Introduction

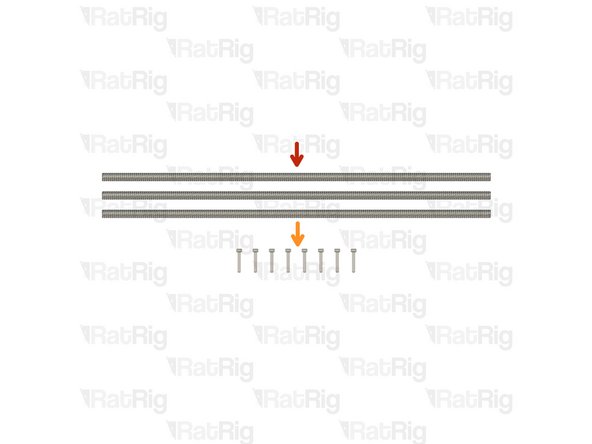

Please note: The lead screw measurements provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, please refer to the following list for the correct lead screw length for your machine:

- 200x200: 3x 280mm lead screws

- 300x300: 3x 380mm lead screws

- 400x400: 3x 480mm lead screws

- 500x500: 3x 580mm lead screws

-

-

1x bed_arm_right_3.1 Printed Part

-

1x bed_arm_left_3.1 Printed Part

-

4x M3x12 Countersink Screw

-

4x 3x35mm Dowel Pin

-

2x Neodymium Magnet

-

4x M3 Nylon Locking Hex Nut

-

-

-

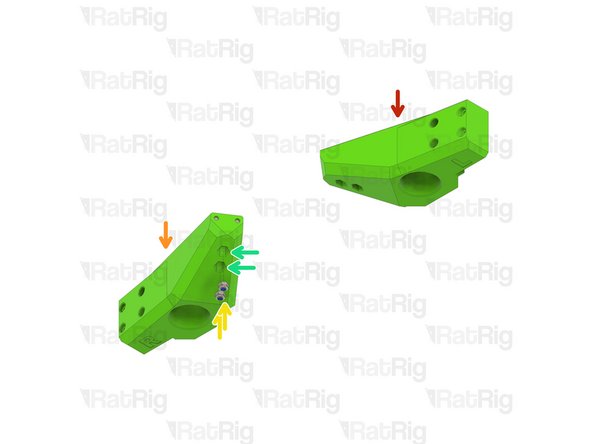

bed_arm_left_3.1 Printed Part

-

bed_arm_right_3.1 Printed Part

-

3x35mm Dowel Pin

-

Insert two dowel pins into each arm as shown

-

Please note: The dowel pins are quite a tight fit. It is recommended to use a pair of pliers to install them by twisting each pin in the same manner you would install a screw

-

Do not use excessive force to install the pins as this can cause damage to the printed part

-

-

-

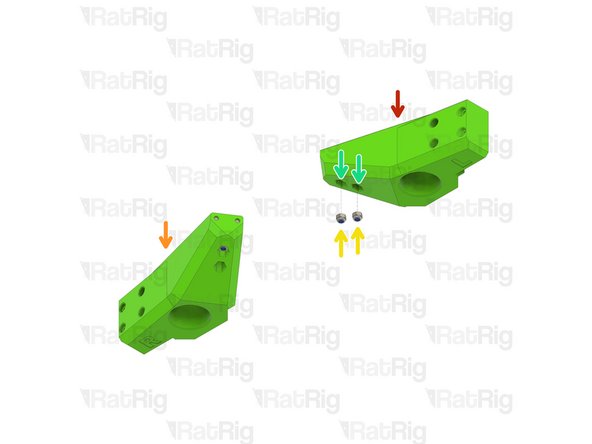

Left Bed Arm Assembly

-

Right Bed Arm Assembly

-

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

-

-

Left Bed Arm Assembly

-

Right Bed Arm Assembly

-

Neodymium Magnet

-

M3x12 Countersink Screw

-

Install two M3x12 countersink screws into each magnet and then install them into the arms as shown

-

Take care not to over tighten the M3x12 screws as you can crack the magnets and/or damage the printed parts

-

Set these assemblies aside until Step 7

-

-

-

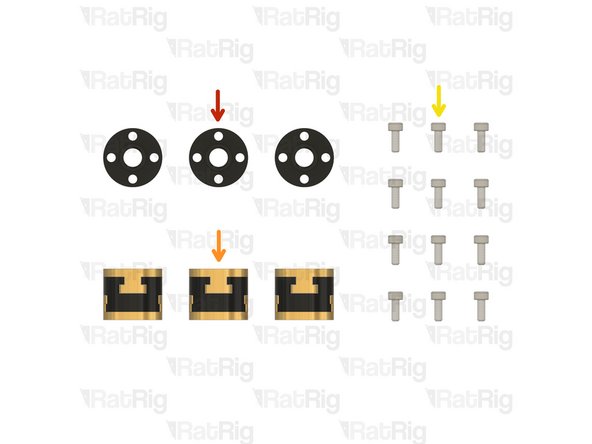

3x TR8x4 POM Lead screw Nut

-

3x Rat Rig Bi-Material Lead Screw Decoupler

-

12x M3x8 Cap Head Screw

-

-

-

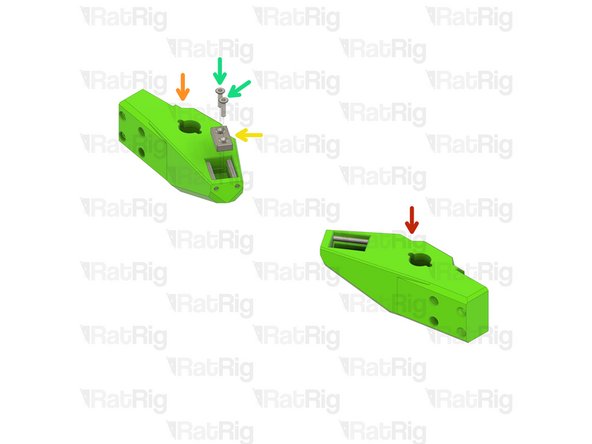

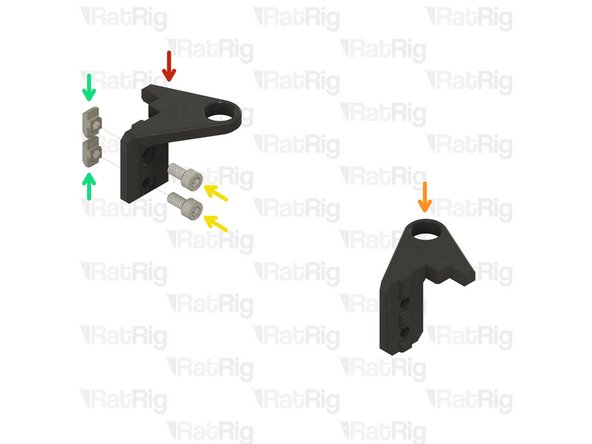

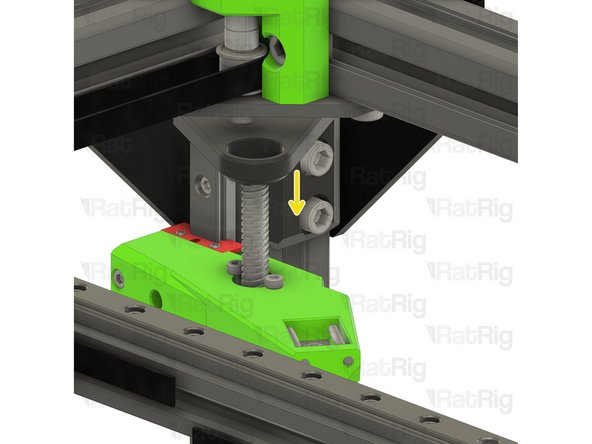

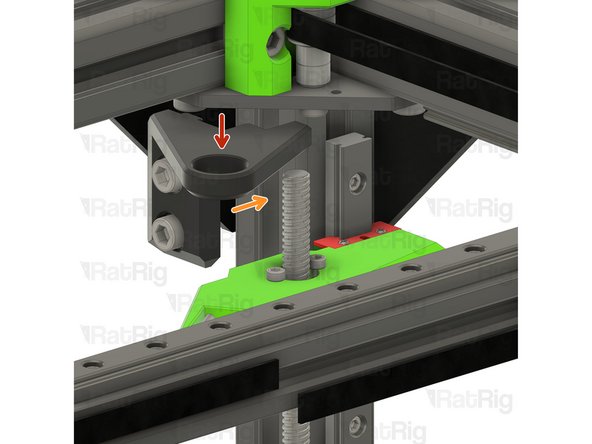

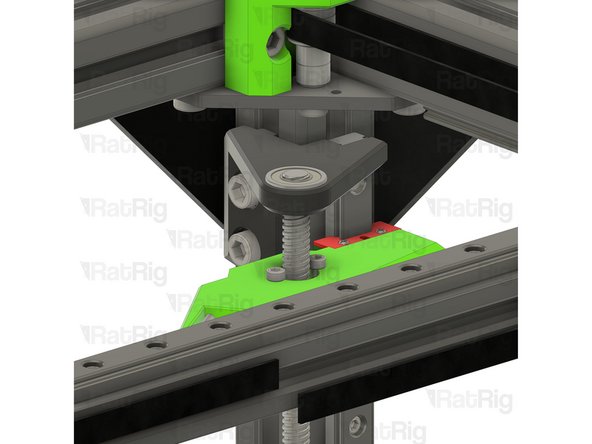

Rat Rig Bi-Material Lead Screw Decoupler

-

TR8x4 POM Lead screw Nut

-

M3x8 Cap Head Screw

-

Assemble all three lead screw decouplers as shown. Set one aside until Step 13, keep the other two for the next step

-

-

-

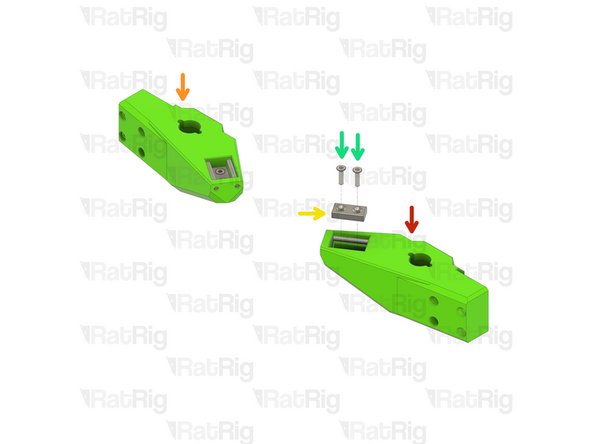

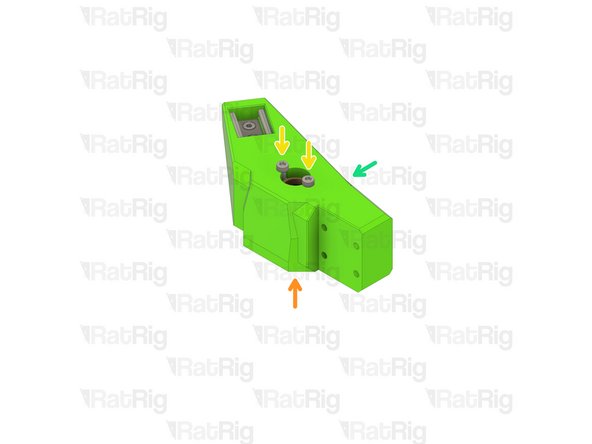

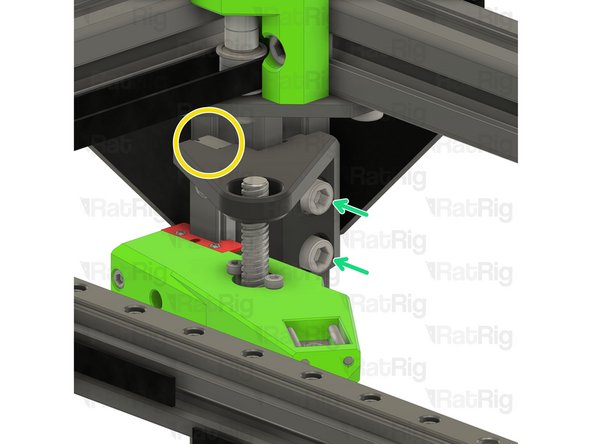

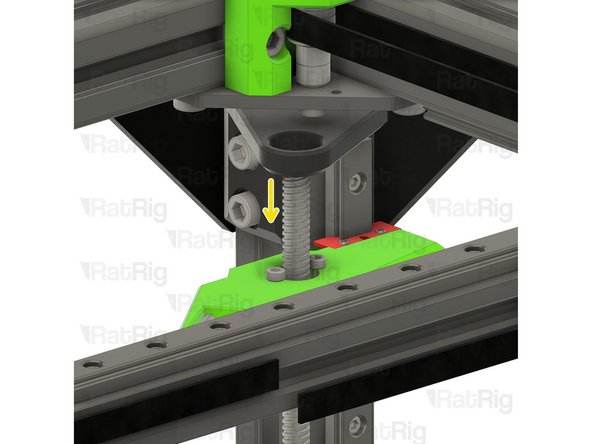

Left bed arm assembly

-

Lead screw decoupler assembly

-

M3x8 Cap Head Screw

-

Install a lead screw decoupler assembly into each arm as shown

-

Take care not to over tighten the M3x8 screws as you damage the printed parts

-

Right bed arm assembly

-

-

-

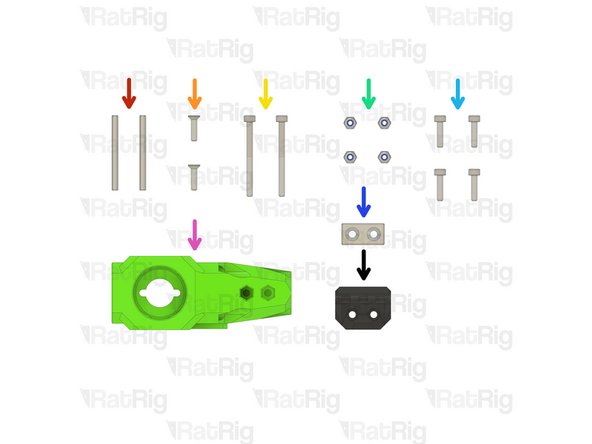

2x 3x35mm Dowel Pin

-

2x M3x12 Countersink Screw

-

2x M3x35 Cap Head Screw

-

4x M3 Nylon Locking Hex Nut

-

4x M3x12 Cap Head Screw

-

1x Neodymium Magnet

-

1x bed_arm_rear_3.1 Printed Part

-

1x bed_cable_relief_3.1 Printed Part

-

-

-

bed_arm_rear_3.1 Printed Part

-

3x35mm Dowel Pin

-

Insert two dowel pins into the arm as shown

-

Please note: The dowel pins are quite a tight fit. It is recommended to use a pair of pliers to install them by twisting each pin in the same manner you would install a screw

-

Do not use excessive force to install the pins as this can cause damage to the printed part

-

-

-

Rear bed arm assembly

-

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

-

-

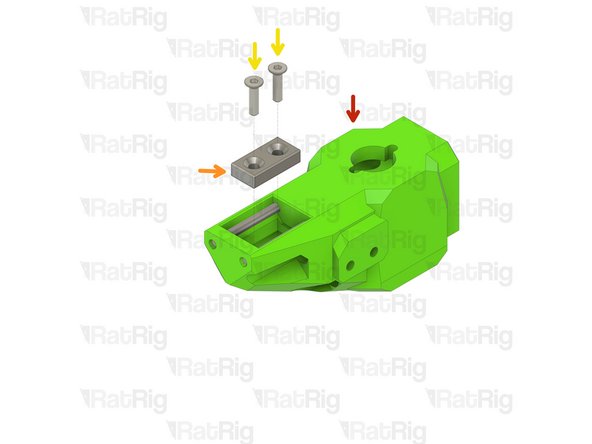

Rear bed arm assembly

-

Neodymium Magnet

-

M3x12 Countersink Screw

-

Install two M3x12 countersink screws into the magnet and then install it into the arm as shown

-

Take care not to over tighten the M3x12 screws as you can crack the magnet and/or damage the printed part

-

-

-

Rear bed arm assembly

-

M3 Nylon Locking Hex Nut

-

bed_cable_relief_3.1 Printed Part

-

M3x35 Cap Head Screw

-

Install the M3x35 screws through the bed_cable_relief_3.1 printed part, rear bed arm, and fasten them into the M3 nylon locking nuts

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

-

-

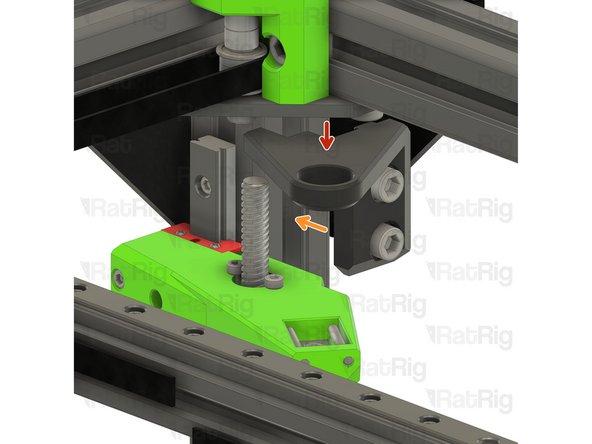

V-Core 3.1 Frame Assembly

-

Rear bed arm assembly

-

M3x12 Cap Head Screw

-

Install the M3x12 screws into the arm as shown, then fasten the arm to the rear linear rail carriage

-

Lead screw decoupler assembly from Step 6

-

M3x8 Cap Head Screw

-

Install a lead screw decoupler assembly into the rear arm as shown

-

Take care not to over tighten the M3 screws as you damage the printed part

-

-

-

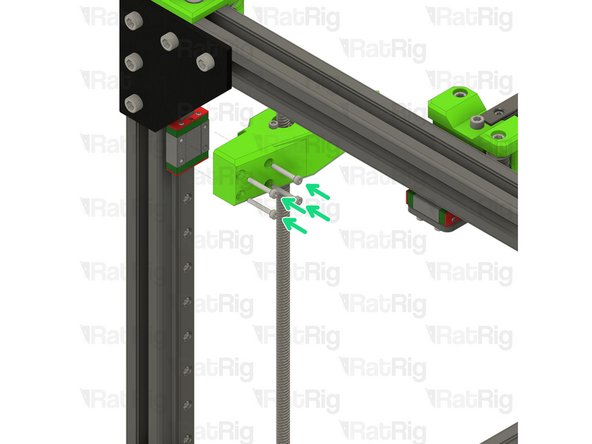

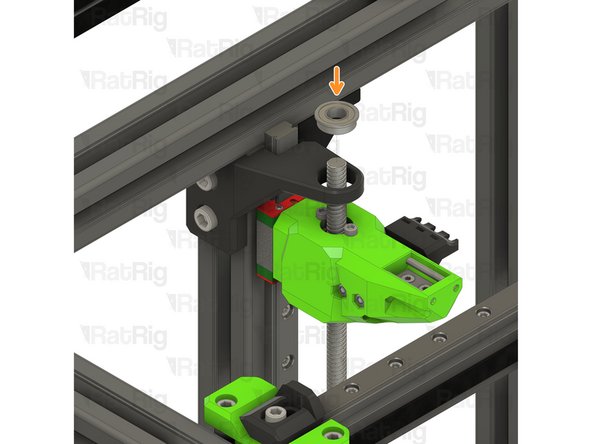

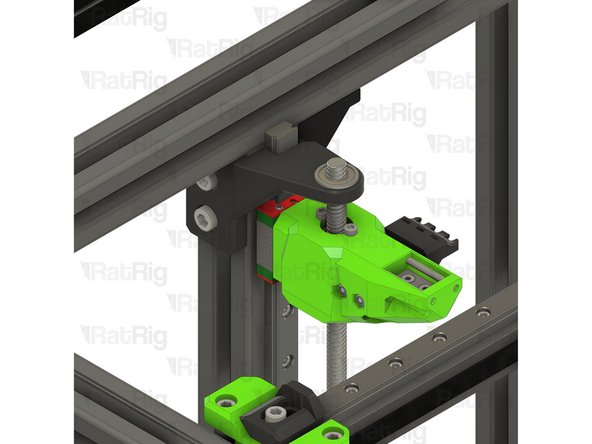

Rear bed arm assembly

-

380mm TR8x4 Lead Screw

-

Install the lead screw through the rear bed arm and decoupler

-

Do not force the lead screw through the POM nut on the decoupler as this can cause damage. It should thread through smoothly

-

Rigid Lead Screw Coupler

-

Continue threading the lead screw through the arm until it reaches the rigid lead screw coupler on the rear Z-axis motor mount

-

Insert the lead screw fully into the rigid coupler

-

Fasten the marked M3 screw to secure the lead screw to the NEMA17 motor

-

-

-

Front right bed arm assembly

-

380mm TR8x4 lead screw

-

Install the lead screw through the front bed arm and decoupler

-

Do not force the lead screw through the POM nut on the decoupler as this can cause damage. It should thread through smoothly

-

Continue threading the lead screw through the arm until it reaches the rigid lead screw coupler on the front right Z-axis motor mount

-

M3x20 Cap Head Screw

-

Install each screw through the bed arm assembly as shown, then fasten the arm to the linear rail carriage

-

-

-

Rigid Lead Screw Coupler

-

Insert the lead screw fully into the rigid coupler

-

Fasten the marked M3 screw to secure the lead screw to the NEMA17 motor

-

-

-

Front left bed arm assembly

-

380mm TR8x4 lead screw

-

Install the lead screw through the front bed arm and decoupler

-

Do not force the lead screw through the POM nut on the decoupler as this can cause damage. It should thread through smoothly

-

Continue threading the lead screw through the arm until it reaches the rigid lead screw coupler on the front left Z-axis motor mount

-

M3x20 Cap Head Screw

-

Install each screw through the bed arm assembly as shown, then fasten the arm to the linear rail carriage

-

-

-

Rigid Lead Screw Coupler

-

Insert the lead screw fully into the rigid coupler

-

Fasten the marked M3 screw to secure the lead screw to the NEMA17 motor

-

-

-

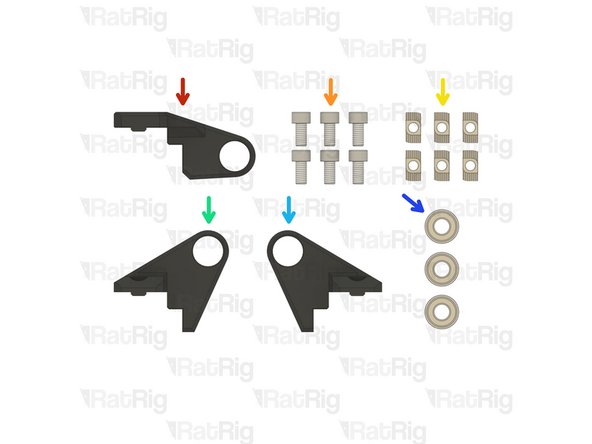

1x lead_screw_constraint_rear_3.1 Printed Part

-

6x M6x12 Cap Head Screw

-

6x 3030 Drop-in T-Nut - M6

-

1x lead_screw_constraint_front_left_3.1 Printed Part

-

1x lead_screw_constraint_front_right_3.1 Printed Part

-

3x F688ZZ Ball Bearing

-

-

-

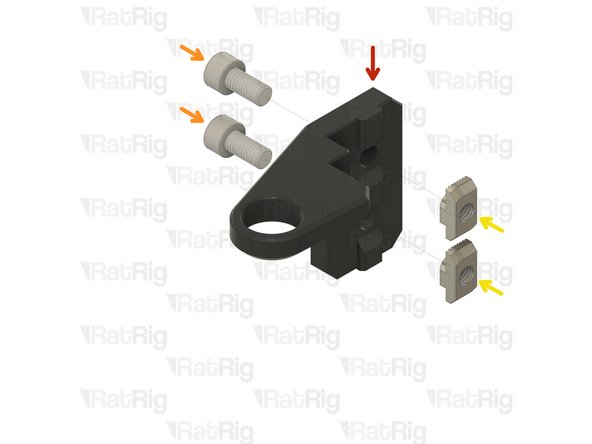

lead_screw_constraint_rear_3.1 Printed Part

-

M6x12 Cap Head Screw

-

Insert an M6x12 cap head screw into each position on the lead screw constraint as shown

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x20 screws. Do not tighten them at this point

-

-

-

lead_screw_constraint_left_3.1 Printed Part

-

lead_screw_constraint_right_3.1 Printed Part

-

M6x12 Cap Head Screw

-

Insert an M6x12 cap head screw into each position on the lead screw constraint as shown

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x20 screws. Do not tighten them at this point

-

-

-

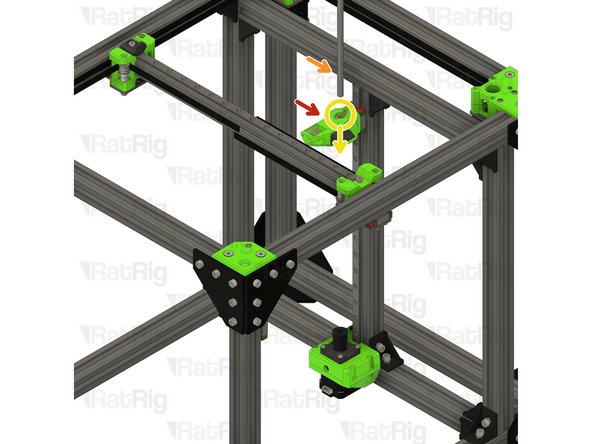

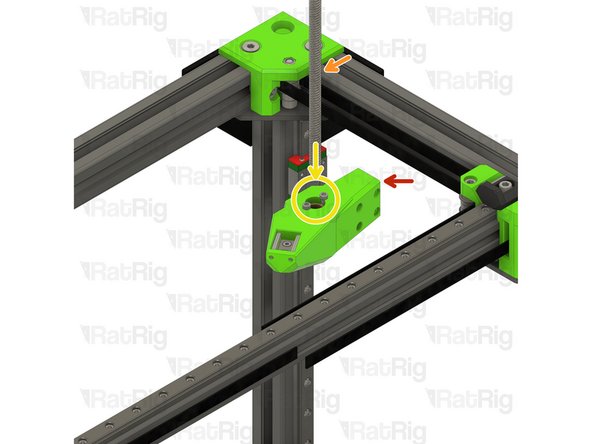

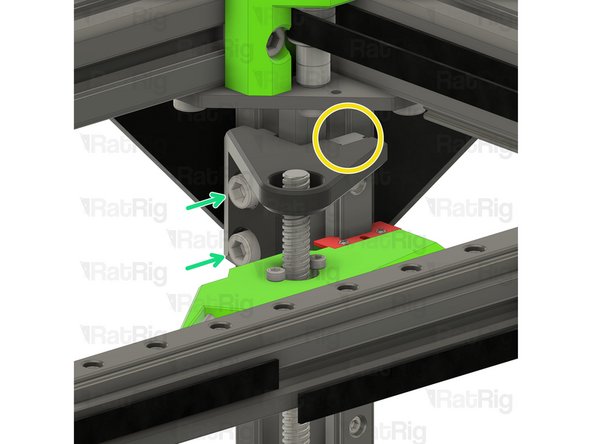

Rear lead screw constraint assembly from Step 21

-

Position the constraint assembly so that the rear lead screw passes through the hole

-

Rotate the constraint assembly clockwise and fit it to the rear 3030 extrusion as shown

-

Push the constraint assembly upwards until it touches the horizontal 3030 extrusion

-

-

-

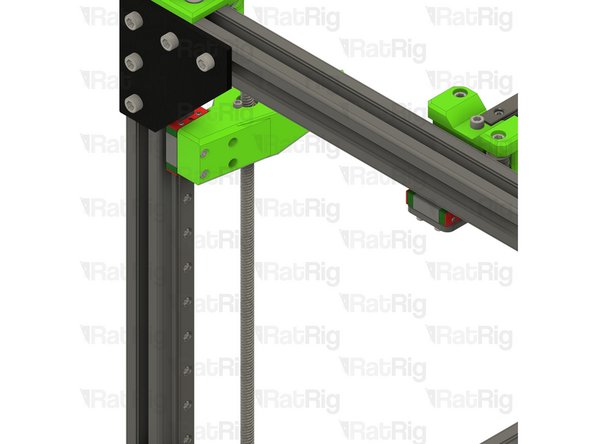

M6x12 Cap Head Screw

-

Fasten both M6x12 screws to secure the constraint assembly to the V-Core 3.1 frame

-

Take care not to over tighten the M6 screws as you damage the printed part

-

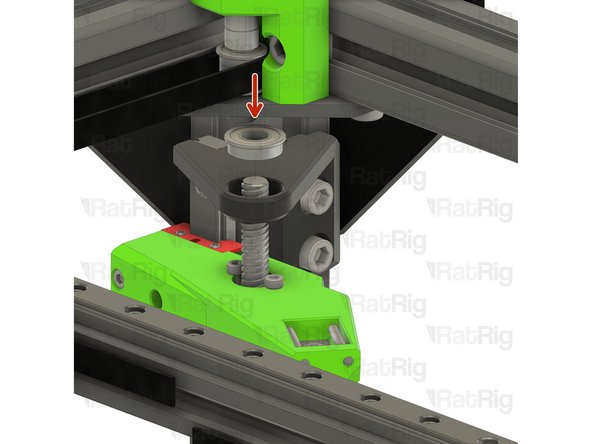

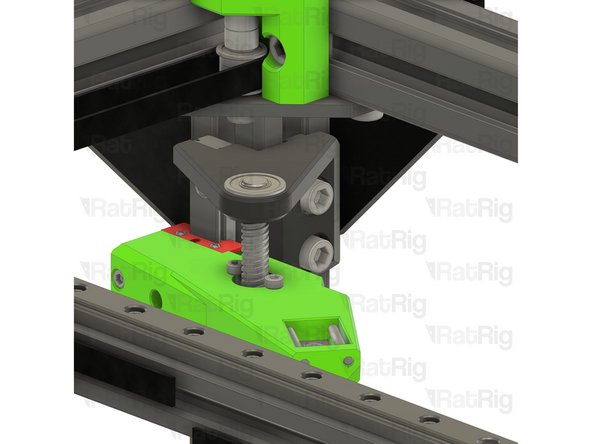

F688ZZ Ball Bearing

-

Fit the bearing onto the lead screw and into the constraint assembly as shown

-

-

-

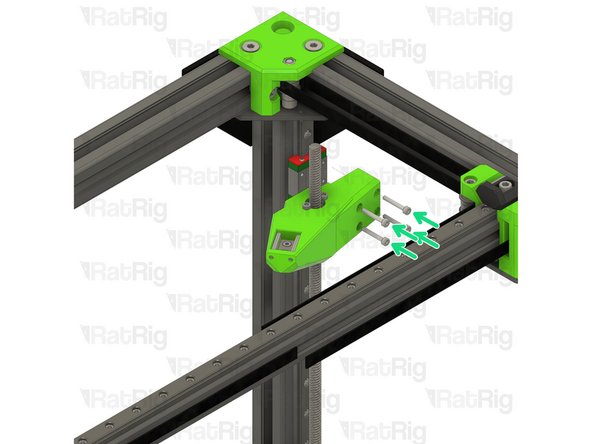

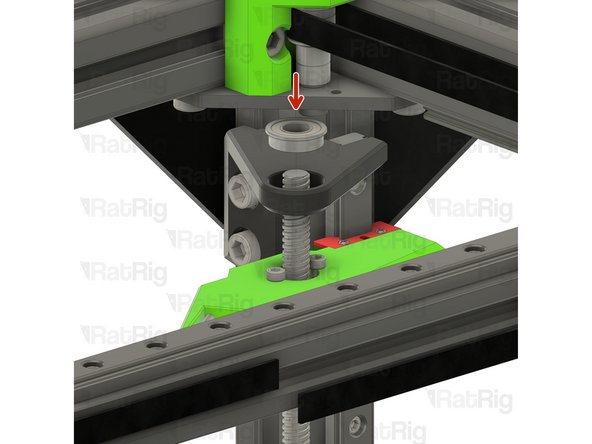

Right lead screw constraint assembly from Step 22

-

Fit the constraint assembly to the frame as shown

-

Push the constraint assembly downwards until its top is flush with the top of the linear rail

-

Fasten both M6x12 screws to secure the constraint assembly to the V-Core 3.1 frame

-

-

-

F688ZZ Ball Bearing

-

Fit the bearing onto the lead screw and into the constraint assembly as shown

-

-

-

Left lead screw constraint assembly from Step 22

-

Fit the constraint assembly to the frame as shown

-

Push the constraint assembly downwards until its top is flush with the top of the linear rail

-

Fasten both M6x12 screws to secure the constraint assembly to the V-Core 3.1 frame

-

-

-

F688ZZ Ball Bearing

-

Fit the bearing onto the lead screw and into the constraint assembly as shown

-

Cancel: I did not complete this guide.

30 other people completed this guide.