-

-

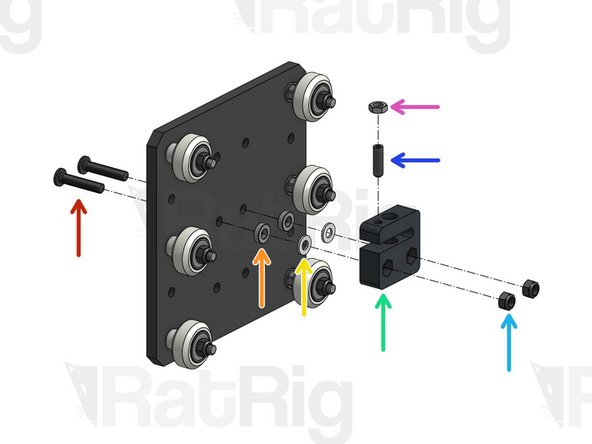

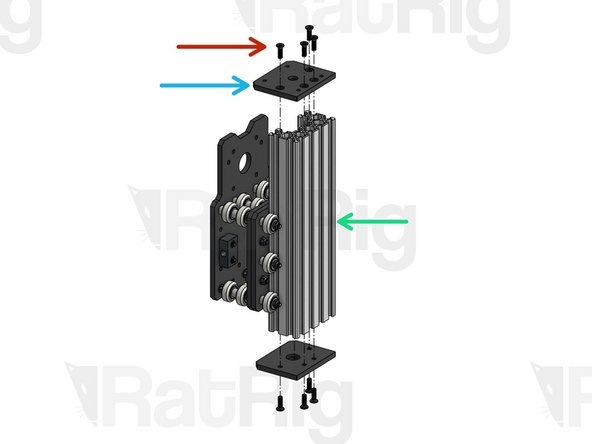

Low Profile Screw M5x25mm

-

Z Plate

-

Aluminium Spacer 3mm

-

Precision Shim 10x5x1mm

-

Nut Block. Tighten one down, while leaving the other one slightly loose.

-

Hex Locking Nut M5

-

Lead Screw. Use it to calibrate the position of your Nut Blocks to remove Backlash, just like you did on your Y Plates.

-

-

-

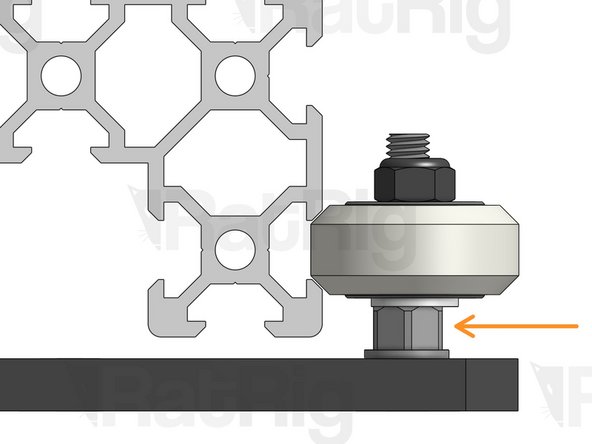

Hex Locking Nut M5

-

Washer M5

-

Eccentric Spacer

-

Precision Shim 10x5x1mm

-

Xtreme V-Wheel

-

Aluminium Spacer 9mm

-

Low Profile Screw M5x60mm

-

Aluminium Spacer 6mm

-

-

-

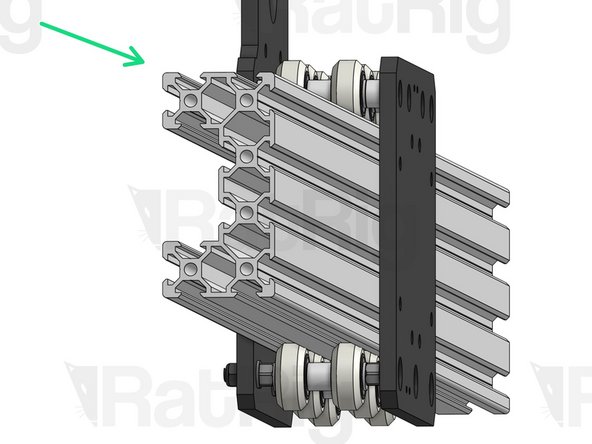

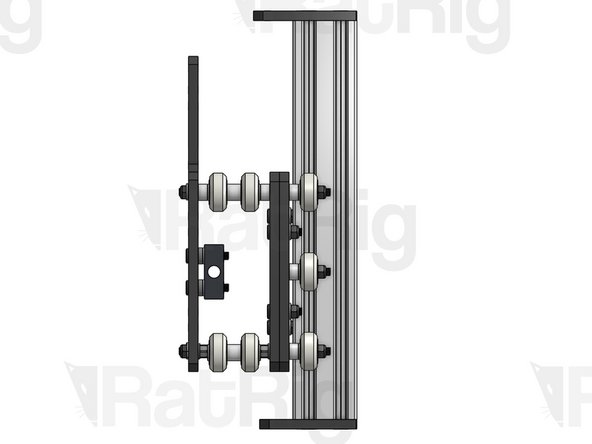

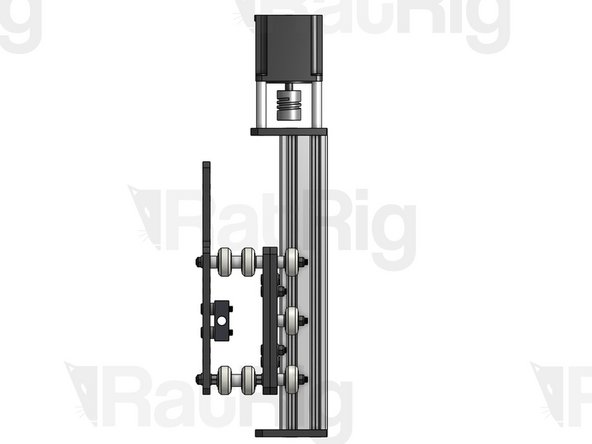

Insert a C-Beam profile (doesn't matter which one at this point) through your assembly.

-

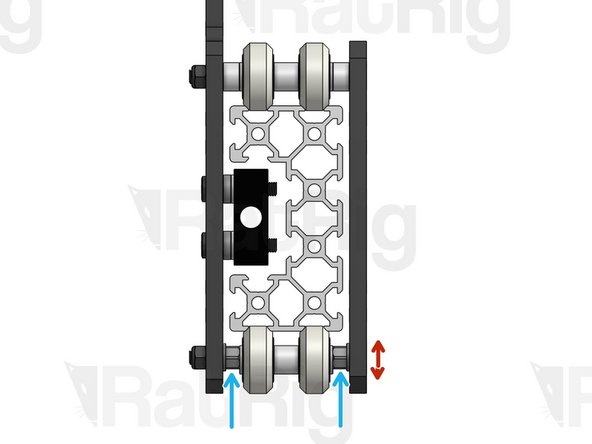

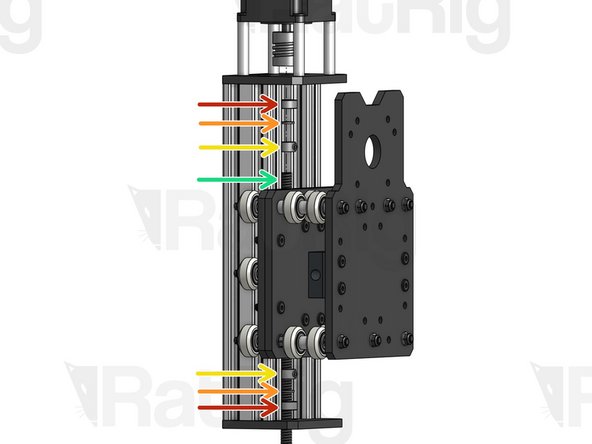

Eccentric Spacers have an off-center through-hole. Because of this, when you rotate them, your entire wheel axis moves laterally. This gives you the adjustment margin you will need to make sure your wheels are grabbing the profile with the correct amount of force.

-

Use a spanner to subtly adjust the position of each eccentric spacer until every wheel is in contact with the profile. You want to find a sweet spot where your carriage is not wobbly and the motion is perfectly smooth, but where there isn't excessive force pressing the wheels against the rail, as this will increase wear on the wheels.

-

-

-

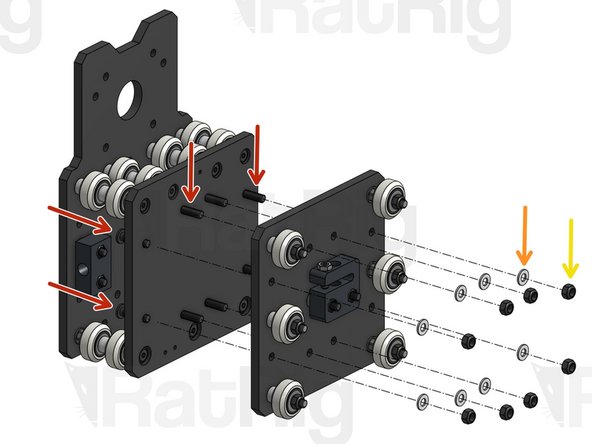

Low Profile Screw M5x27mm

-

Aluminium Spacer 6mm

-

Z Plate

-

Eccentric Spacer

-

Precision Shim 10x5x1mm

-

Xtreme V-Wheel

-

Hex Locking Nut M5

-

-

-

Low Profile Screw M5x25mm

-

Aluminium Spacer 3mm

-

Precision Shim 10x5x1mm

-

Anti-backlash Nut Block

-

Hex Locking Nut M5

-

Set Screw M5x16mm

-

Hex Nut M5

-

You will tighten this later once you're ready to calibrate your Anti-backlash nut. For now, leave the Hex Nut in place but in a loose position.

-

-

-

Low Profile Screw M5x15mm

-

Z End Mount Plate

-

250mm C-Beam

-

Use a spanner to subtly adjust the position of each eccentric spacer until every wheel is in contact with the profile. You want to find a sweet spot where your carriage is not wobbly and the motion is perfectly smooth, but where there isn't excessive force pressing the wheels against the rail, as this will increase wear on the wheels.

-

Fully tighten the top End Mount, but leave the bottom one slightly loose. This will give you room for adjustment in a bit.

-

-

-

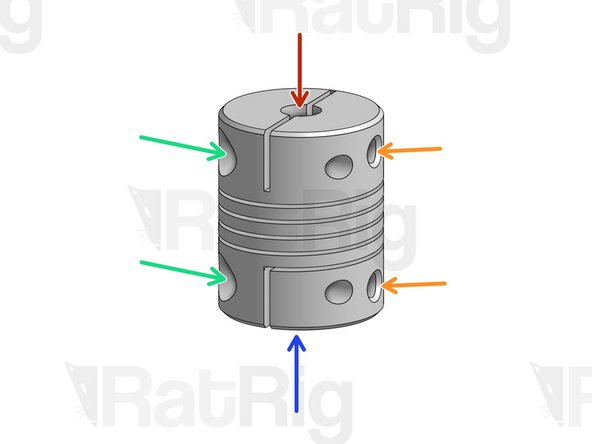

Flexible couplings allow you to connect 2 rods with different diameters while providing some flexibility at the joint.

-

Smaller diameter rod is inserted here

-

Larger diameter rod is inserted here

-

These larger screws act like a clamp on the entire coupling. Tighten these first.

-

These set screws press directly against the tip of each rod, locking it in place.

-

-

-

Low Profile Screw M5x50mm

-

Nema 23 Motor

-

The wire on the motor should be towards the back of the X-Carriage-Assembly.

-

Aluminium Spacer 40mm

-

Flexible Coupling - 1/4" x 8mm

-

Attach the 1/4'' end of the flexible coupling to the motor shaft. The shaft is shaped like a "D". Align the flat surface of the D with the Set Screw on the Flexible coupling and tighten it.

-

-

-

688ZZ Ball Bearing

-

Precision Shim 12x8x1mm

-

Lock Collar 8mm

-

Lead Screw 281mm

-

Once the Lead Screw passes through the Nut Block, hold the carriage firmly with one hand and try to pull/push the lead screw, without turning it. If you find any wiggle room, tighten the Set Screw on the Anti-backlash nut until all play disappears. Then, tighten the hex nut. This nut may require tuning from time to time. Do not overtighten, as this may overconstrain the lead screw.

-

Attach the 8mm end of the flexible coupling to the lead screw. Tighten the clamping screws first, and both set screws afterwards.

-

Tighten the set screws on the Lock Collars, to lock the position of the bearings and shims straight against the top/bottom End Mounts. The end mounts have holes to accommodate the bearings, which should fit inside them.

-

Fully tighten the screws on the bottom End Mount, which you left slightly loose on step 7.

-

Almost done!

Finish Line