Introduction

BEFORE STARTING:

Before beginning this guide, you must prepare all the necessary wires for the assembly. Below is a list of the required wires. The following nomenclature will be used: (Wire Length)_(AWG)_(Wire Color)_(A-End Connector)_(B-End Connector)_(ID number).

Use a small piece of tape to label each wire to ensure a smooth assembly process.

- 700mm - 16AWG RED (A-Ferrule, B-Ferrule) (4)

- 700mm - 16AWG BLACK (A-Ferrule, B-Fork) (5)

- 120mm - 16AWG RED (A-Fork, B-Fork) (6)

- 600mm - 16AWG RED (A-Fork, B-Ferrule) (7)

- 600mm - 16AWG BLACK (A-Fork, B-Ferrule) (8)

- 150mm - 22AWG BLACK (A-Fork, B-Ferrule) (9)

- 150mm - 22AWG RED (A-Ferrule, B-Ferrule) (10)

- 150mm - 22AWG BLACK (A-Ferrule, B-Ferrule) (11)

- 500mm - 22AWG RED (A-Ferrule, B-Fork) (12)

- 2x 500mm - 22AWG BLACK (A-Ferrule, B-Fork) (13)

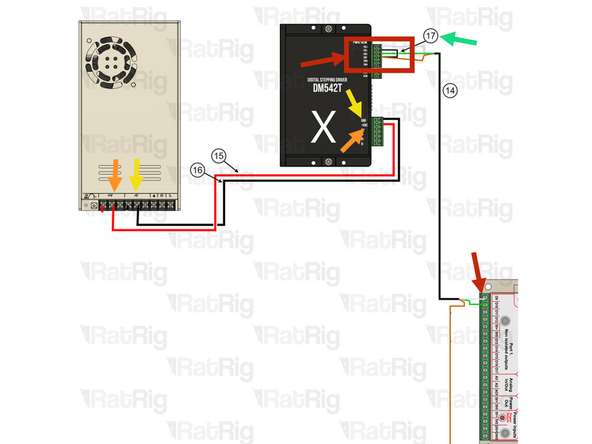

- 4x 550mm - Multicore 3 Conductor - 24AWG BLACK (A-(3x)Ferrule, B-(3x)Ferrule) (14)

- 4x 800mm - 16AWG RED (A-Fork, B-Ferrule) (15)

- 4x 800mm - 16AWG BLACK (A-Fork, B-Ferrule) (16)

- 4x 30mm - 22AWG BLACK (A-Ferrule, B-Ferrule) (17)

- 3x 100mm - 22AWG RED (A-Ferrule, B-Ferrule) (18)

- 900mm - Multicore 2 Conductor - 24AWG (A-2xFerrule, B-2xFerrule) (19)

- 100mm - 16AWG BLACK (A-Ferrule, B-Ferrule) (20)

-

-

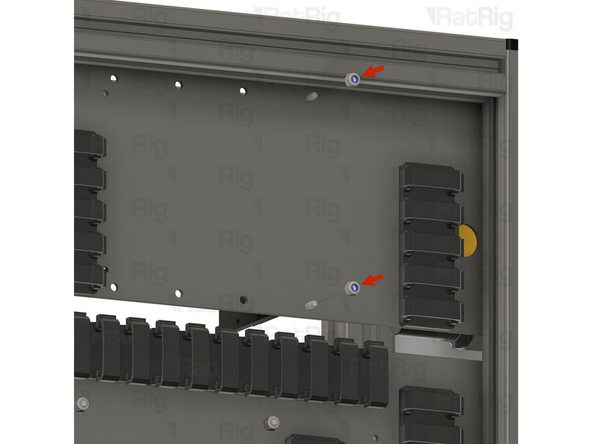

The DM542T stepper drivers allow current and micro-stepping control, resulting in a vast range of configurations.

-

Adjust the switches on the drivers for each stepper motor

-

Depressing switches 1 and 2 while simultaneously elevating switch 3 establishes a current of 2.69 amperes, marginally below the rated current for the stepper motors. This configuration is designed to enhance performance and extend the operational lifespan of the components.

-

The upwwards positioning of switch 4 ensures that only half of the designated current is provided to the stepper motors when they are at a standstill, thus preventing the potential for overheating in both the stepper motors and the associated drivers.

-

STRONGHOLD PRO Elevating Switches 5 and 6 with the downward orientation of Switches 7 and 8 configures the pulse/revolution rate to 1600, in conjunction with the ball screws, this specific arrangement ensures that the axis traverses a distance of 1mm for each full revolution accomplished by the stepper motor, with the exception of the Z axis.

-

Repeat for the other DM542T stepper drivers

-

-

-

There is a small switch on top of the DM542T stepper driver, ensure it is set to 5V as the AXBB signal is 5V.

-

Repeat for the other DM542T stepper drivers

-

-

-

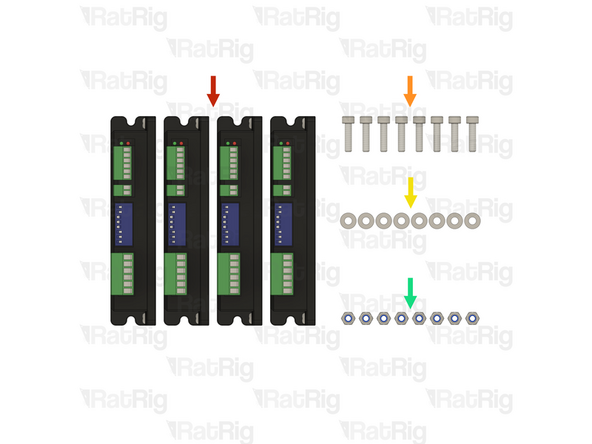

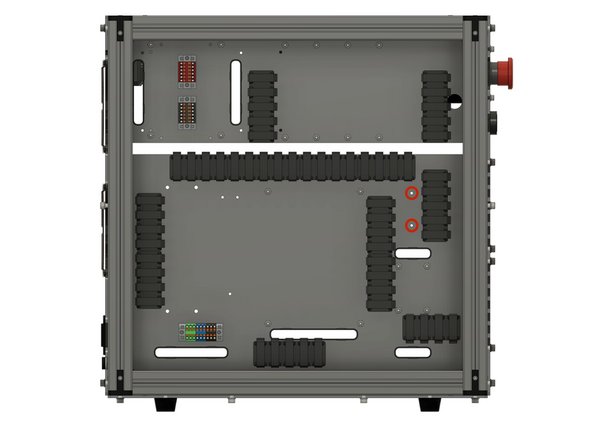

4x Stepper driver - OMC DM542T

-

8x M4x16 cap head screw

-

8x M4 washer

-

8x M4 locking hex nut

-

-

-

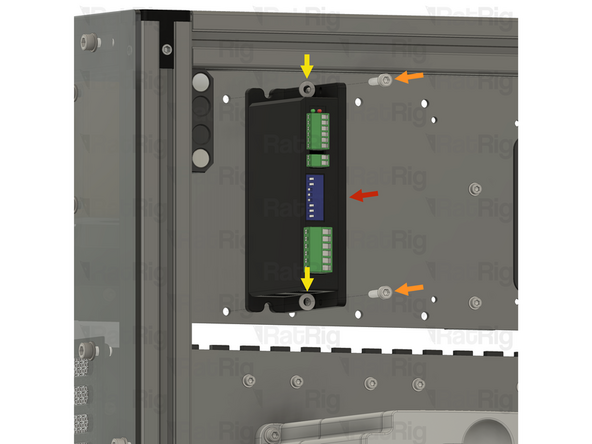

1x Stepper driver - OMC DM542T

-

2x M4x16 cap head screw

-

2x M4 washer

-

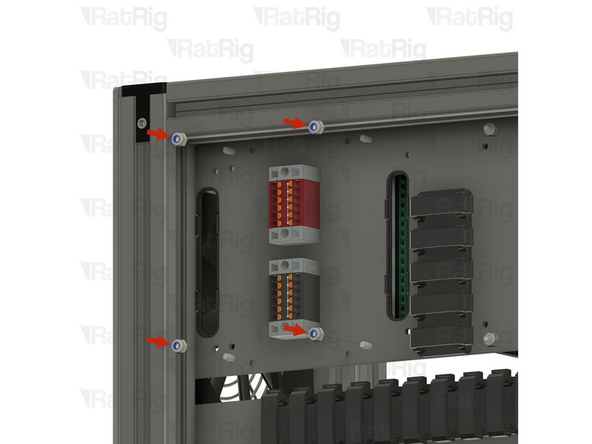

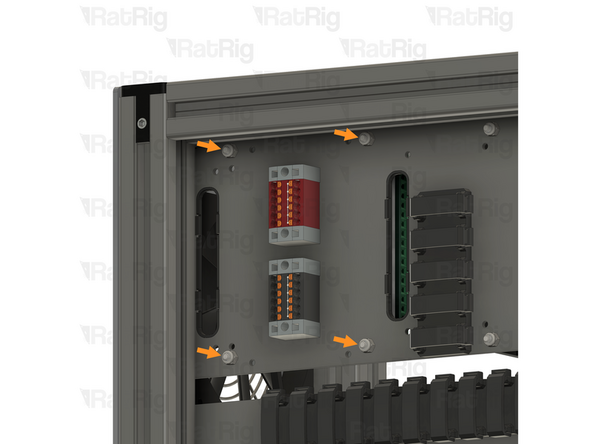

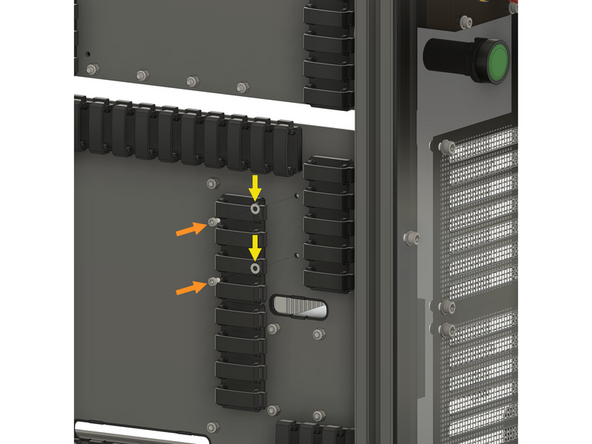

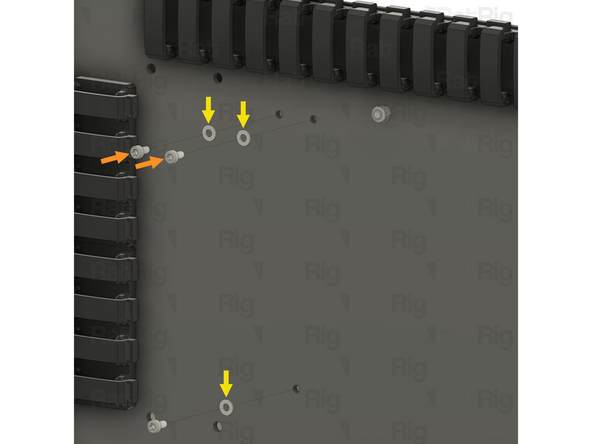

Install an M4 washer on to each M4x16 screw

-

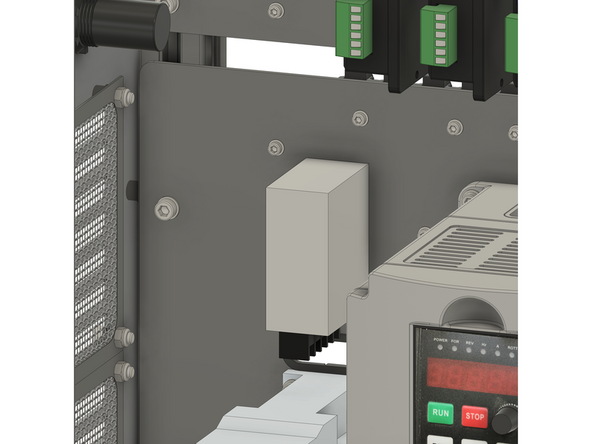

Align the stepper driver with the holes on the panel, and insert an M4x16 screw through the stepper driver and panel as shown

-

Keep supporting the stepper driver until the locking hex nuts are installed in the next step

-

-

-

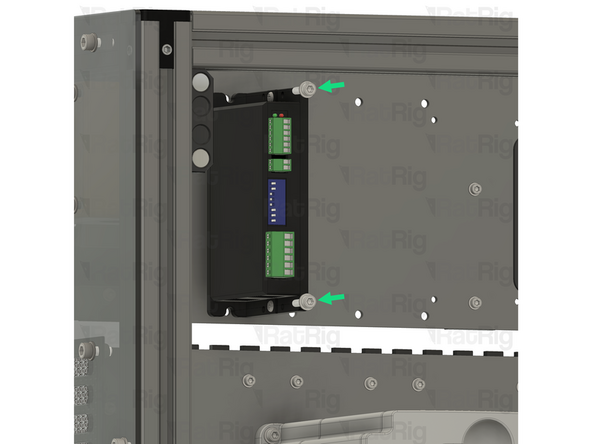

2x M4 locking hex nut

-

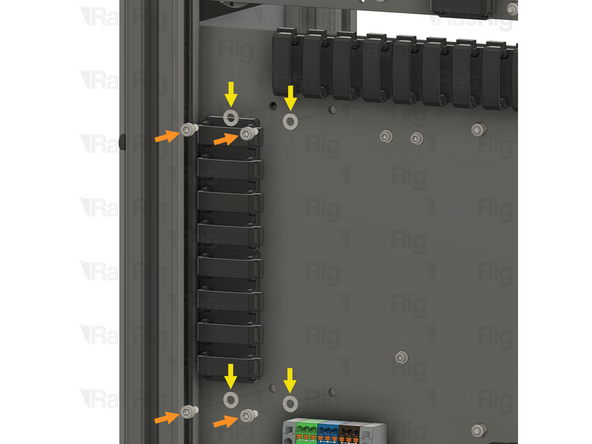

Install an M4 locking hex nut on to each of the M4x16 screws and tighten them to secure the stepper driver to the panel

-

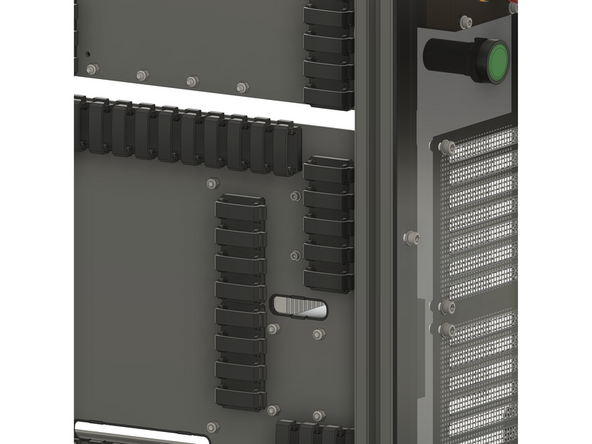

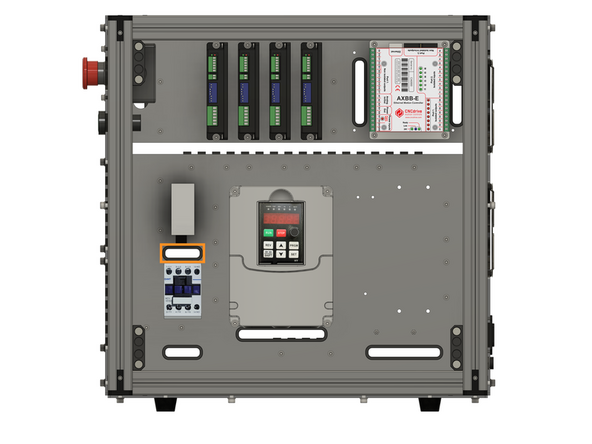

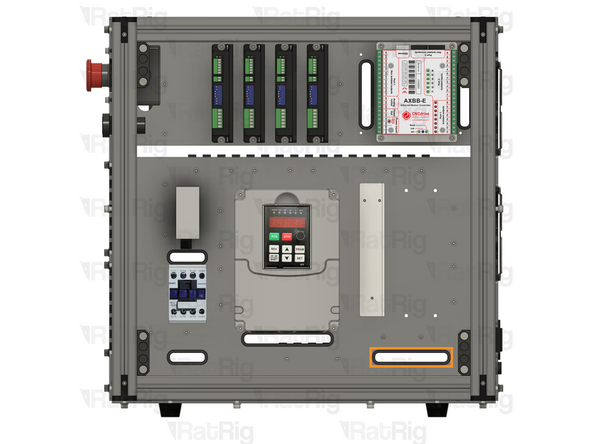

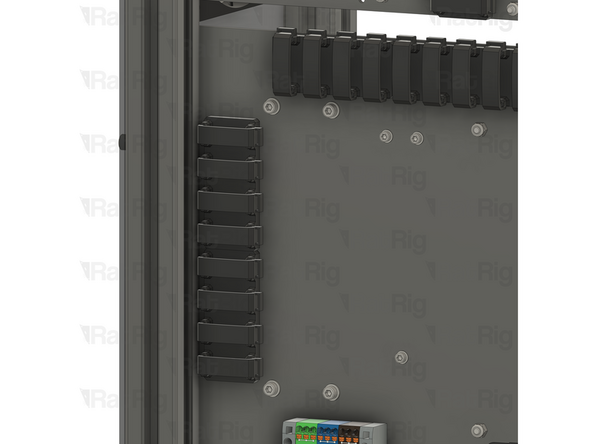

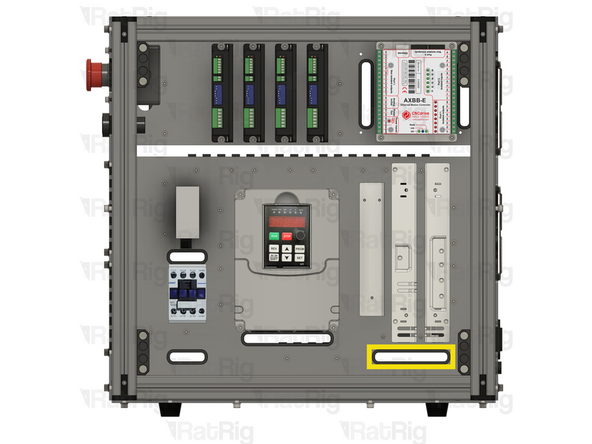

Repeat the previous step, and this step, to install the remaining 3 stepper drivers as shown

-

-

-

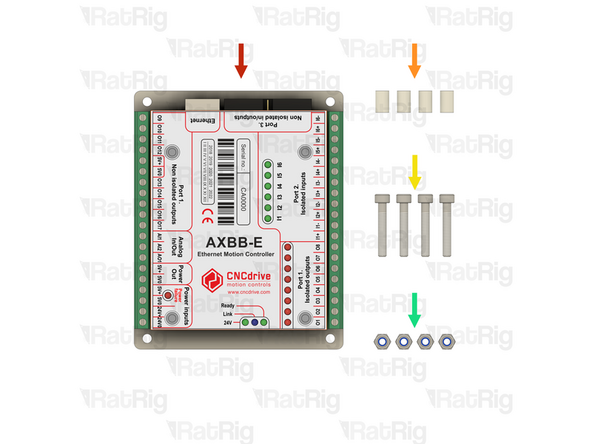

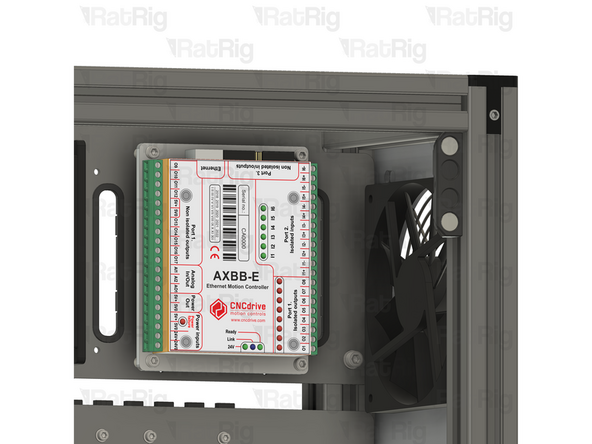

1x CNCDrive AXBB-E CNC controller

-

4x Spacer - Nylon - 4.2x6.3x10mm

-

4x M4x25 cap head screw

-

4x M4 locking hex nut

-

-

-

1x CNCDrive AXBB-E CNC controller

-

4x Spacer - Nylon - 4.2x6.3x10mm

-

4x M4x25 cap head screw

-

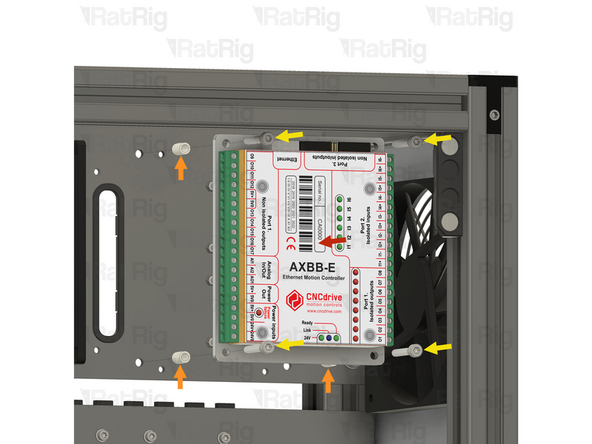

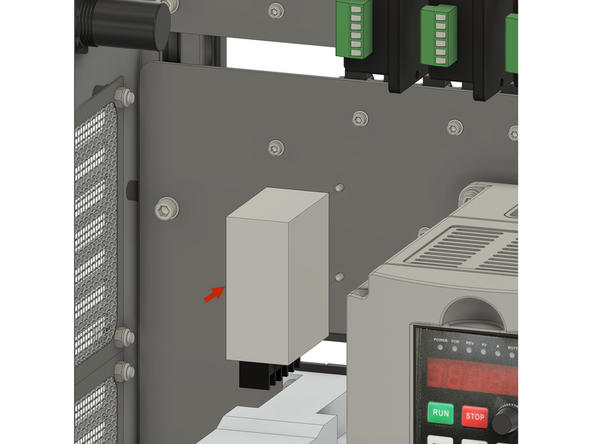

Install an M4x25 screw through each mounting hole on the AXBB-E CNC controller

-

Install a nylon spacer on to each M4x25 screw

-

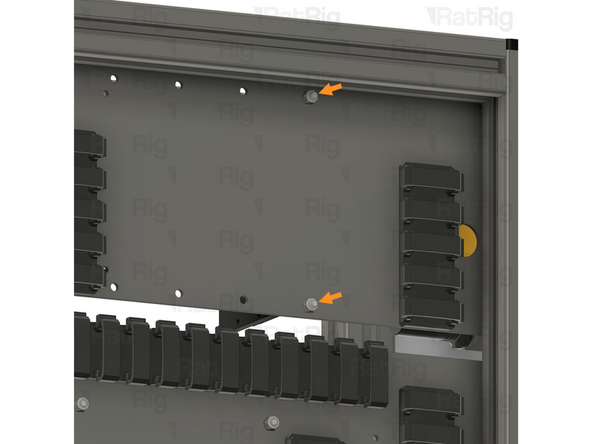

Align the M4x25 screws with the holes in the panel as shown

-

Keep supporting the AXBB-E CNC controller until the locking hex nuts are installed in the next step

-

-

-

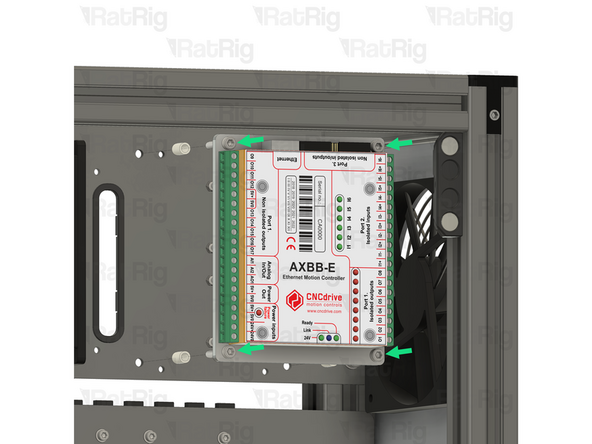

4x M4 locking hex nut

-

Install an M4 locking hex nut on to each of the M4x25 screws and tighten them to secure the AXBB-E CNC controller to the panel

-

-

-

5x M3x6 cap head screw

-

5x M3 washer

-

1x Meanwell RS-15-5 5V power supply

-

1x Meanwell RSP-75-24 24V power supply

-

-

-

It is recommended to wire the power supply before installing it in the electronics enclosure. Please connect the following wires:

-

XXmm - 18AWG BROWN (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG BLUE (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG YELLOW/GREEN (A-Fork, B-Ferrule) (XX)

-

2x 400mm - 22AWG BLACK (A-Ferrule, B-Fork) (13) Overlay the two forks in the screw terminal.

-

400mm - 22AWG RED (A-Ferrule, B-Fork) (12)

-

Connect all the wires above to the power supply, using the fork connectors on each wire

-

After insertion, attempt to pull the wire to verify that it is securely attached

-

-

-

Install the component using the designated holes

-

2x M3x6 cap head screw

-

2x M3 washer

-

Install an M3 washer on to each M3x6 screw and insert them into the marked holes

-

-

-

1x Meanwell RS-15-5 5V power supply

-

Install the power supply as shown, securing it by screwing the M3x6 screws into the threaded holes on the side of the PSU body

-

Feed all of the power supply wires through the designated slot

-

-

-

It is recommended to wire the power supply before installing it in the electronics enclosure. Please connect the following wires:

-

600mm - 16AWG RED (A-Fork, B-Ferrule) (7)

-

600mm - 22AWG BLACK (A-Fork, B-Ferrule) (8)

-

XXmm - 18AWG YELLOW/GREEN (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG BLUE (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG BROWN (A-Fork, B-Ferrule) (XX)

-

Connect all the wires above to the power supply, using the fork connectors on each wire

-

After insertion, attempt to pull the wire to verify that it is securely attached

-

-

-

Install the component using the designated holes

-

3x M3x6 cap head screw

-

3x M3 washer

-

Install an M3 washer on to each M3x6 screw and insert them into the marked holes

-

-

-

1x Meanwell RSP-75-24 24V power supply

-

Install the power supply as shown, securing it by screwing the M3x6 screws into the threaded holes on the side of the PSU body

-

Feed all of the power supply wires through the designated slot

-

-

-

2x Meanwell RSP-320-48 48V power supply

-

4x M4x8 cap head screw

-

4x M4 washer

-

-

-

It is recommended to wire the power supply before installing it in the electronics enclosure. Please connect the following wires:

-

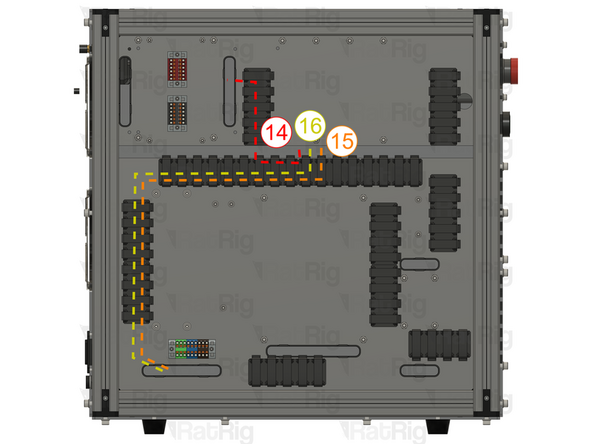

2x 800mm - 16AWG RED (A-Fork, B-Ferrule) (15)

-

2x 800mm - 16AWG BLACK (A-Fork, B-Ferrule) (16)

-

XXmm - 18AWG YELLOW/GREEN (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG BLUE (A-Fork, B-Ferrule) (XX)

-

XXmm - 18AWG BROWN (A-Fork, B-Ferrule) (XX)

-

Connect all the wires above to the power supply, using the fork connectors on each wire

-

After insertion, attempt to pull the wire to verify that it is securely attached

-

-

-

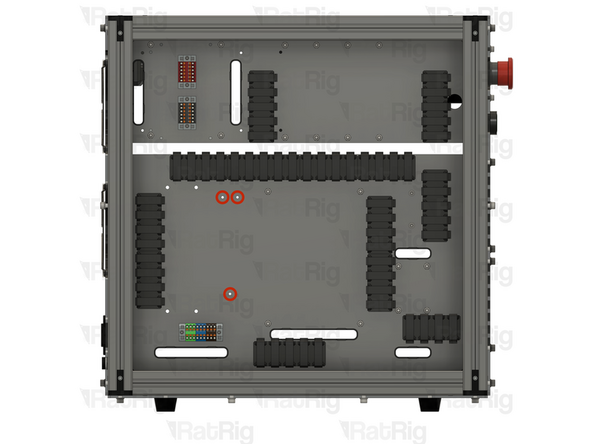

Install the component using the designated holes

-

4x M4x8 cap head screw

-

4x M4 washer

-

Install an M4 washer on to each M4x8 screw and insert them into the marked holes

-

-

-

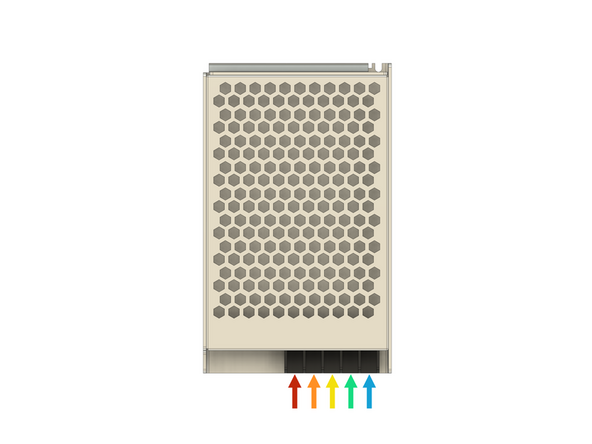

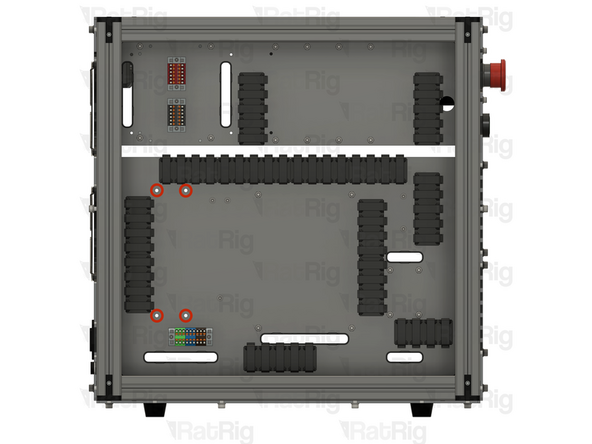

2x Meanwell RSP-320-48 48V power supply

-

Install the power supply as shown, securing it by screwing the M4x8 screws into the threaded holes on the side of the PSU body

-

Repeat to install the second power supply, paying attention to the orientation

-

Feed all of the wires from both power supplies through the designated slot

-

-

-

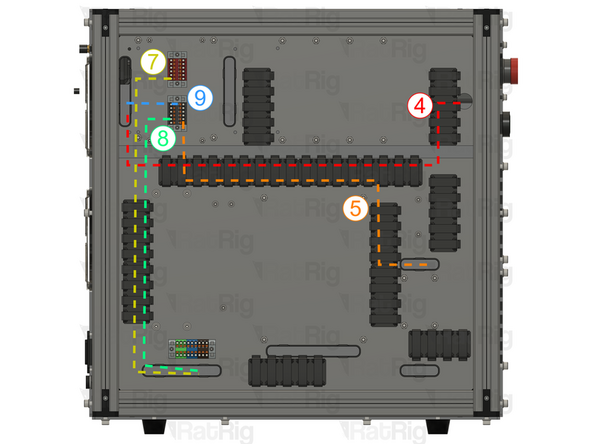

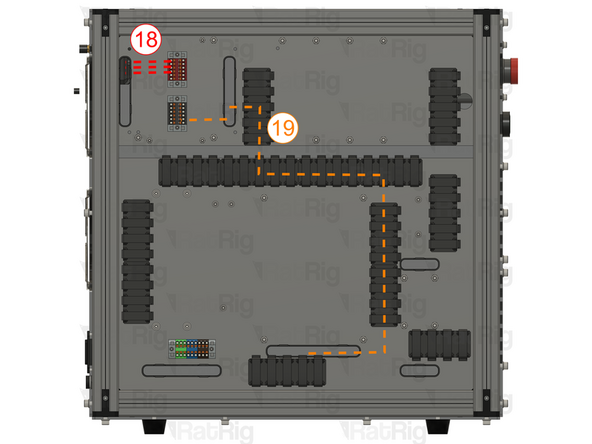

Route the wires on the back of the enclosure as shown.

-

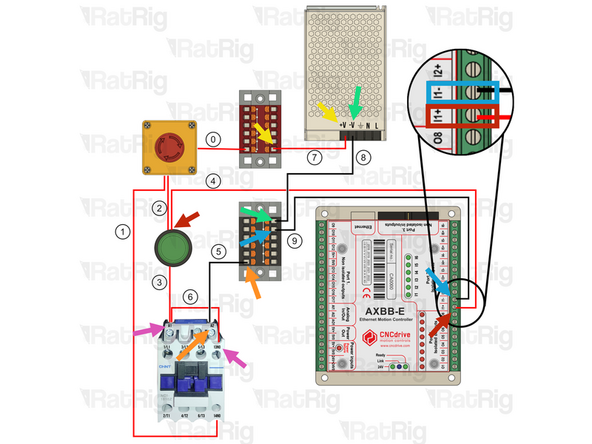

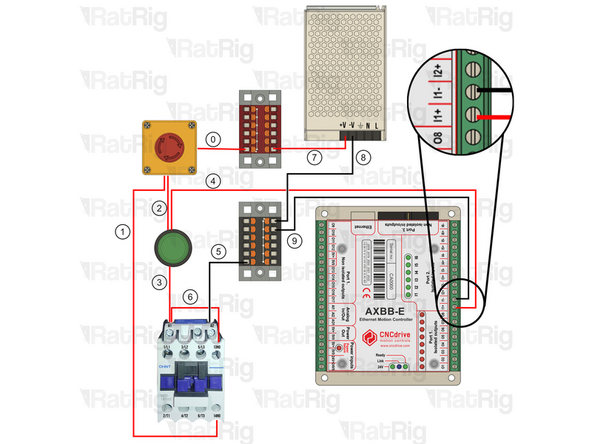

700mm - 16AWG RED (A-Ferrule, B-Ferrule) (4) Connect the wire from the start button (in) to the I1+ terminal on port2 of the AXBB-E

-

700mm - 16AWG BLACK (A-Ferrule, B-Fork) (5) Connect the ferrule in the Black PTFix block and the fork on the A2 terminal of the contactor.

-

600mm - 16AWG RED (A-Fork, B-Ferrule) (7) Connect the ferrule into the Red PTFix block, the fork end should have been connected to the power supply here.

-

600mm - 16AWG BLACK (A-Fork, B-Ferrule) (8) Connect the ferrule into the Black PTFix block, the fork end should have been connected to the power supply here.

-

150mm - 22AWG BLACK (A-Fork, B-Ferrule) (9) Connect one end of the wire to the Black PTFix block and the other to the I1- terminal on port 2 of the AXBB-E

-

120mm - 16AWG RED (A-Fork, B-Fork) (6) Connect the wire from terminal 13NO on hte contactor to the A1 terminal on the contactor. A1 should have 2 Forks inserted.

-

-

-

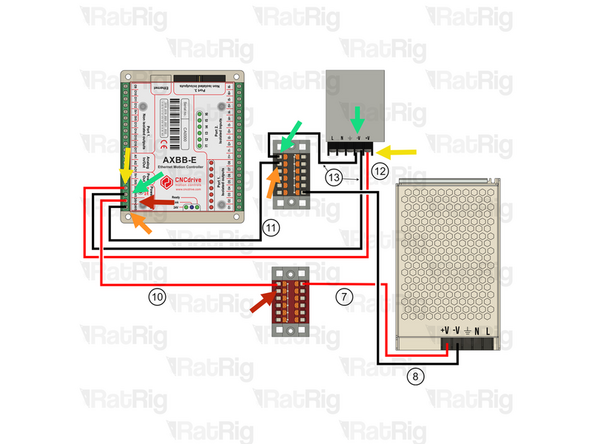

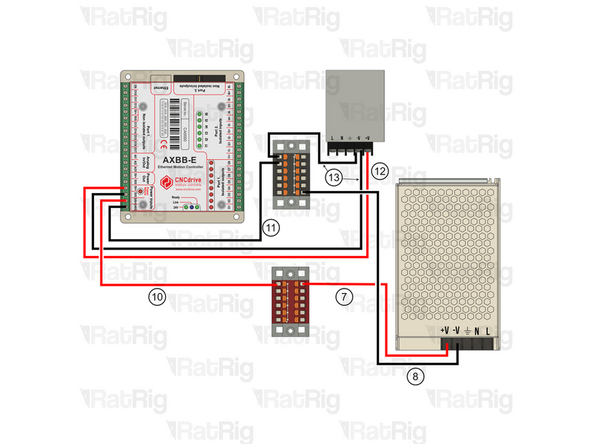

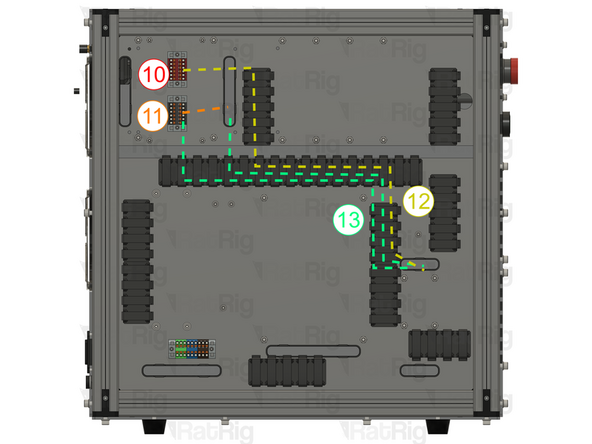

Route the wires on the back of the enclosure as shown.

-

150mm - 22AWG RED (A-Ferrule, B-Ferrule) (10) Connect the wire from the Red PTFix block to the +24V input on the AXBB-E

-

150mm - 22AWG BLACK (A-Ferrule, B-Ferrule) (11) Connect the wire from the Black PTFix block to the -24V input on the AXBB-E

-

500mm - 22AWG RED (A-Ferrule, B-Fork) (12) Connect the fork end to the +V terminal on the 5V power supply and the ferrule end in the 5V+ terminal on the AXBB-E.

-

2x 500mm - 22AWG BLACK (A-Ferrule, B-Fork) (13) Connect the wire from the -V terminal on the 5V Power supply using the fork connector and connect the ferrule in the Black PTFix block. The second (13) wire should be connected from the -V terminal on the 5V Power supply using the fork connector and then connected to the AXBB-E 5V0 terminal

-

-

-

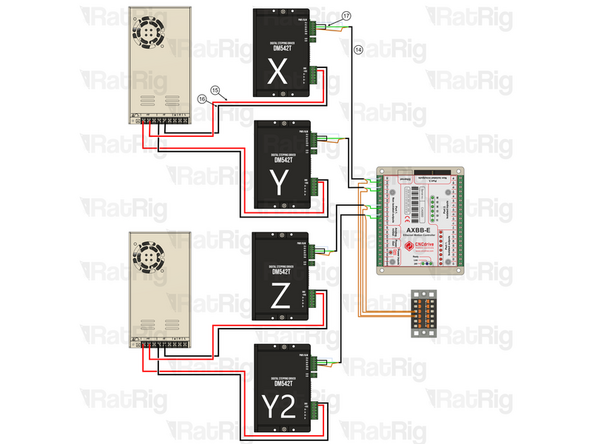

Ignore Y2 if you are wiring a Rat Rig Mill. Repeat the Steps to connect all drivers.

-

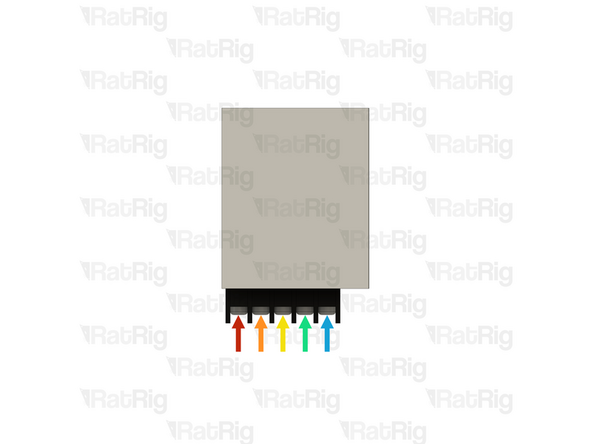

4x 550mm - Multicore 3 Conductor - 24AWG BLACK (A-(3x)Ferrule, B-(3x)Ferrule) (14)

-

DRIVER SIDE: Connect the white wire to PUL+ , the green wire to DIR+ and the brown wire to DIR-

-

AXBB-E Side: Connect the white wire to 09 , the green wire to 010 and the brown wire to the Black PTFix Block

-

Follow the order and connect stepper Y( PUL+ to 011, DIR+ to 012), then Z( PUL+ to 013, DIR+ to 014), Lastly Y2( PUL+ to 015, DIR+ to 016)

-

4x 30mm - 22AWG BLACK (A-Ferrule, B-Ferrule) (17) To jump DIR- with PUL-

-

4x 800mm - 16AWG RED (A-Fork, B-Ferrule) (15) The Fork terminals should be already wired to the 48V Power supplies here. Then connect it to +VDC on the driver.

-

4x 800mm - 16AWG BLACK (A-Fork, B-Ferrule) (16) The Fork terminals should be already wired to the 48V Power supplies here. Then connect it to GND on the driver.

-

-

-

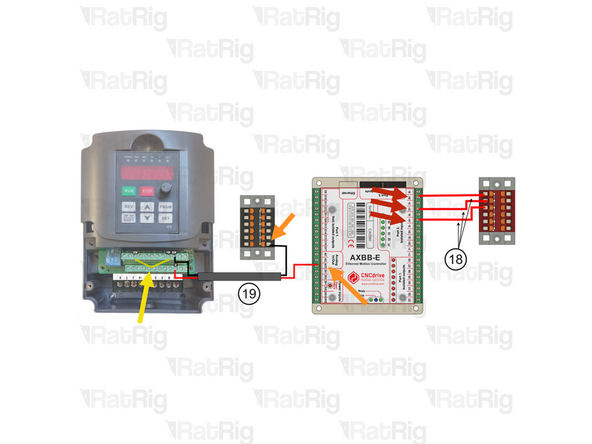

3x 100mm - 22AWG RED (A-Ferrule, B-Ferrule) (18) Connect one end to the Red PTFix block and the other to I6+ terminal on port 2 of the AXBB-E.

-

Repeat the previous Step and connect I5+ and I4+ the the Red PTFix Block.

-

900mm - Multicore 2 Conductor - 24AWG (A-2xFerrule, B-2xFerrule) (19) Connect the 2 wire cable to from the VFD and AXBB-E

-

Use the Red wire for the VI terminal on the VFD and A01 analog input on the AXBB-E

-

Use the Black wire for the black PTFix Block and ACM terminal on the VFD.

-

100mm - 16AWG BLACK (A-Ferrule, B-Ferrule) (20) Connect the FOR terminal with the DCM terminal on the VFD

-

-

-

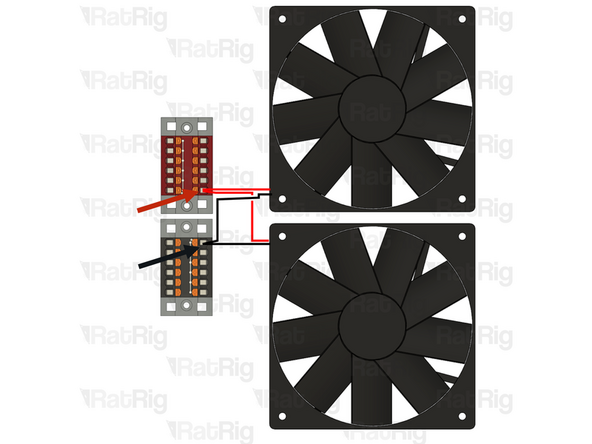

Cut the JST connectors on the cooling fans and crimp both red wires in the same ferrule, then insert it into the Red PTFix Block.

-

Cut the JST connectors on the cooling fans and crimp both black wires in the same ferrule, then insert it into the Black PTFix Block.

-