Introduction

Please note: The bed measurements provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, please refer to the following list for the correct bed measurement for your machine:

- 200x200: 229x229x5mm

- 300x300: 329x329x6mm

- 400x400: 429x429x6mm

- 500x500: 529x529x6mm

-

-

1x 329x329x6mm Machined Bed Plate

-

3x Aluminium Spacer - 6mm

-

3x Threaded Steel Ball

-

3x M5x16 Countersink Screw

-

-

-

To prevent scratches, the bed plate is shipped with a protective film on both sides.

-

Gently peel off the protective film.

-

Repeat for the other side.

-

The magnetic sheet and heater pad will be installed later during the commissioning guide. Do not install them now.

-

-

-

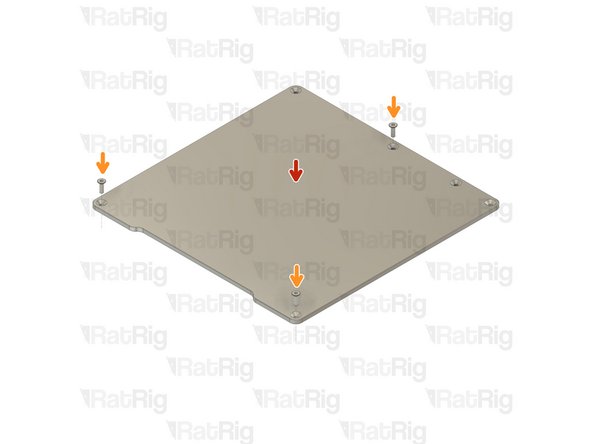

329x329x6mm Machined Bed Plate

-

M5x16 Countersink Screw

-

Insert an M5x16 countersink screw into each of the positions shown on the bed

-

Aluminium Spacer - 6mm

-

Threaded Steel Ball

-

Add an aluminium spacer and threaded steel ball to each of the M5x16 screws

-

Set the bed assembly aside until Step 9

-

-

-

1x y_max_endstop_slider_3.1 Printed Part

-

1x y_max_endstop_block_3.1 Printed Part

-

2x M3x12 Cap Head Screw

-

1x Endstop Module

-

1x M5 Nylon Locking Hex Nut

-

1x 3030 Drop-in T-Nut - M5

-

1x M5x12 Cap Head Screw

-

1x M5x10 Cap Head Screw

-

-

-

y_max_endstop_block_3.1 Printed Part

-

M5 Nylon Locking Hex Nut

-

M5x10 Cap Head Screw

-

3030 Drop-in T-Nut - M5

-

Loosely thread the 3030 T-Nut onto the M5x10 screw. Do not tighten it at this point.

-

-

-

M3x12 Cap Head Screw

-

Endstop Module

-

y_max_endstop_slider_3.1 Printed Part

-

Install an M3x12 screw through each hole on the endstop module and screw it into the printed part

-

M5x12 Cap Head Screw

-

Install the M5x12 screw through the y_max_endstop_slider printed part and fasten it into the M5 nylon hex nut

-

-

-

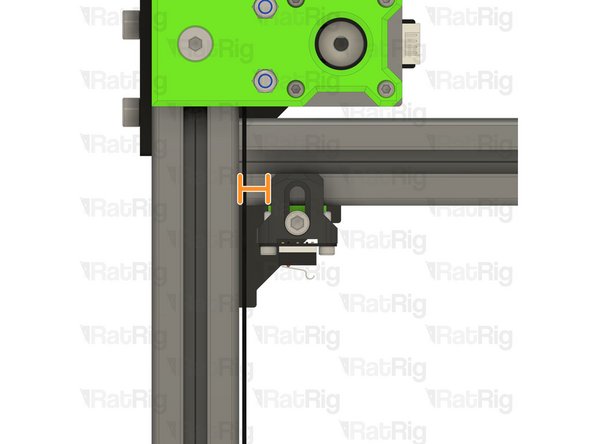

Position the y-axis endstop on to the V-Core 3.1 frame as shown

-

Check that the distance shown measures 11mm

-

Fasten the M5x10 screw to secure the y-axis endstop assembly to the frame

-

-

-

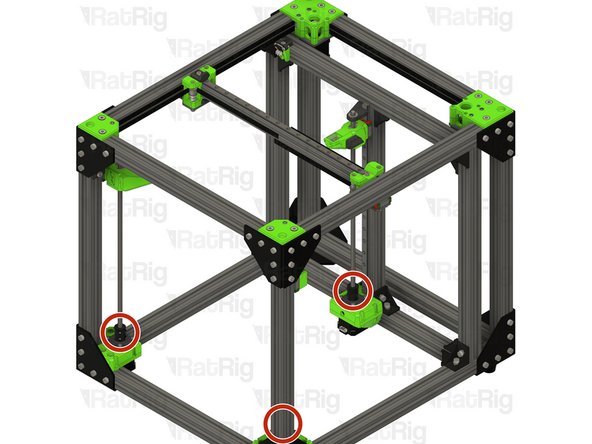

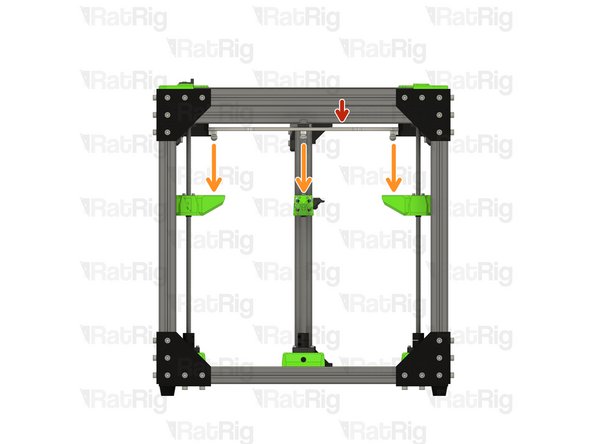

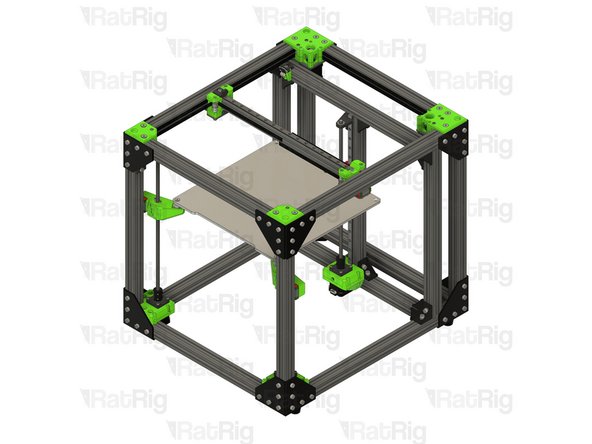

Rotate each z-axis lead screw counter-clockwise to lower the bed arms

-

Stop when the arms are roughly half way down

-

-

-

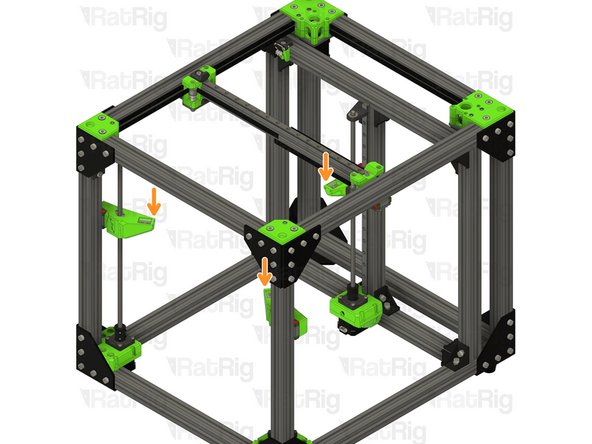

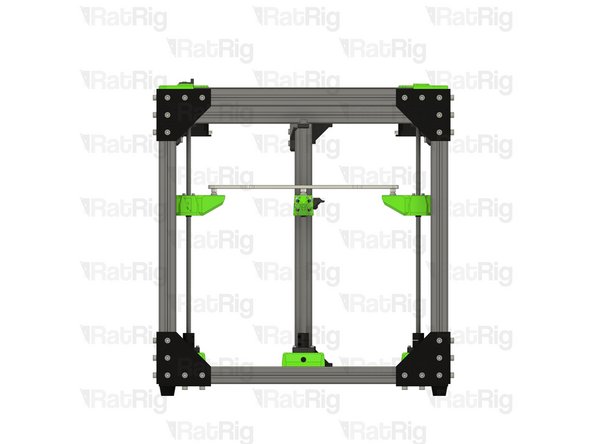

Bed assembly from Step 2

-

Install the bed onto the z-axis arms. Each ball on the bed should rest on the dowel pins in each arm

-

-

-

Follow the guide with the EVA heat insert assembly or the EVA hex nut assembly

-

Continue with the next guide: 09. EVA 3.0 Heat Insert Assembly

-

Continue with the next guide: 10. EVA 3.0 Hex Nut Assembly

-

Cancel: I did not complete this guide.

29 other people completed this guide.