Video Overview

-

-

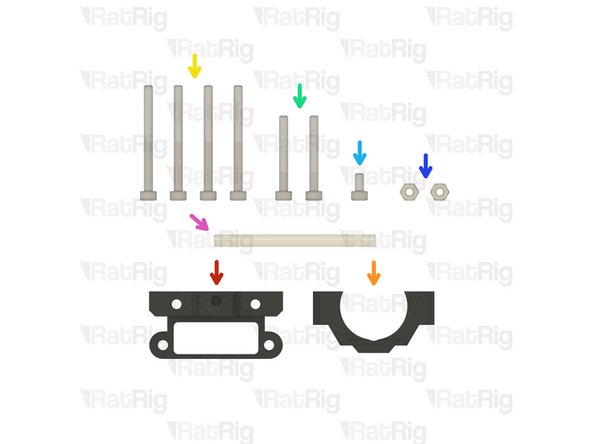

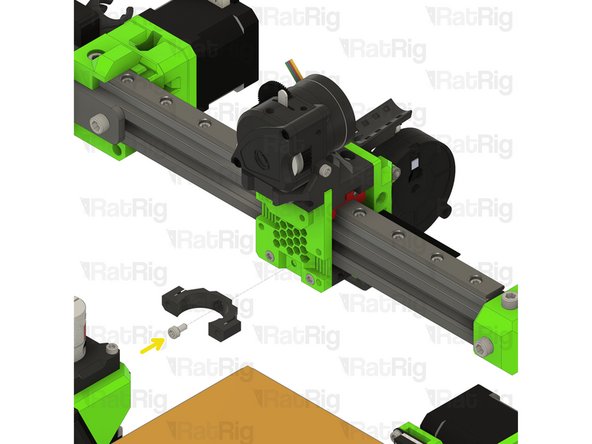

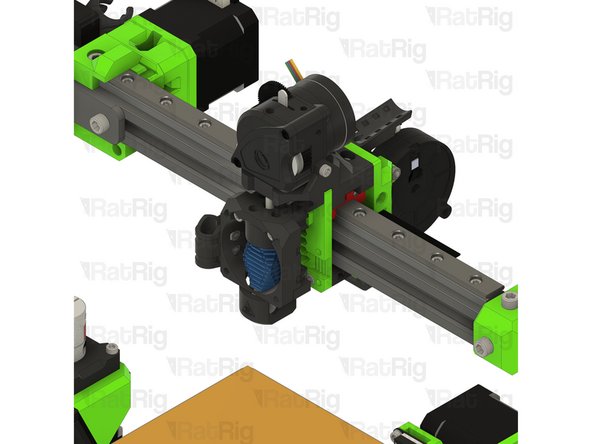

universal_face & back_cartesian printed parts

-

cartesian_cable_fin printed part

-

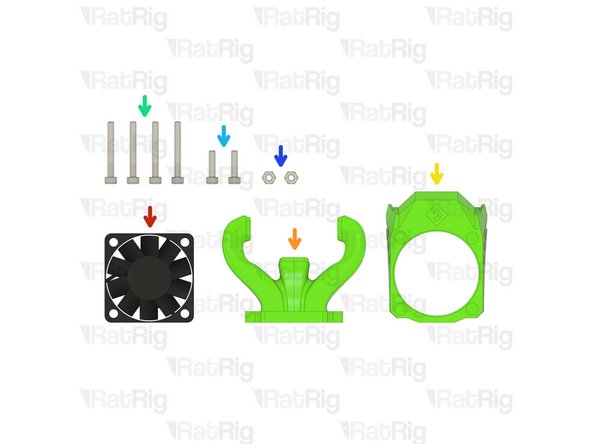

13x M3 Hex Nut

-

2x M3x30 Cap Head Screw

-

1x M3x25 Cap Head Screw

-

1x M3x12 Cap Head Screw

-

600mm 2GT 6mm Wide Timing Belt

-

1x 24v 5015 Blower Fan

-

-

-

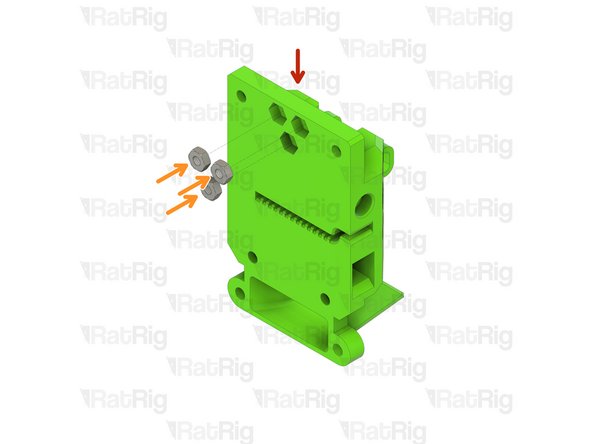

universal_face printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the five positions shown

-

Set this assembly aside until Step 21

-

-

-

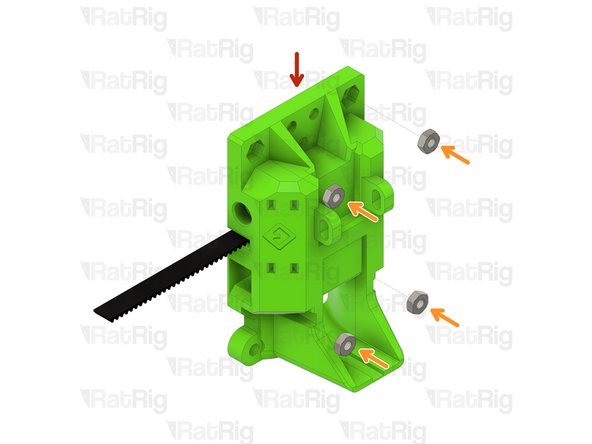

back_cartesian printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the three positions shown

-

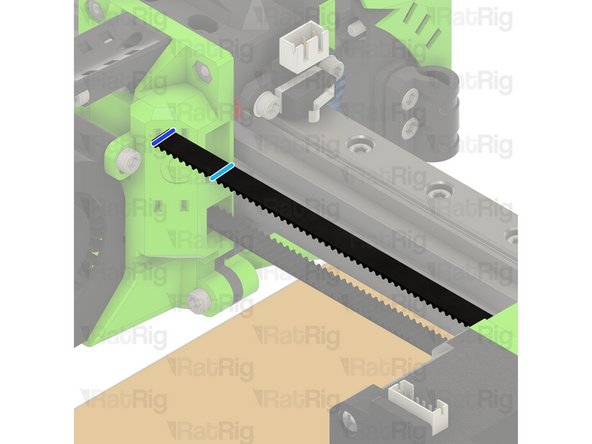

600mm 2GT 6mm Wide Timing Belt

-

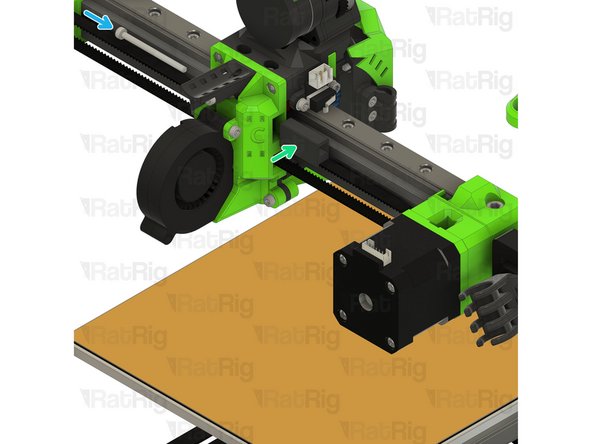

Install one end of the timing belt into the printed part as shown

-

-

-

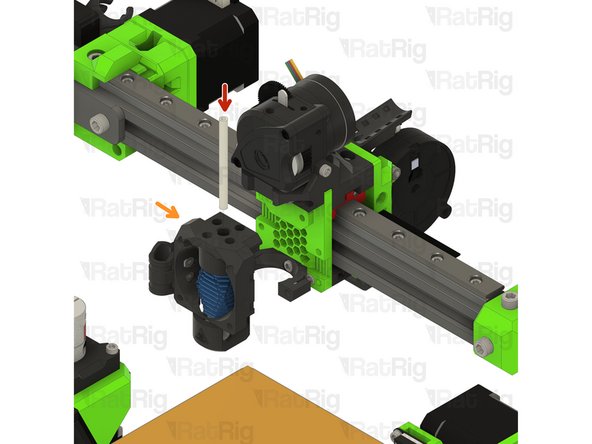

Assembly from Step 3

-

M3 Hex Nut

-

Install an M3 hex nut into each of the four positions shown

-

-

-

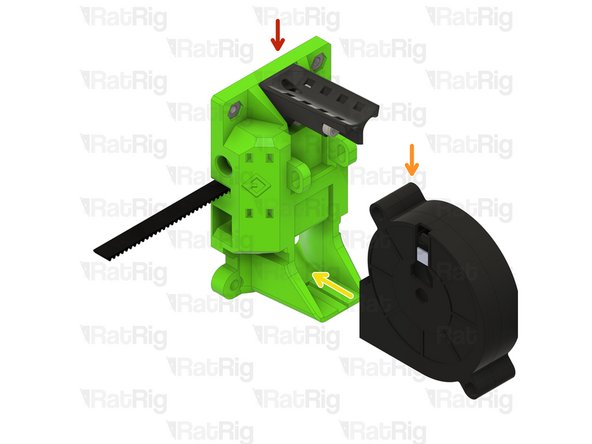

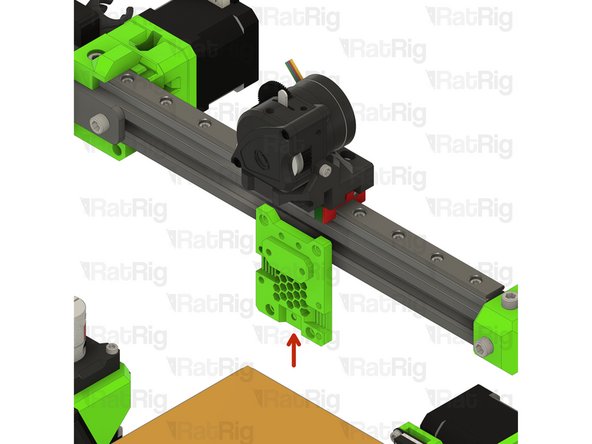

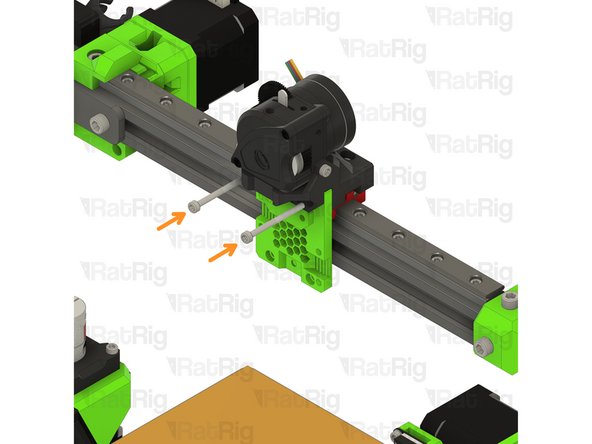

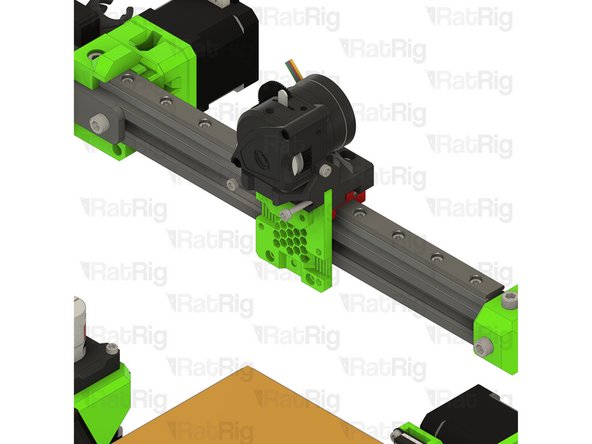

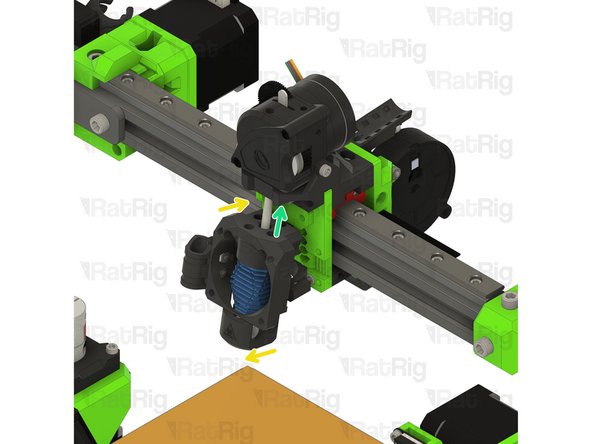

Assembly from Step 4

-

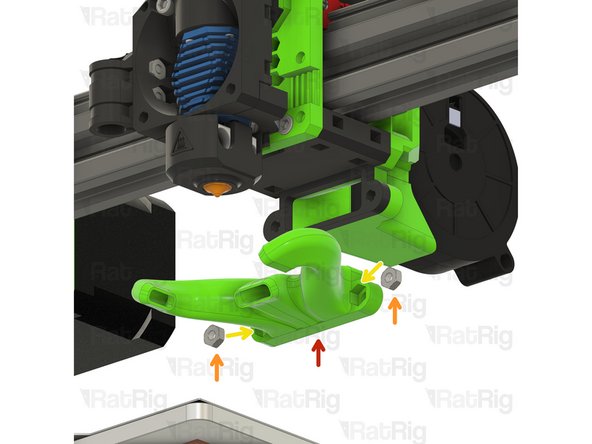

cartesian_cable_fin printed part

-

M3x30 Cap Head Screw

-

M3x12 Cap Head Screw

-

Take care not to over tighten the M3 screws as you can damage the printed parts

-

-

-

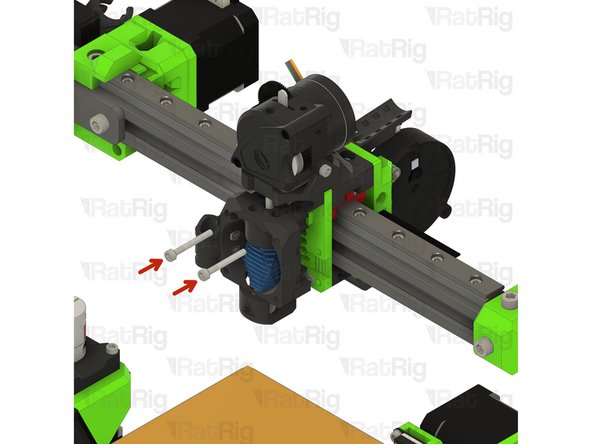

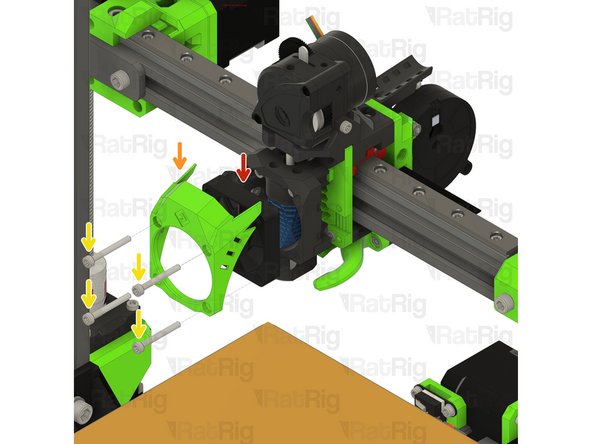

Assembly from Step 5

-

24v 5015 Blower Fan

-

Install the 5015 fan into the cartesian_back printed part as shown

-

M3x25 Cap Head Screw

-

M3 Hex Nut

-

Secure the fan in place by fitting the M3x25 screw and M3 hex nut as shown

-

Take care not to over tighten the M3x25 screw as you can damage the printed part

-

Set this assembly aside until Step 22

-

-

-

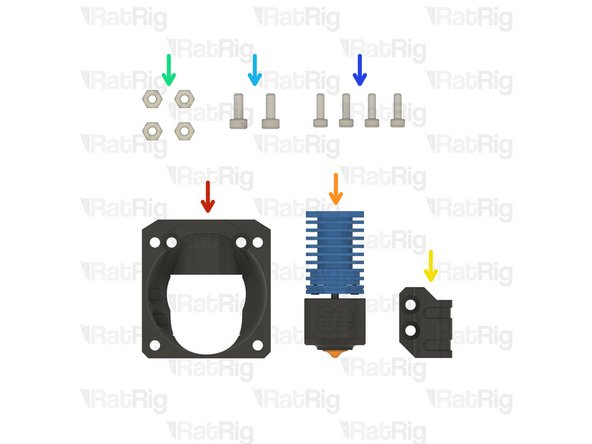

bmo_face printed part

-

1x Assembled Pheatus Dragonfly BMO hot end

-

Refer to the documentation supplied with the hot end for instructions on assembly

-

LJ8_probe_mount_8mm printed part

-

4x M3 Hex Nut

-

2x M3x8 Cap Head Screw

-

4x M2.5x8 Cap Head Screw

-

These screws are provided with the Pheatus Dragonfly BMO hot end

-

-

-

bmo_face printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

-

-

Assembly from Step 8

-

M2.5x8 Cap Head Screw

-

Assembled Pheatus Dragonfly BMO hot end

-

Secure the Pheatus Dragonfly BMO hot end to the printed part using the M2.5x8 screws

-

Take care not to over tighten the M2.5x8 screws as you can damage the printed parts or the threads in the hot end heatsink

-

-

-

Assembly from Step 9

-

LJ8_probe_mount_8mm printed part

-

M3x8 Cap Head Screw

-

Loosely thread the M3x8 screws into the M3 nuts. Do not tighten them at this point

-

Set this assembly aside until Step 26

-

-

-

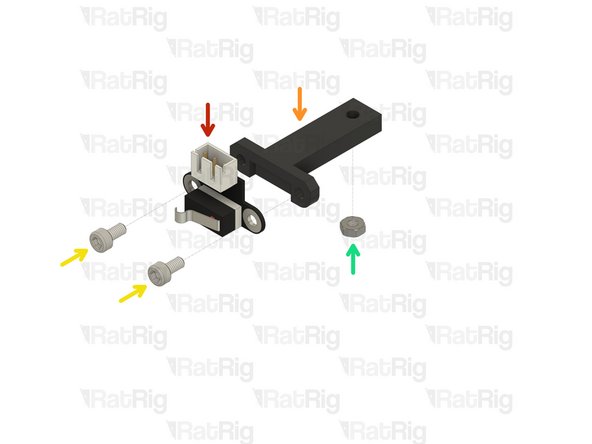

1x Limit Switch

-

1x M3 Hex Nut

-

3x M3 Square Nut (Included with the Bondtech LGX Lite)

-

3x M3x8 Cap Head Screw

-

6x M3x10 Cap Head Screw

-

top_endstop_angled printed part

-

1x Bondtech LGX Lite Extruder

-

top_mgn12_lgx_lite printed part

-

-

-

Limit Switch

-

top_endstop_angled printed part

-

M3x8 Cap Head Screw

-

Secure the limit switch to the printed part using the M3x8 screws

-

Take care not to over tighten the M3x8 screws as you can damage the printed part

-

M3 Hex Nut

-

Insert the M3 hex nut into the underside of the printed part

-

Set this assembly aside until Step 18

-

-

-

Bondtech LGX Lite extruder

-

Remove the two M3x25 screws holding the Bondtech LGX Lite together

-

Carefully remove the face plate from the LGX Lite assembly

-

-

-

M3 Square Nut

-

Insert one M3 square nut into each of the marked holes on the LGX Lite

-

Re-install the LGX Lite face plate

-

-

-

Bondtech LGX Lite extruder

-

Carefully separate the LGX Lite motor and back plate from the assembly as shown

-

-

-

M3 Square Nut

-

Insert one M3 square nut into the marked hole on the LGX Lite

-

Re-install the LGX Lite back plate and motor

-

-

-

Re-install the two M3x25 screws, these secure the Bondtech LGX Lite together

-

Set the LGX Lite aside until Step 19

-

-

-

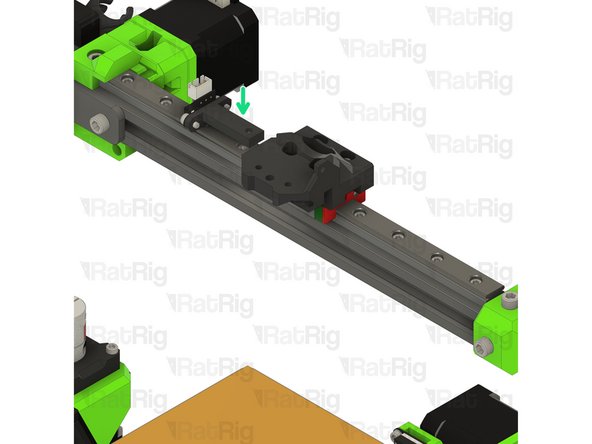

top_mgn12_lgx_lite printed part

-

M3x10 Cap Head Screw

-

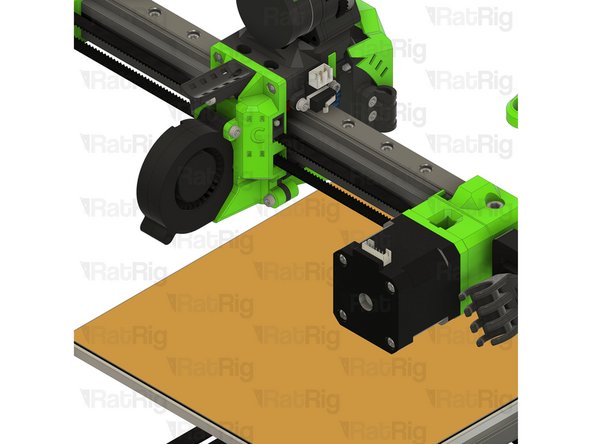

Fasten all four M3x10 screws to secure the EVA top to the MGN12 carriage

-

Slide the X-axis left and right along the rail to make sure it moves smoothly

-

If the carriage binds at all, slightly loosen the M3x10 screws and check again

-

X-axis end stop assembly from Step 12

-

M3x8 Cap Head Screw

-

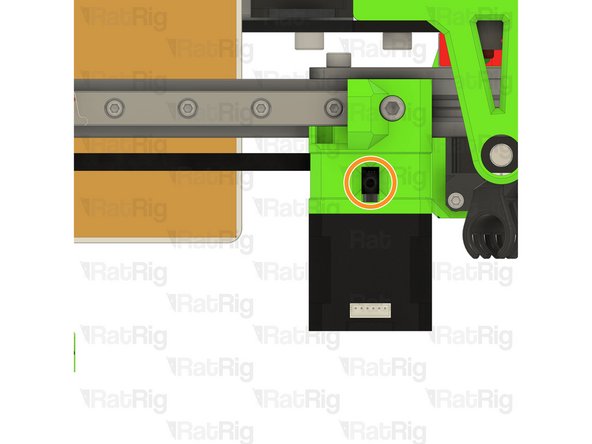

Insert the end stop assembly as shown and secure in place with the M3x8 screw

-

-

-

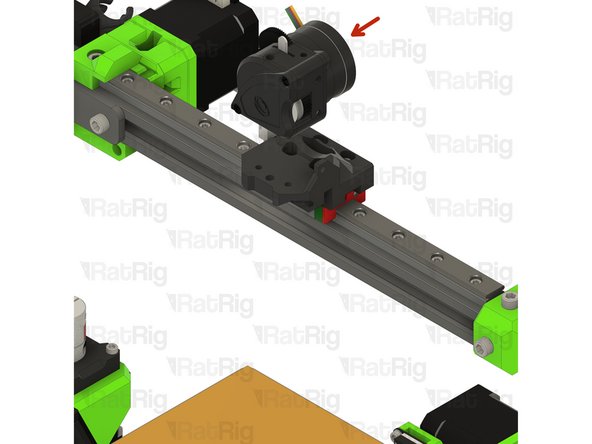

Bondtech LGX Lite extruder

-

M3x10 Cap Head Screw

-

M3x8 Cap Head Screw

-

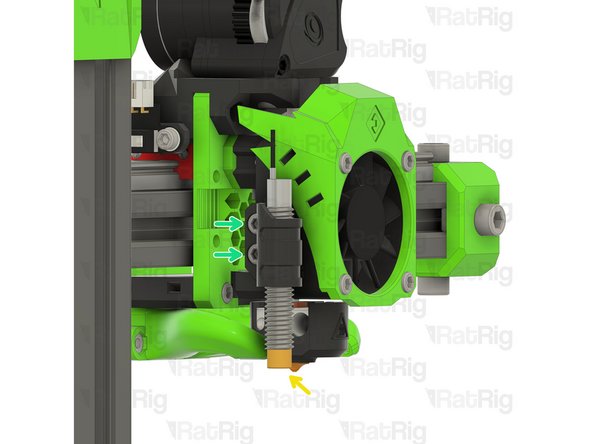

Insert the three M3 screws as shown, fasten them to secure the LGX Lite extruder to the EVA top

-

Take care not to over tighten the M3 screws as you can damage the printed part

-

-

-

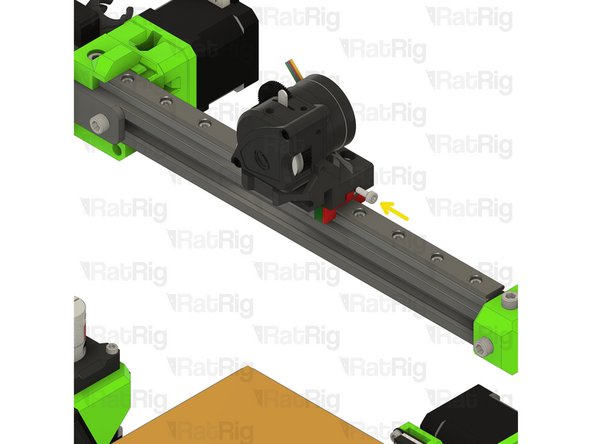

bottom_mgn12_short_duct printed part

-

bmo_support printed part

-

4x M3x35 Cap Head Screw

-

2x M3x25 Cap Head Screw

-

1x M3x6 Cap Head Screw

-

2x M3 Hex Nut

-

1x 53mm PTFE Tube

-

-

-

EVA face assembly from Step 2

-

Insert the EVA face into the EVA top as shown

-

M3x35 Cap Head Screw

-

Insert the M3x35 screws partially to hold the EVA face in place. They will be fully secured in the next step

-

-

-

EVA back assembly from Step 6

-

Align the EVA back with the top

-

Fully insert and fasten the M3x35 screws, securing the EVA back in place

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

-

-

bottom_mgn12_short_duct printed part

-

M3x35 Cap Head Screw

-

Position the EVA bottom_mgn12_short_duct printed part as shown

-

Secure it in place by inserting and fastening the M3x35 screws into the EVA back

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

-

-

M3x10 Cap Head Screw

-

Insert and fasten the two M3x10 screws as shown to securely assemble the LGX Lite and EVA parts

-

Take care not to over tighten the M3x10 screws as you can damage the printed parts

-

-

-

bmo_support printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

M3x6 Cap Head Screw

-

Secure the bmo_support part to the EVA face using the M3x6 screw

-

Take care not to over tighten the M3x6 screw as you can damage the printed parts

-

-

-

PTFE Tube - 53mm

-

Hot end assembly from Step 10

-

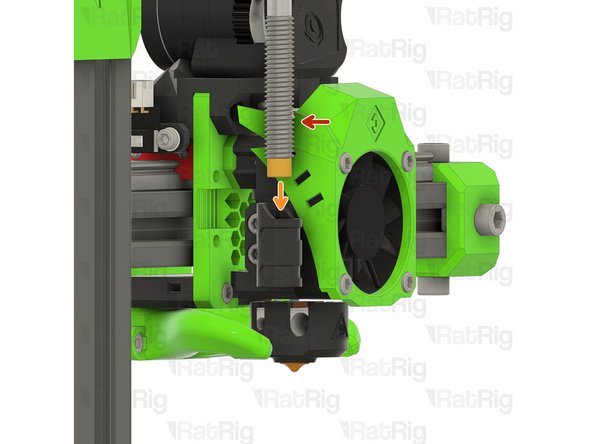

Insert the length of PTFE tube into the hot end assembly as shown

-

Rotate the hot end assembly as shown

-

Line up the end of the PTFE tube with the hole in the underside of the LGX Lite extruder mount and push the hot end assembly upwards

-

Rotate the bottom of the hot end assembly towards the EVA assembly

-

When properly lined up, the hot end assembly should rest atop the BMO-support printed part as shown

-

-

-

M3x25 Cap Head Screw

-

Insert the M3x25 screws through the hot end assembly fasten them to secure it to the EVA assembly

-

Take care not to over tighten the M3x25 screws as you can damage the printed parts

-

-

-

1x 40x10 24V Fan

-

trihorn_duct printed part

-

shroud printed part

-

The design of the EVA shroud may vary

-

4x M3x25 Cap Head Screw

-

2x M3x12 Cap Head Screw

-

2x M3 Hex Nut

-

-

-

trihorn_duct printed part

-

M3 Hex Nut

-

Insert an M3 hex nut into each of the shown positions on the trihorn_duct

-

Position the trihorn_duct as shown

-

M3x12 Cap Head Screw

-

Insert the M3x12 screws as shown and fasten them to secure the trihorn_duct to the EVA assembly

-

Take care not to over tighten the M3x12 screws as you can damage the printed parts

-

-

-

40x10 24V Fan

-

shroud printed part

-

M3x25 Cap Head Screw

-

Insert an M3x25 through each hole in the shroud as shown. Install the 40x10 fan onto the screws and then secure the shroud and fan to the EVA assembly.

-

Take care not to over tighten the M3x25 screws as you can damage the printed parts

-

-

-

1x M3x40 Cap Head Screw

-

tension_slider_6mm_belt_M3s printed part

-

M3 Square Nut

-

-

-

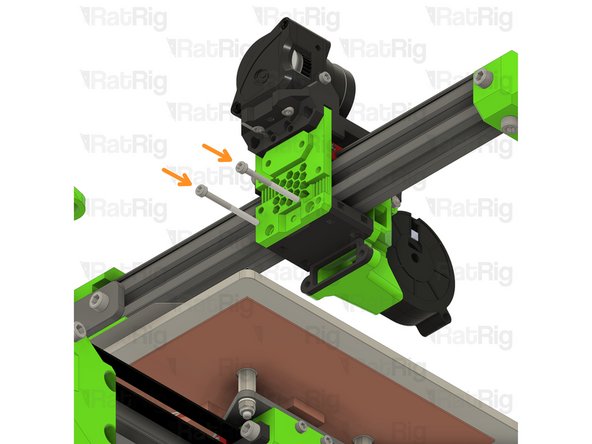

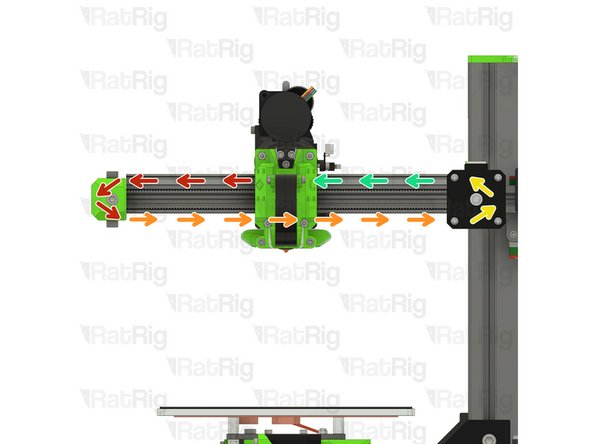

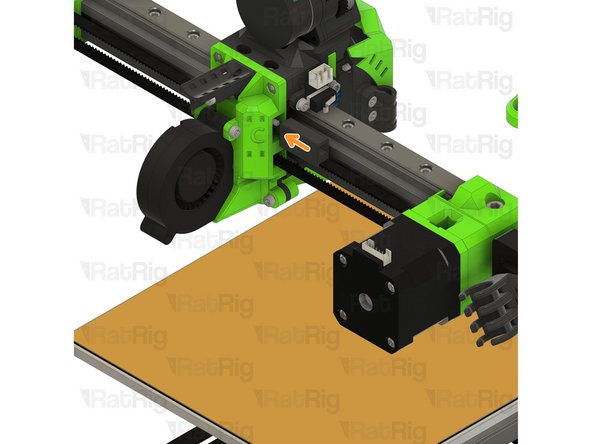

Take the free end of the X-axis timing belt and feed it around the idler pulley

-

Continue along the underside of the X-axis, passing through the hole in the EVA assembly

-

Feed it around the X-axis stepper motor pulley...

-

...and continue back to the EVA assembly

-

Pull the belt and mark where it meets the EVA assembly. This can be with a marker, or simply by holding it

-

Measure 16mm, or count 8 teeth on the belt, from the position marked previously. Double check your measurements and then cut the belt at this point

-

The belt can be cut with regular scissors.

-

It is better to cut the belt too long than too short! If you are unsure, cut it longer than expected, you can always remove more if needed

-

-

-

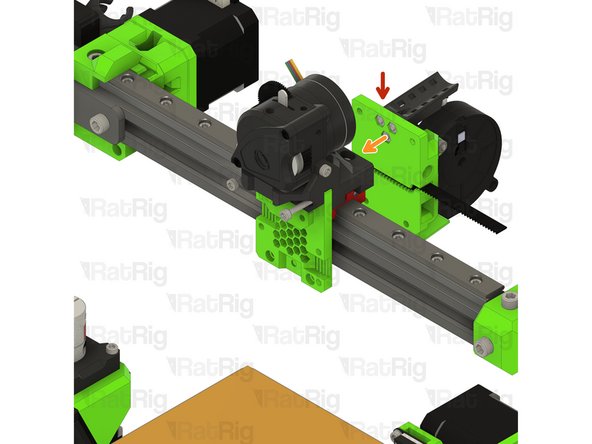

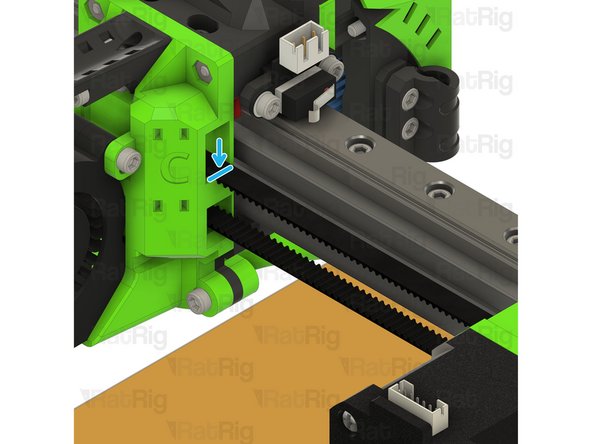

tension_slider_6mm_belt_M3s printed part

-

M3 Square Nut

-

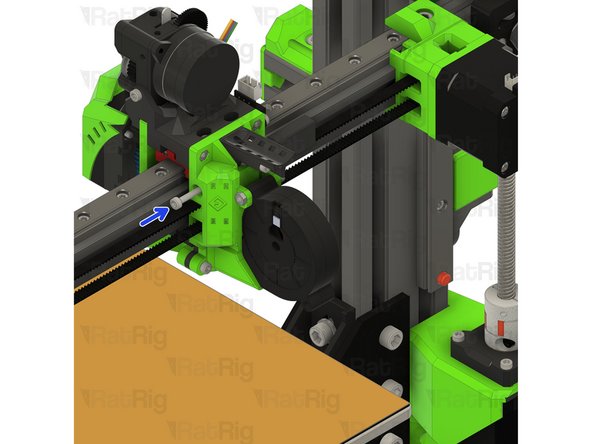

Insert the M3 square nut into the end of the tension_slider printed part as shown

-

Cut end of 2GT 6mm timing belt

-

Insert the end of the belt into the printed part as shown

-

M3x40 Cap Head Screw

-

Insert the M3x40 screw into the EVA assembly as shown. This will be used to tension the belt in the next step

-

-

-

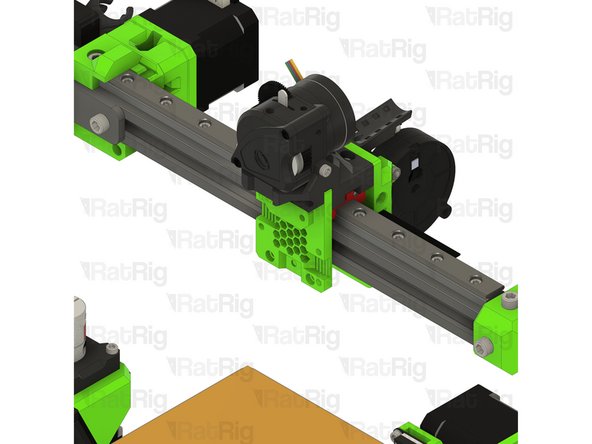

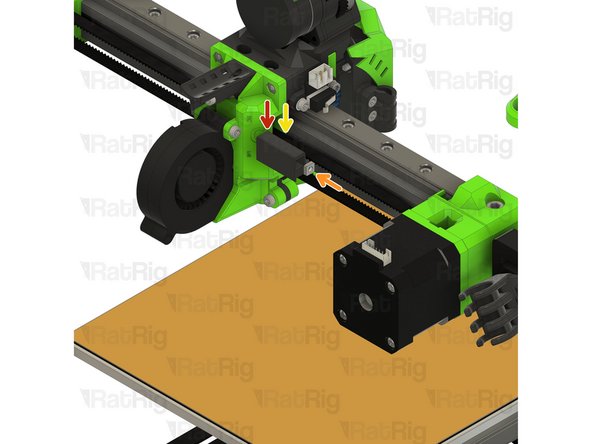

M3x40 Cap Head Screw

-

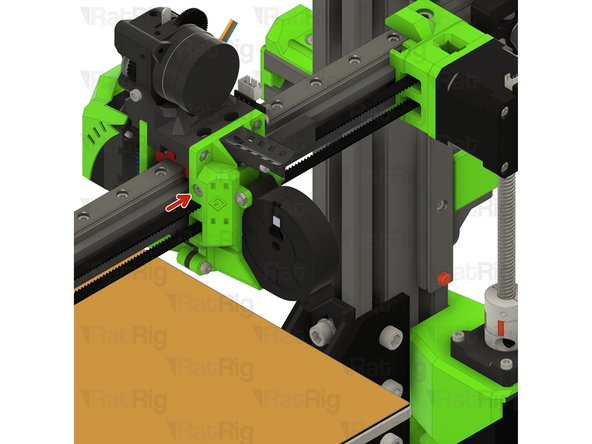

Fully insert the M3x40 screw as shown

-

Insert the tension_slider assembly into the EVA assembly as shown and secure by tightening the M3x40 screw

-

You can now adjust the tension of the X-axis belt:

-

Tighten the M3x40 screw to increase belt tension

-

Loosen the M3x40 screw to decrease belt tension

-

-

-

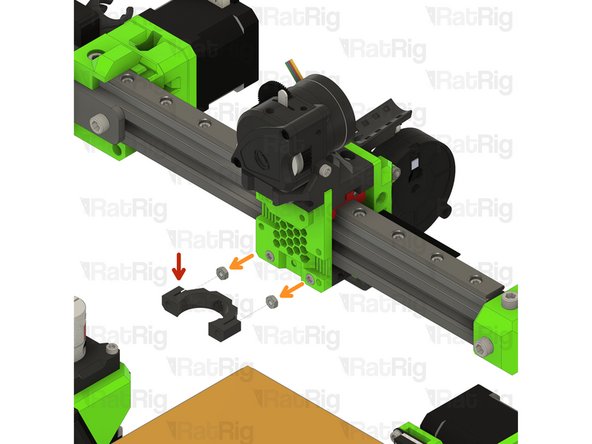

Slowly move the completed EVA assembly along the X-axis a few times. This will allow the pulley on the stepper motor to align itself

-

Secure the pulley to the stepper motor shaft by tightening both grub screws as shown

-

-

-

8mm Inductive Probe

-

Insert the probe as shown

-

Position the probe so that its tip is 1-2mm above the height of the nozzle

-

Secure the probe in place by tightening the two M3x8 screws

-

Cancel: I did not complete this guide.

17 other people completed this guide.