Introduction

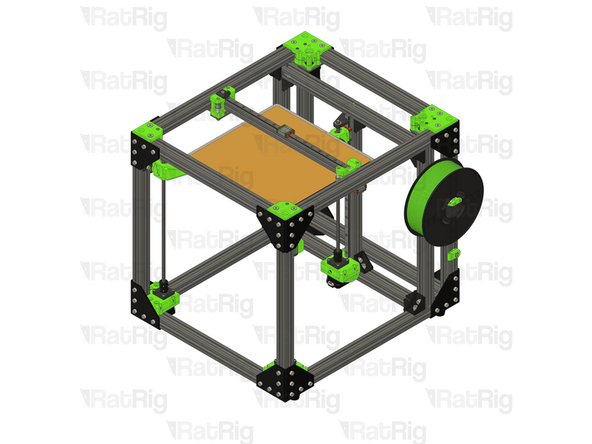

This guide provides a thorough overview of the disassembly of the EVA3, the preparation of the V-Core 3.1 frame, and the installation procedure for the Rat Rig toolhead V1.0 Upgrade Kit.

The Rat Rig Toolheads are streamlined to be used specifically with our favourite combination:

Orbiter V2

Phaetus Rapido UHF hot end

4028 part cooling fan

Rat Rig “SuperPinda” Probe by P&F

-

-

This guide is divided into 3 parts, to help you quickly find the instructions you need:

-

Disassembling the EVA 3.0

-

Preparing the V-Core 3.1 for the upgrade kit

-

Installing the Rat Rig toolhead v1.0 upgrade kit

-

-

-

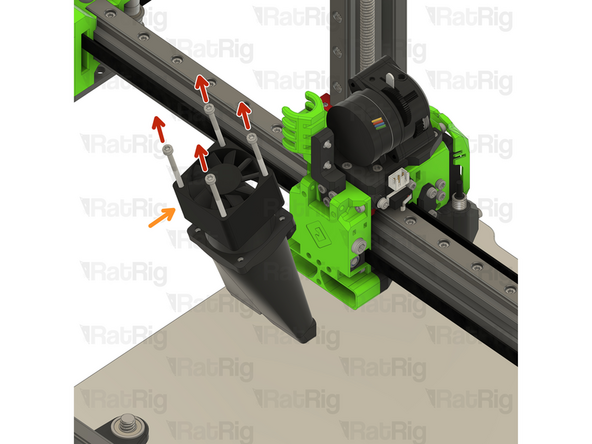

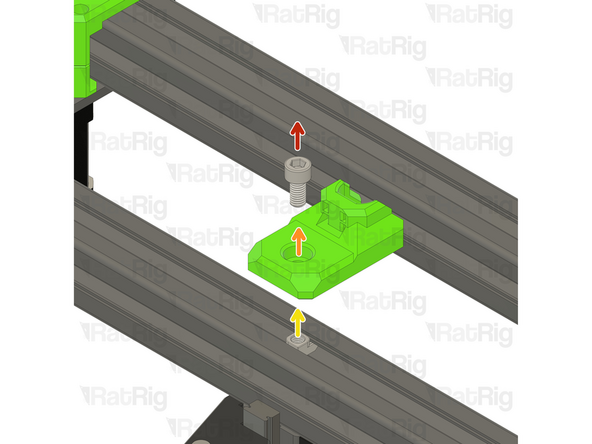

Remove the M3x25 Cap Head Screw

-

Remove the Hex Nut - M3

-

Remove the M3 Nylon Locking Hex Nut

-

Remove the M3x35 Cap Head Screw

-

Remove the 40mm_fan_duct assembly as shown

-

-

-

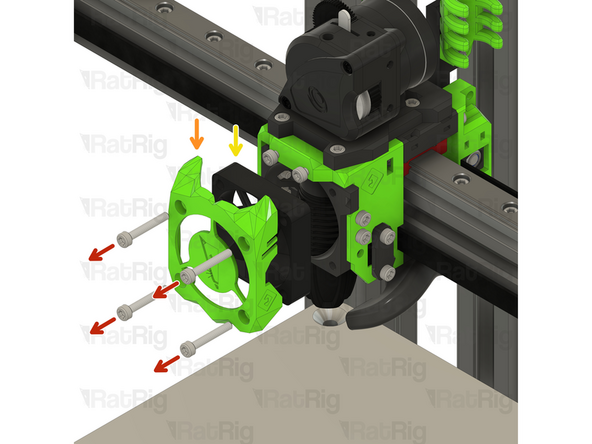

Remove the four M3x35 Cap Head Screws

-

Remove the 4028 Part Cooling Fan from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

Remove the four Hex Nuts - M3

-

-

-

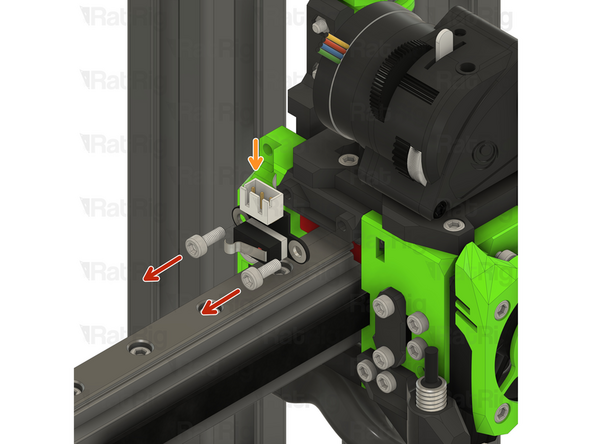

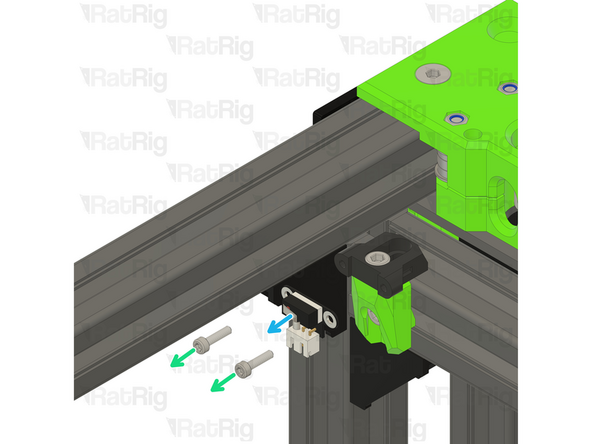

Remove the two M3x8 Cap Head Screws

-

Disconnect the Endstop Module and set it aside, it will be re-used on the Rat Rig Toolhead V1.0

-

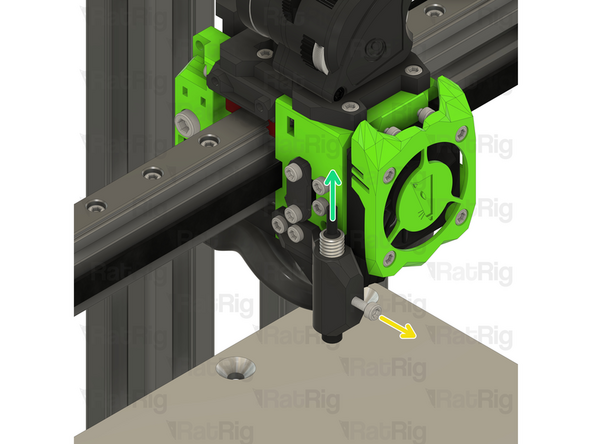

Loosen the M3x8 Cap Head Screw

-

Remove the Z-probe from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

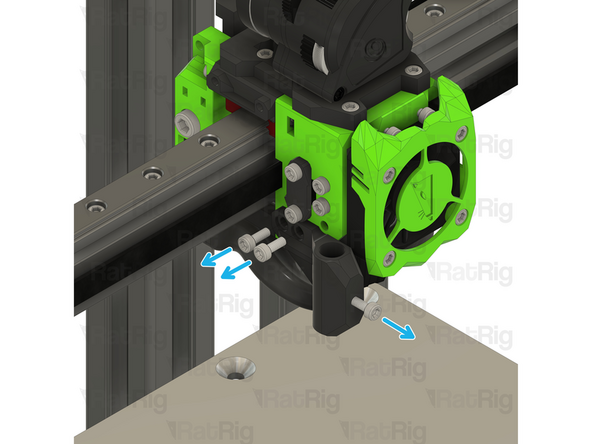

Remove the three M3x8 Cap Head Screws

-

-

-

Remove the four M3x20 Cap Head Screws

-

Remove the ratrig_eva3_shroud Printed Part

-

Remove the 4010 Axial Fan from the assembly, it will be re-used on the Rat Rig Toolhead V1.0

-

Remove the four M3x8 Cap Head Screws

-

-

-

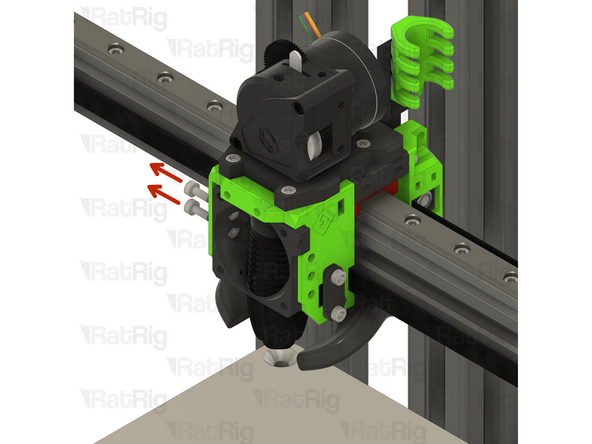

Remove the four M3x8 Cap Head Screws

-

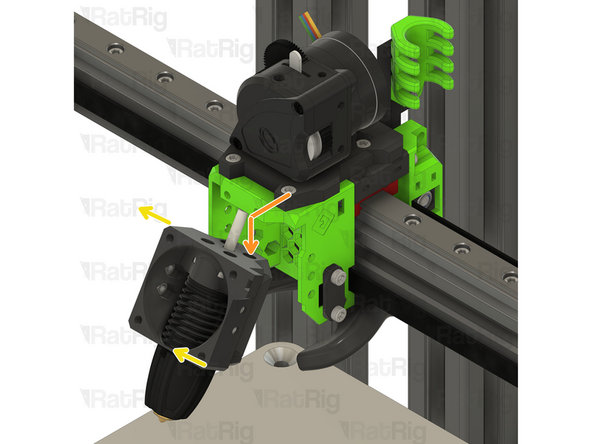

Gently push the hotend assembly down and away from the toolhead-

-

Rotate the hot end assembly into position as shown

-

-

-

Remove the PTFE line

-

Remove the four M2.5x8 Cap Head Screws

-

Remove the Rapido hotend from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

Tip: Insert the four M2.5x8 Cap Head Screws back in the Rapido hotend mounting points to avoid losing them.

-

-

-

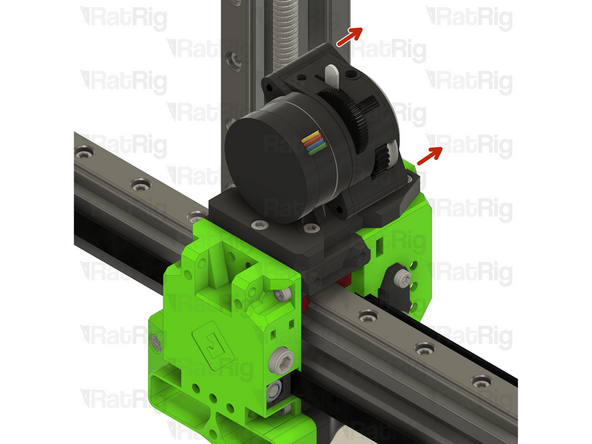

Remove the two M3x25 screws on the face of the LGX Lite which secure the motor in place

-

Remove the Bondtech LGX Lite motor from the back of the LGX Lite extruder

-

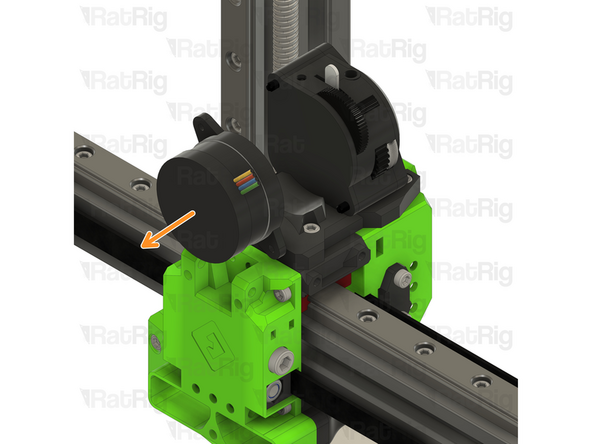

Remove the three M3x12 Cap Head Screws

-

-

-

Remove the two M3x8 Cap Head Screws

-

Remove the extruder assembly

-

The new Rat Rig toolhead uses the Orbiter V2,

-

Remove the M3x8 Cap Head Screws holding the LGX Lite to the EVA3 drive_lgx_lite Printed Part

-

Reassemble the LGX Lite so you can safely store it.

-

-

-

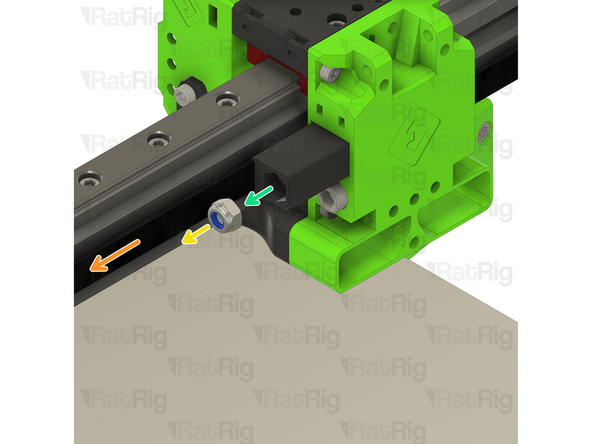

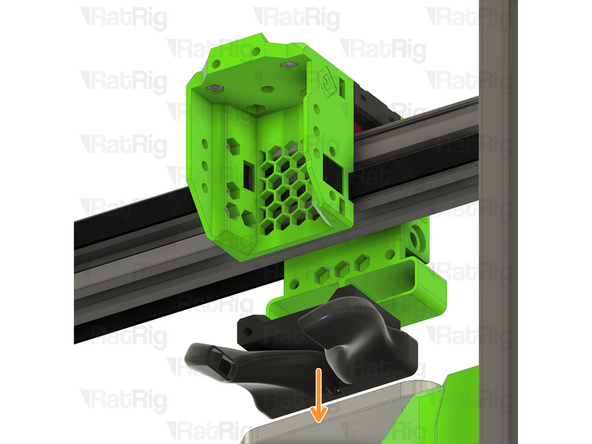

Loosen the M5x40 Cap Head Screw

-

Pull the belt to help remove the CoreXY belt grabber

-

Remove the M5 nylon locking nut

-

Remove the belt grabber from the toolhead

-

Repeat the previous steps and remove the other CoreXY belt grabber

-

-

-

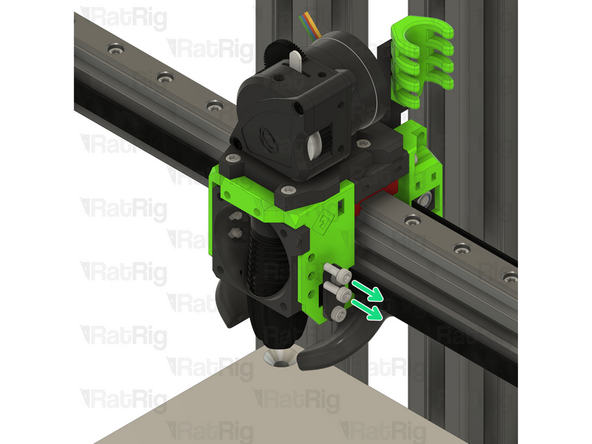

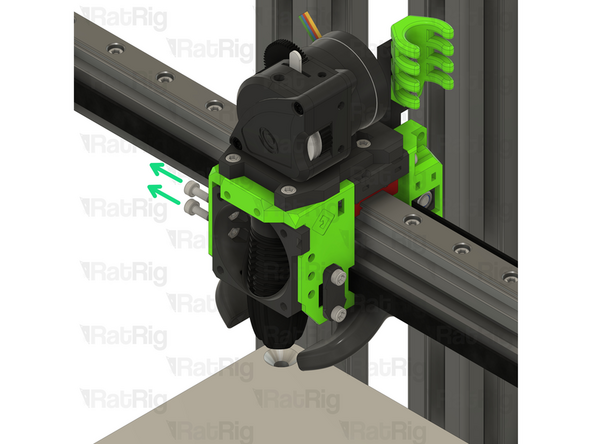

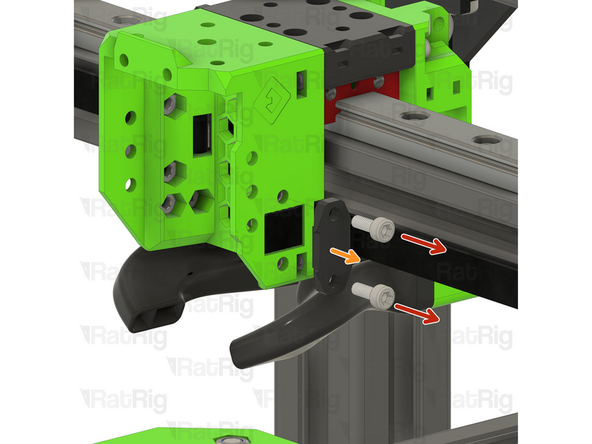

Remove the two M3x8 Cap Head Screws

-

Remove the belt front belt holder

-

Repeat the previous steps for the other front belt holder

-

-

-

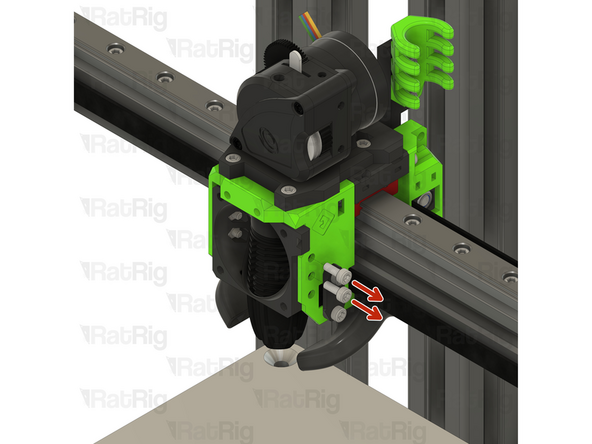

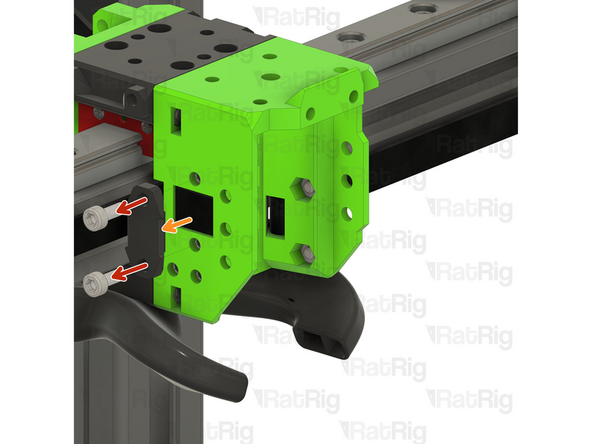

Remove the two M3x35 Cap Head Screws

-

Pull down on the EVA horn ducts

-

-

-

Remove the two M3x35 Cap Head Screws

-

Pull on the EVA3 front assembly to remove it

-

Pull on the EVA3 back assembly to remove it

-

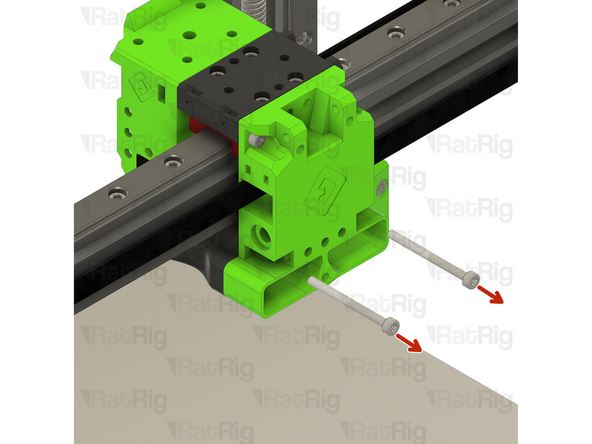

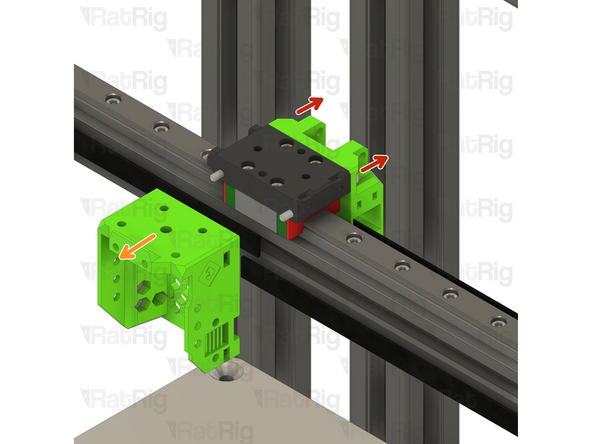

Remove the four M3x8 Cap Head Screws

-

Remove the EVA3 mgn12 mount

-

-

-

Some components of the V-Core 3.1 need to be upgraded to support the new Rat Rig Toolhead. The following steps will show you how.

-

-

-

Locate the rear cable holder

-

Remove the M6x12 Cap Head Screw

-

Remove the electronics_wire_guide_rear printed part from the frame

-

Remove the M6 3030 Drop in T-nut

-

Locate the Y endstop mount

-

Remove the two M3x12 Cap Head Screws

-

Disconnect the Enstop Module and set it aside, it will be re-used on the Rat Rig Toolhead V1.0

-

-

-

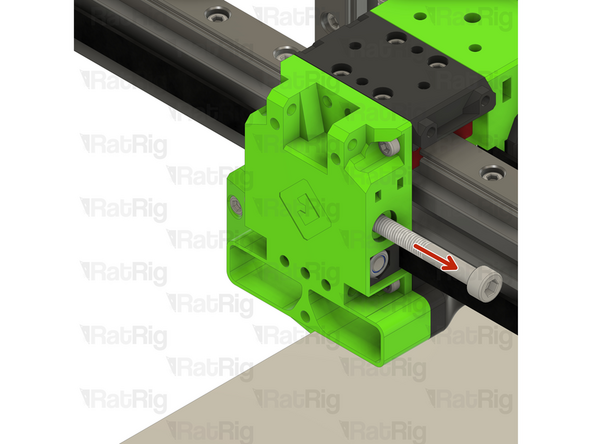

Remove the M5x12 Cap Head Screw

-

Remove the Y_max_endstop_slider printed part

-

Remove the M5x10 Cap Head Screw

-

Remove the Y endstop_max_block printed part

-

Remove the M5 3030 Drop in T-nut

-

-

-

Remove the M5x18 Cap Head Screw

-

Remove the EVA3 endstop block

-

Avoid moving the machine around at this point, os the M5 Drop in T-nut doesn't slide around on the gantry extrusion.

-

-

-

The V-Core 3.1 is now ready to receive the Rat Rig Toolhead V1.0 Upgrade kit

-

-

-

The next steps will cover the assembly of the Rat Rig toolhead V1.0 upgrade kit

-

-

-

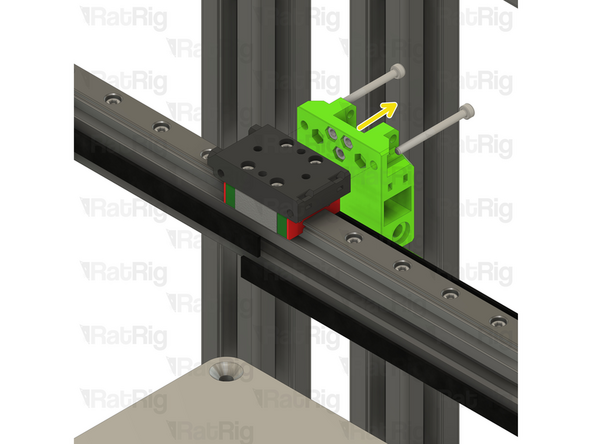

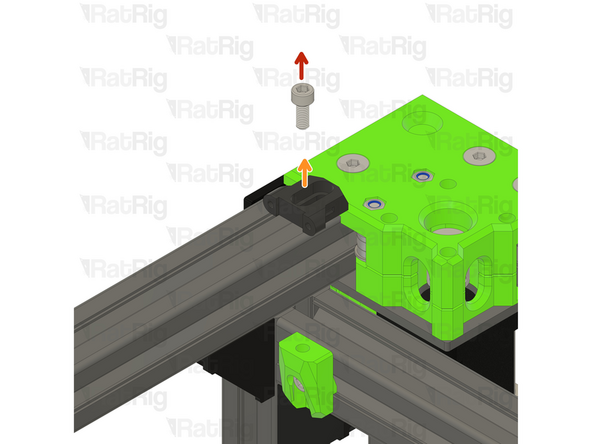

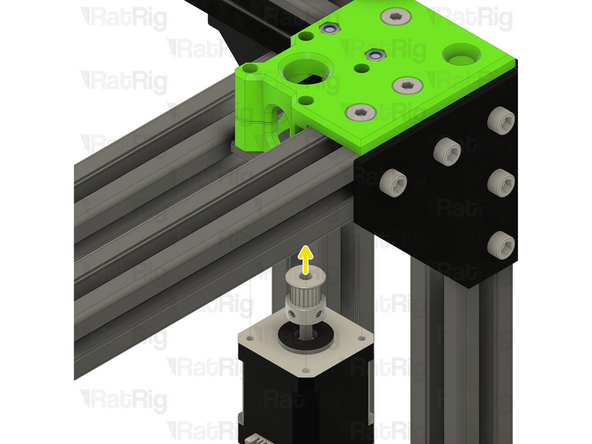

M5x18 Cap Head Screw

-

x_endstop printed part

-

Carefully insert the M5x18 Cap Head Screw into the already existing M5 Drop in T-nut

-

-

-

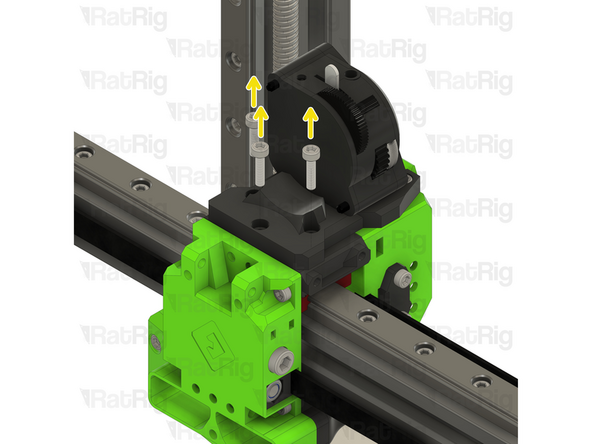

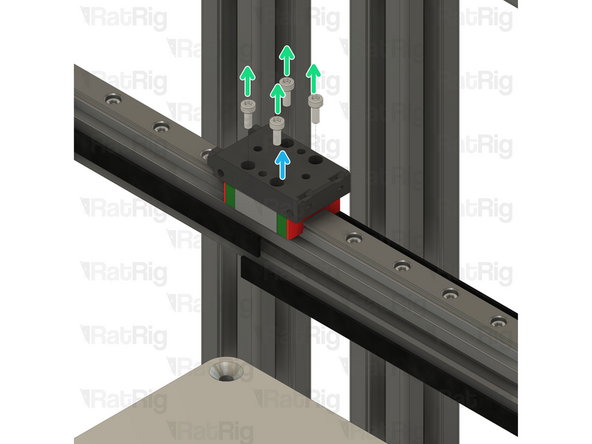

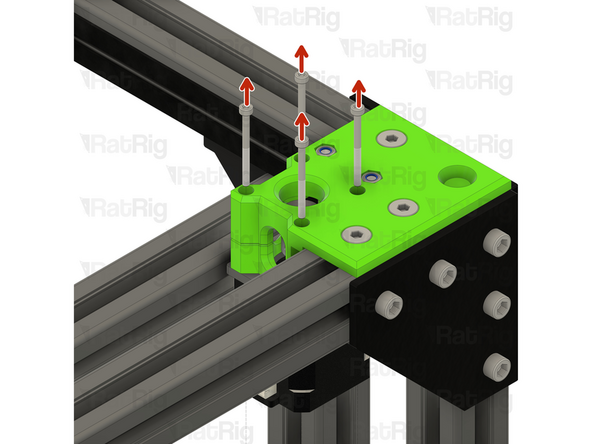

Remove the M3x45 Cap Head Screws

-

Remove the Stepper motor

-

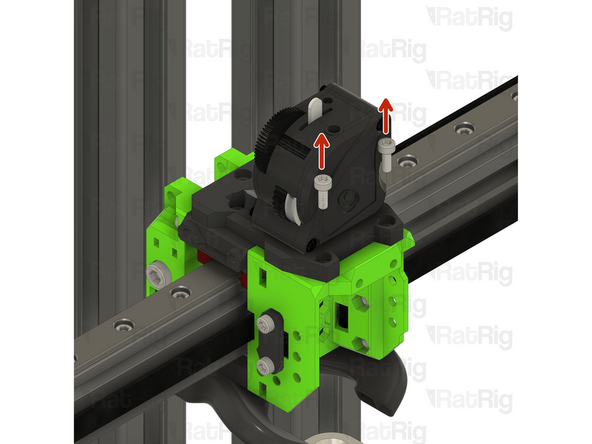

Remove the M5x40 Cap Head Screws

-

-

-

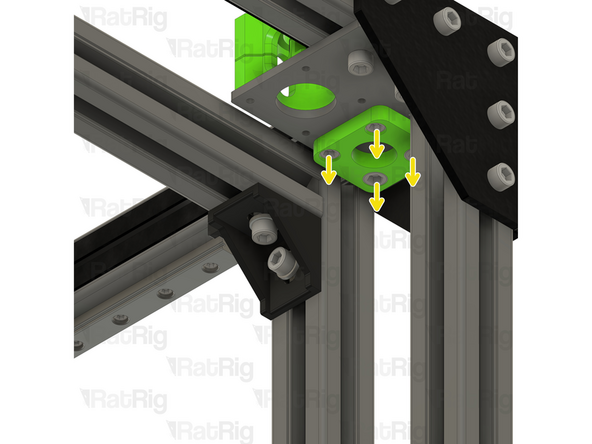

Remove the three M6x14 Screws

-

If the M6 Drop in T-nuts fall off, loosely thread them in the screws so you can easly reinstall the CoreXY motor cage top easily.

-

Remove the CoreXY motor cage top

-

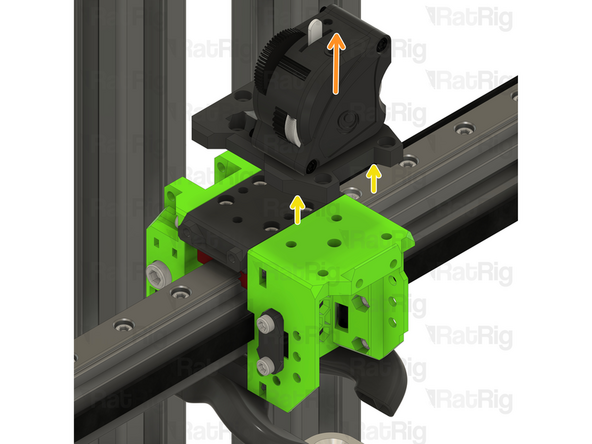

Remove both of the old belts, then insert the two new ones following the same paths

-

Reinstall the CoreXY motor cage top

-

-

-

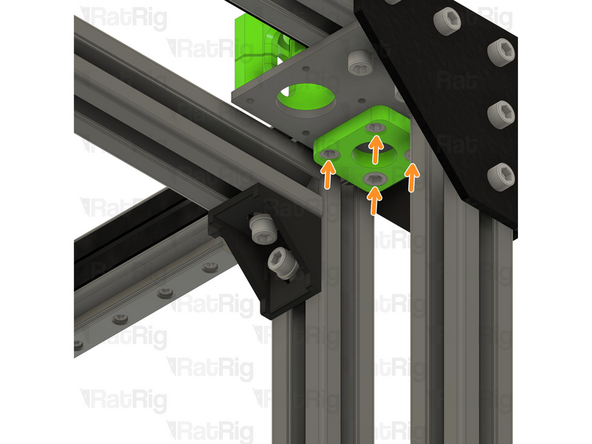

Tighten the three marked M6x14 screws to secure the CoreXY motor cage top to the frame

-

Tighten the M5x40 screws to secure the bearing stacks into the CoreXY motor cage top

-

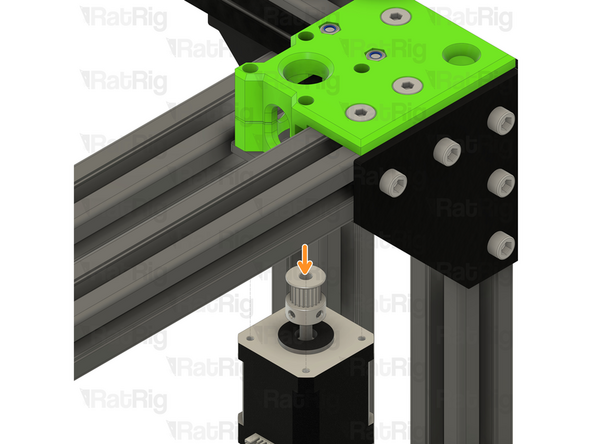

Position the NEMA17 motor up and into the motor cage from below, it will be secured in the next step

-

-

-

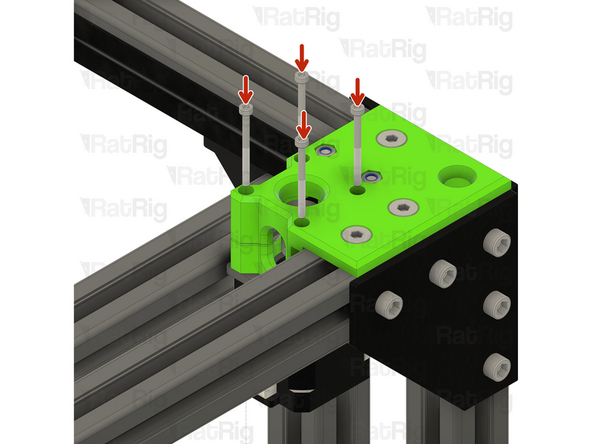

Insert the M3x35 screws into the xy_motor_cage_left_top as shown, and fasten them to secure the NEMA17 motor to the mount

-

Check the alignment of the timing pulley, the belt should be on the middle of the pulley as shown

-

Adjust the pulley up or down if required to make sure the belt is in the middle of the pulley

-

Fasten both M3 grub screws to securely mount the timing pulley to the NEMA17 motor shaft

-

Repeat Steps 21 - 24 for the other CoreXY motor mount cage.

-

-

-

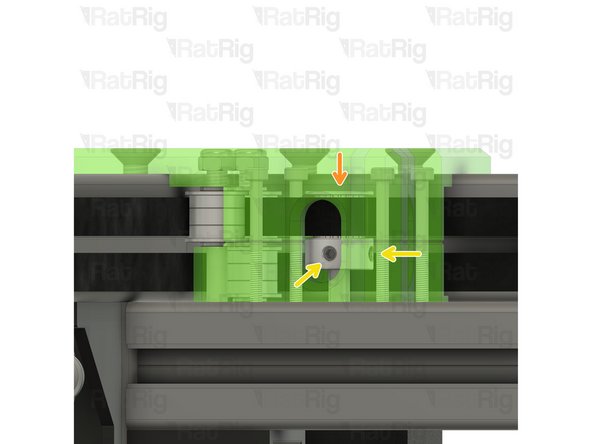

This step is not mandatory, it's just a Rat Rig tip on how to feed the belts on the idlers.

-

Zip Tie

-

The wider the zip tie is, the easier the process will be

-

Bend the tip of the zip tie a little bit and feed it between the printed part and the idler, as shown

-

Insert the belt between the zip tie and the idler

-

Slowly feed the belt and pull the zip tie at the same time

-

-

-

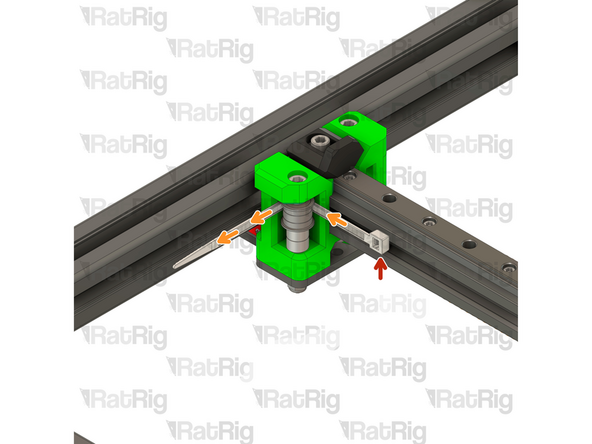

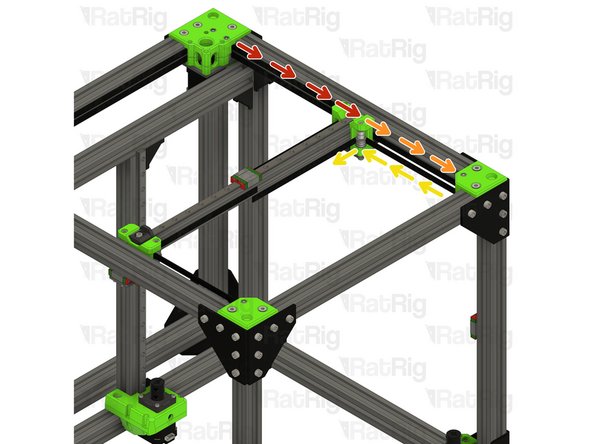

Take the loose end of the top CoreXY belt on the left hand side:

-

Feed the belt behind the left xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the left xy_joiner

-

Take the loose end of the bottom CoreXY belt on the left hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-

-

-

Take the loose end of the bottom CoreXY belt on the right hand side:

-

Feed the belt behind the right xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the right xy_joiner

-

Take the loose end of the top CoreXY belt on the right hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-