Video Overview

-

-

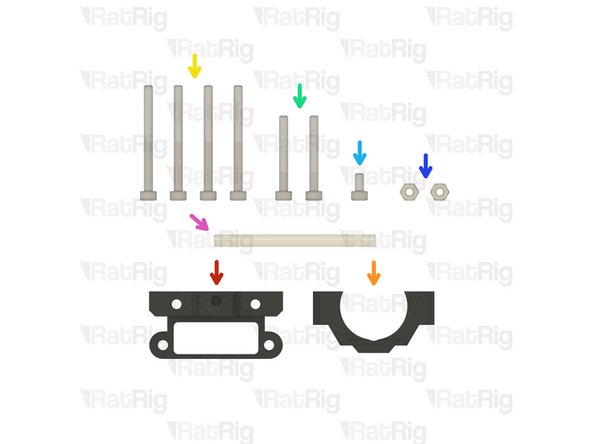

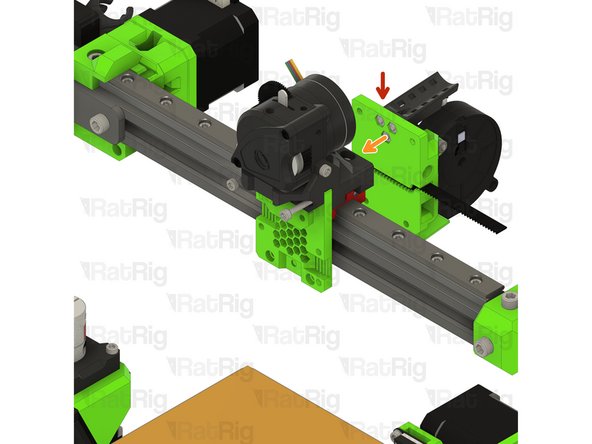

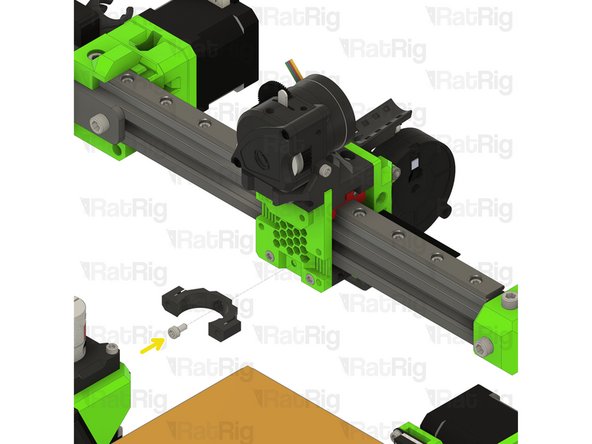

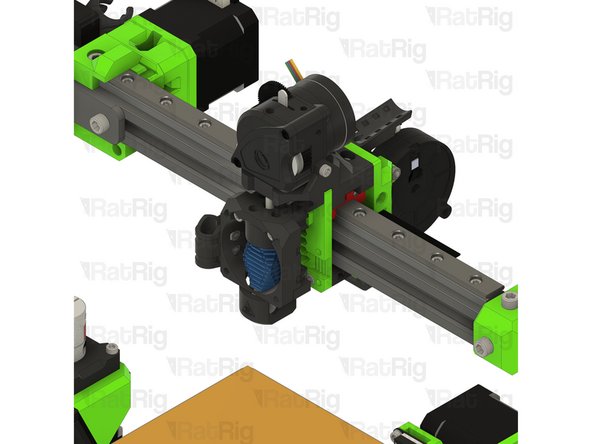

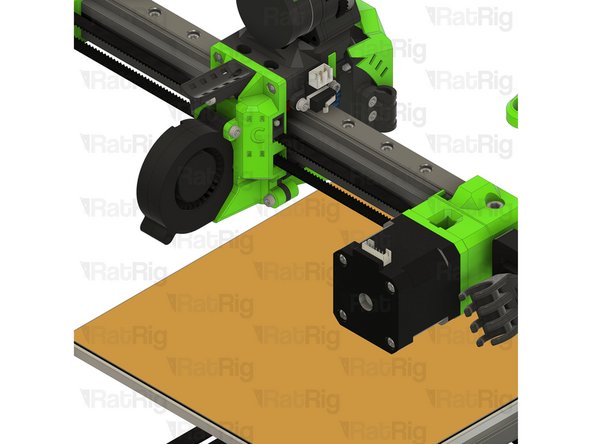

universal_face & back_cartesian printed parts

-

cartesian_cable_fin printed part

-

13x M3 Hex Nut

-

2x M3x30 Cap Head Screw

-

1x M3x25 Cap Head Screw

-

1x M3x12 Cap Head Screw

-

600mm 2GT 6mm Wide Timing Belt

-

1x 24v 5015 Blower Fan

-

-

-

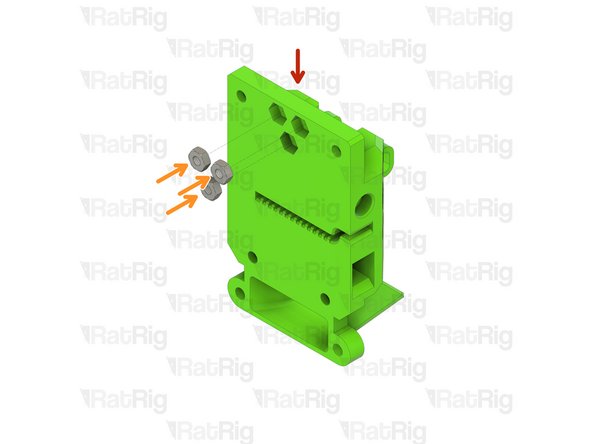

universal_face printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the five positions shown

-

Set this assembly aside until Step 21

-

-

-

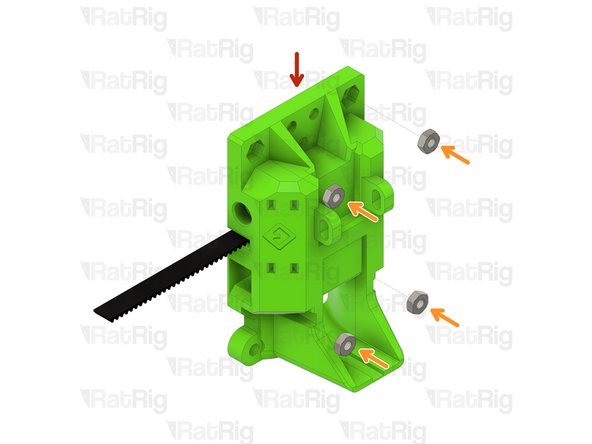

back_cartesian printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the three positions shown

-

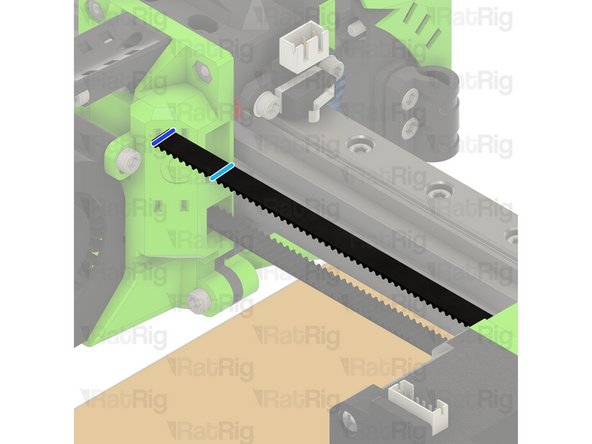

600mm 2GT 6mm Wide Timing Belt

-

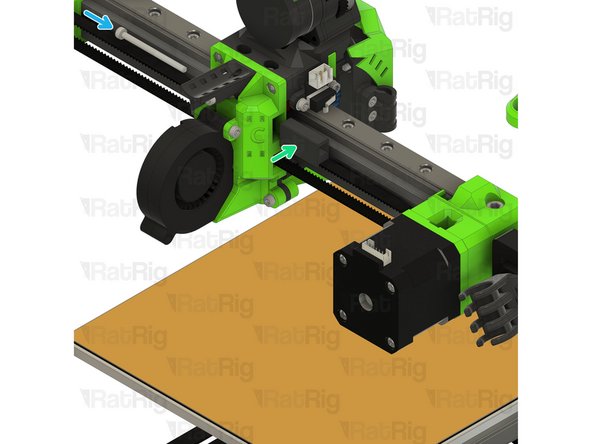

Install one end of the timing belt into the printed part as shown

-

-

-

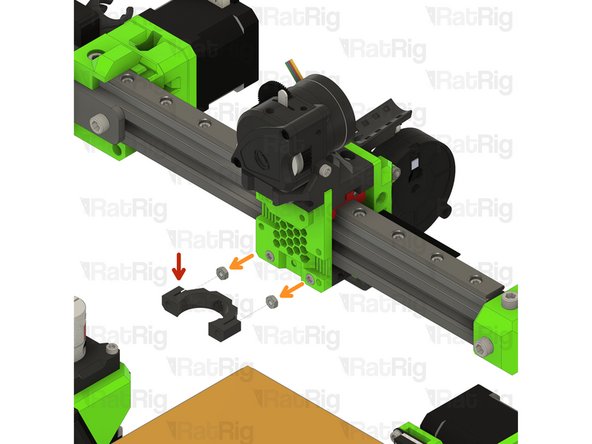

Assembly from Step 3

-

M3 Hex Nut

-

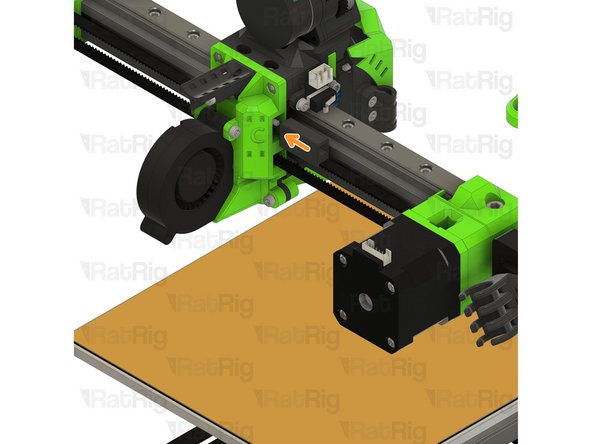

Install an M3 hex nut into each of the four positions shown

-

-

-

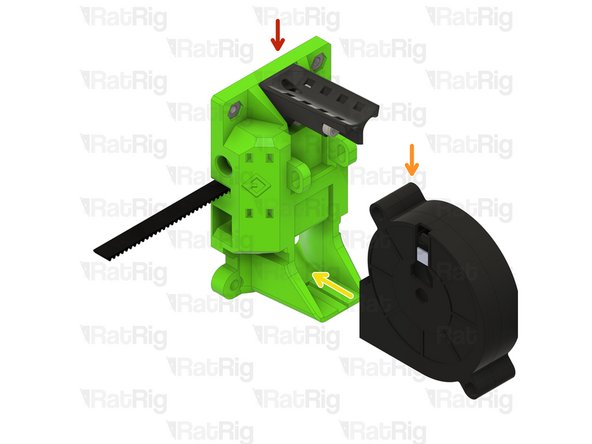

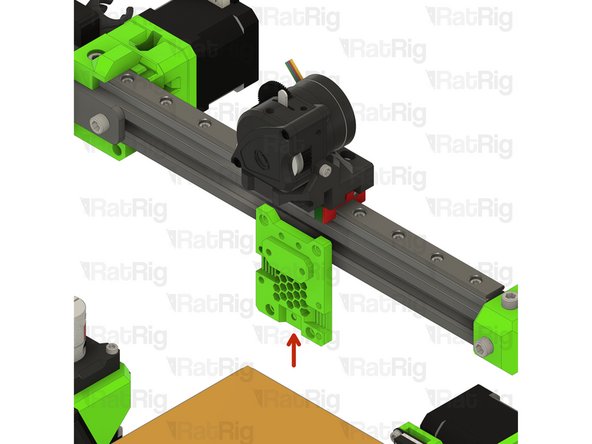

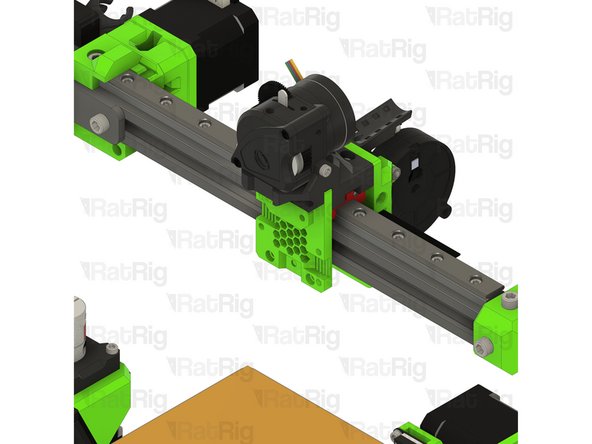

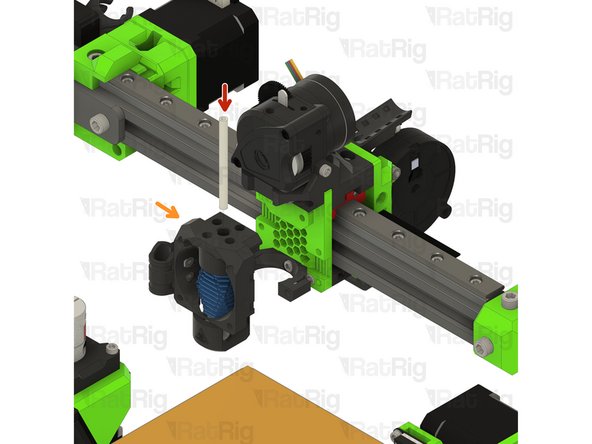

Assembly from Step 4

-

cartesian_cable_fin printed part

-

M3x30 Cap Head Screw

-

M3x12 Cap Head Screw

-

Take care not to over tighten the M3 screws as you can damage the printed parts

-

-

-

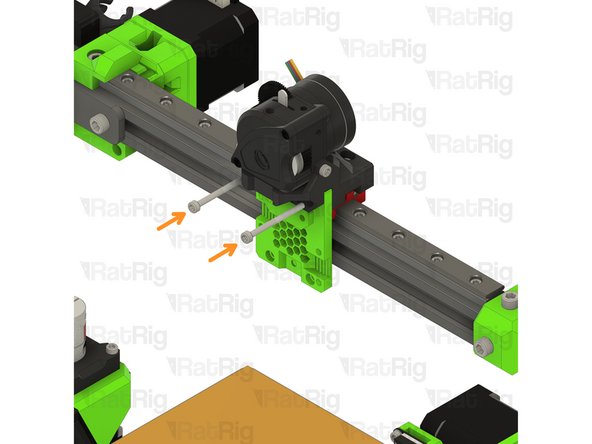

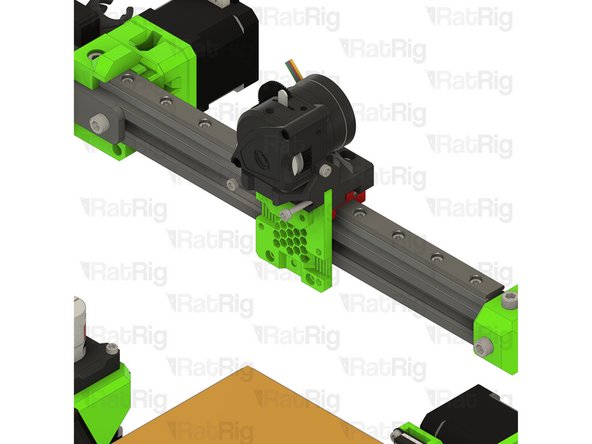

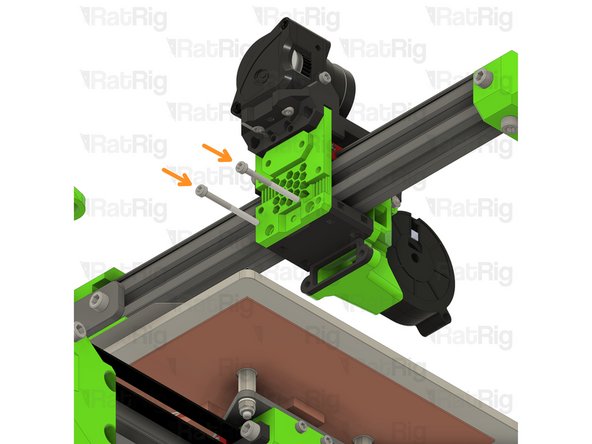

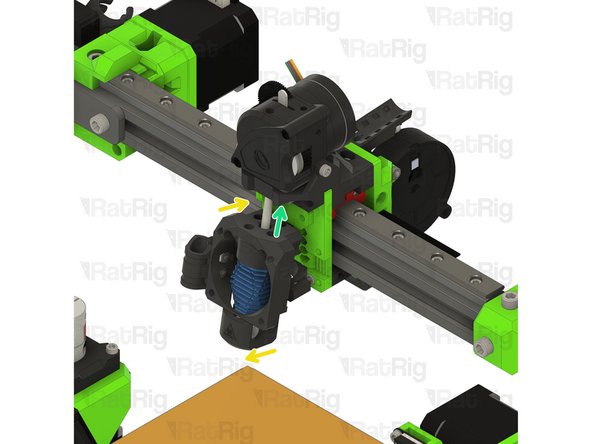

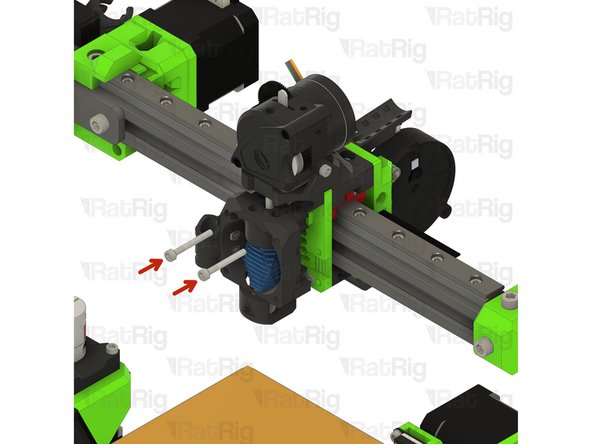

Assembly from Step 5

-

24v 5015 Blower Fan

-

Install the 5015 fan into the cartesian_back printed part as shown

-

M3x25 Cap Head Screw

-

M3 Hex Nut

-

Secure the fan in place by fitting the M3x25 screw and M3 hex nut as shown

-

Take care not to over tighten the M3x25 screw as you can damage the printed part

-

Set this assembly aside until Step 22

-

-

-

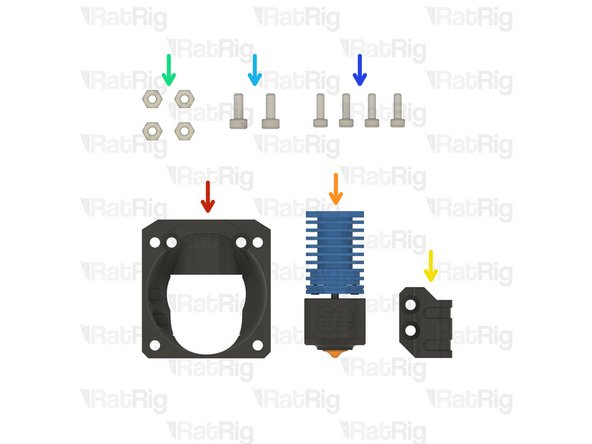

bmo_face printed part

-

1x Assembled Pheatus Dragonfly BMO hot end

-

Refer to the documentation supplied with the hot end for instructions on assembly

-

LJ8_probe_mount_8mm printed part

-

4x M3 Hex Nut

-

2x M3x8 Cap Head Screw

-

4x M2.5x8 Cap Head Screw

-

These screws are provided with the Pheatus Dragonfly BMO hot end

-

-

-

bmo_face printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

-

-

Assembly from Step 8

-

M2.5x8 Cap Head Screw

-

Assembled Pheatus Dragonfly BMO hot end

-

Secure the Pheatus Dragonfly BMO hot end to the printed part using the M2.5x8 screws

-

Take care not to over tighten the M2.5x8 screws as you can damage the printed parts or the threads in the hot end heatsink

-

-

-

Assembly from Step 9

-

LJ8_probe_mount_8mm printed part

-

M3x8 Cap Head Screw

-

Loosely thread the M3x8 screws into the M3 nuts. Do not tighten them at this point

-

Set this assembly aside until Step 26

-

-

-

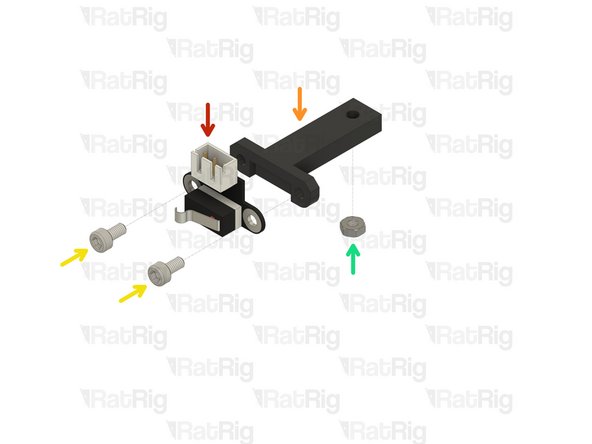

1x Limit Switch

-

1x M3 Hex Nut

-

3x M3 Square Nut (Included with the Bondtech LGX Lite)

-

3x M3x8 Cap Head Screw

-

6x M3x10 Cap Head Screw

-

top_endstop_angled printed part

-

1x Bondtech LGX Lite Extruder

-

top_mgn12_lgx_lite printed part

-

-

-

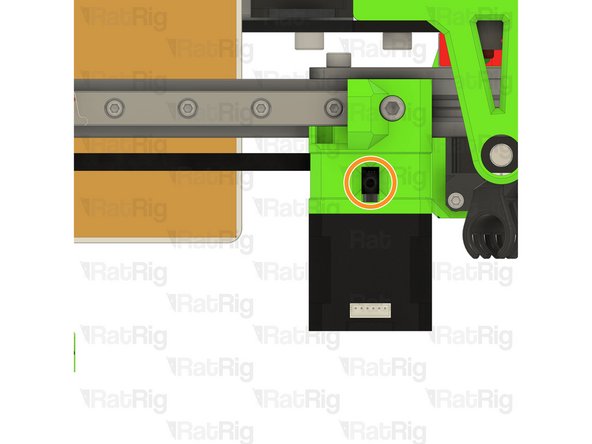

Limit Switch

-

top_endstop_angled printed part

-

M3x8 Cap Head Screw

-

Secure the limit switch to the printed part using the M3x8 screws

-

Take care not to over tighten the M3x8 screws as you can damage the printed part

-

M3 Hex Nut

-

Insert the M3 hex nut into the underside of the printed part

-

Set this assembly aside until Step 18

-

-

-

Bondtech LGX Lite extruder

-

Remove the two M3x25 screws holding the Bondtech LGX Lite together

-

Carefully remove the face plate from the LGX Lite assembly

-

-

-

M3 Square Nut

-

Insert one M3 square nut into each of the marked holes on the LGX Lite

-

Re-install the LGX Lite face plate

-

-

-

Bondtech LGX Lite extruder

-

Carefully separate the LGX Lite motor and back plate from the assembly as shown

-

-

-

M3 Square Nut

-

Insert one M3 square nut into the marked hole on the LGX Lite

-

Re-install the LGX Lite back plate and motor

-

-

-

Re-install the two M3x25 screws, these secure the Bondtech LGX Lite together

-

Set the LGX Lite aside until Step 19

-

-

-

top_mgn12_lgx_lite printed part

-

M3x10 Cap Head Screw

-

Fasten all four M3x10 screws to secure the EVA top to the MGN12 carriage

-

Slide the X-axis left and right along the rail to make sure it moves smoothly

-

If the carriage binds at all, slightly loosen the M3x10 screws and check again

-

X-axis end stop assembly from Step 12

-

M3x8 Cap Head Screw

-

Insert the end stop assembly as shown and secure in place with the M3x8 screw

-

-

-

Bondtech LGX Lite extruder

-

M3x10 Cap Head Screw

-

M3x8 Cap Head Screw

-

Insert the three M3 screws as shown, fasten them to secure the LGX Lite extruder to the EVA top

-

Take care not to over tighten the M3 screws as you can damage the printed part

-

-

-

bottom_mgn12_short_duct printed part

-

bmo_support printed part

-

4x M3x35 Cap Head Screw

-

2x M3x25 Cap Head Screw

-

1x M3x6 Cap Head Screw

-

2x M3 Hex Nut

-

1x 53mm PTFE Tube

-

-

-

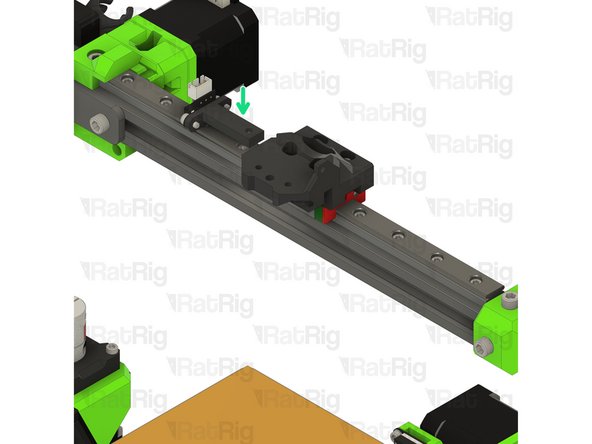

EVA face assembly from Step 2

-

Insert the EVA face into the EVA top as shown

-

M3x35 Cap Head Screw

-

Insert the M3x35 screws partially to hold the EVA face in place. They will be fully secured in the next step

-

-

-

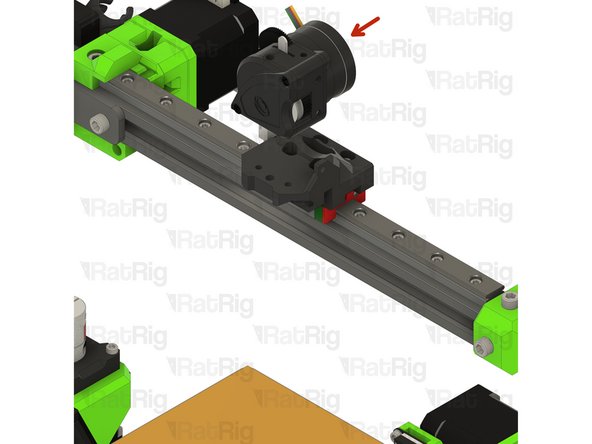

EVA back assembly from Step 6

-

Align the EVA back with the top

-

Fully insert and fasten the M3x35 screws, securing the EVA back in place

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

-

-

bottom_mgn12_short_duct printed part

-

M3x35 Cap Head Screw

-

Position the EVA bottom_mgn12_short_duct printed part as shown

-

Secure it in place by inserting and fastening the M3x35 screws into the EVA back

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

-

-

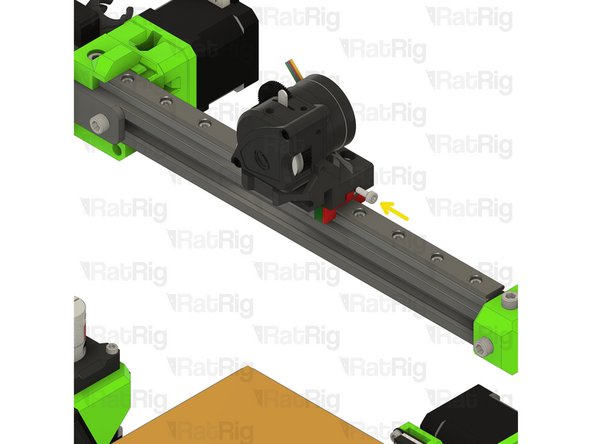

M3x10 Cap Head Screw

-

Insert and fasten the two M3x10 screws as shown to securely assemble the LGX Lite and EVA parts

-

Take care not to over tighten the M3x10 screws as you can damage the printed parts

-

-

-

bmo_support printed part

-

M3 Hex Nut

-

Install an M3 hex nut into each of the two positions shown

-

M3x6 Cap Head Screw

-

Secure the bmo_support part to the EVA face using the M3x6 screw

-

Take care not to over tighten the M3x6 screw as you can damage the printed parts

-

-

-

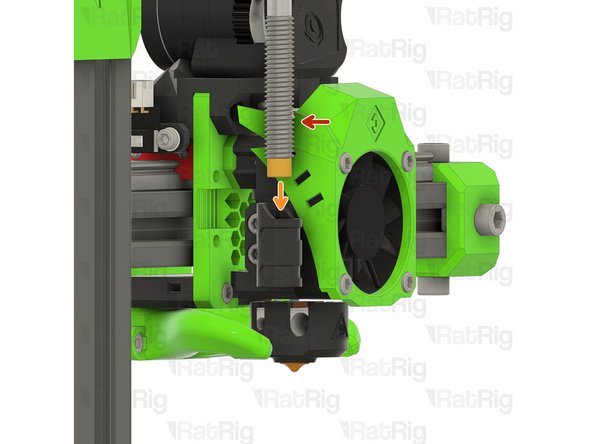

PTFE Tube - 53mm

-

Hot end assembly from Step 10

-

Insert the length of PTFE tube into the hot end assembly as shown

-

Rotate the hot end assembly as shown

-

Line up the end of the PTFE tube with the hole in the underside of the LGX Lite extruder mount and push the hot end assembly upwards

-

Rotate the bottom of the hot end assembly towards the EVA assembly

-

When properly lined up, the hot end assembly should rest atop the BMO-support printed part as shown

-

-

-

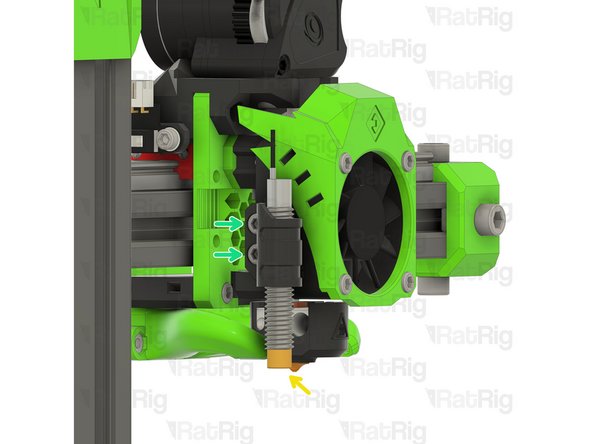

M3x25 Cap Head Screw

-

Insert the M3x25 screws through the hot end assembly fasten them to secure it to the EVA assembly

-

Take care not to over tighten the M3x25 screws as you can damage the printed parts

-

-

-

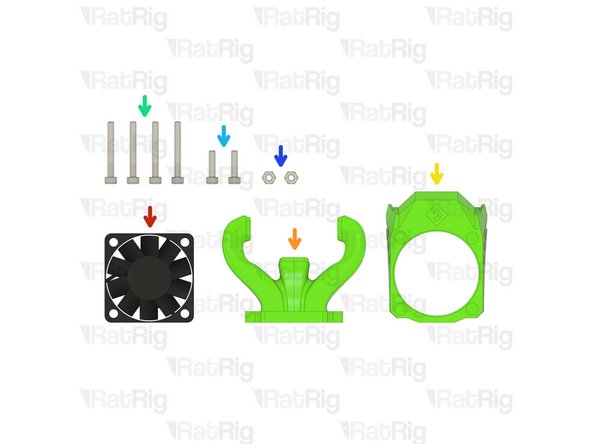

1x 40x10 24V Fan

-

trihorn_duct printed part

-

shroud printed part

-

The design of the EVA shroud may vary

-

4x M3x25 Cap Head Screw

-

2x M3x12 Cap Head Screw

-

2x M3 Hex Nut

-

-

-

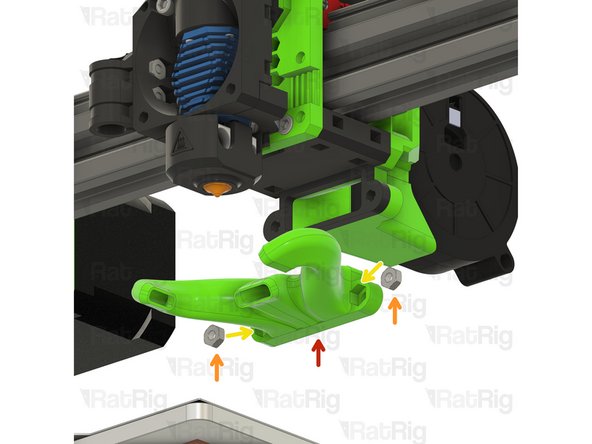

trihorn_duct printed part

-

M3 Hex Nut

-

Insert an M3 hex nut into each of the shown positions on the trihorn_duct

-

Position the trihorn_duct as shown

-

M3x12 Cap Head Screw

-

Insert the M3x12 screws as shown and fasten them to secure the trihorn_duct to the EVA assembly

-

Take care not to over tighten the M3x12 screws as you can damage the printed parts

-

-

-

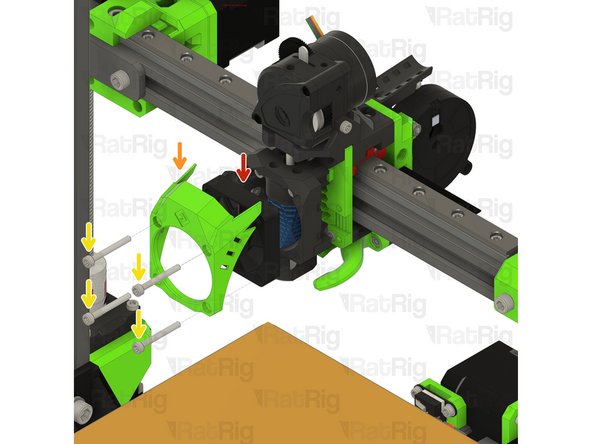

40x10 24V Fan

-

shroud printed part

-

M3x25 Cap Head Screw

-

Insert an M3x25 through each hole in the shroud as shown. Install the 40x10 fan onto the screws and then secure the shroud and fan to the EVA assembly.

-

Take care not to over tighten the M3x25 screws as you can damage the printed parts

-

-

-

1x M3x40 Cap Head Screw

-

tension_slider_6mm_belt_M3s printed part

-

M3 Square Nut

-

-

-

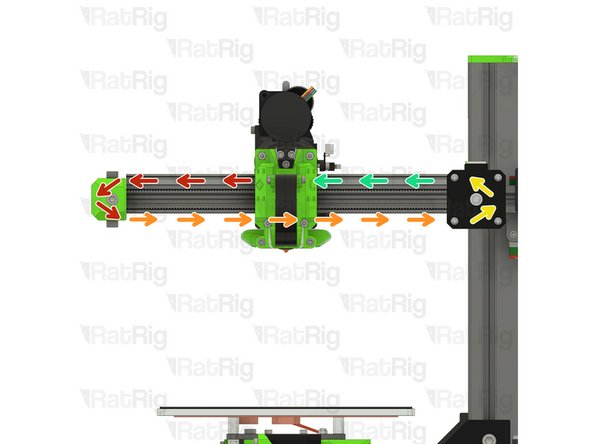

Take the free end of the X-axis timing belt and feed it around the idler pulley

-

Continue along the underside of the X-axis, passing through the hole in the EVA assembly

-

Feed it around the X-axis stepper motor pulley...

-

...and continue back to the EVA assembly

-

Pull the belt and mark where it meets the EVA assembly. This can be with a marker, or simply by holding it

-

Measure 16mm, or count 8 teeth on the belt, from the position marked previously. Double check your measurements and then cut the belt at this point

-

The belt can be cut with regular scissors.

-

It is better to cut the belt too long than too short! If you are unsure, cut it longer than expected, you can always remove more if needed

-

-

-

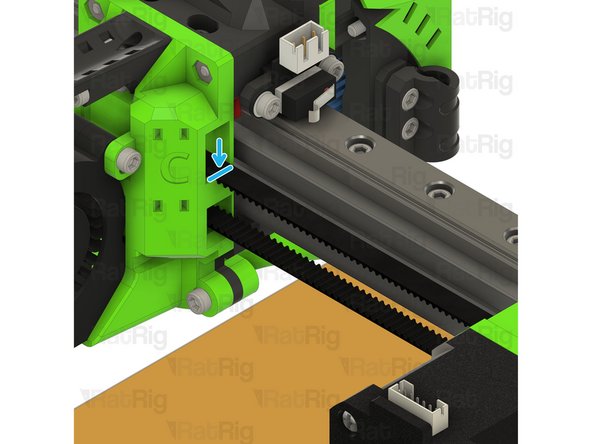

tension_slider_6mm_belt_M3s printed part

-

M3 Square Nut

-

Insert the M3 square nut into the end of the tension_slider printed part as shown

-

Cut end of 2GT 6mm timing belt

-

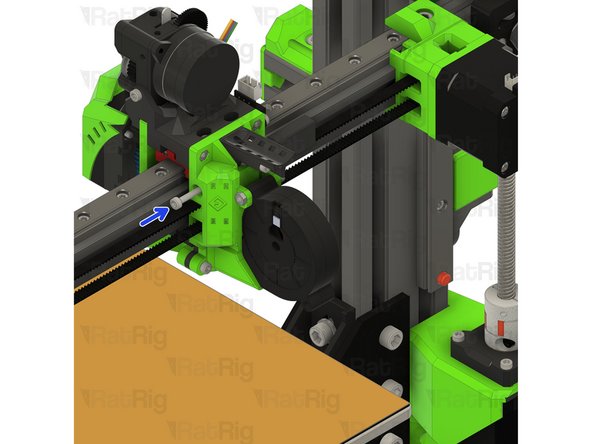

Insert the end of the belt into the printed part as shown

-

M3x40 Cap Head Screw

-

Insert the M3x40 screw into the EVA assembly as shown. This will be used to tension the belt in the next step

-

-

-

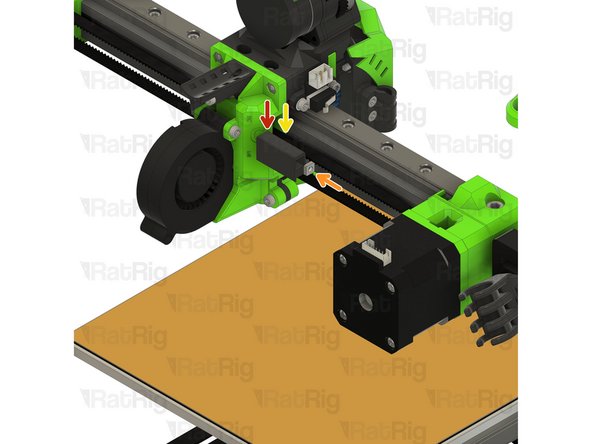

M3x40 Cap Head Screw

-

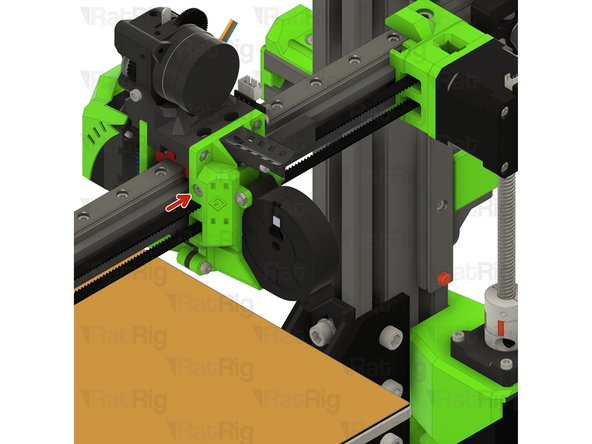

Fully insert the M3x40 screw as shown

-

Insert the tension_slider assembly into the EVA assembly as shown and secure by tightening the M3x40 screw

-

You can now adjust the tension of the X-axis belt:

-

Tighten the M3x40 screw to increase belt tension

-

Loosen the M3x40 screw to decrease belt tension

-

-

-

Slowly move the completed EVA assembly along the X-axis a few times. This will allow the pulley on the stepper motor to align itself

-

Secure the pulley to the stepper motor shaft by tightening both grub screws as shown

-

-

-

8mm Inductive Probe

-

Insert the probe as shown

-

Position the probe so that its tip is 1-2mm above the height of the nozzle

-

Secure the probe in place by tightening the two M3x8 screws

-

Check the hole for the PTFE filament guide in the printed extruder support and clear it as needed BEFORE you mount the extruder. I didn't and had to backtrack. No guidance on which way to mount the fan that cools the heatsink either, hope I got it right The fan body has no arrows for spin or flow. I THINK flow is towards the label, other fans here are like this.

Check the hole for the PTFE filament guide in the printed extruder support and clear it as needed BEFORE you mount the extruder. I didn't and had to backtrack. No guidance on which way to mount the fan that cools the heatsink either, hope I got it right The fan body has no arrows for spin or flow. I THINK flow is towards the label, other fans here are like this.

Cancel: I did not complete this guide.

17 other people completed this guide.