-

-

It is recommended to have the following tools available for assembling the Compact CNC Electronics Enclosure:

-

Allen Key / Hex Wrenches in the following sizes: 2mm, 3mm & 5mm

-

Wire cutters & a wire stripper

-

Crimping tool (JST-XH, Molex-Micro fit and 18-14AWG Fork + Spade terminals)

-

Cross slot / phillips and flat screwdrivers

-

Soldering Iron with an M3 heat insert tip

-

-

-

The following printed parts need preparation:

-

4x compact_cnc_electronics_corner printed part

-

2x compact_cnc_electronics_btt_rodent printed part

-

2x compact_cnc_electronics_psu printed part

-

This part also has sacrificial layers which need to be cleared

-

36x M3 heat insert

-

-

-

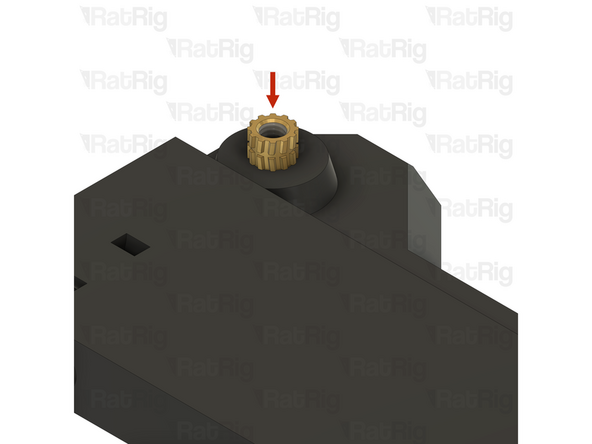

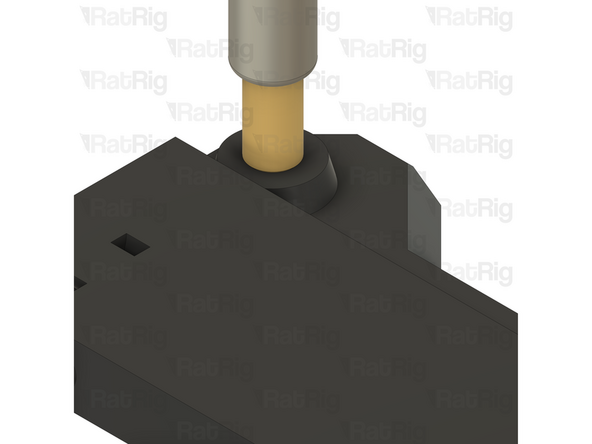

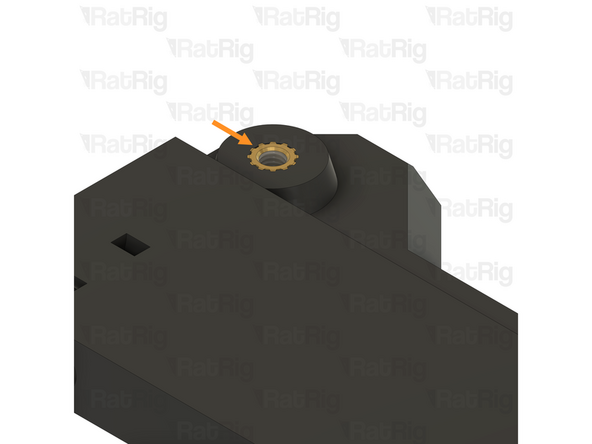

These steps show how to install an M3 heat insert into the printed parts

-

M3 heat insert

-

Soldering iron with M3 heat insert tip

-

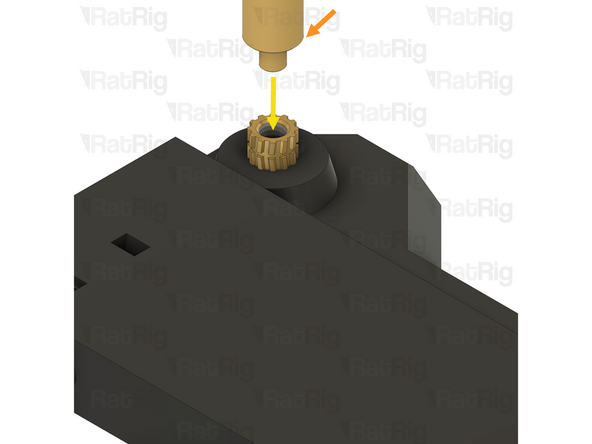

Align the soldering iron tip with the heat insert

-

Be careful not to burn yourself!

-

-

-

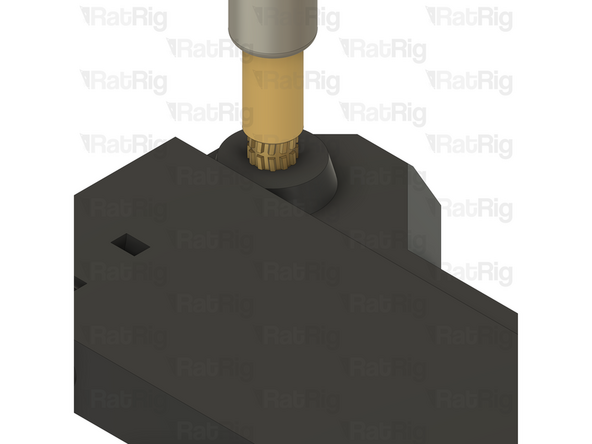

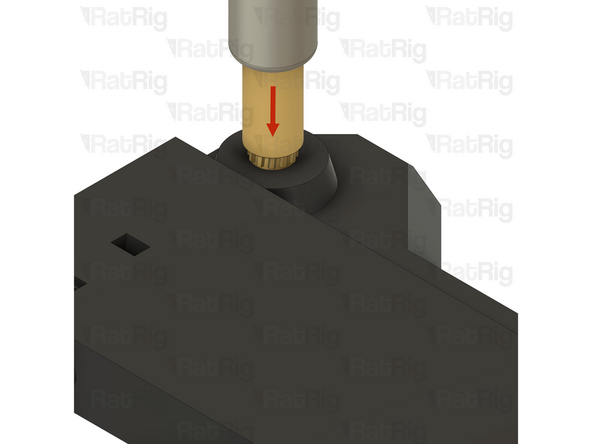

Slowly press the heat insert into the printed part

-

Ensure the heat insert is flush with the printed part, or even a little below the surface

-

Avoid having a heat insert higher than the printed part, this can cause assembly issues

-

Remove the soldering iron

-

Be careful not to burn yourself!

-

-

-

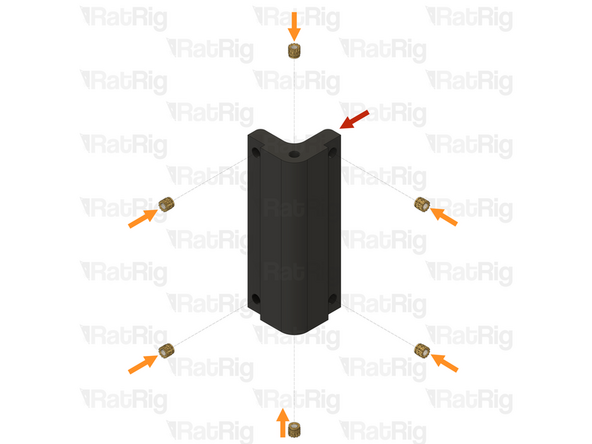

compact_cnc_electronics_corner printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

Repeat for all 4 compact_cnc_electronics_corner printed parts

-

Set these assemblies aside until Step XX

-

-

-

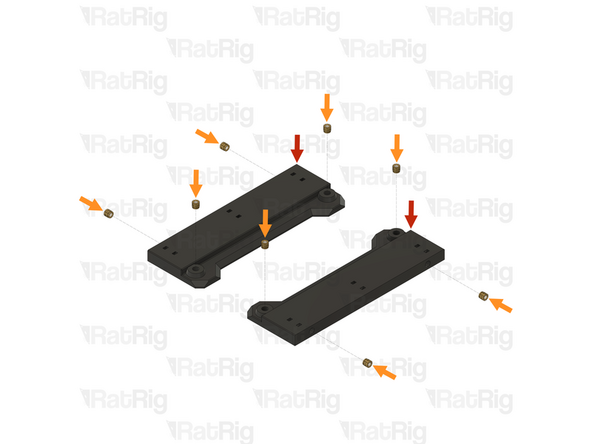

compact_cnc_electronics_btt_rodent printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

-

-

compact_cnc_electronics_psu printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

Repeat for both compact_cnc_electronics_psu printed parts

-

Set these assemblies aside until Step 15

-

-

-

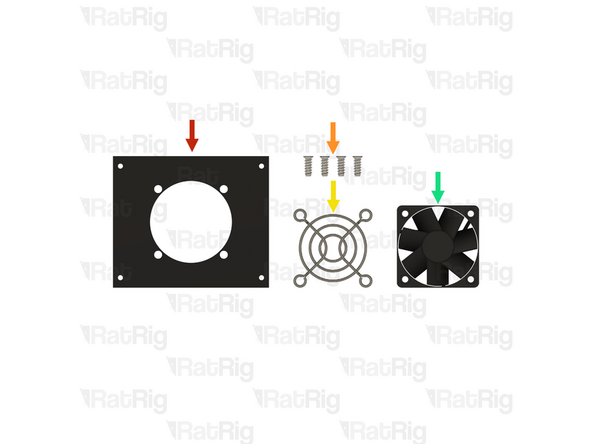

1x compact_cnc_rear_cooling_panel

-

4x Self tapping screw - fan - 12mm

-

1x 50mm fan grille

-

1x 50x15mm 24V fan

-

-

-

4x Self tapping screw - fan - 12mm

-

1x 50mm fan grille

-

1x compact_cnc_rear_cooling_panel

-

1x 50x15mm 24V fan

-

Insert the screws through the fan grille, through the panel, and then thread them into the fan body

-

-

-

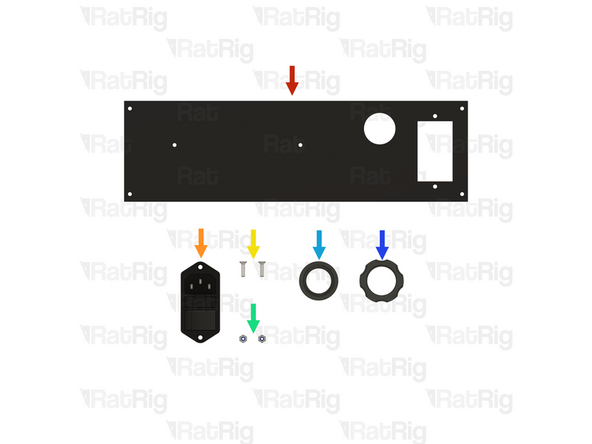

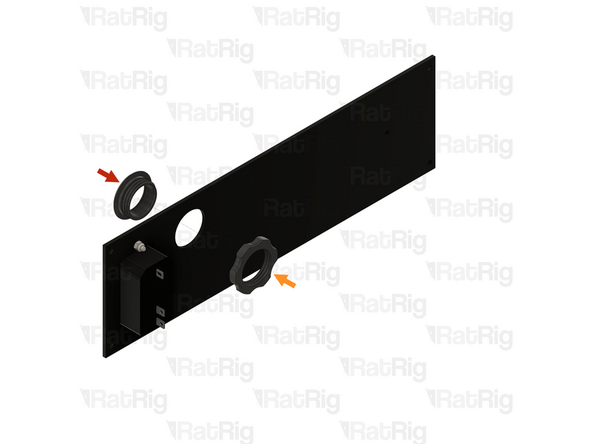

1x compact_cnc_left_panel

-

1x Switchable & fused IEC inlet

-

2x M3x12 Countersink screw

-

2x M3 locking hex nut

-

1x compact_cnc_electronics_panel_collar printed part

-

1x compact_cnc_electronics_panel_collar_nut printed part

-

-

-

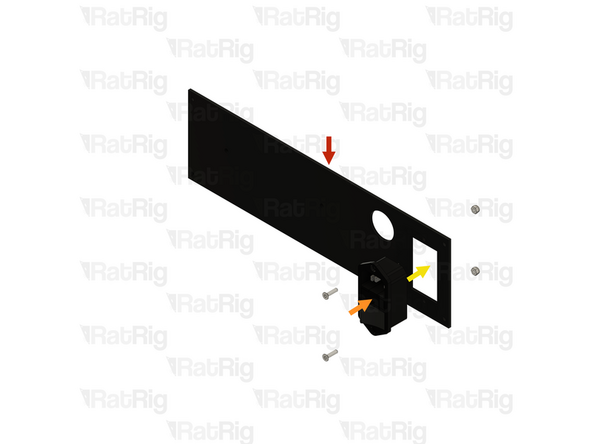

1x compact_cnc_left_panel

-

1x Switchable & fused IEC inlet

-

Insert the IEC inlet into the panel as shown

-

2x M3x12 Countersink screw

-

2x M3 locking hex nut

-

Tighten the M3 screws to secure the IEC inlet to the panel

-

-

-

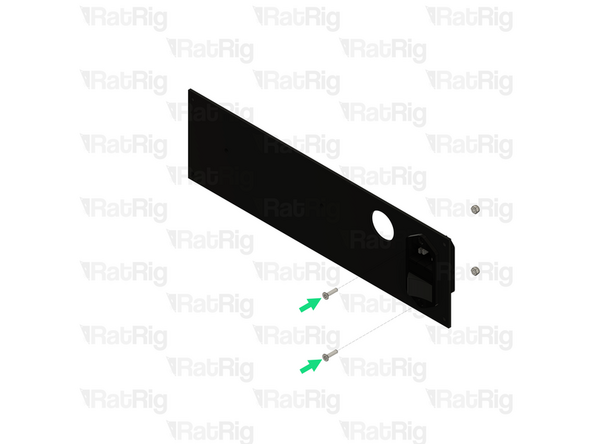

1x compact_cnc_electronics_panel_collar printed part

-

1x compact_cnc_electronics_panel_collar_nut printed part

-

Do not overtighten the printed nut as you can damage the printed parts

-

-

-

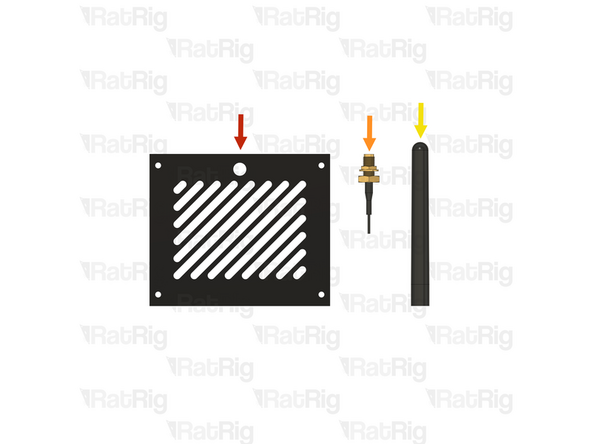

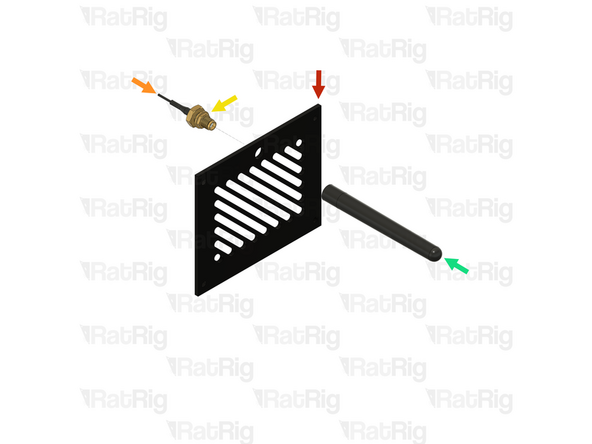

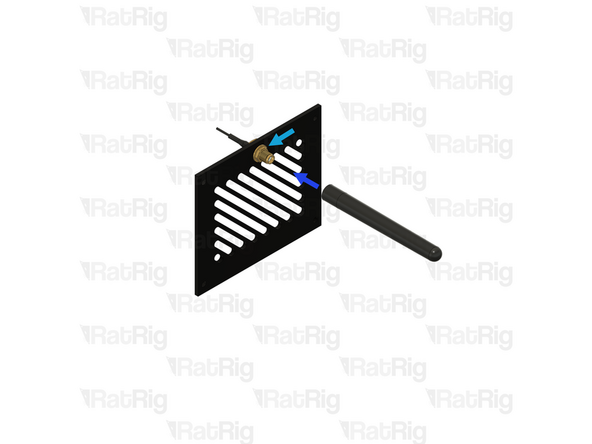

1x compact_cnc_top_panel

-

1x IPEX to SMA female WiFi pigtail

-

1x SMA 2.4GHz Wifi antenna

-

-

-

1x compact_cnc_top_panel

-

1x IPEX to SMA female WiFi pigtail

-

Remove the marked nut from the WiFi pigtail, then insert the pigtail into the panel

-

1x SMA 2.4GHz Wifi antenna

-

Secure the WiFi pigtail to the panel by reinstalling the nut

-

Screw the WiFi antenna onto the WiFi pigtail

-

-

-

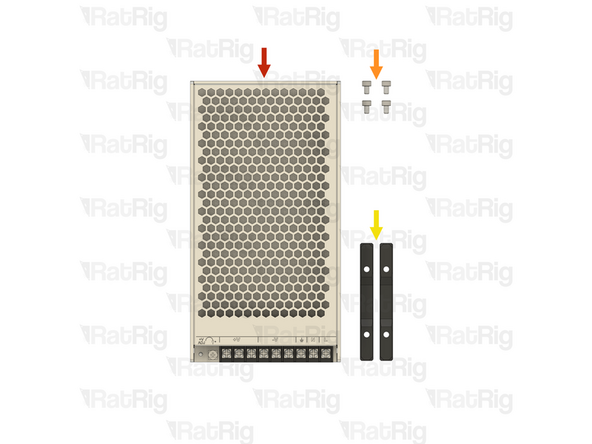

1x Weho LRS-250-24 fanless PSU

-

4x M4x6 cap head screw

-

2x PSU mount assemblies from Step 7

-