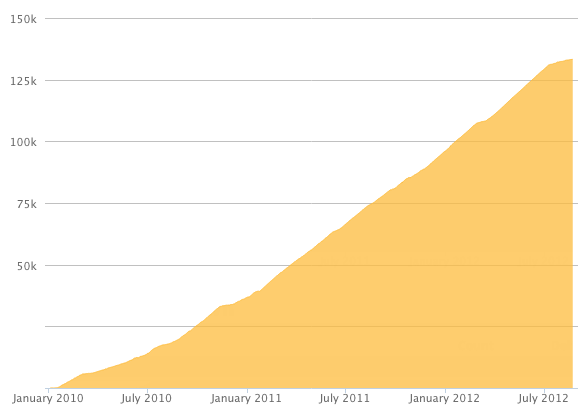

Reputation over time

It looks like this user hasn't gained any reputation yet.

Once they have, you'll be able to view a graph of their reputation gained over time.

Here's a preview of what the graph will look like:

Reputation Breakdown

No reputation gained yet.

481