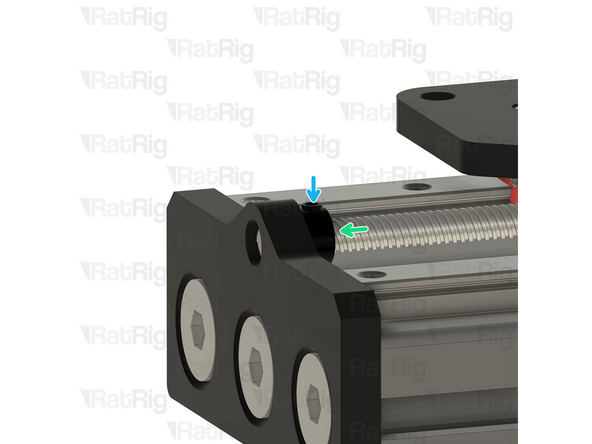

281mm TR8x8 Lead Screw

-

2x Precision Shim 12x8x1mm

-

Thrust Bearing F8-16M

-

2x Lock Collar 8mm

-

2x 688ZZ Ball Bearing

-

-

-

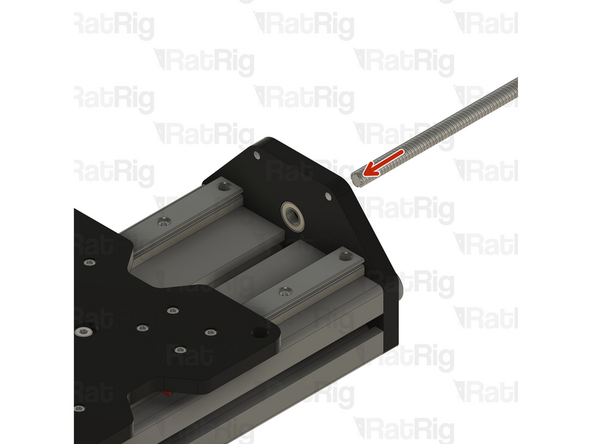

Insert the Lead Screw through the hole in the ball bearing

-

-

-

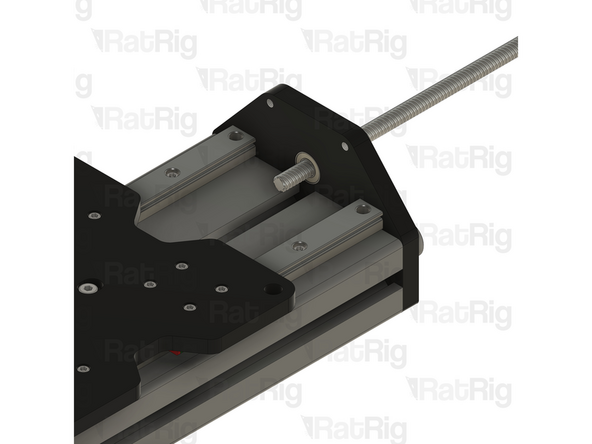

Precision Shim

-

Lock Collar

-

Slide the components into the Lead Screw

-

Do not tighten the screw on the Lock Collar yet.

-

-

-

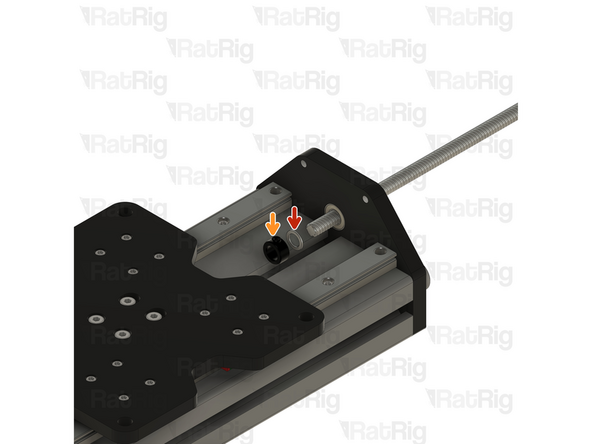

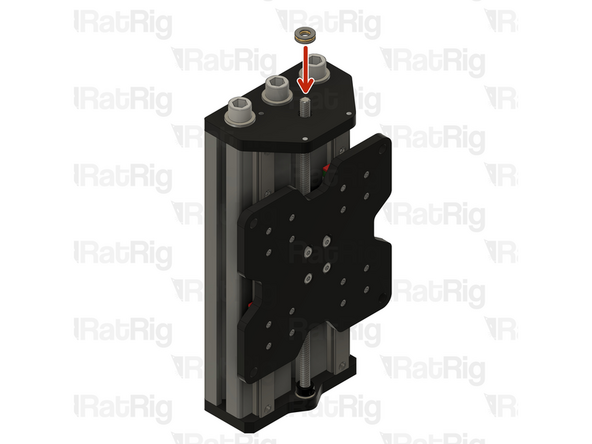

Thread the lead Screw in to the Nut Blocks on the XZ Plate and push the assembly

-

Lock Collar

-

Precision Shim

-

Push the exposed end of the Lead Screw through the hole in the ball bearing

-

Tighten the Screws on the Lock Collars to avoid the lead screw from falling in the next steps

-

-

-

Install the Thrust Bearing F8-16M on to the Lead Screw

-

Be careful that the bearing does not fall off whilst this assembly is set aside

-

Cancel: I did not complete this guide.

One other person completed this guide.