Video Overview

-

-

1x 362mm 2020 Extrusion

-

1x V-Minion X-Plate

-

2x M3 Nylon Locking Hex Nut

-

3x 2020 Square T-Nut - M5

-

2x 2020 Drop-in T-Nut - M5

-

4x M3x8 Cap Head Screw

-

5x M5x10 Cap Head Screw

-

x_gantry_end_cap printed part

-

-

-

V-Minion X-Plate

-

M3x8 Cap Head Screw

-

Slide the Z-axis up and down the rail to make sure it moves smoothly

-

If the carriage binds at all, slightly loosen the M3x8 screws and check again

-

M5x10 Cap Head Screw

-

2020 Square T-Nut - M5

-

Loosely thread the 2020 square T-Nuts onto the M5x10 screws. Do not tighten them at this point

-

-

-

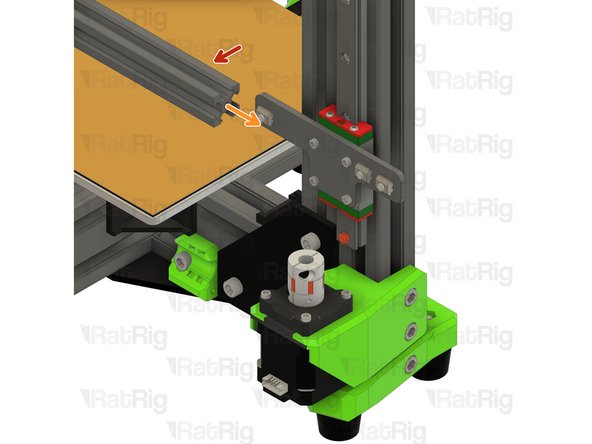

362mm 2020 Extrusion

-

Slide the 2020 extrusion onto the 2020 square T-nuts as shown

-

Make sure that the 2020 extrusion end is flush with the side of the V-Minion X-Plate

-

Fasten the three M5x10 screws to secure the 2020 extrusion to the X-Plate

-

-

-

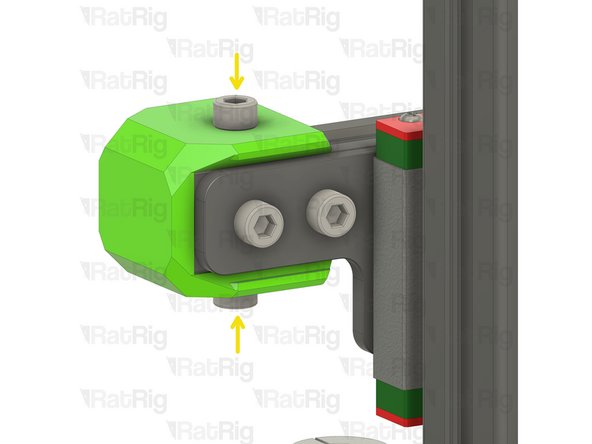

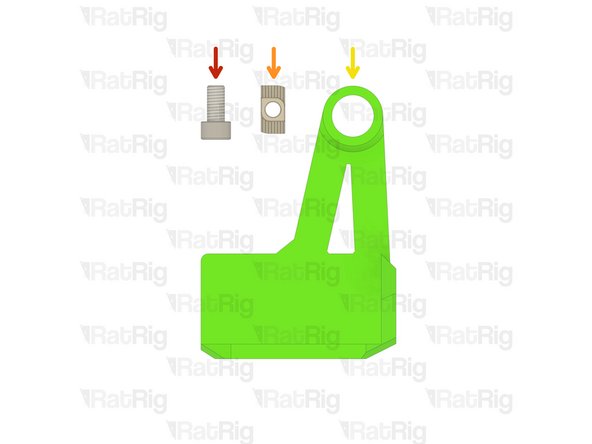

x_gantry_end_cap printed part

-

M3 Nylon Locking Hex Nut

-

Insert the M3 nylon locking nuts into the printed part as shown

-

M5x10 Cap Head Screw

-

2020 Drop-in T-Nut - M5

-

Loosely thread the 2020 T-Nuts onto the M5x10 screws. Do not tighten them at this point

-

-

-

X-axis end cap assembly

-

Slide the X-axis cap onto the end of the 2020 extrusion

-

Fasten both M5x10 screws to secure the X-axis cap to the extrusion

-

Take care not to over tighten the M5x10 screws as you can damage the printed part

-

-

-

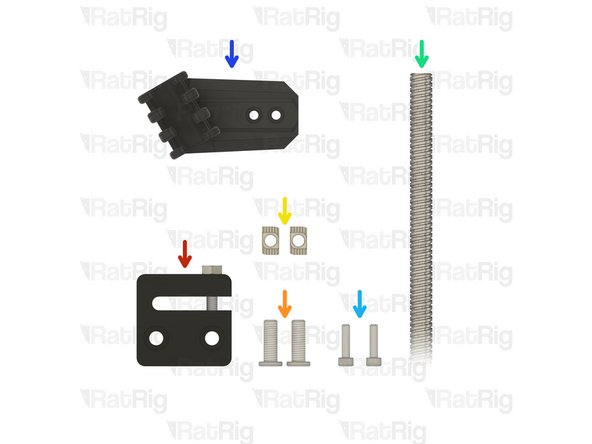

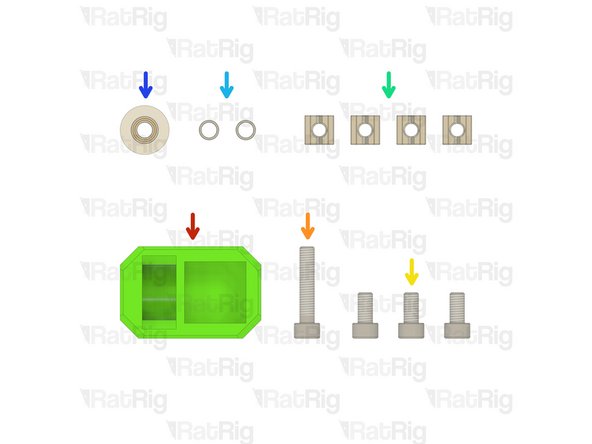

1x Anti-Backlash Nut Block

-

2x M5x15 Low Profile Cap Head Screw

-

2x 2020 Drop-in T-Nut - M5

-

1x 250mm TR8*4 Leadscrew

-

2x M3x12 Cap Head Screw

-

x_wire_holder printed part

-

-

-

Anti-Backlash Nut Block

-

The following parts are provided with the anti-backlash nut

-

M4 Grub Screw

-

M4 Nut

-

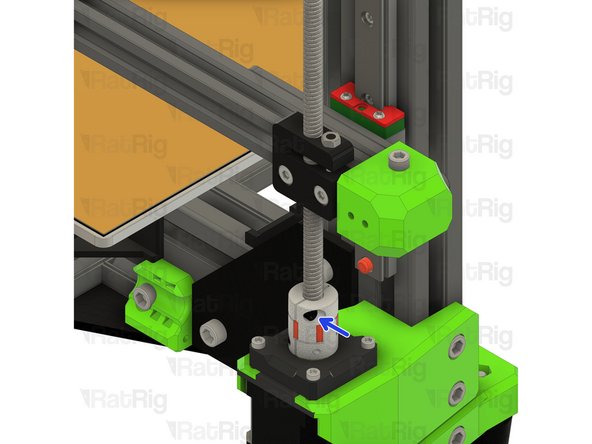

Install the M4 grub screw into the anti-backlash nut block as shown. Stop turning the grub screw when it touches the bottom part of the nut block

-

Secure the grub screw by installing the M4 nut as shown

-

-

-

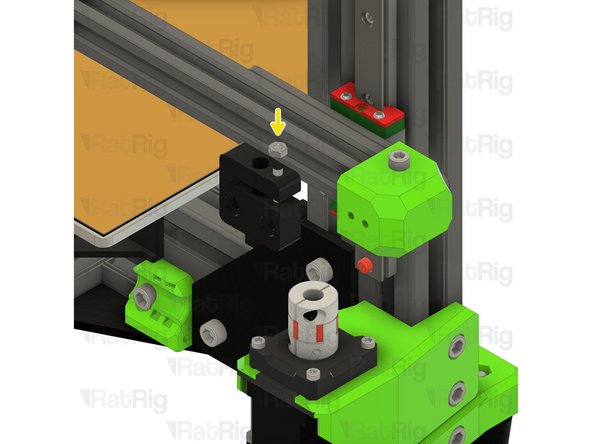

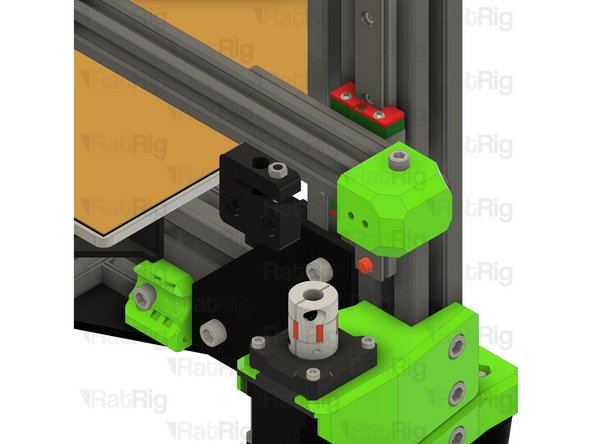

Anti-Backlash Nut Block

-

M5x15 Low Profile Cap Head Screw

-

2020 Drop-in T-Nut - M5

-

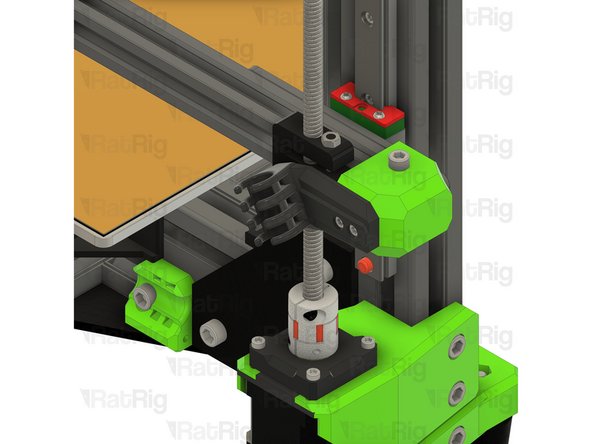

Loosely thread the 2020 T-Nuts onto the M5x15 screws. Do not tighten them at this point

-

Fit the anti-backlash nut block to the 2020 extrusion, but do not tighten the M5x15 screws fully

-

Thread the leadscrew through the anti-backlash nut block...

-

...and into the Z-axis spider coupler

-

Do not fasten the M5x15 screws, or the M3 screw on the spider coupler yet. We will do so after aligning everything in the next step

-

-

-

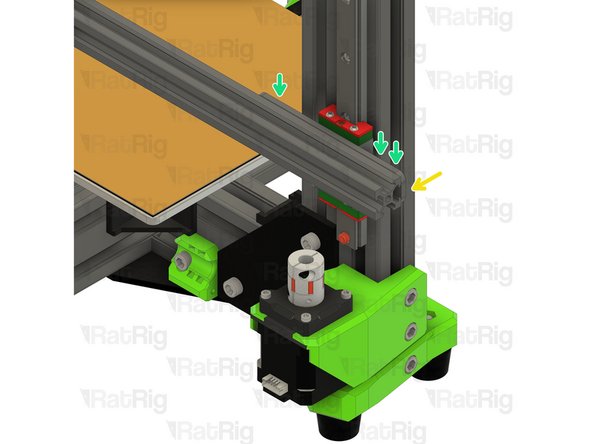

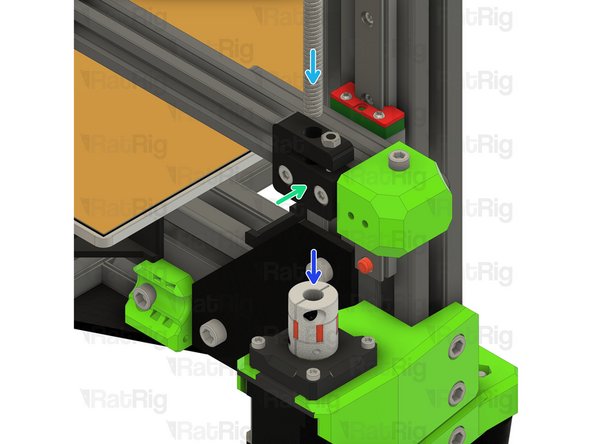

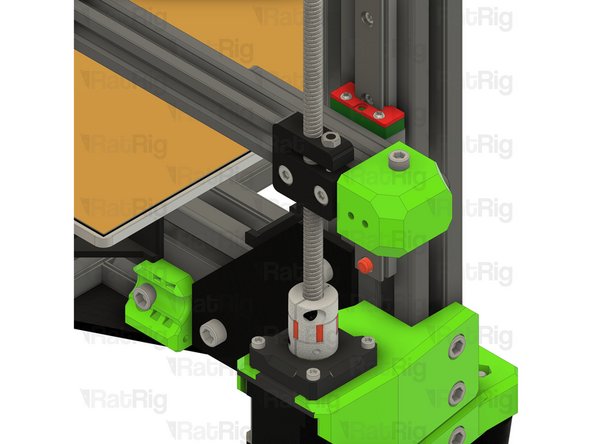

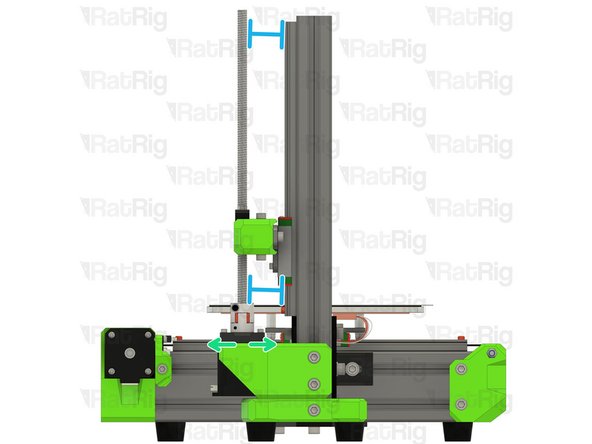

Begin by loosening the four M3x18 screws on the Z-axis stepper motor

-

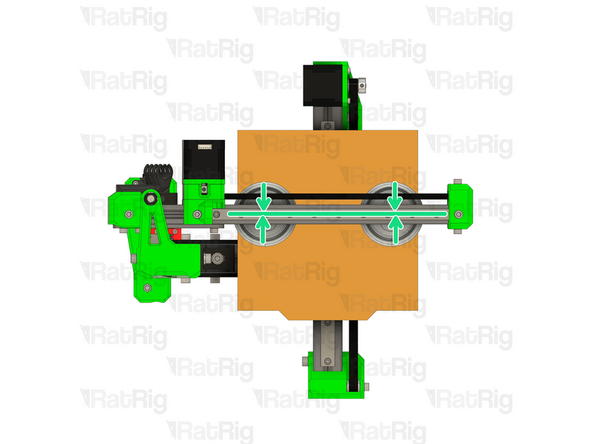

To align the leadscrew, look at the V-Minion from above, as pictured:

-

Adjust the position of the anti-backlash nut left or right until the leadscrew is in-line with the Z-axis stepper motor

-

Secure the two M5x15 screws when this is achieved

-

Adjust the position of the Z-axis motor forwards and backwards until the leadscrew is parallel with the frame

-

Secure the four M3x18 screws when this is achieved

-

Take care not to over tighten the M3x18 screws as you can damage the printed parts

-

Fasten the M3 screw on the spider coupler to secure the leadscrew

-

-

-

x_wire_holder printed part

-

M3x12 Cap Head Screw

-

Fasten the x_wire_holder to the X-axis using the M3x12 screws

-

Take care not to over tighten the M3x12 screws as you can damage the printed parts

-

-

-

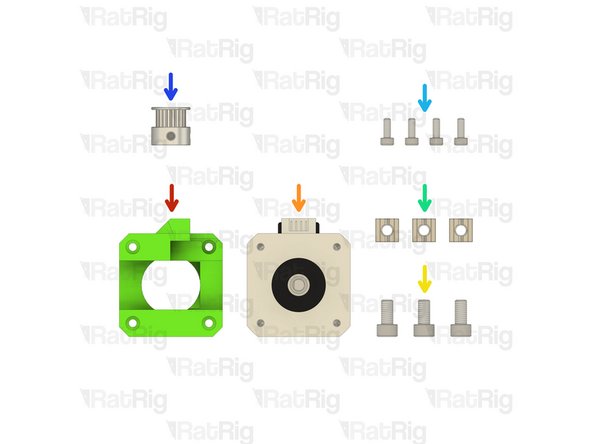

x_motor_cage printed part

-

1x 40mm NEMA17 Stepper Motor

-

3x M5x10 Cap Head Screw

-

3x 2020 Square T-Nut - M5

-

4x M3x8 Cap Head Screw

-

1x 20 Tooth 2GT Timing Pulley for 6mm Belt

-

-

-

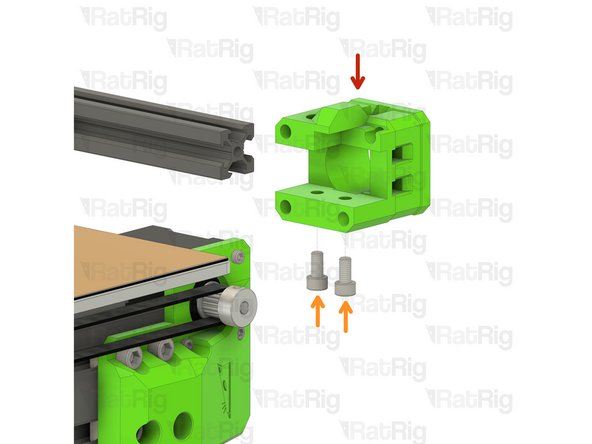

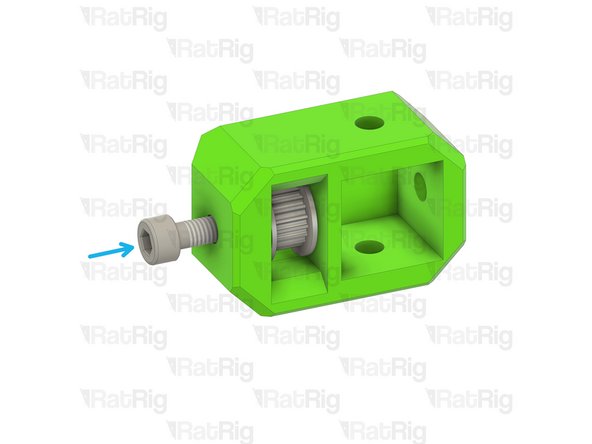

x_motor_cage printed part

-

M5x10 Cap Head Screw

-

2020 Square T-Nut - M5

-

Loosely thread the 2020 T-Nuts onto the M5x10 screws. Do not tighten them at this point

-

-

-

x_motor_cage printed part

-

M5x10 Cap Head Screw

-

2020 Square T-Nut - M5

-

Loosely thread the 2020 T-Nut onto the M5x10 screw. Do not tighten it at this point

-

-

-

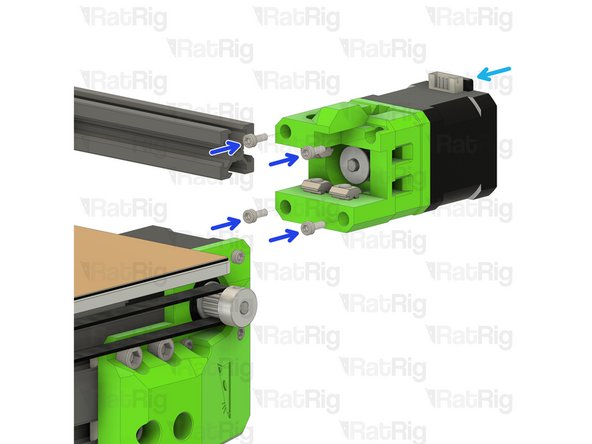

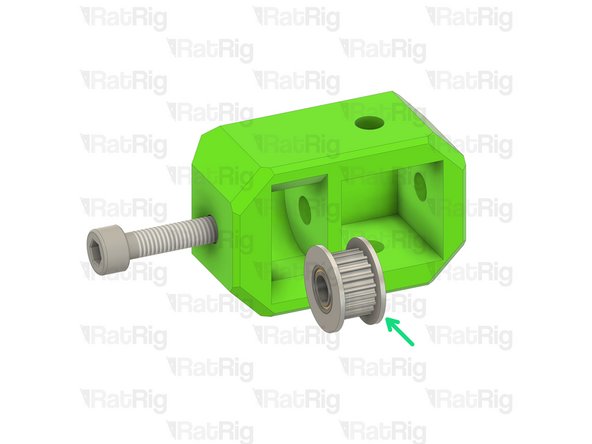

Assembly from Step 12

-

20 Tooth 2GT Timing Pulley for 6mm Belt

-

40mm NEMA17 Stepper Motor

-

Position the timing pulley as shown. Do not fully tighten the grub screws yet as the alignment will need to be adjusted later

-

Insert the stepper motor into the mount as shown

-

M3x8 Cap Head Screw

-

Fasten the stepper motor to the mount using the M3x8 screws

-

Take care not to over tighten the M3x8 screws as you can damage the printed parts

-

-

-

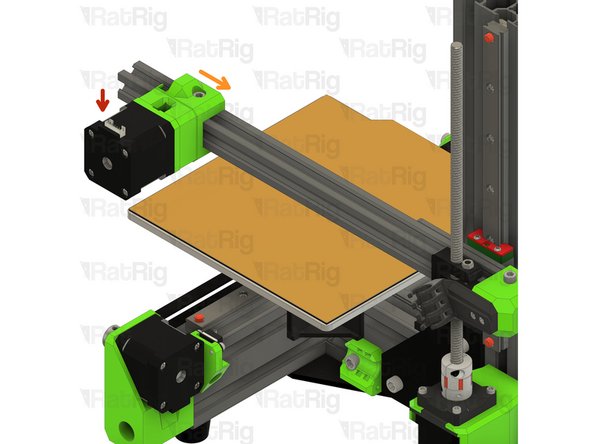

X-axis motor assembly from Step 13

-

Install the X-axis motor assembly onto the 2020 extrusion as shown

-

Push the assembly all the way along the X-axis for the moment

-

Do not fasten the M5x10 screws yet, this will be done later

-

-

-

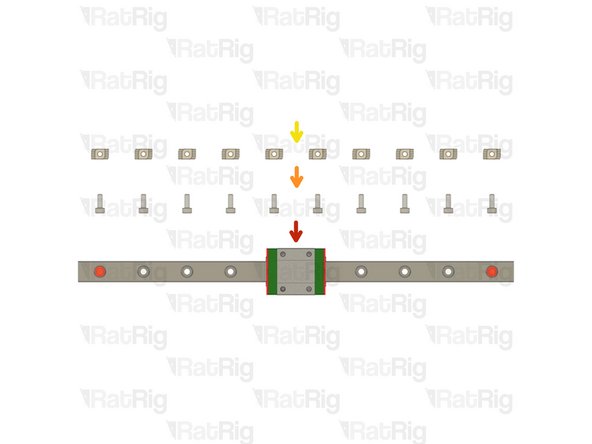

1x 250mm MGN12 Linear Rail

-

10x M3x8 Cap Head Screw

-

10x 2020 Drop-in T-Nut - M3

-

Please refer to the Rat Rig Linear Rail Guide (Steps 1 & 2) for full details on preparing the rails before installation.

-

The linear rail carriages are not interchangeable. Do not try to use a carriage on a different linear rail than the one it was supplied with.

-

-

-

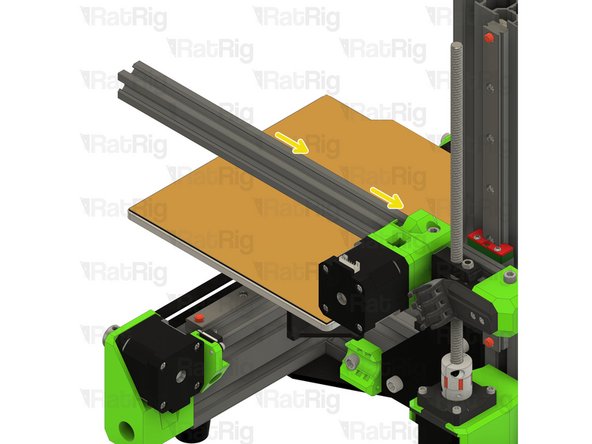

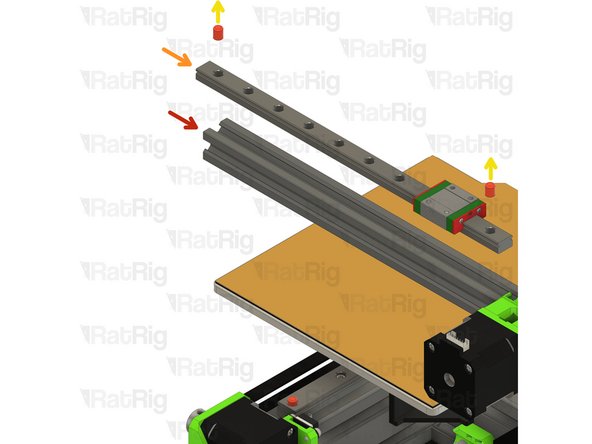

Frame assembly from Step 14

-

MGN12 Linear Rail

-

Remove the plastic stops installed in the ends of the linear rail

-

Do not allow the linear rail carriage to leave the end of the rail.

-

Insert an M3x8 screw in each of the holes on the linear rail

-

Loosely thread a 2020 T-Nut onto each of the M3x8 screws

-

Slot the assembled linear rail into the X-axis 2020 extrusion, do not fasten any of the M3x8 screws yet

-

-

-

x_idler printed part

-

1x M5x25 Cap Head Screw

-

3x M5x10 Cap Head Screw

-

4x 2020 Square T-Nut - M5

-

2x Micro Precision Shim

-

1x 20 Tooth 2GT Idler Pulley for 6mm Belt

-

-

-

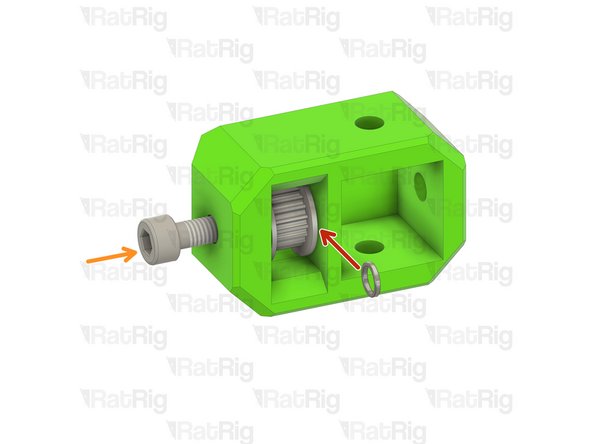

x_idler printed part

-

M5x25 Cap Head Screw

-

Install one precision micro shim onto the M5x25 screw

-

Install the toothed 2GT idler onto the M5x25 screw

-

Insert the M5x25 cap head screw further in preparation for the next step

-

-

-

Similar to the Y-axis idler assembly, install the second precision micro shim onto the M5x25 screw

-

The assembly should have a micro precision shim on either side of the toothed idler

-

Fully insert the M5x25 as shown

-

M5x10 Cap Head Screw

-

2020 Square T-Nut - M5

-

Loosely thread the 2020 T-Nuts onto the M5 screws. Do not tighten them at this point

-

-

-

2020 Square T-Nut - M5

-

Insert one 2020 T-nut into the top of the 2020 X-axis extrusion as shown...

-

... and one into the underside of the extrusion

-

Install the X-axis idler onto the end of the 2020 X-axis extrusion

-

M5x10 Cap Head Screw

-

Insert one M5x10 screw in both the top and bottom of the X-axis idler, loosely fastening them into the 2020 T-nuts in the extrusion

-

-

-

Make sure the 2020 extrusion is fully inserted into the X-axis idler

-

Fasten all three M5x10 screws

-

Take care not to over tighten the M5x10 screws as you can damage the printed part

-

Fasten the M5x25 screw

-

Check that the toothed idler rotates without binding. If the idler is difficult to rotate, loosen the M5x25 screw until the idler rotates smoothly

-

Take care not to over tighten the M5x25 screw as you can damage the printed part

-

-

-

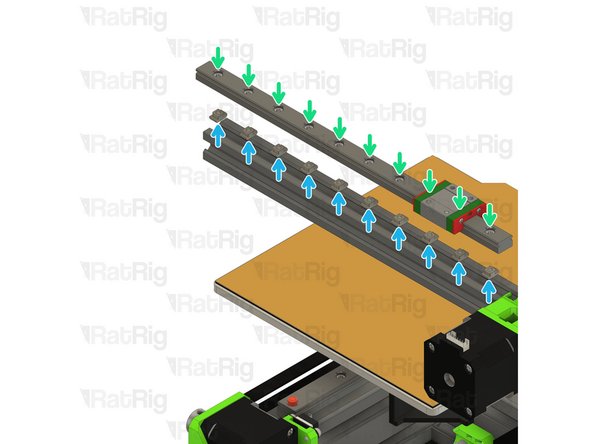

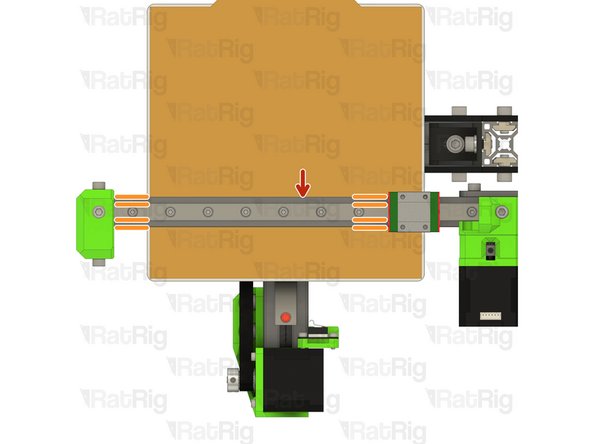

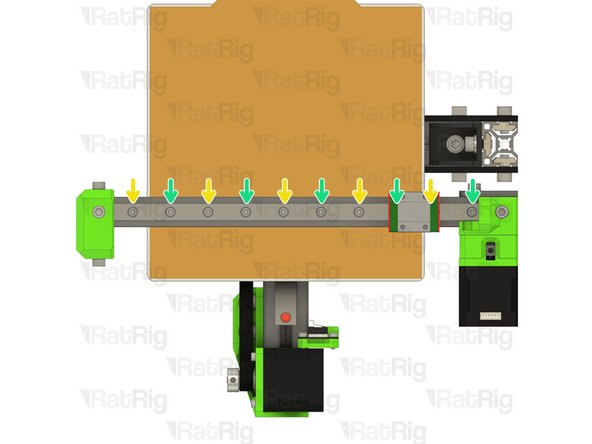

MGN12 Linear Rail

-

Make sure the linear rail is centred on the 2020 extrusion

-

The measurement between the linear rail and the side of the 2020 extrusion should be 4mm at all points

-

Fasten the M3x8 screws, starting from the left side

-

Double check the position of the linear rail

-

Fasten the remaining M3x8 screws, starting from the left side

-

Check that the carriage runs smoothly along the length of the rail

-

-

-

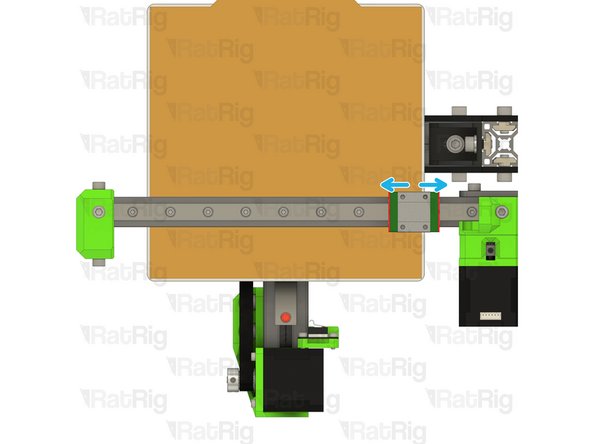

Push the X-axis motor as shown, it should be flush with the end of the linear rail

-

Fasten the marked M5x10 screw

-

Fasten the two marked M5x10 screws to fully secure the X-axis motor into place

-

Take care not to over tighten the M5x10 screws as you can damage the printed part

-

-

-

1x M6x12 Cap Head Screw

-

1x 3030 Drop-in T-Nut - M6

-

z_cap printed part

-

-

-

z_cap printed part

-

M6x12 Cap Head Screw

-

3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nut onto the M6x12 screw. Do not tighten it at this point

-

Install the z_cap as shown

-

Fasten the M6x12 screw to secure the cap to the V-Minion frame

-

Take care not to over tighten the M6x12 screw as you can damage the printed part

-

-

-

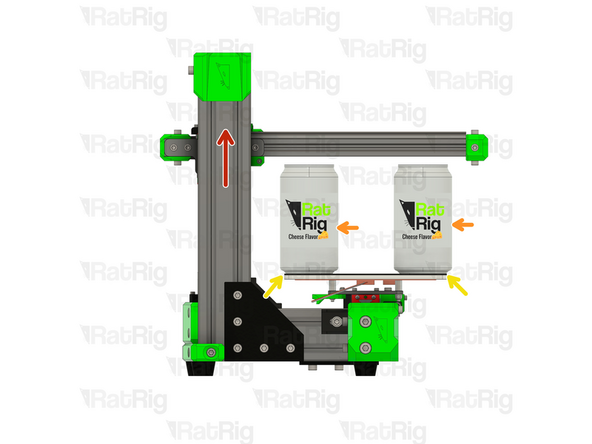

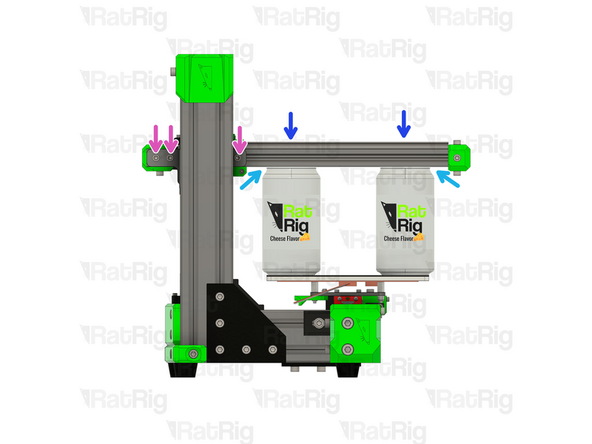

Rotate the lead screw to lift the X-axis

-

Place two soda cans on top of the bed

-

Use two soda cans of the same brand if possible. Soda cans have very good dimension tolerances due to shipping and brand refill, this makes them a easy to source precise tool.

-

Make sure the Cans are fully seated on the bed

-

Place the Cans on the middle of the X-axis

-

Lossen the screws on the X-gantry plate

-

Cans are not included in the Rat Rig Kit!

-

-

-

Rotate the lead screw to lower the X-axis

-

If the X-axis is lowered too far, the gap on the right soda can will increase

-

Rotate the lead screw to lift the X-axis

-

If the X-axis is lifted too much, the gap on the left soda can will increase

-

Adjust the height of the X-axis until the gap on both soda cans is the same

-

Push the X-axis down with 2 fingers to really make sure the extrusion sits flush with the cans.

-

Re-tighten the screws on the X-gantry plate, making sure the gap on both soda cans remains the same

-

Cancel: I did not complete this guide.

21 other people completed this guide.