-

-

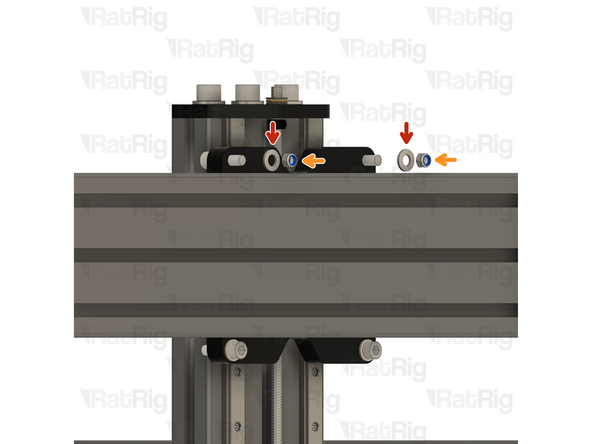

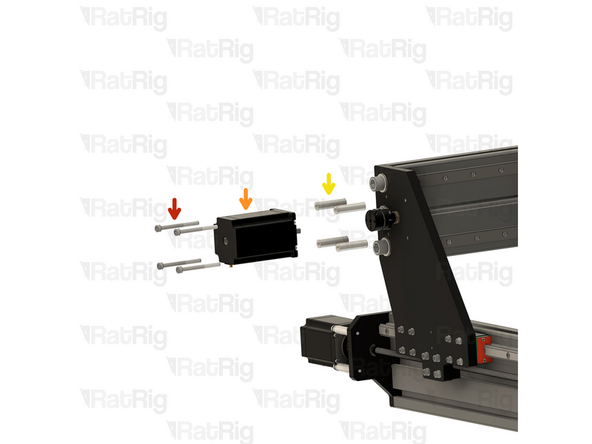

Z- Axis Assembly

-

4x M8x30 Cap Head Screw

-

4x M8 Nylon Locking Hex Nut

-

8x M8 Washer

-

-

-

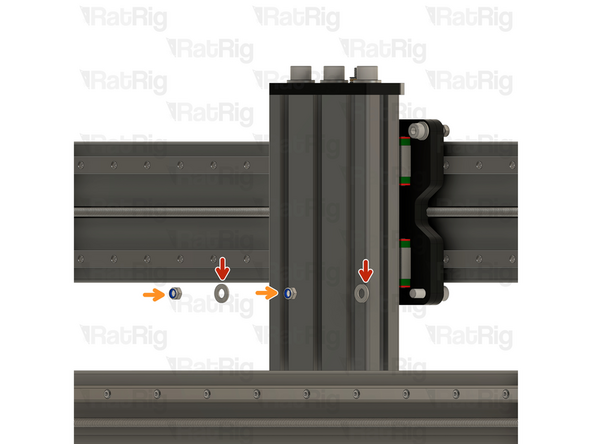

Make sure the top Z plate is at the top

-

Once all four holes are aligned, install an M8 washer on to each M8x30 screw and insert them through the XZ plates, screwing them into the ball screw block

-

The top fasteners must be inserted from the front

-

The bottom fasteners must be inserted from the back

-

-

-

Insert an M8 Washer on to each screw

-

Thread a Nylon Locking Hex Nut into each Screw and tighten everything

-

Double check the orientation of the screws before proceeding:

-

The top screws must be inserted from the front

-

The bottom screws must be inserted from the back

-

-

-

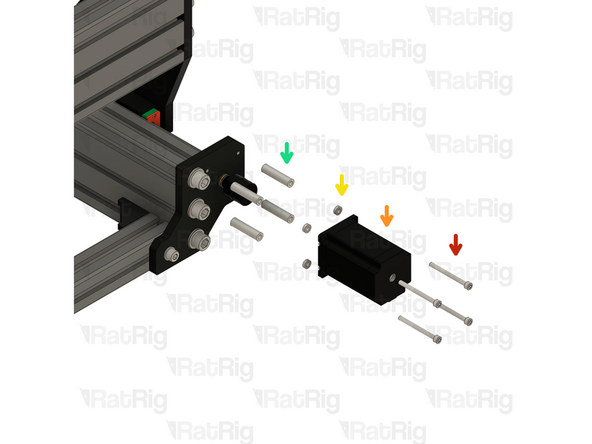

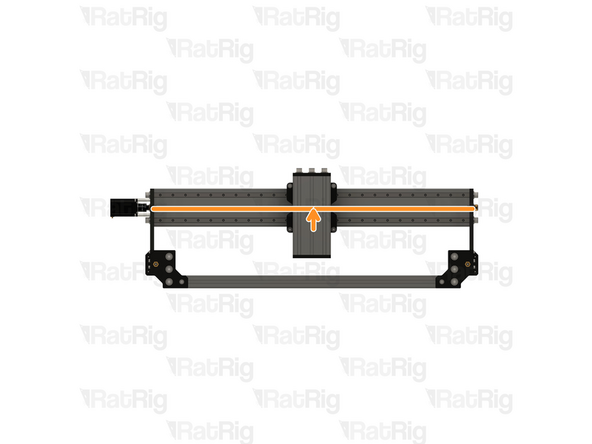

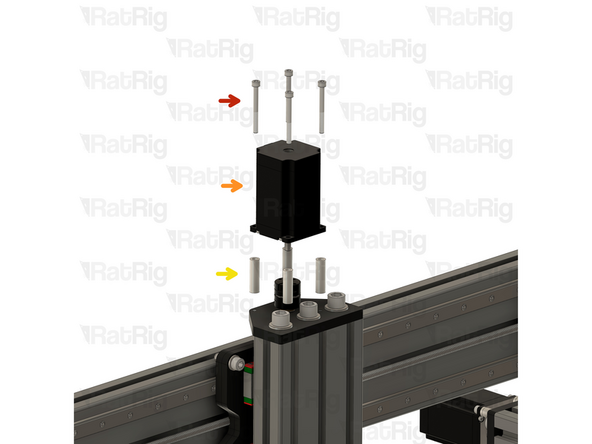

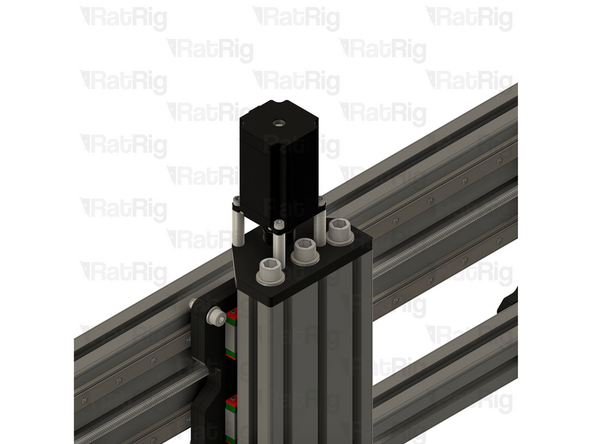

4x Nema 23 Stepper Motor High Torque

-

12x 40mm Aluminium Spacer

-

4x 35mm Aluminium Spacer

-

4x Coupler - Disk Type

-

12x M5x55 Cap Head Screw

-

4x M5x50 Cap Head Screw

-

4x 3mm Aluminium Spacer

-

-

-

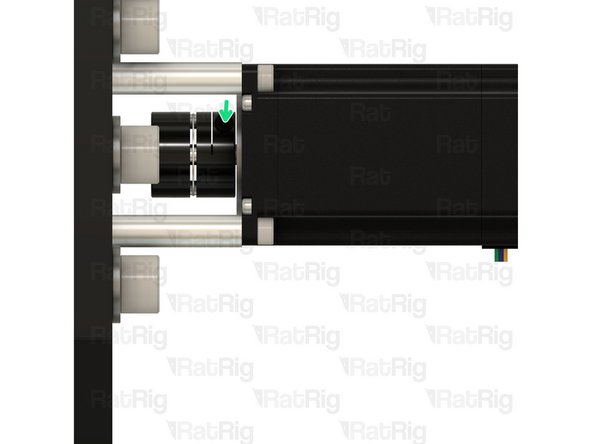

Coupler - Disk Type

-

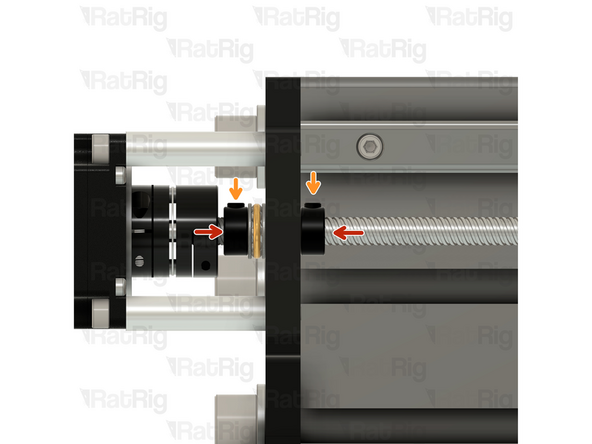

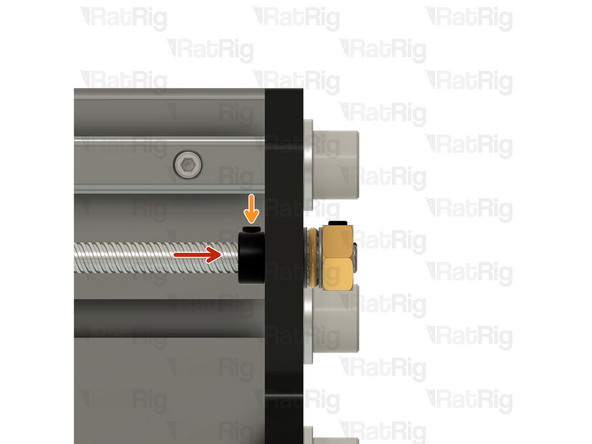

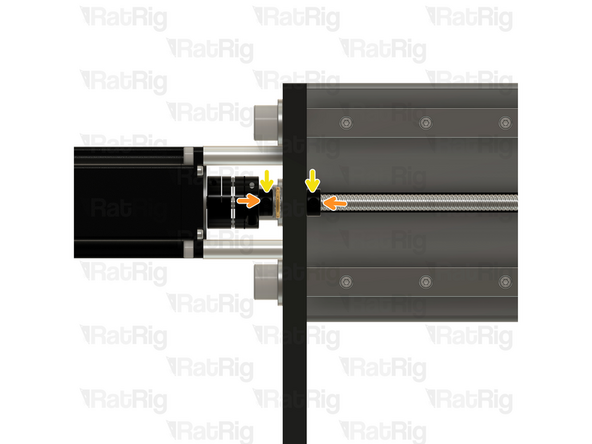

Insert the coupler on to the end of the Y-Axis Lead Screw

-

Tighten the Screw on the Coupler

-

-

-

4x M5x55 Cap Head Screw

-

Nema 23 Stepper Motor High Torque

-

4x 40mm Aluminium Spacer

-

4x 3mm Aluminium Spacer

-

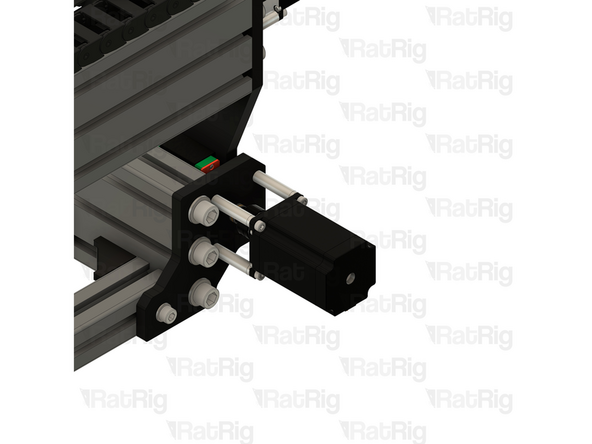

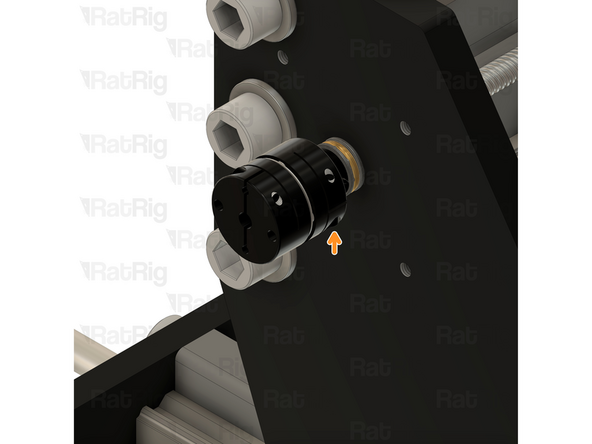

Using a 2.5mm hex key, tighten the marked screw to secure the disc coupler to the NEMA23 shaft

-

Rotate the lead screw by hand until the marked screw is accessible. It's required that both Y-Axis lead screw are rotated simultaneously since they are atatched to the X-gantry.

-

-

-

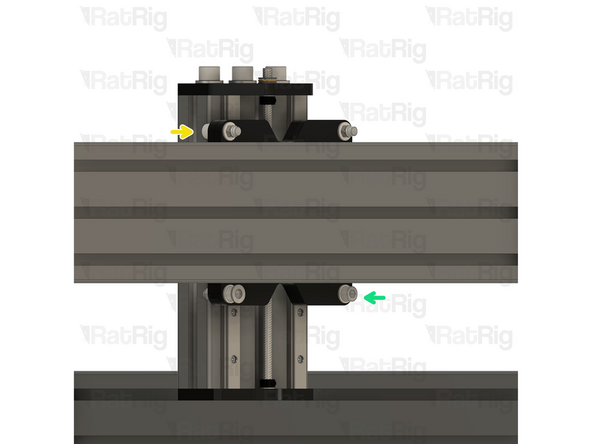

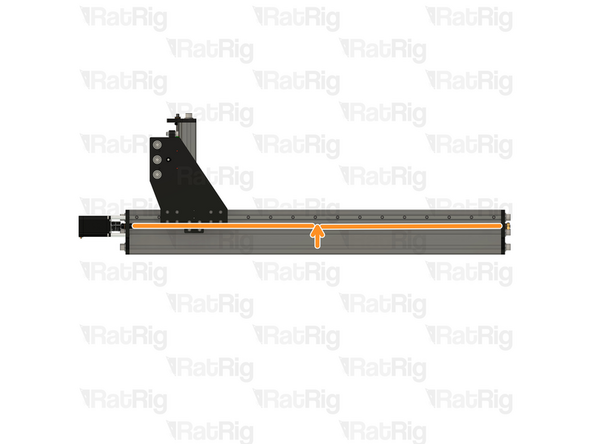

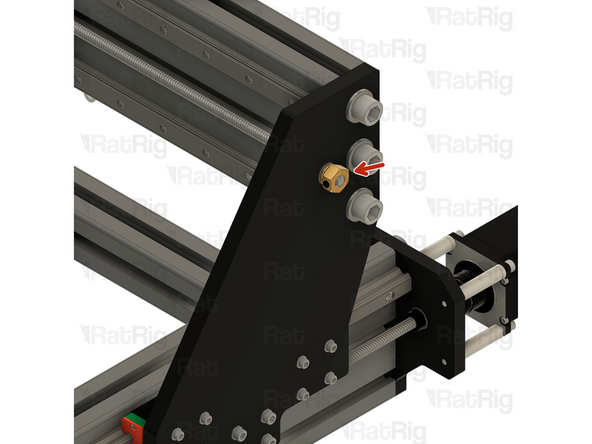

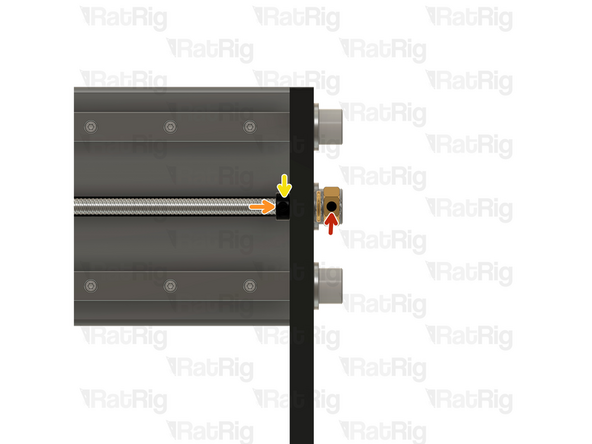

Tighten the Tensioning Nut until the lead screw is straight

-

If you are building a bigger StrongHold ONE then sag on the Lead Screw should be more noticeable, requiring a bit more tension to keep it straight

-

Don't overtighten the tensioning nut as it will lead to binding and malfunction of the axis

-

Tighten the screw on the tensioner nut once the lead screw is properly adjusted

-

-

-

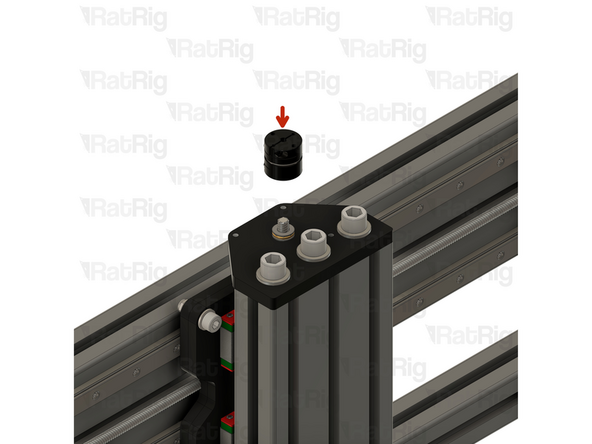

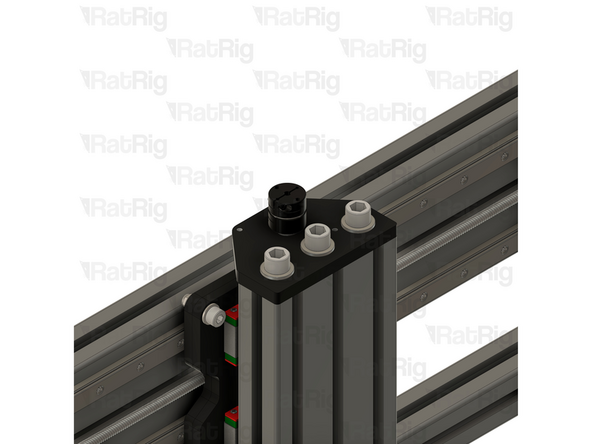

Push both Lock Collars against the plate

-

Tighten the Lock Collar screw

-

Repeat for the Lock Collar on the other end of the Lead Screw

-

-

-

Repeat Steps 5 through 8 to install the remaining Y-Axis Stepper Motor

-

-

-

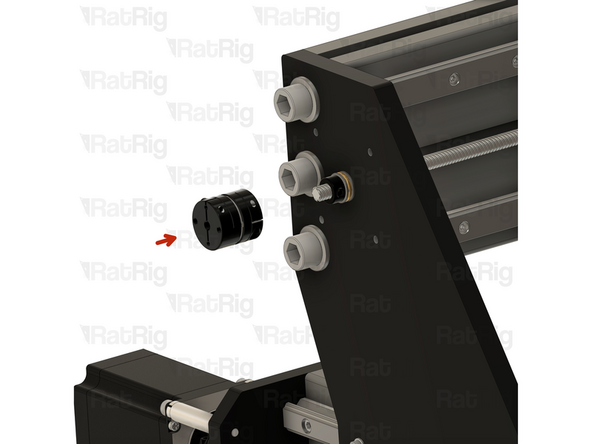

Coupler - Disk Type

-

Insert the coupler on to the end of the X-Axis Lead Screw

-

Tighten the Screw on the Coupler

-

-

-

4x M5x55 Cap Head Screw

-

Nema 23 Stepper Motor High Torque

-

4x 40mm Aluminium Spacer

-

Using a 2.5mm hex key, tighten the marked screw to secure the disc coupler to the NEMA23 shaft

-

Rotate the coupler by hand until the marked screw is accessible

-

-

-

Tighten the Tensioning Nut until the lead screw is straight

-

If you are building a bigger StrongHold ONE CNC then the sag on the Lead Screw should be more noticeable, requiring a bit more tension to keep it straight

-

Don't overtighten the tensioning nut as it will lead to binding and malfunction of the axis

-

-

-

Tighten the screw on the tensioner nut once the lead screw is properly adjusted

-

Push both Lock Collars against the plate

-

Tighten the Lock Collar screw

-

Repeat for the Lock Collar on the other end of the Lead Screw

-

-

-

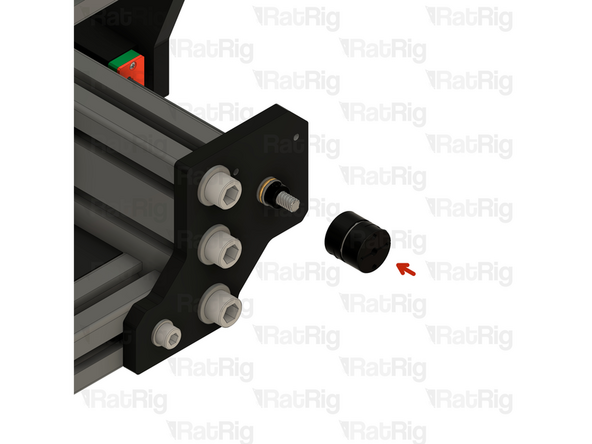

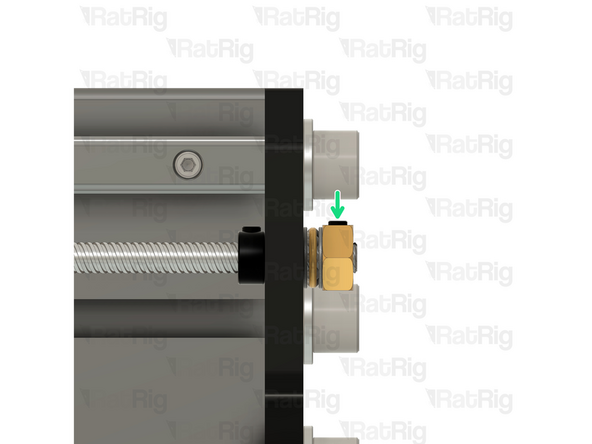

Coupler - Disk Type

-

Insert the coupler on to the end of the Z-Axis Lead Screw

-

Tighten the Screw on the Coupler

-

-

-

4x M5x50 Cap Head Screw

-

Nema 23 Stepper Motor High Torque

-

4x 35mm Aluminium Spacer

-

Using a 2.5mm hex key, tighten the marked screw to secure the disc coupler to the NEMA23 shaft

-

Rotate the coupler by hand until the marked screw is accessible

-

Cancel: I did not complete this guide.

One other person completed this guide.