-

-

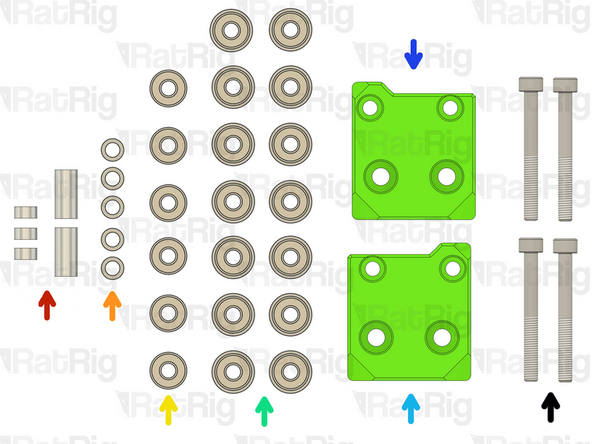

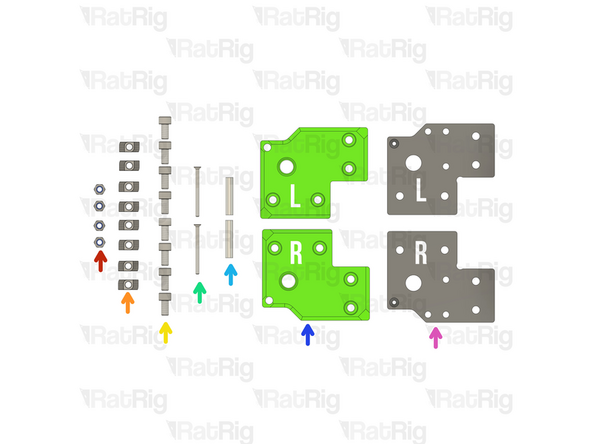

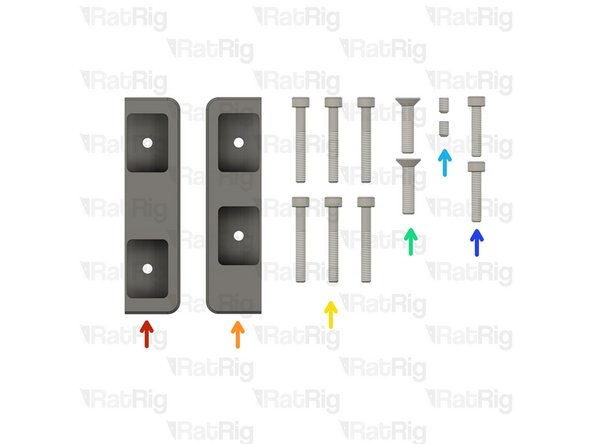

Right Stepper motor plate assembly from Step 27 of chapter 01.Frame assembly

-

Left Stepper motor plate assembly from Step 27 of chapter 01.Frame assembly

-

2x Nema 17 Stepper motor - HT - 48mm

-

2x 20 Tooth 2GT Timing Pulley for 9mm Belt

-

6x M3x6 Countersink Screws

-

-

-

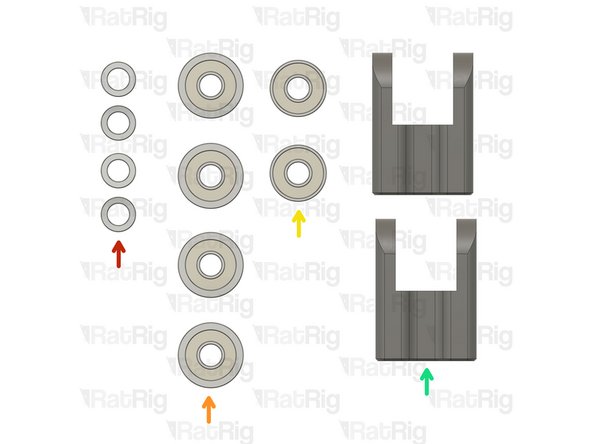

3x Aluminium spacer 5x8x4mm + 1x Aluminium spacer 5x8x14mm + Aluminium spacer 5x8x17mm

-

5x Mini precision shim 8x5x1mm

-

6x Ball bearing 695ZZ

-

14x Ball bearing F695ZZ

-

Right vc4_motor_spacer

-

Left vc4_motor_spacer

-

4x M5x45 Cap Head Screws

-

6x Heavy-Duty Idler – The latest V-Core 4 kits now feature these heavy-duty idlers as a replacement for the previously used bearing stack assemblies.

-

-

-

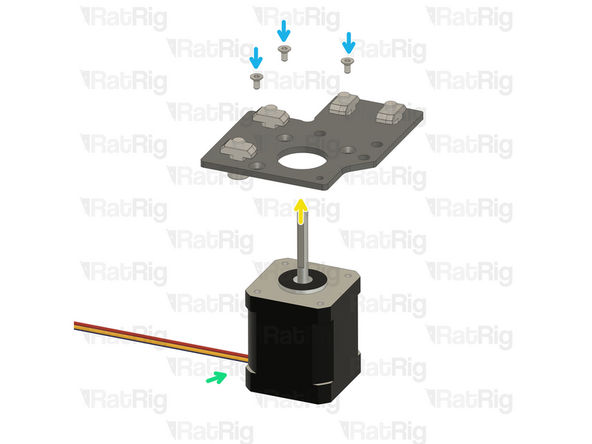

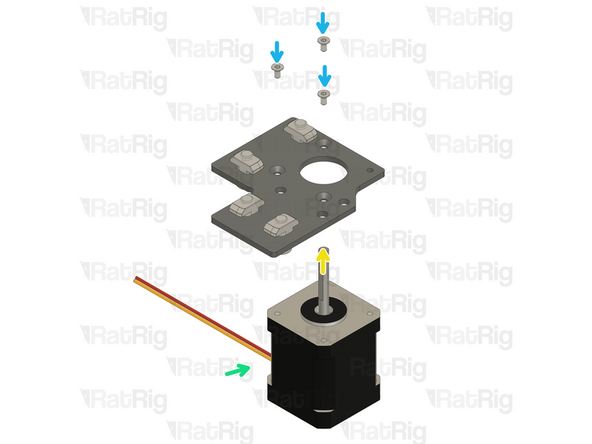

Right Stepper motor plate assembly from Step 27 of chapter 01.Frame assembly

-

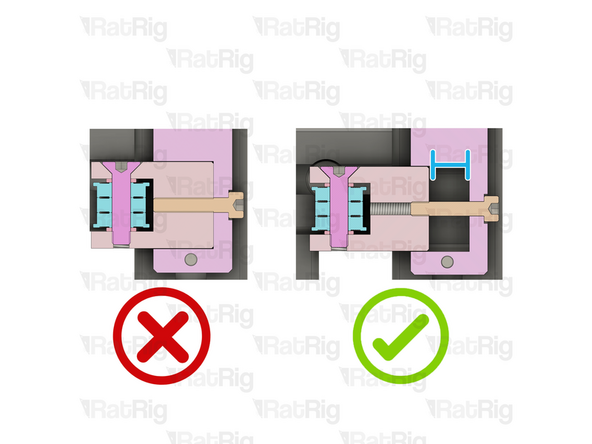

Ensure the t-nuts are on the same side as the countersink bores.

-

Nema 17 Stepper motor - HT - 48mm

-

Be mindful of the cable orientation, it should replicate the image.

-

3x M3x6 Countersink Screws

-

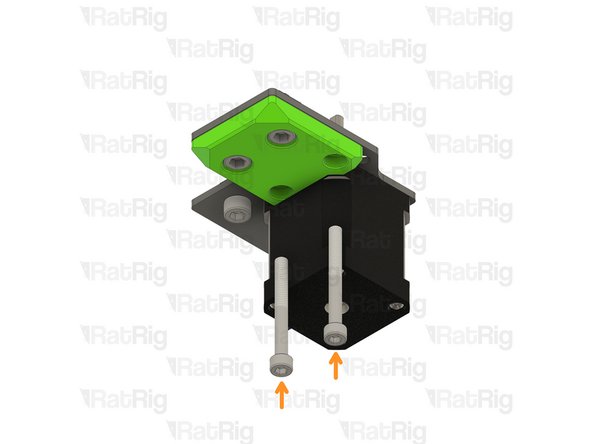

Insert the M3x6 screws into the Right Stepper motor plate assembly as shown, and fasten them to secure the NEMA17 motor.

-

-

-

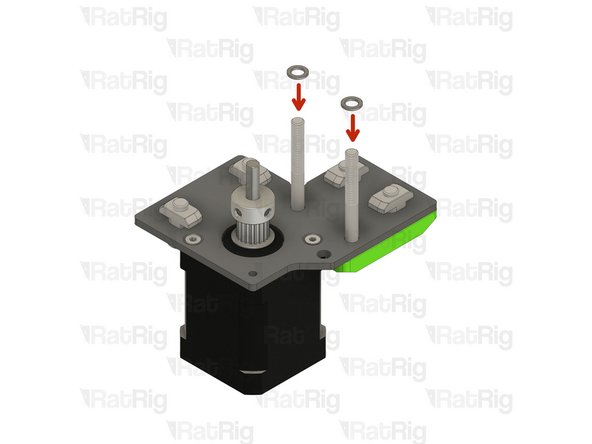

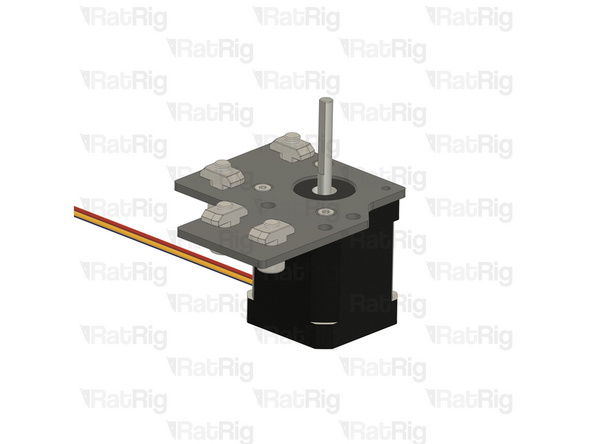

Refer to the side of the assembly which has the M5 holes

-

Remove the two M6x12 Cap Head Screws

-

Remove the two 3030 Drop-in T-Nut - M6

-

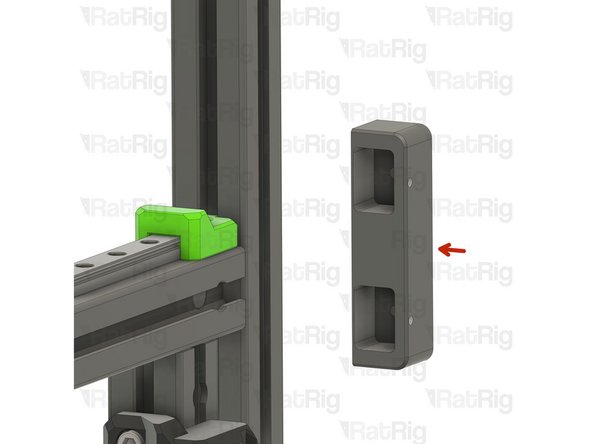

Right vc4_motor_spacer

-

Install the printed part next to the nema 17 stepper motors, and make sure the holes are aligned.

-

Insert the two M6x12 Cap Head Screws

-

Insert the two 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x12 screws. Do not tighten them at this point.

-

-

-

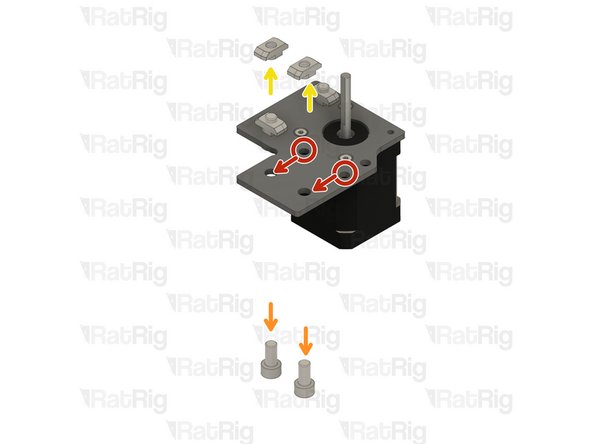

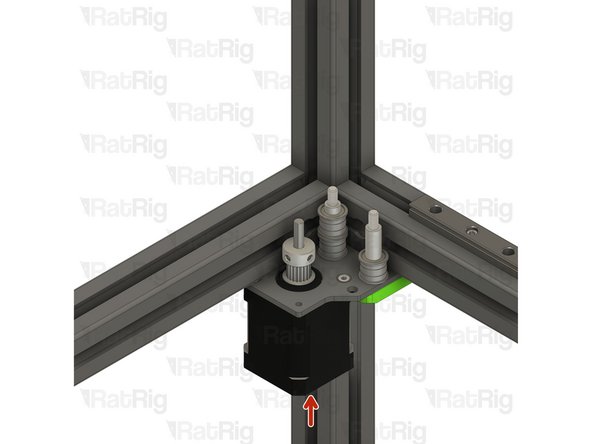

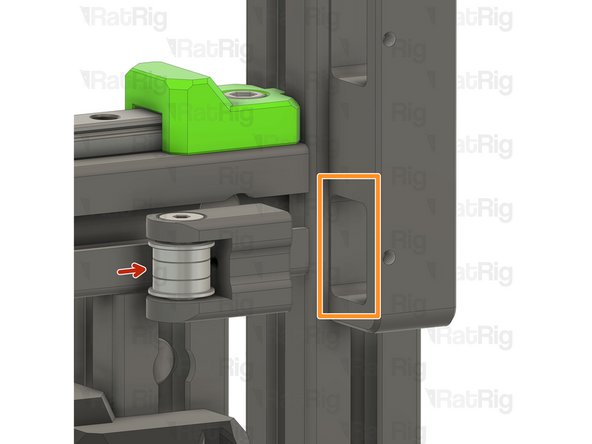

Ensure the right vc4_motor_spacer printed part is aligned with the plate

-

Insert the M5x45 Cap Head Screws all the way

-

Once inserted, the printed part should be able to hold them in place

-

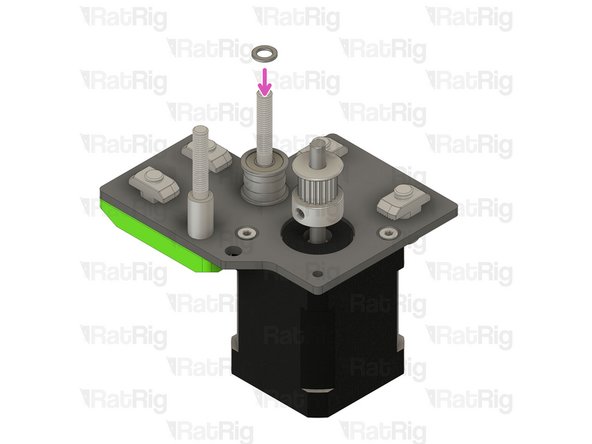

Install the timing pulley onto the NEMA17 shaft, oriented as shown

-

The timing pulley will be aligned and fully secured in a later step.. Do not tighten the M3 grub screws

-

-

-

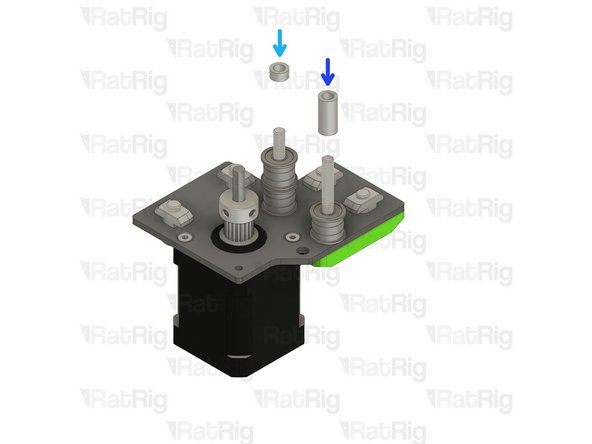

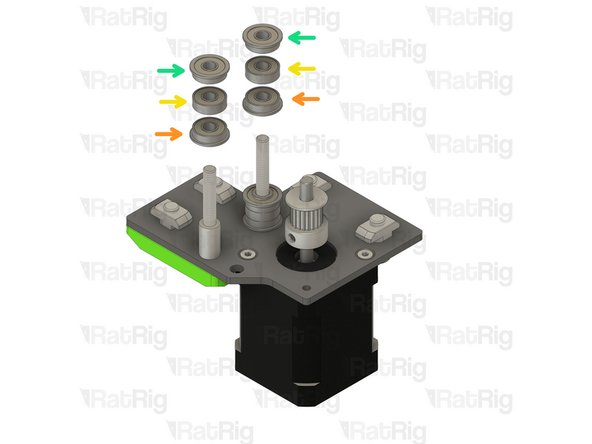

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Insert a Mini Precision Shim on the rear M5x45 Screw

-

-

-

Install the following components on the rear M5x45 Screw in the order shown in the image:

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Install an Aluminium spacer 5x8x4mm on the rear M5x45 Screw

-

Install an Aluminium spacer 5x8x17mm on the front M5x45 Screw

-

Set the assembly aside, let's assemble the left stepper motor.

-

-

-

Left Stepper motor plate assembly from Step 27 of chapter 01.Frame assembly

-

Ensure the t-nuts are on the same side as the countersink bores.

-

Nema 17 Stepper motor - HT - 48mm

-

Be mindful of the cable orientation, it should replicate the image.

-

3x M3x6 Countersink Screws

-

Insert the M3x6 screws into the Right Stepper motor plate assembly as shown, and fasten them to secure the NEMA17 motor.

-

-

-

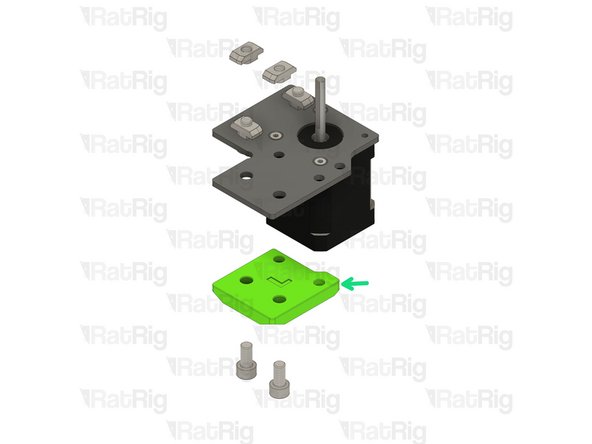

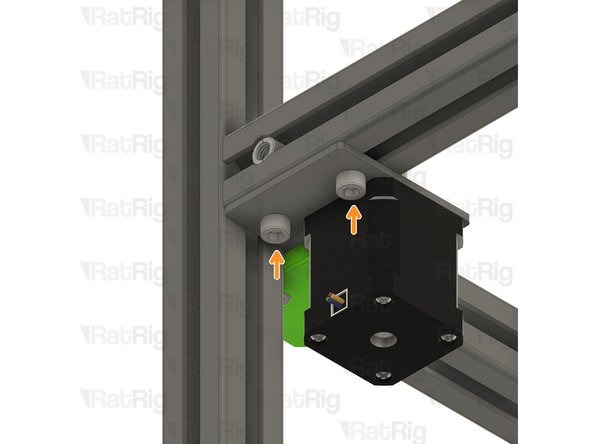

Refer to the side of the assembly which has the M5 holes

-

Remove the two M6x12 Cap Head Screws

-

Remove the two 3030 Drop-in T-Nut - M6

-

Left vc4_motor_spacer

-

Install the printed part next to the nema 17 stepper motors, and make sure the holes are aligned.

-

Insert the two M6x12 Cap Head Screws

-

Insert the two 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x12 screws. Do not tighten them at this point.

-

-

-

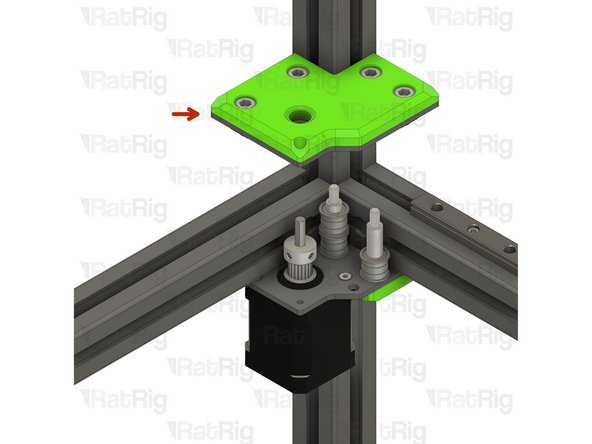

Ensure the left vc4_motor_spacer printed part is aligned with the plate

-

Insert the M5x45 Cap Head Screws all the way

-

Once inserted, the printed part should be able to hold them in place

-

Install the timing pulley onto the NEMA17 shaft, oriented as shown

-

The timing pulley will be aligned and fully secured in a later step. Do not tighten the M3 grub screws

-

-

-

Insert a Mini Precision Shim on the rear M5x45 Screw

-

Install an Aluminium spacer 5x8x14mm on the front M5x45 Screw

-

Install the following components on the rear M5x45 Screw in the order shown in the image:

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Insert a Mini Precision Shim on the rear M5x45 Screw

-

-

-

Install the following components in the order shown in the image:

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Aluminium spacer 5x8x4mm

-

Set the assembly aside. it will be used in a few steps

-

-

-

4x M5 Hex Locking nut

-

8x 3030 Drop-in T-Nut - M6

-

8x M6x12 Cap Head Screws

-

2x M3x40 Countersink Screw

-

2x Aluminium Spacer 3x6x30mm

-

The metal plates are not marked with "R" or "L" Please refer to the orientation to help identify them.

-

vc4_trim_coreXY_right and vc4_trim_coreXY_left

-

vc4_xy_motor_upper_right and vc4_xy_motor_upper_left

-

-

-

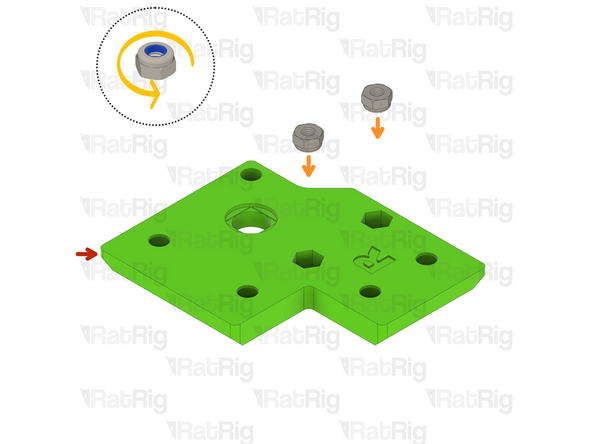

vc4_trim_coreXY_right

-

2x M5 Hex Locking nut

-

Insert the M5 Hex Locking nut upside down.

-

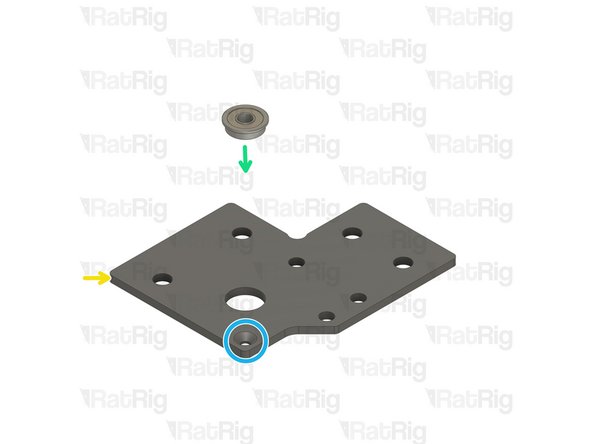

vc4_xy_motor_upper_right

-

Ball bearing F695ZZ

-

Insert the Ball bearing F695ZZ with the flange at the top

-

Ensure the bearing flange is on the same side as the countersink bore.

-

-

-

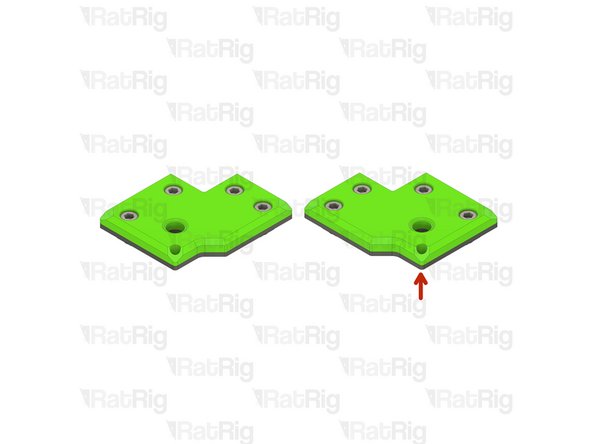

vc4_xy_motor_upper_right assembly

-

vc4_trim_coreXY_right assembly

-

Insert the four M6x12 Cap Head Screws

-

Insert the four 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x12 screws. Do not tighten them at this point.

-

-

-

Repeat Steps 14 and 15 and complete the left assembly

-

-

-

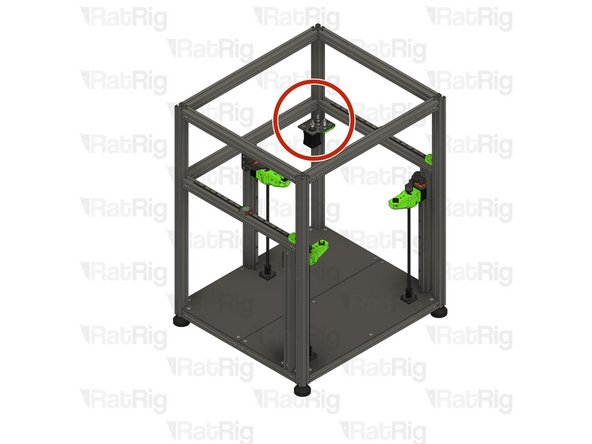

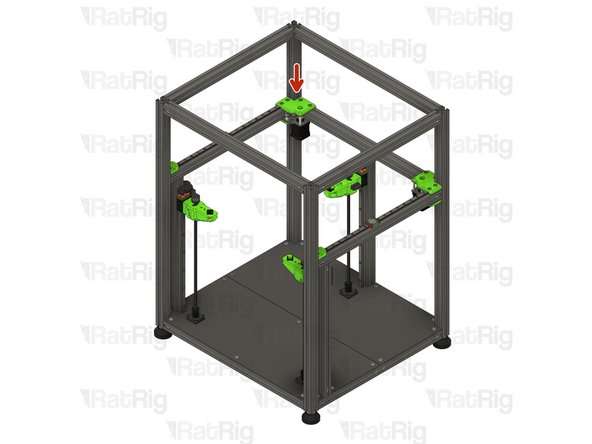

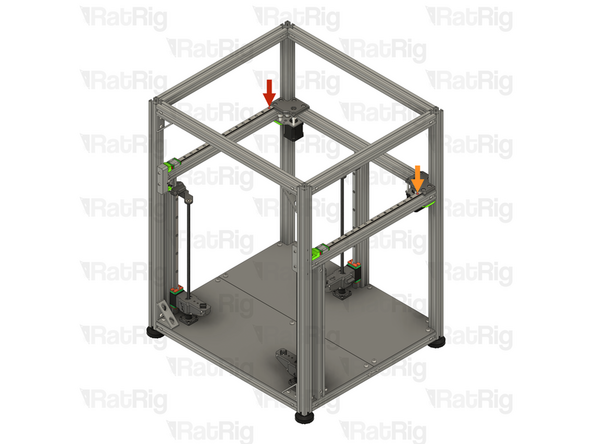

Place the right stepper motor assembly from Step 7 in the frame

-

-

-

Install the right stepper motor assembly to the V-Core 4 frame as shown

-

Tighten the four M6x12 screws to secure the motor_plate assembly to the frame

-

Make sure the plate is fully seated against the 3030 extrusion before tightening the M6x12 screws

-

Take care not to over tighten the M6x12 screws as you can damage the printed parts

-

-

-

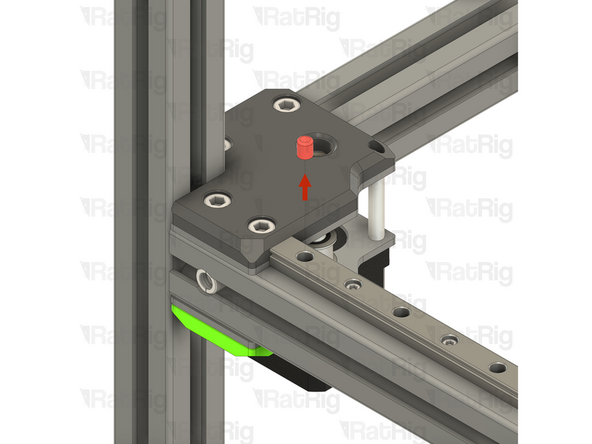

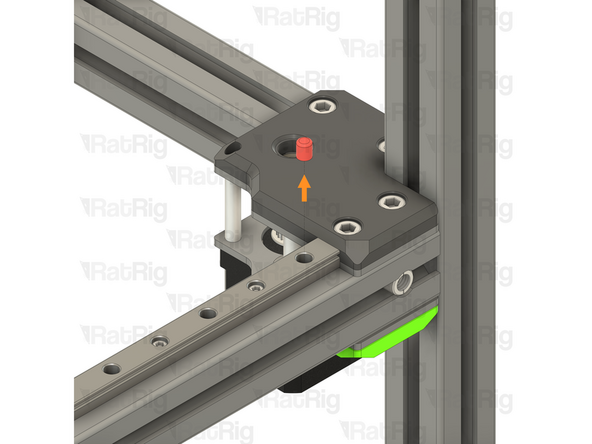

Right top stepper motor assembly from Step 15

-

Make sure the plate is fully seated against the 3030 extrusion.

-

Insert the Aluminium Spacer 3x6x30mm between the top and bottom plates

-

Insert the M3x40 countersink screw through the top plate, the aluminium spacer 3x6x30mm, and the bottom plate. Do not thread it to the stepper motor at this stage

-

-

-

Progressively tighten both M5x45 screws, alternating between them, so the top plate assembly is pulled down uniformly.

-

Take care not to over tighten the M5x45 screws as you can damage the printed parts

-

Tighten the M3x40 countersink screw to to nema 17 stepper motor thread.

-

Tighten the four M6x12 screws to secure the motor_plate assembly to the frame

-

Make sure the plate is fully seated against the 3030 extrusion before tightening the M6x12 screws

-

Take care not to over tighten the M6x12 screws as you can damage the printed parts

-

-

-

Repeat Steps 17 to 20 and install the left stepper motor to the V-Core 4 frame.

-

-

-

Rat Rig V-Core 4.0 - Tensioner Body - Right v1.0

-

Rat Rig V-Core 4.0 - Tensioner Body - Left v1.0

-

6x M4x30 Cap Head Screw

-

2x M5x22 Countersink Screw

-

2x M4x6 Set Screw

-

2x M4x20 Cap Head Screw

-

-

-

4x Mini precision shim 8x5x1mm

-

4x Ball bearing F695ZZ

-

2x Ball bearing 695ZZ

-

2x Rat Rig V-Core 4.0 - Tensioner Arm v1.0

-

2x Heavy-Duty Idler – The latest V-Core 4 kits now feature these heavy-duty idlers as a replacement for the previously used bearing stack assemblies.

-

-

-

Rat Rig V-Core 4.0 - Tensioner Arm v1.0

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the top)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the bottom)

-

Mini Precision Shim

-

-

-

Insert the M5x22 Countersink Screw and tighten it to secure the assembly.

-

Repeat Steps 25 and 26 to assemble another tensioner arm

-

-

-

Rat Rig V-Core 4.0 - Tensioner Body - Right v1.0

-

3x M4x30 Cap Head Screws

-

Insert the screws through the holes on the V-Core 4 frame extrusion and thread them in the Tensioner Body - Right v1.0.

-

Tighten the M4x30 cap head screws.

-

-

-

Front tensioner arm assembly from Step 26

-

Insert the tensioner arm in the lower slot of the tensioner body.

-

Make sure the tensioner arm has cleared the hole on the tensioner body.

-

M4x20 Cap Head Screw

-

Insert the screw trough the tensioner body and lightly thread it to the tensioner arm.

-

The M4x20 screw must be partially, but not fully, threaded into the tensioner arm. This allows the largest possible range for tensioning the belts further in the guide.

-

-

-

M4x6 Set Screw

-

Tighten the Screw to secure the tensioner arm in place

-

Repeat Steps 27 to 29 and assemble the Left front tensioner

-

-

-

If you installed the Y-axis linear rail plastic stops in step 12 and step 14 of the Y-Axis Assembly guide, remove them now

-

Left-hand Y-axis linear rail plastic stop

-

Right-hand Y-axis linear rail plastic stop

-

The plastic stops are no longer required and can be discarded

-

Cancel: I did not complete this guide.

10 other people completed this guide.