-

-

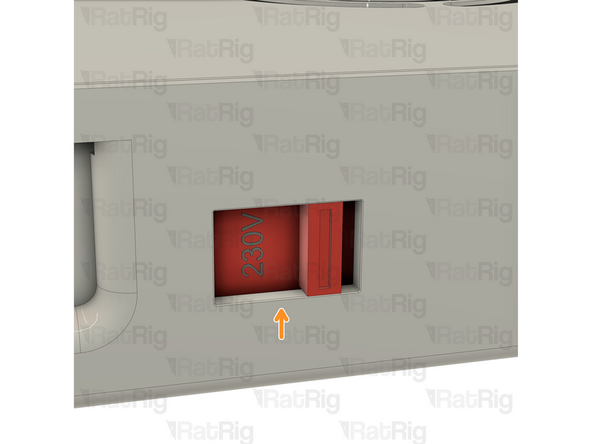

On the right side of the power supply there is a switch.

-

This switch needs to be set to the mains voltage in your country. Either 115V (most common in the USA / Canada), or 230V.

-

Setting this to the incorrect input voltage may destroy the power supply and anything connected to it.

-

Keep in mind that milling is a very messy job and debris may fly into the power supply. This could cause it to fail or catch fire! Please be aware!

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

This procedure can be found on the OpenBuilds Documentation, for further information click here.

-

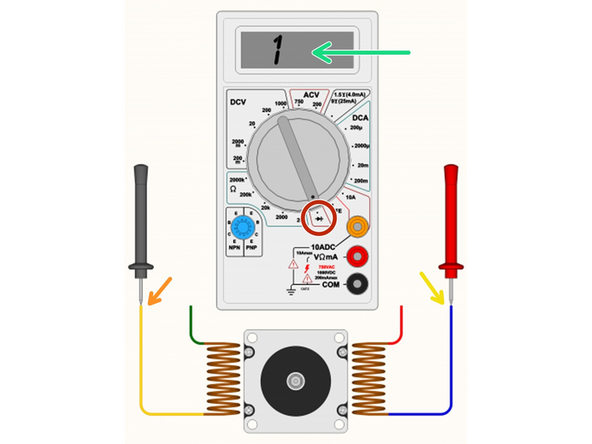

Follow this step if you have access to a multimeter, otherwise skip to Step 8.

-

Set your multimeter to Continuity / Diode Test mode.

-

Start with any random wire, and touch that to the Black/Negative probe on your multimeter.

-

Select any remaining wire and touch it with the Red/Positive probe of your multimeter:

-

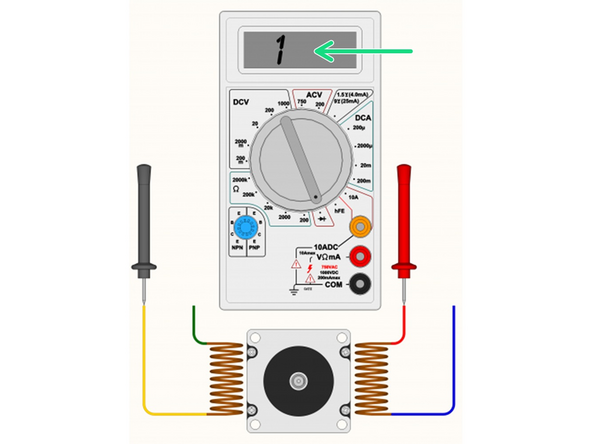

If the multimeter shows [1 or 0L] it means “no connection” - indicating we did not find a coil between these two wires. Some multimeters also “beep” when it does find a connection, so if there is no beep noise, it also could indicate the coil is not between these two wires.

-

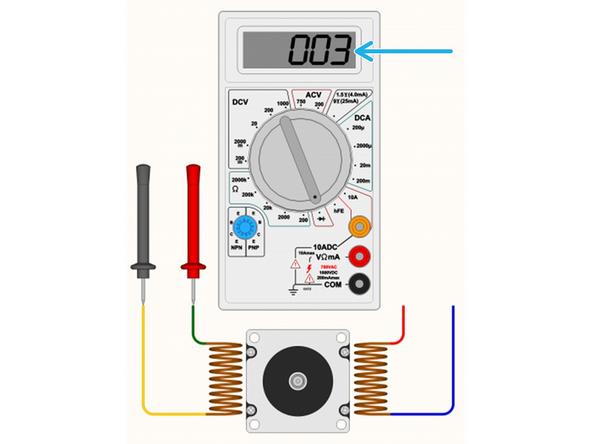

If you see a reading on the multimeter. The actual number does not matter too much, it's more important that it has some low value reading, and that the multimeter no longer displays [1] on the display. Some multimeters may “beep” when you have continuity between the wires (circuit completed by the coil in between).

-

Segment off these two wires and label them as belonging to a coil. It's important to not lose track of the coil pairs.

-

-

-

This procedure can be found on the OpenBuilds Documentation, for further information click here.

-

Follow this step if you don't have access to a multimeter. If you already identified all coil pairs in the previous step, please proceed to step 9.

-

If the two wires you joined together belong to the same coil, the shaft will become significantly harder to turn by hand.

-

If that shaft still spins easily, you have not identified a coil yet, and you must try a different combination of wires.

-

If you join together two wires that do result in the motor presenting resistance against turning, you can label these two wires as belonging to the same coil.

-