Introduction

Please note: All measurements provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, the following adjustments can be made to the stated extrusion lengths:

- 200x200: Remove 100mm

- 400x400: Add 100mm

- 500x500: Add 200mm

It is strongly recommended to assemble the frame on a known flat surface (such as a solid table, work surface or similar). Assembling the frame on a carpeted floor, or other non-flat surface, can cause the finished frame to not be square. This can cause issues with print quality and performance.

The V-Core 3.1 frame is built upside down. This is done to aid in keeping all critical sections of the frame square.

-

-

A dedicated set of guides for building an enclosed V-Core 3.1 using the Enclosure 2.0 kit is available here.

-

Please only follow this guide when building a non-enclosed V-Core 3.1 printer.

-

-

-

2x 450mm 3030 Extrusion

-

2x 440mm 3030 Extrusion

-

1x 420mm 3030 Extrusion

-

10x 90 Degree Corner Assembly

-

-

-

450mm 3030 Extrusion

-

440mm 3030 Extrusion

-

420mm 3030 Extrusion

-

90 Degree Corner Assembly

-

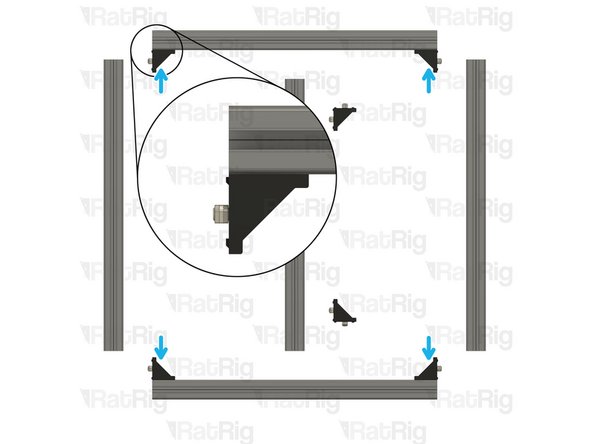

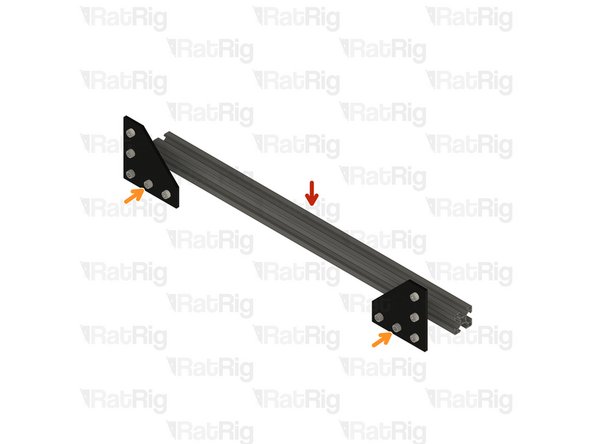

Install one corner assembly onto each end of both 440mm 3030 extrusions as shown. Tighten the M6x12 screw to secure them.

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

Assemble the 450mm and 440mm extrusions together as shown, making sure the extrusion joints are square

-

Tighten the remaining M6x12 screws to secure the exterior of the subframe together

-

-

-

420mm 3030 Extrusion

-

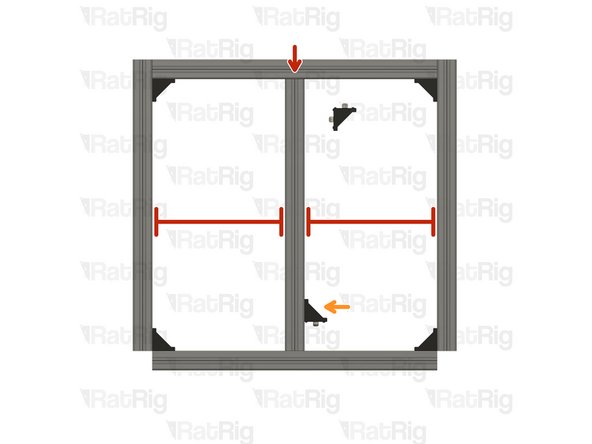

Position the extrusion as shown. The measurements shown should be equal and will be 205mm for a 300x300 frame

-

90 Degree Corner Assembly

-

Install the corner assembly as shown, and secure both M6x12 screws

-

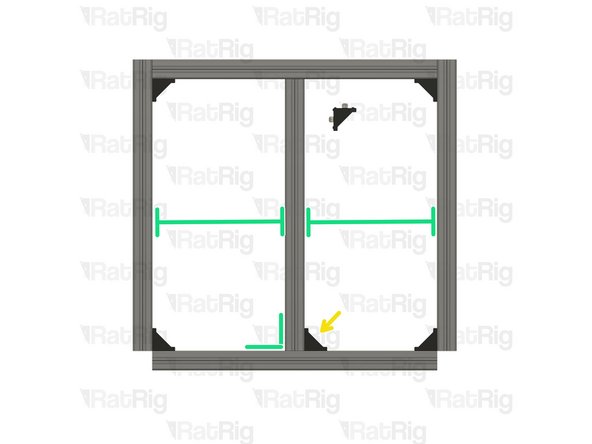

Check that the 420mm extrusion is positioned correctly and is square

-

Install the corner assembly as shown, and secure both M6x12 screws

-

Check that the 420mm extrusion is positioned correctly and is square

-

-

-

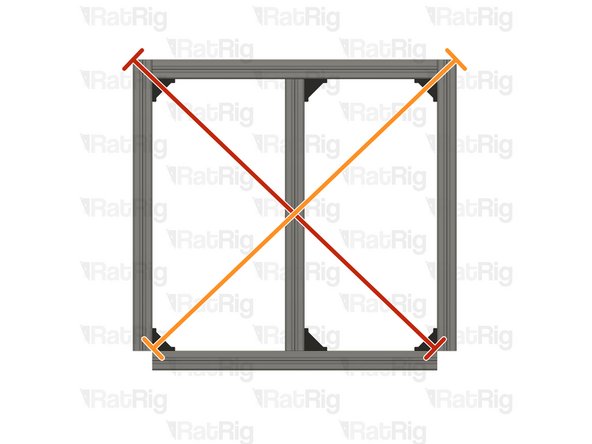

Measure both of the distances shown using a long ruler (preferred), or a tape measure. The measurements should be equal to each other, and should be as close as possible to the following:

-

200x200: 509.3mm

-

300x300: 650.7mm

-

400x400: 792.1mm

-

500x500: 933.5mm

-

If the measurements are not equal, and are not close to those shown above, double check all corners are square and then check again

-

-

-

90 Degree Corner Assembly

-

Install one corner assembly onto each position shown. Tighten the M6x12 screw to secure them.

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

Set this assembly aside until Step 15

-

-

-

510mm 3030 Extrusion

-

Corner Plate Assembly

-

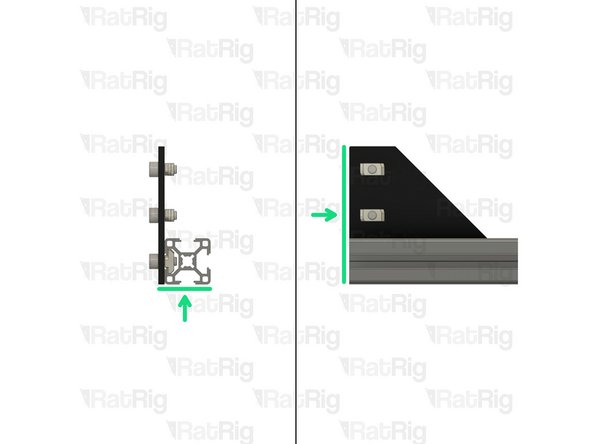

Secure the corner plates to the extrusion by fastening the five M6x12 screws

-

Check all of the corner plates to make sure they are square to the extrusion, and flush with the ends

-

-

-

Assembly from the previous step

-

Corner plate assembly

-

Secure the corner plates to the extrusion by fastening the five M6x12 screws

-

Check all of the corner plates to make sure they are square to the extrusion, and flush with the ends

-

-

-

4x 505mm 3030 Extrusion

-

4x 440mm 3030 Extrusion

-

2x Base Corner Plate Assembly A

-

2x Base Corner Plate Assembly B

-

2x 90 Degree Corner Assembly

-

-

-

Assemblies from Step 8

-

440mm 3030 Extrusion

-

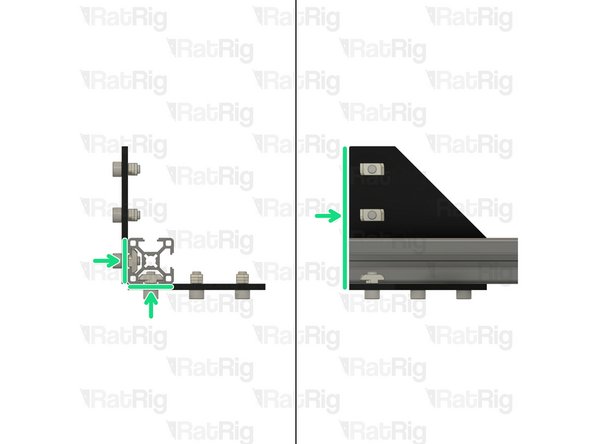

Install one 440mm 3030 extrusion onto the top and bottom of one corner assembly as shown

-

Tighten the marked M6x12 screws to secure the 3030 extrusions to the corner assembly

-

Install the opposing corner assembly onto the other ends of the 3030 extrusions as shown

-

Tighten the marked M6x12 screws to secure the corner assembly to the 3030 extrusions

-

Repeat the above steps for the second assembly

-

-

-

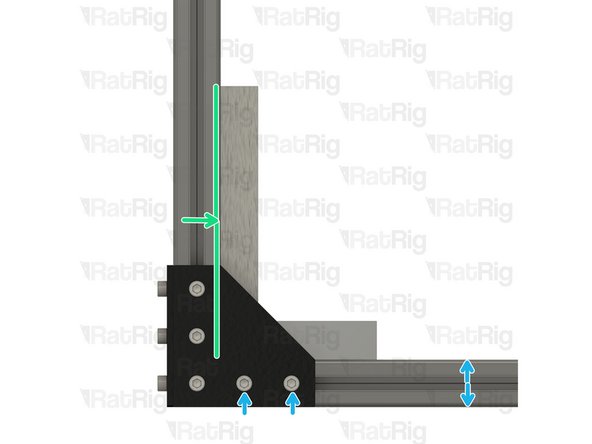

It is highly recommended to check the end assemblies for squareness before proceeding

-

End assembly

-

Place an engineers square on the lower 3030 extrusion as shown

-

Carefully slide the square towards the corner

-

If the connection between extrusions is square, there should be no gap between the long edge of the square and the extrusion next to it

-

If the connection is not square, loosen the M6x12 screws connecting the corner plate to this extrusion, adjust in the directions shown and then check for squareness again

-

Repeat this process for all four corners on the assembly and then repeat everything for the second end assembly

-

-

-

End Assembly

-

505mm 3030 Extrusion

-

Install one 505mm 3030 extrusion onto each side of the end assembly as shown

-

Tighten both the marked M6x12 screws, and the corresponding ones on the other side, to secure the 3030 extrusions to the end assembly

-

Install the opposing end assembly onto the other ends of the 3030 extrusions as shown

-

Tighten both the marked M6x12 screws, and the corresponding ones on the other side, to secure the end assembly to the 3030 extrusions

-

-

-

It is highly recommended to check the frame assembly for squareness before proceeding

-

Partial V-Core 3.1 Frame Assembly

-

Place an engineers square on the lower 3030 extrusion as shown

-

Carefully slide the square towards the corner

-

If the connection between extrusions is square, there should be no gap between the long edge of the square and the extrusion next to it

-

If the connection is not square, loosen the M6x12 screws connecting the corner plate to this extrusion, adjust in the directions shown and then check for squareness again

-

Repeat this process for all four corners on the partial frame assembly

-

-

-

To proceed with the assembly, the four marked corner plate assemblies must be removed

-

Corner Plate Assembly to remove

-

Loosen the three marked M6x12 screws on each plate and place them aside

-

You will require two of the corner plate assemblies for Step 17 and two for Step 19

-

-

-

If you plan to use an electronics panel, it is highly recommended to assemble and install it now. Installing a single, large, panel after further assembly is not possible

-

If you do not plan to use an electronics panel, or plan to use a split panel, you may skip to Step 17

-

22x M6x12mm Cap Head Screw

-

22x M6 Washer

-

22x 3030 Drop-in T-Nut - M6

-

Electronics Panel Assembly

-

3x Cable Guide Printed Part ( Provided in the Electronics Extra Kit )

-

Fasten all M6x12 screws to secure the electronics panel to the electronics subframe assembly

-

-

-

V-Core 3.1 Frame Assembly

-

Electronics Subframe Assembly

-

Pay attention to the orientation of the electronics subframe

-

Slot the electronics subframe assembly into the V-Core 3.1 frame assembly as shown

-

The gap shown between the V-Core 3.1 frame and the electronics subframe should measure 47mm minus the thickness of your electronics panel on all machine sizes

-

For example: Using a 4mm thick electronics panel, the gap would measure 43mm (47mm minus 4mm)

-

Once positioned correctly, tighten the marked M6x12 screws to secure the electronics subframe in place

-

-

-

505mm 3030 Extrusion

-

Place the 505mm 3030 extrusion into the frame as shown

-

Tighten the marked M6x12 screw to secure the 505mm 3030 extrusion to the electronics subframe

-

Re-install the two 90 degree corner assemblies as shown

-

Tighten all of the M6x12 screws on the two 90 degree corner assemblies

-

-

-

V-Core 3.1 frame assembly

-

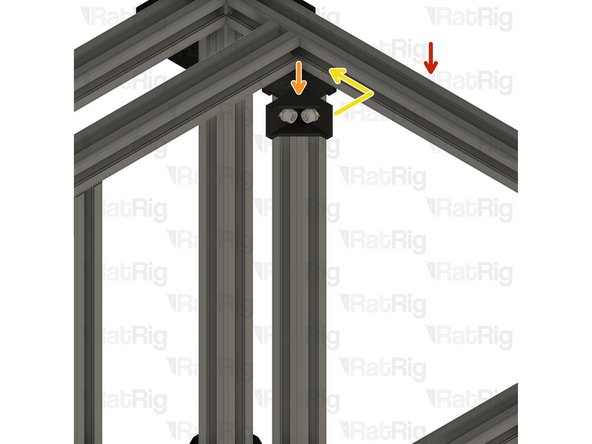

90 degree corner assembly

-

Install the corner assembly into the corner of the two 3030 extrusions as shown

-

Tighten both M6x12 screws to secure the corner assembly to both the main frame and the subframe

-

-

-

505mm 3030 Extrusion

-

Place the 505mm 3030 extrusion into the frame as shown

-

Tighten the marked M6x12 screw to secure the 505mm 3030 extrusion to the electronics sub frame

-

Re-install the two 90 degree corner assemblies as shown

-

Tighten all of the M6x12 screws on the two 90 degree corner assemblies

-

-

-

V-Core 3.1 frame assembly

-

90 degree corner assembly

-

Install the corner assembly into the corner of the two 3030 extrusions as shown

-

Tighten both M6x12 screws to secure the corner assembly to both the main frame and the subframe

-

-

-

Base corner plate assembly A

-

Base corner plate assembly B

-

Install each corner plate assembly onto the marked corners

-

Tighten the three marked M6x12 screws on each corner plate

-

Tighten the marked M5x18 screw on each corner plate

-

Turn the V-Core 3.1 frame assembly over, and rest it on its feet

-

Cancel: I did not complete this guide.

27 other people completed this guide.

One Comment

I think it is worth to update the frame build guide couse this one builds the most important parts at the end. Check this video: