-

-

It is recommended to have the following tools available for assembling the Compact CNC Electronics Enclosure:

-

Allen Key / Hex Wrenches in the following sizes: 2mm, 3mm & 5mm

-

Wire cutters & a wire stripper

-

Crimping tool (JST-XH, Molex-Micro fit and 18-14AWG Fork + Spade terminals)

-

Cross slot / phillips and flat screwdrivers

-

Soldering Iron with an M3 heat insert tip

-

-

-

The following printed parts need preparation:

-

4x compact_cnc_electronics_corner printed part

-

2x compact_cnc_electronics_btt_rodent printed part

-

2x compact_cnc_electronics_psu printed part

-

This part also has sacrificial layers which need to be cleared

-

36x M3 heat insert

-

-

-

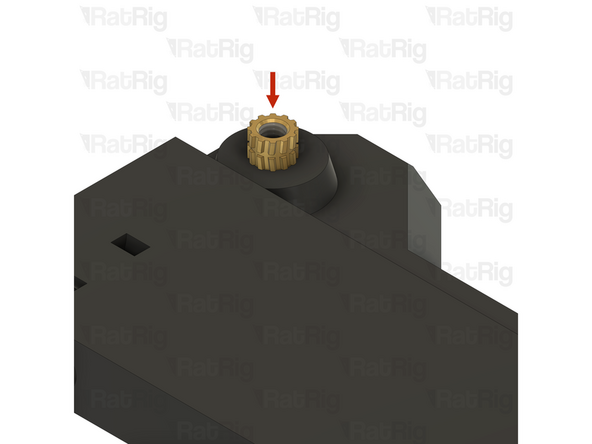

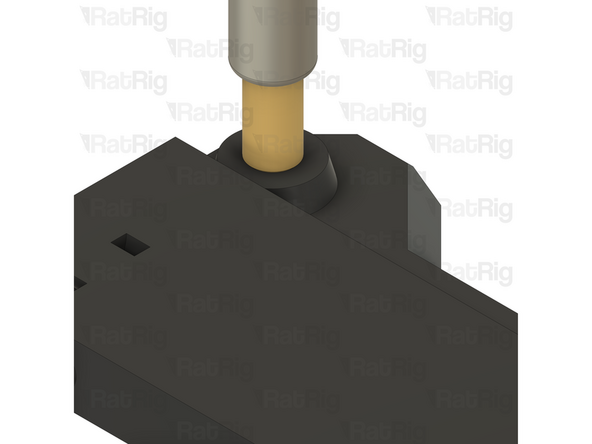

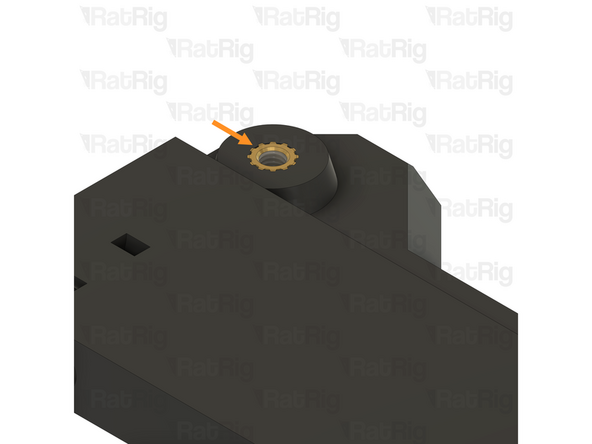

These steps show how to install an M3 heat insert into the printed parts

-

M3 heat insert

-

Soldering iron with M3 heat insert tip

-

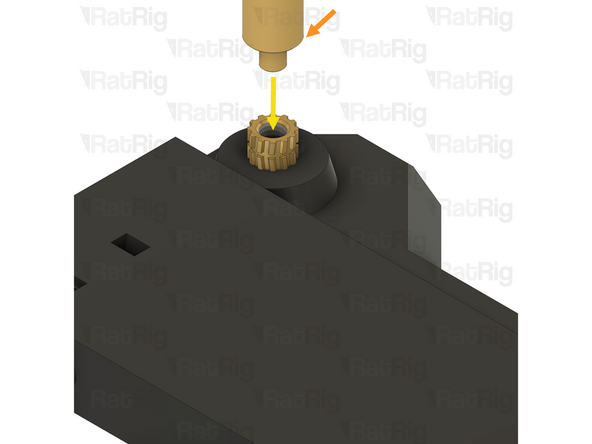

Align the soldering iron tip with the heat insert

-

Be careful not to burn yourself!

-

-

-

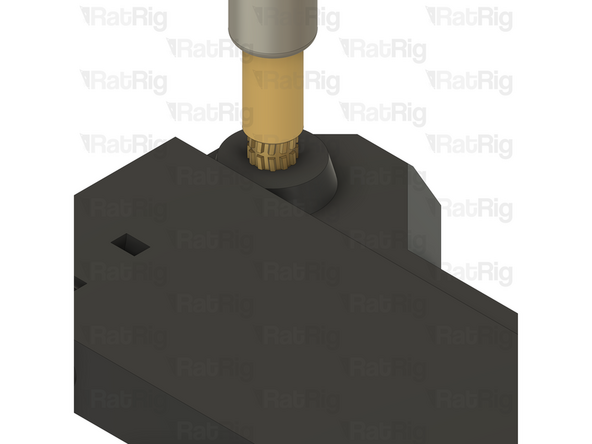

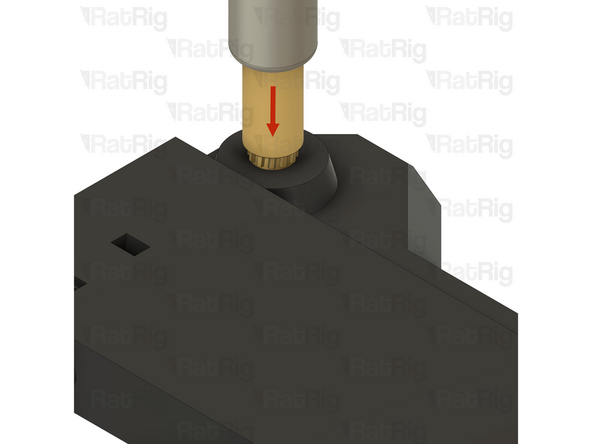

Slowly press the heat insert into the printed part

-

Ensure the heat insert is flush with the printed part, or even a little below the surface

-

Avoid having a heat insert higher than the printed part, this can cause assembly issues

-

Remove the soldering iron

-

Be careful not to burn yourself!

-

-

-

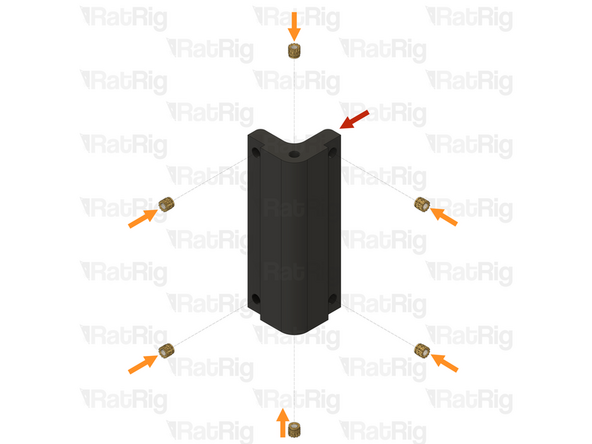

compact_cnc_electronics_corner printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

Repeat for all 4 compact_cnc_electronics_corner printed parts

-

Set these assemblies aside until Step 19

-

-

-

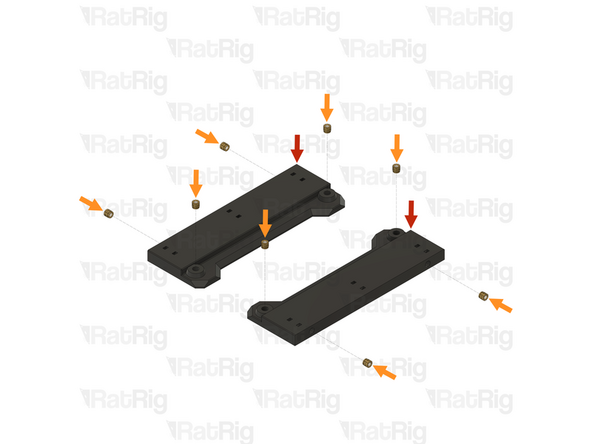

compact_cnc_electronics_btt_rodent printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

Set these assemblies aside until Step 17

-

-

-

compact_cnc_electronics_psu printed part

-

M3 heat insert

-

Install the M3 heat inserts into the indicated holes

-

Repeat for both compact_cnc_electronics_psu printed parts

-

Set these assemblies aside until Step 15

-

-

-

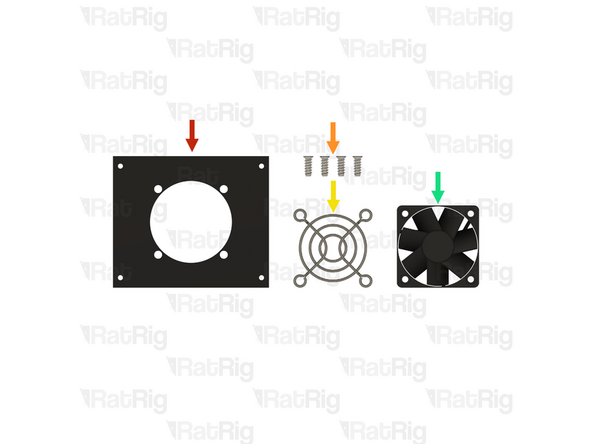

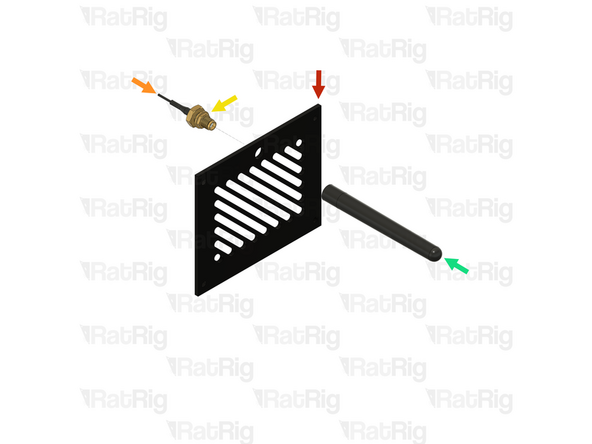

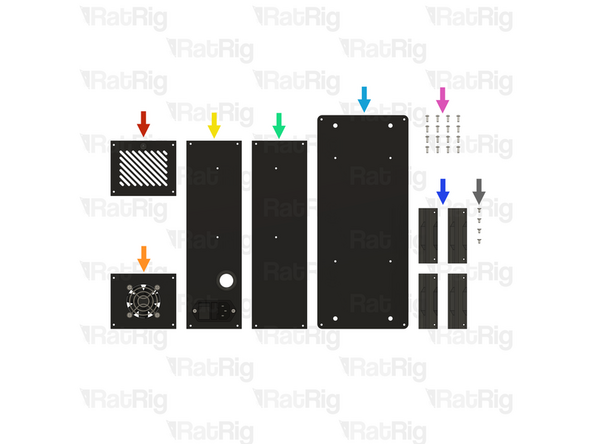

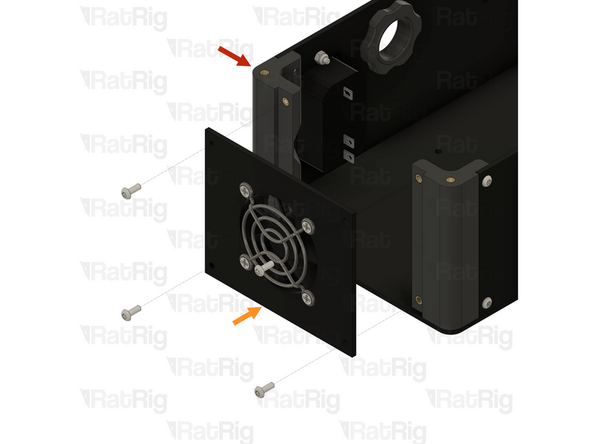

1x compact_cnc_rear_cooling_panel

-

4x Self tapping screw - fan - 12mm

-

1x 50mm fan grille

-

1x 50x15mm 24V fan

-

-

-

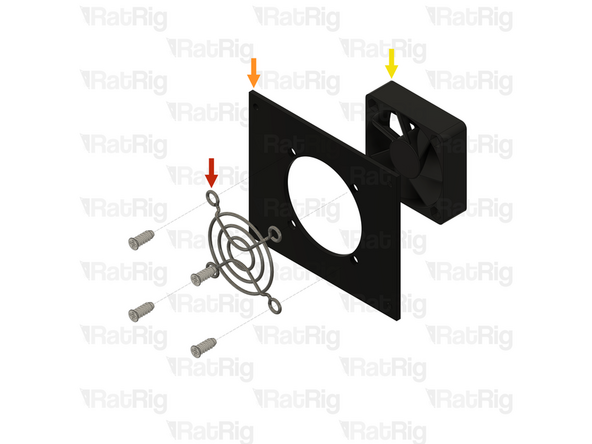

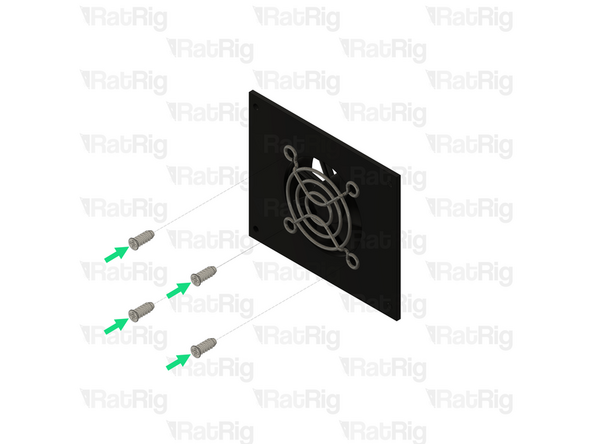

1x 50mm fan grille

-

1x compact_cnc_rear_cooling_panel

-

1x 50x15mm 24V fan

-

4x Self tapping screw - fan - 12mm

-

Insert the screws through the fan grille, through the panel, and then thread them into the fan body

-

Set this panel assembly aside until Step 19

-

-

-

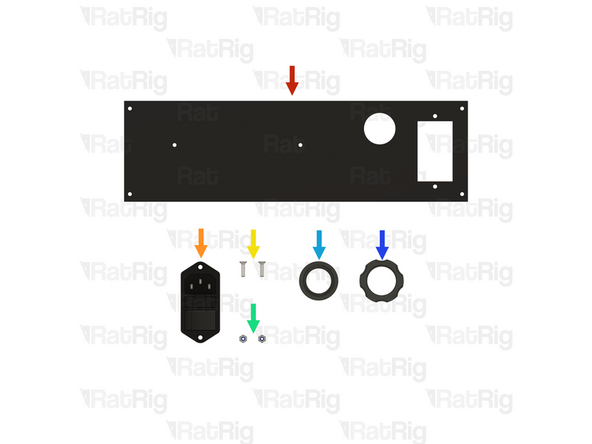

1x compact_cnc_left_panel

-

1x Switchable & fused IEC inlet

-

2x M3x12 Countersink screw

-

2x M3 locking hex nut

-

1x compact_cnc_electronics_panel_collar printed part

-

1x compact_cnc_electronics_panel_collar_nut printed part

-

-

-

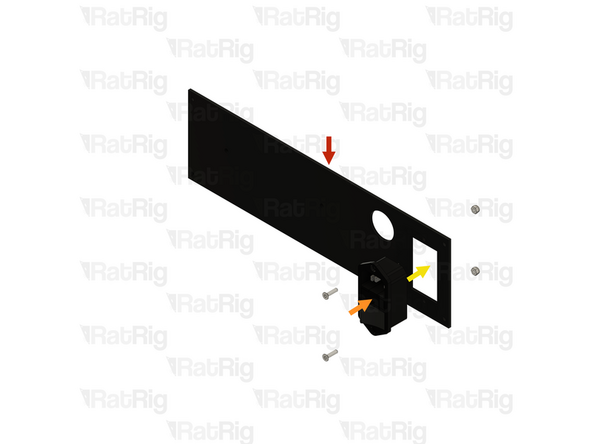

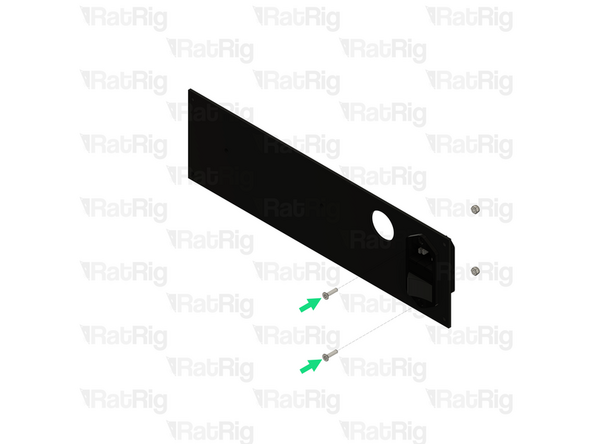

1x compact_cnc_left_panel

-

1x Switchable & fused IEC inlet

-

Insert the IEC inlet into the panel as shown

-

2x M3x12 Countersink screw

-

2x M3 locking hex nut

-

Tighten the M3 screws to secure the IEC inlet to the panel

-

-

-

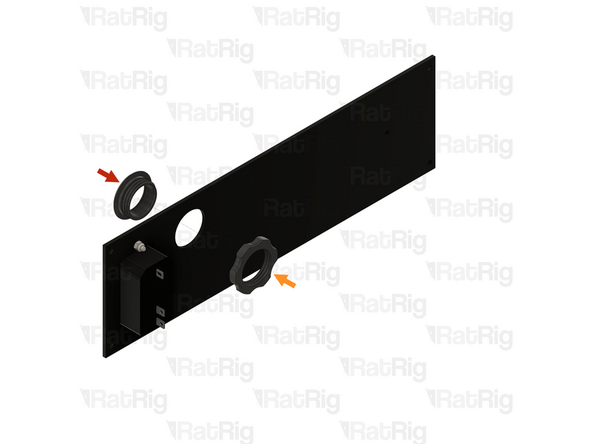

1x compact_cnc_electronics_panel_collar printed part

-

1x compact_cnc_electronics_panel_collar_nut printed part

-

Do not overtighten the printed nut as you can damage the printed parts

-

Set this panel assembly aside until Step 19

-

-

-

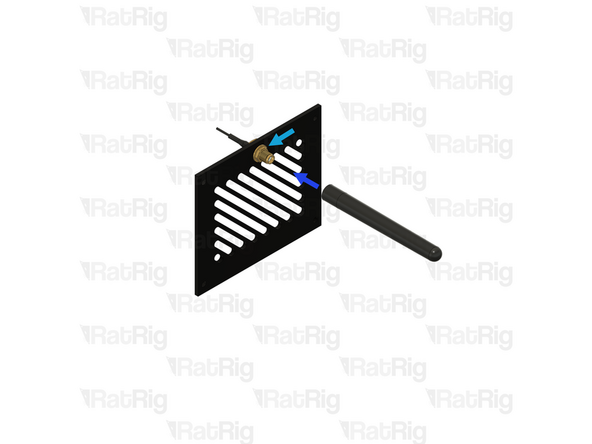

1x compact_cnc_top_panel

-

1x IPEX to SMA female WiFi pigtail

-

1x SMA 2.4GHz Wifi antenna

-

-

-

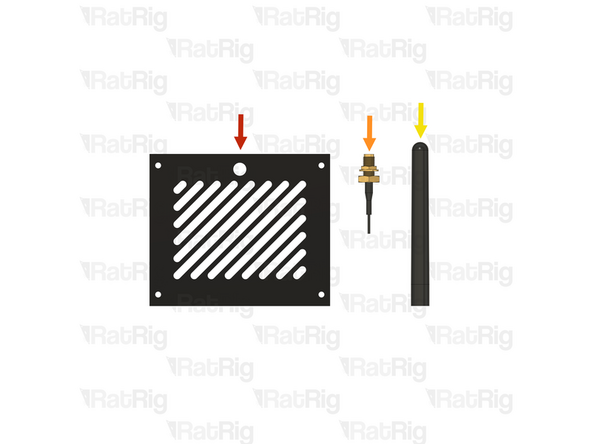

1x compact_cnc_top_panel

-

1x IPEX to SMA female WiFi pigtail

-

Remove the marked nut from the WiFi pigtail, then insert the pigtail into the panel

-

1x SMA 2.4GHz Wifi antenna

-

Secure the WiFi pigtail to the panel by reinstalling the nut

-

Screw the WiFi antenna onto the WiFi pigtail

-

Set this panel assembly aside until Step 19

-

-

-

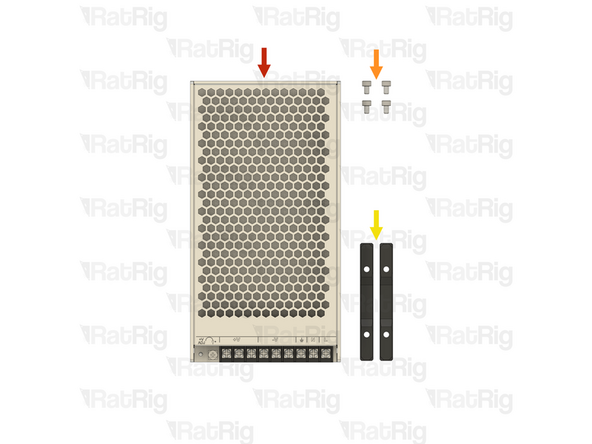

1x Weho LRS-250-24 fanless PSU

-

4x M4x6 cap head screw

-

2x PSU mount assemblies from Step 7

-

-

-

1x Weho LRS-250-24 fanless PSU

-

2x PSU mount assemblies

-

4x M4x6 cap head screw

-

Align the PSU mounts with the holes on the PSU. Secure them to the PSU using the M4x6 cap head screws

-

Take care not to over-tighten the screws as you can damage the printed parts

-

Set the PSU assembly aside until Step 25

-

-

-

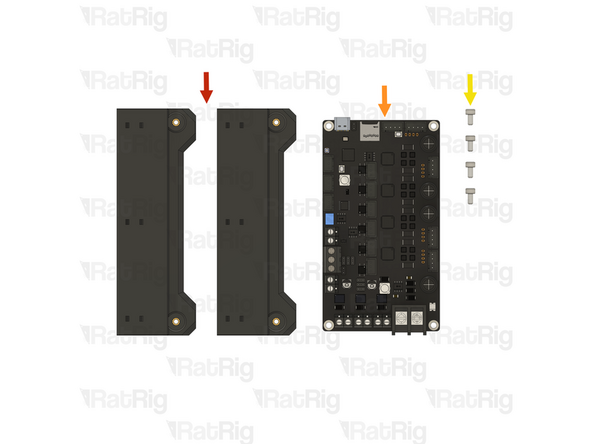

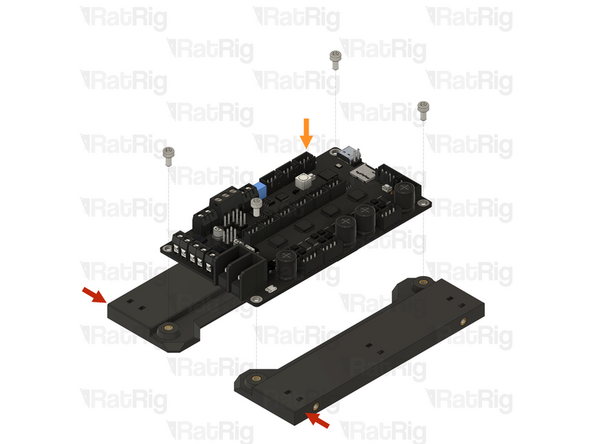

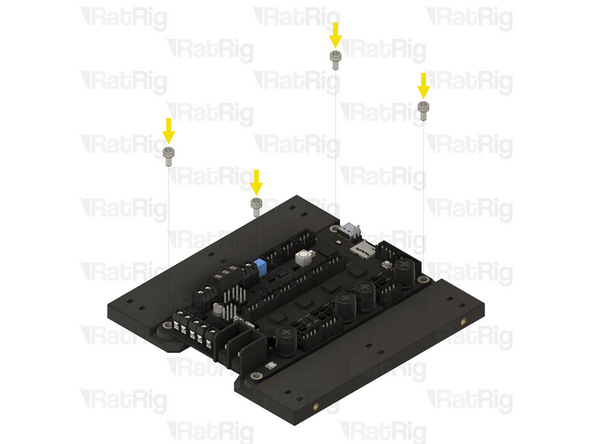

2x Rodent mount assemblies from Step 6

-

1x BIGTREETECH Rodent CNC Controller

-

4x M3x6 cap head screw

-

-

-

2x Rodent mount assemblies

-

1x BIGTREETECH Rodent CNC controller

-

4x M3x6 cap head screw

-

Align the Rodent CNC controller with the holes on the mounts. Secure the controller to the mounts using the M3x6 cap head screws

-

Take care not to over-tighten the screws as you can damage the printed parts or the controller

-

Set the controller assembly aside until Step 25

-

-

-

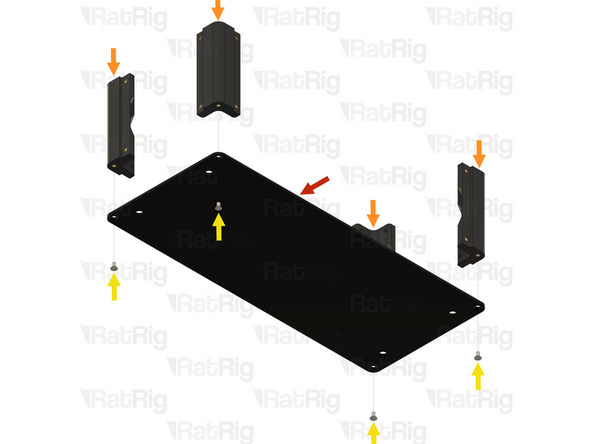

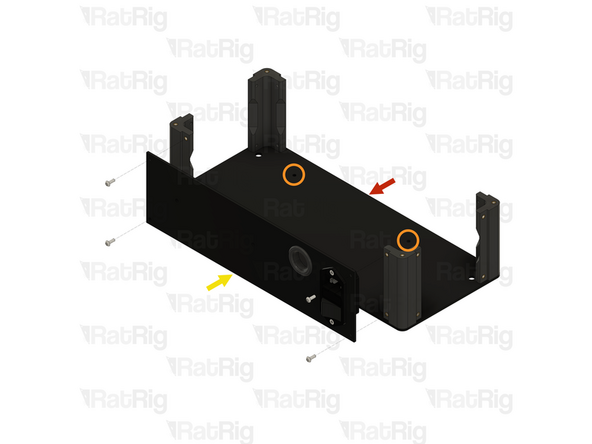

1x compact_cnc_bottom_panel

-

4x Corner assembly

-

4x M3x6 countersunk screw

-

Align each corner assembly with the bottom panel, secure them together with an M3x6 countersunk screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

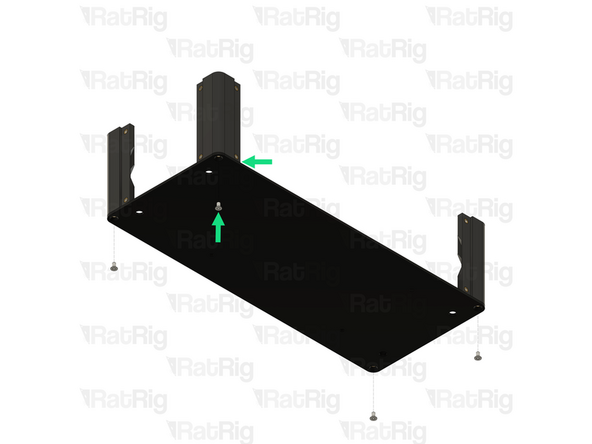

1x Enclosure assembly from the previous step

-

Ensure the assembly is oriented as shown. Pay attention to the marked holes to help orient it correctly

-

1x Left panel assembly

-

4x M3x8 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

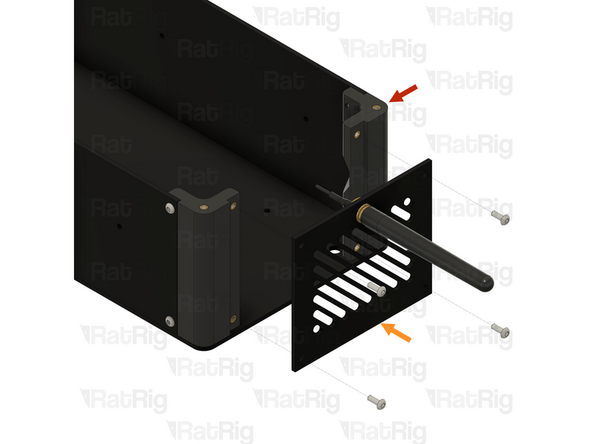

1x Enclosure assembly from the previous step

-

1x compact_cnc_right_panel

-

4x M3x8 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

1x Enclosure assembly from the previous step

-

1x Cooling panel assembly

-

4x M3x8 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

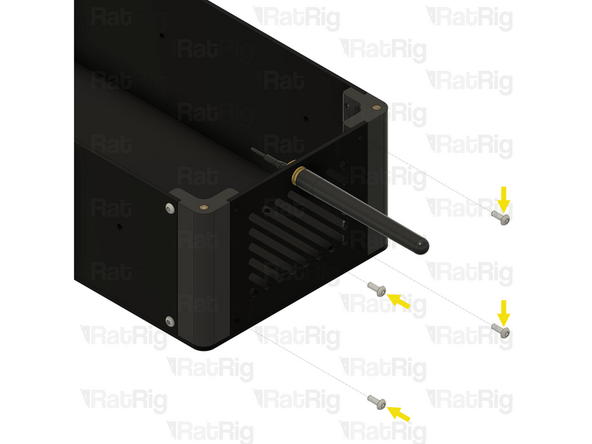

1x Enclosure assembly from the previous step

-

1x Top panel assembly

-

4x M3x8 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

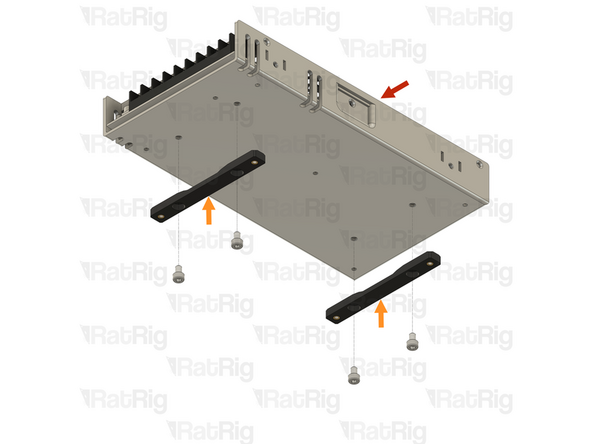

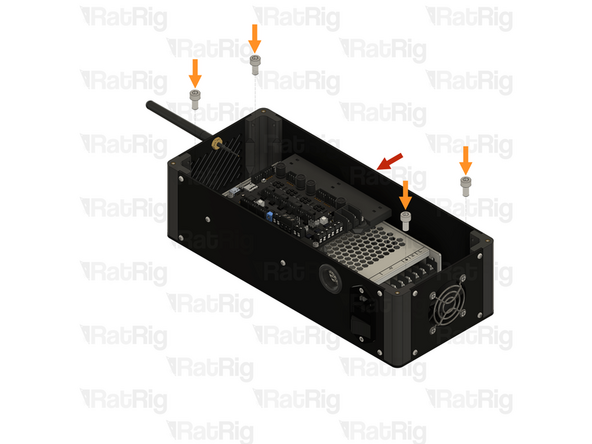

-

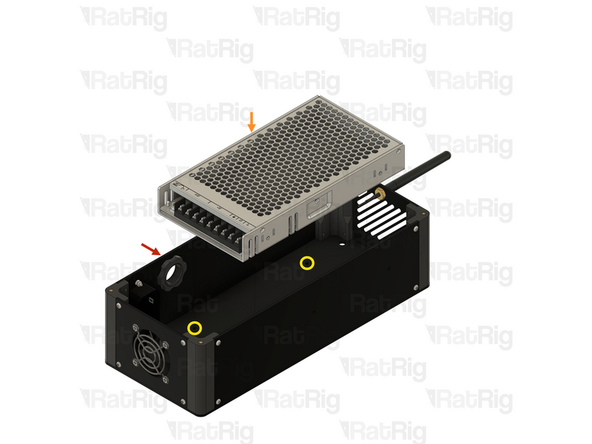

1x Enclosure assembly

-

1x PSU assembly

-

Align the holes in the PSU mounts with the holes in the bottom panel

-

4x M3x8 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

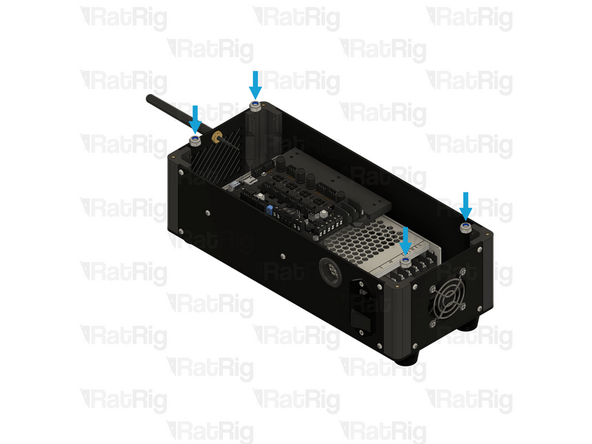

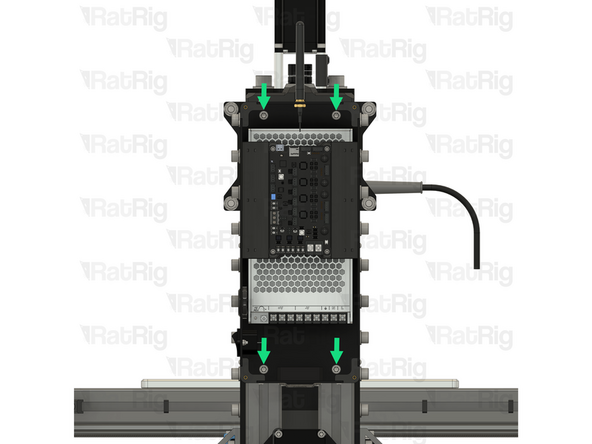

1x Enclosure assembly

-

1x Rodent CNC controller assembly

-

Align the Rodent CNC controller assembly with the holes in the side panels

-

4x M3x20 button head screw

-

Take care not to over-tighten the screws as you can damage the printed parts

-

-

-

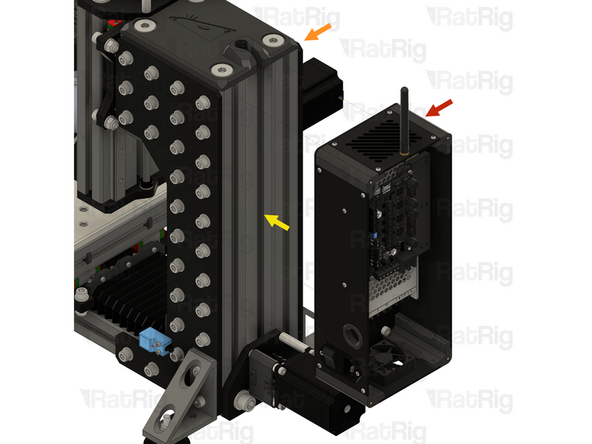

The compact CNC electronics enclosure supports two mounting options:

-

1. Standalone

-

The electronics enclosure can be assembled with rubber feet, allowing it to sit next to the machine it controls

-

Proceed to Step 29 for standalone assembly instructions

-

2. Mounted to the Rat Rig Mill

-

The electronics enclosure can be mounted directly to the back of the Rat Rig Mill

-

Proceed to Step 31 for instructions on mounting to the Rat Rig Mill

-

-

-

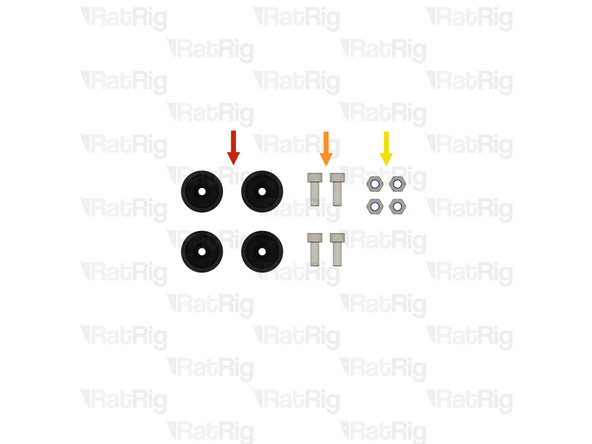

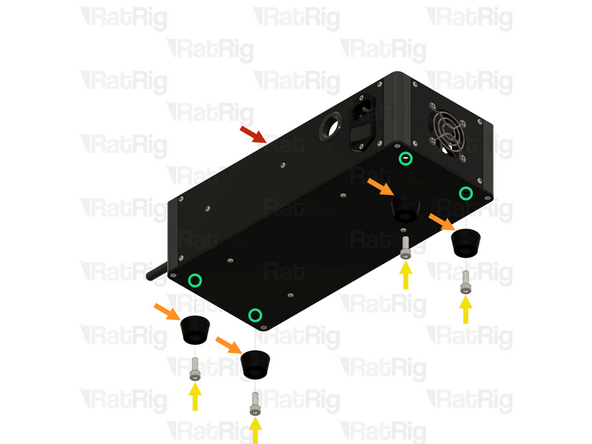

4x Rubber foot with metal insert

-

4x M6x16 cap head screw

-

4x M6 locking hex nut

-

-

-

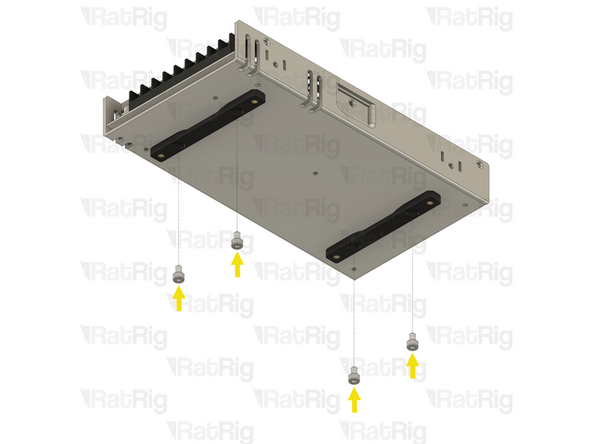

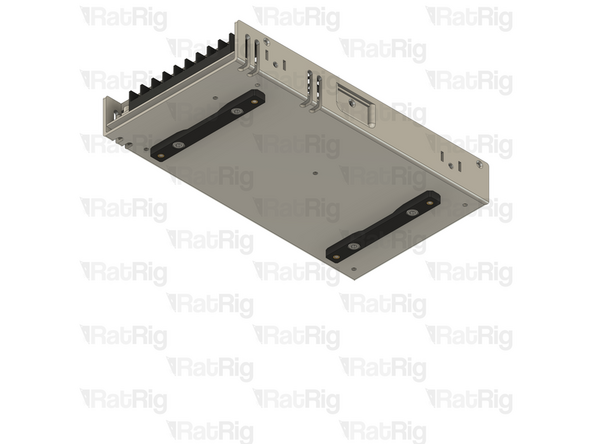

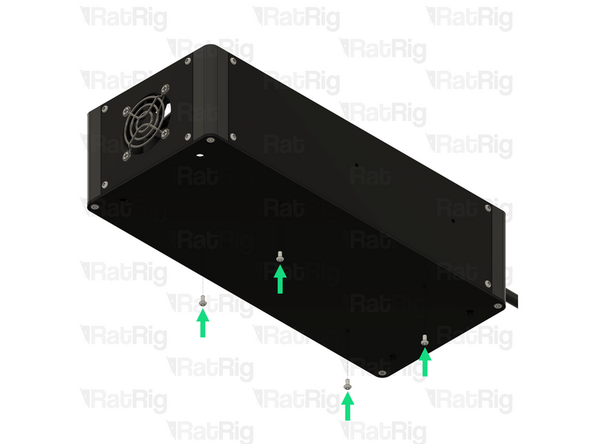

1x Enclosure assembly

-

4x Rubber foot with metal insert

-

4x M6x16 cap head screw

-

Insert an M6x16 cap head screw into each foot and through hole in the base panel

-

4x M6 locking hex nut

-

Proceed to Step 34 for the final steps

-

-

-

4x M6x12 cap head screw

-

4x T-nut drop-in for 4040 - M6

-

-

-

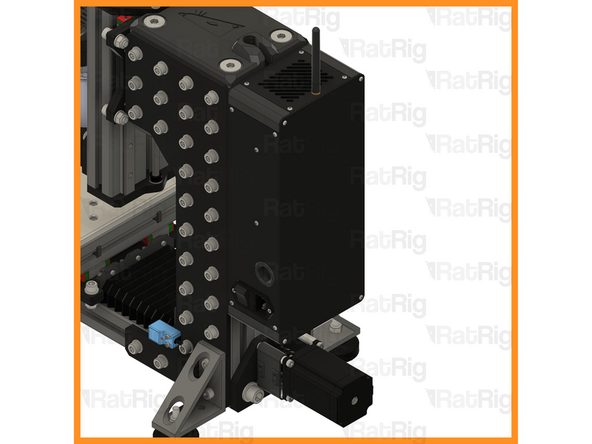

1x Enclosure assembly

-

4x M6x12 cap head screw

-

4x T-nut drop-in for 4040 - M6

-

Loosely thread a 4040 T-Nut on to each M6x12 screw. Do not tighten them at this point.

-

-

-

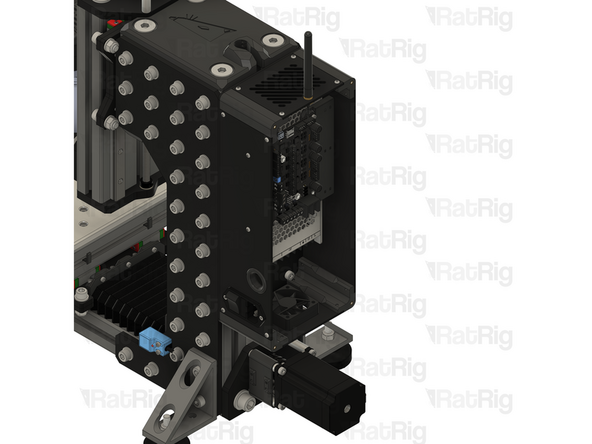

1x Enclosure assembly

-

1x Rat Rig Mill

-

Align the electronics enclosure with the back of the Rat Rig Mill as shown

-

Tighten all 4x M6x12 cap head screws to secure the electronics enclosure to the Rat Rig Mill

-

Proceed to Step 34 for the final steps

-

-

-

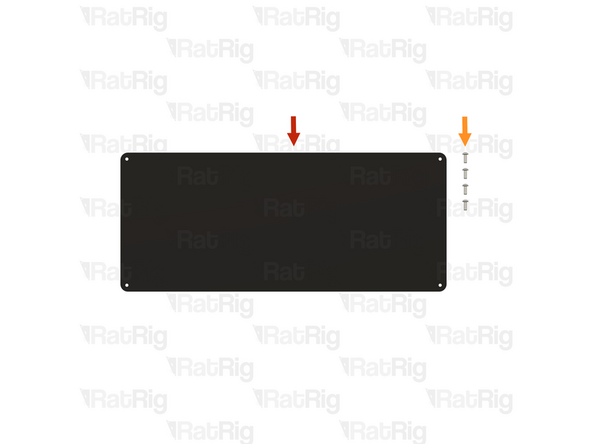

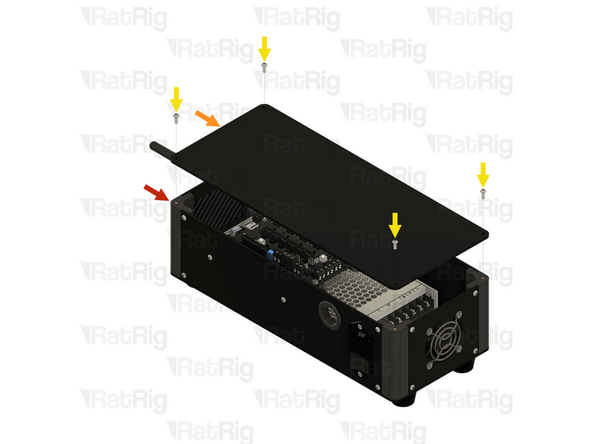

1x Enclosure assembly

-

1x compact_cnc_cover_panel

-

4x M3x8 button head screw

-

Almost done!

Finish Line