Introduction

Please note: The CNC Enclosure - Mill is not supplied with the enclosure panels, they must be sourced separately.

DXF and STEP files for the panels are available on the documentation website.

-

-

It is recommended to have the following tools available for assembling the CNC Enclosure - Mill:

-

Allen Key / Hex Wrenches in the following sizes: 3mm, 4mm & 5mm

-

A tape measure

-

A pair of scissors

-

-

-

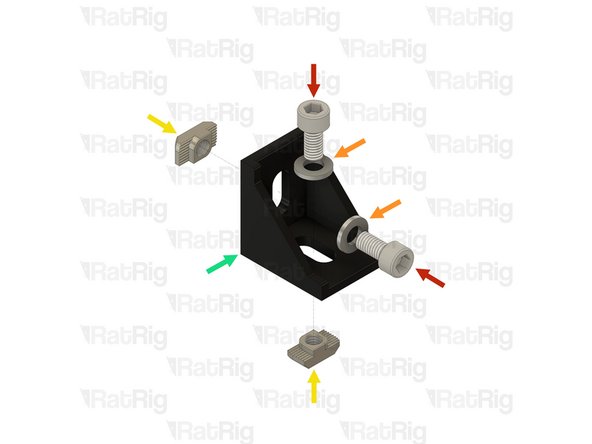

28x 3030 cast 90 degree corner

-

56x M6x12 cap head screw

-

56x M6 washer

-

56x T-nut drop-in for 3030 - M6

-

-

-

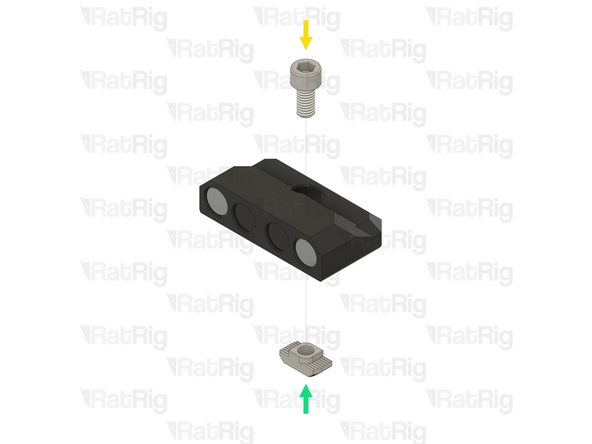

2x M6x12 cap head screw

-

2x M6 washer

-

2x T-nut drop-in for 3030 - M6

-

1x 3030 cast 90 degree corner

-

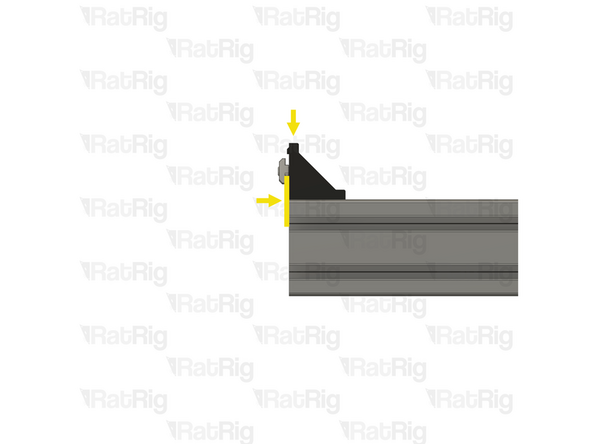

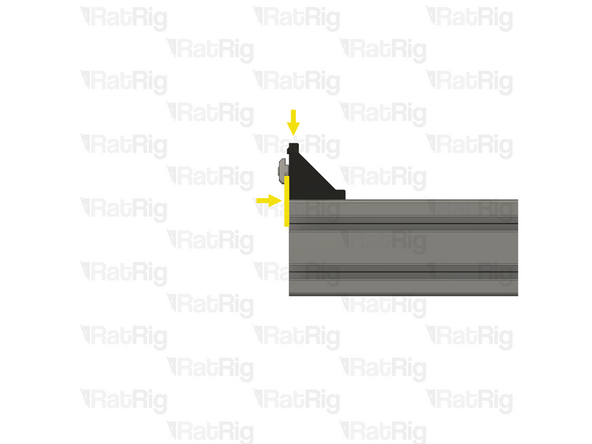

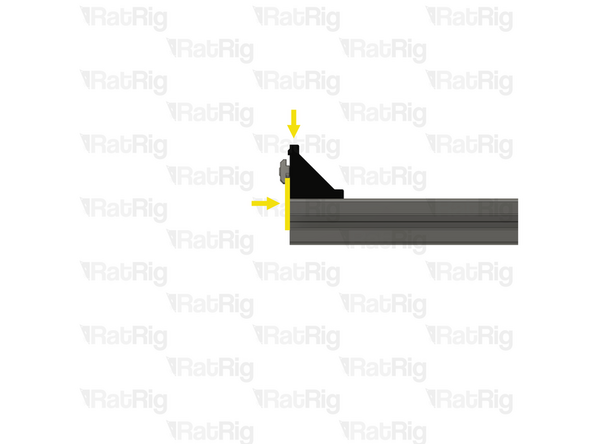

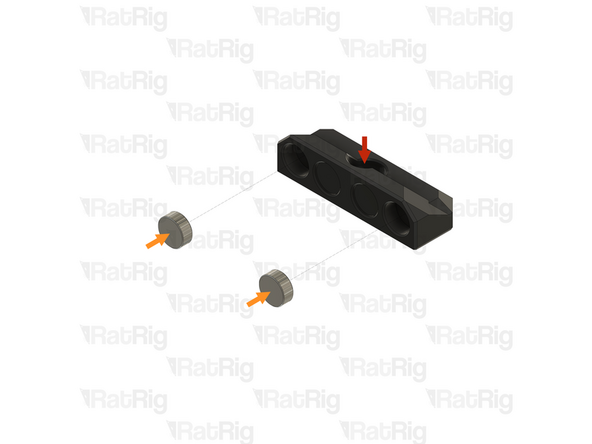

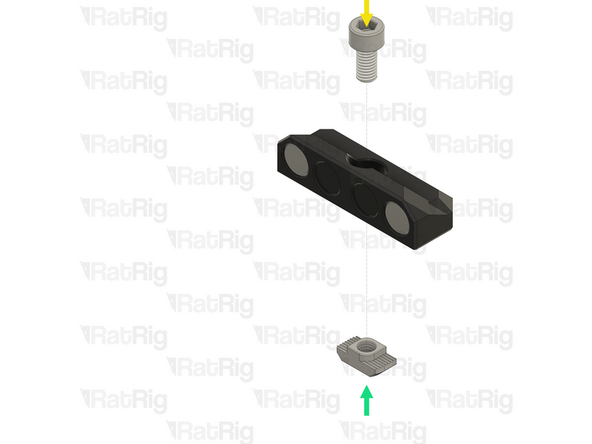

Loosely thread a 3030 T-nut on to each M6x12 screw. Do not tighten them at this point

-

-

-

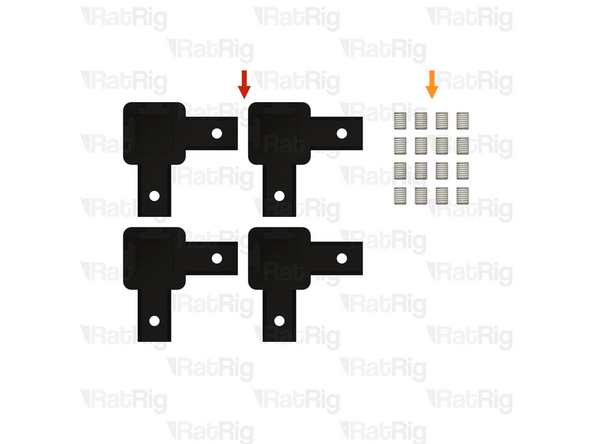

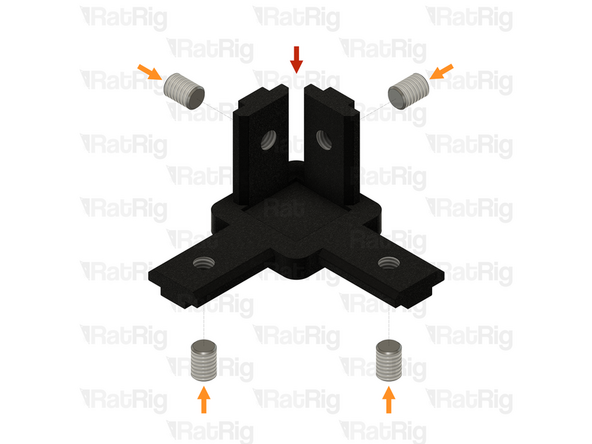

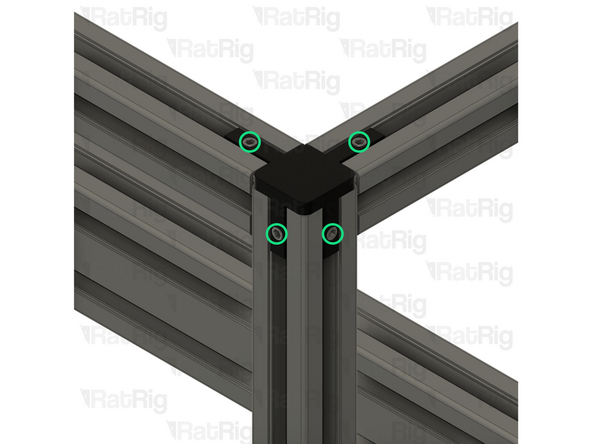

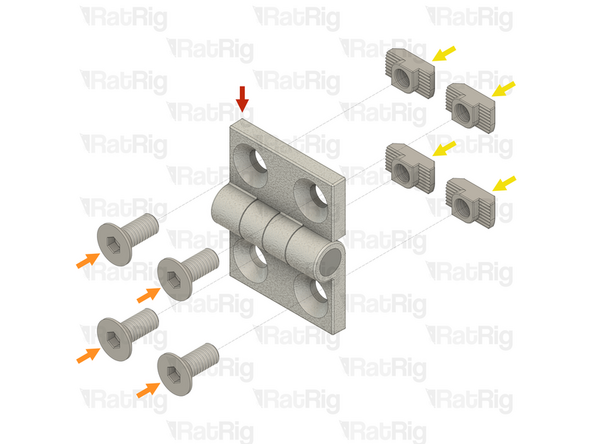

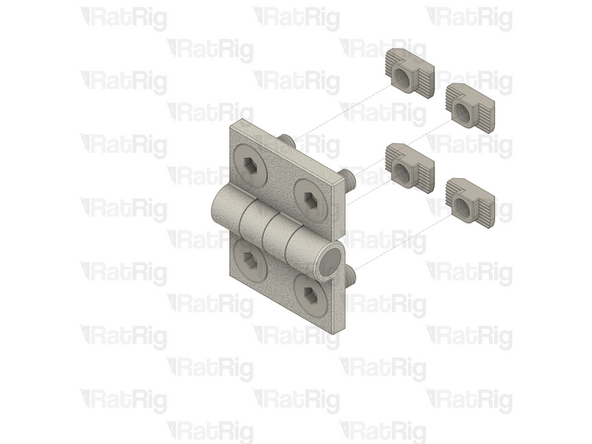

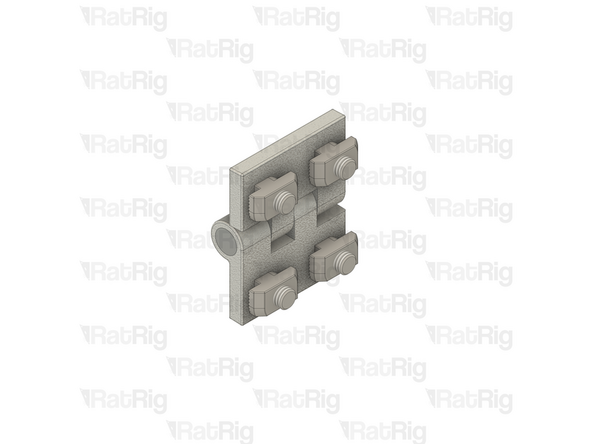

1x Inside hidden three way corner

-

4x M6x8 set screw

-

Insert an M6x8 set screw into each of the holes on the inside corner as shown

-

Set these assemblies aside until Step 17

-

-

-

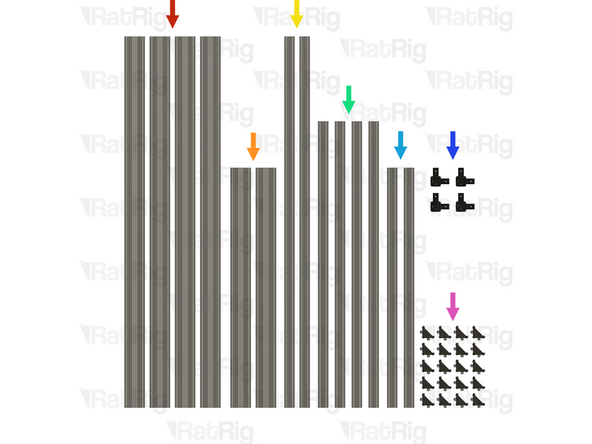

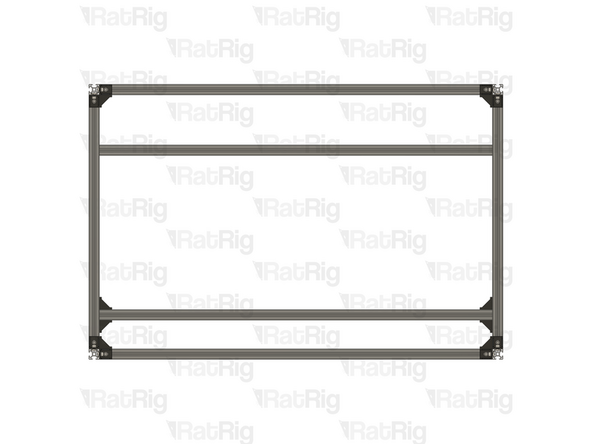

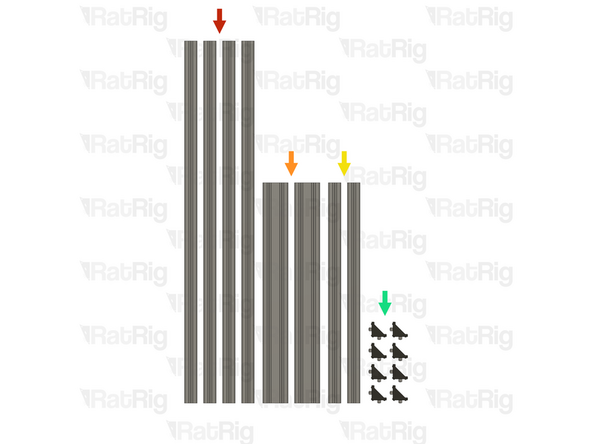

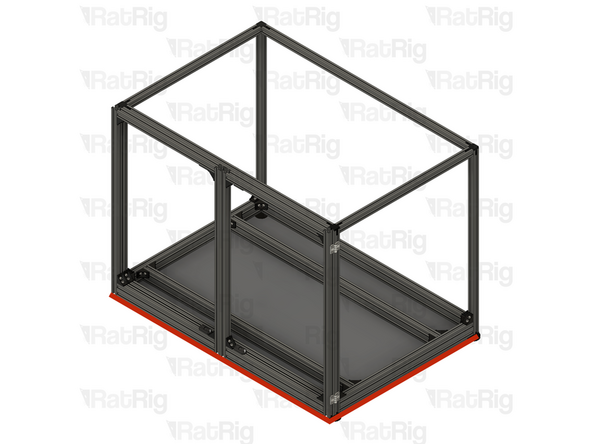

4x 1102mm 3060 extrusion

-

2x 712mm 3060 extrusion

-

2x 1102mm 3030 extrusion

-

4x 850mm 3030 extrusion

-

2x 712mm 3030 extrusion

-

4x Inside hidden three way corner assemblies

-

20x 3030 cast 90 degree corner assemblies

-

-

-

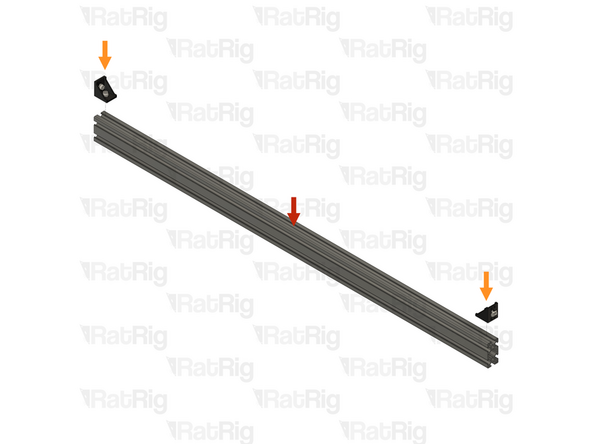

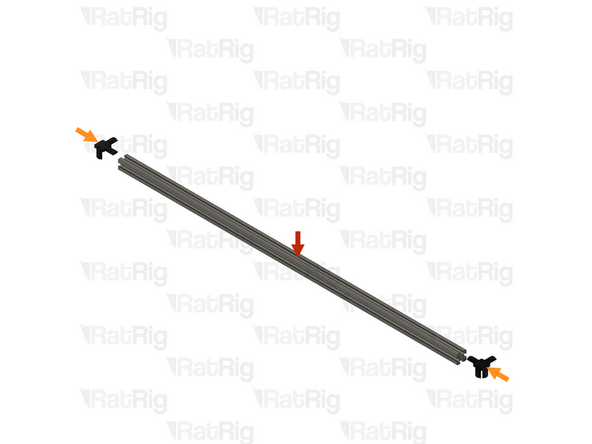

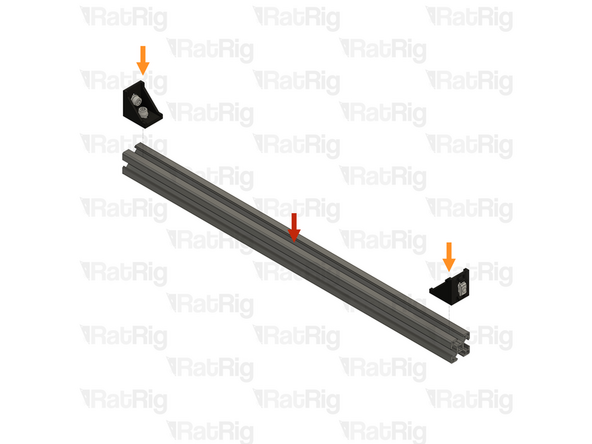

1x 1102mm 3060 extrusion

-

2x 3030 cast 90 degree corner assemblies

-

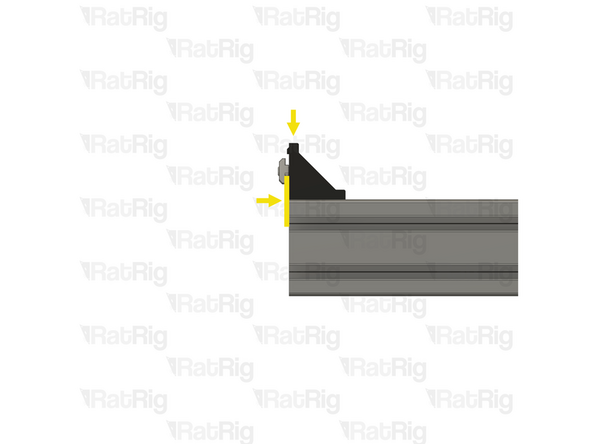

Install one corner assembly onto each end of the 1102mm 3060 extrusions as shown. Tighten the M6x12 screw to secure them.

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

Set these assemblies aside until Step 9

-

-

-

1x 712mm 3060 extrusion

-

2x 3030 cast 90 degree corner assemblies

-

Install one corner assembly onto each end of the 712mm 3060 extrusions as shown. Tighten the M6x12 screw to secure them

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

-

-

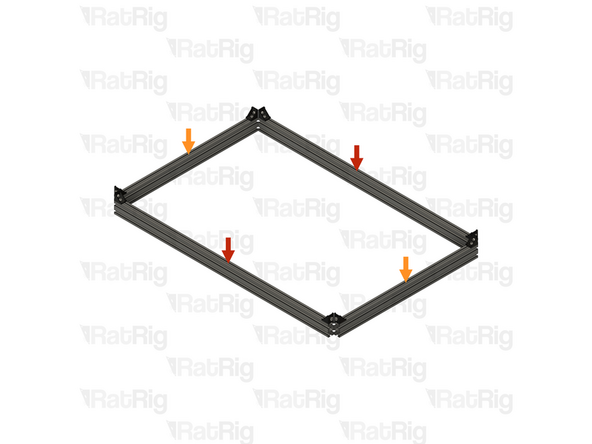

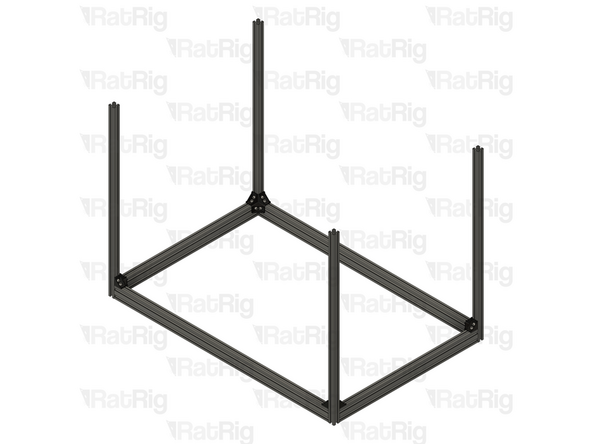

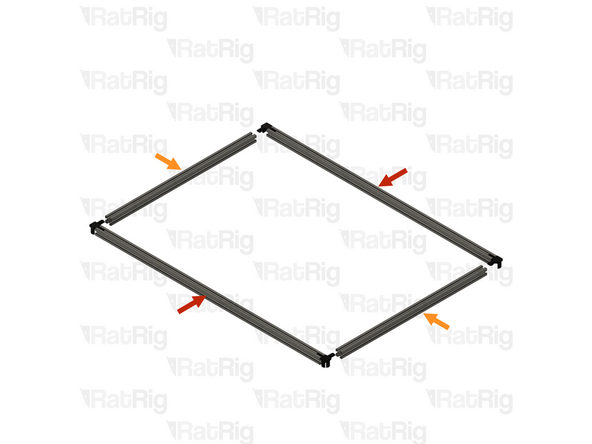

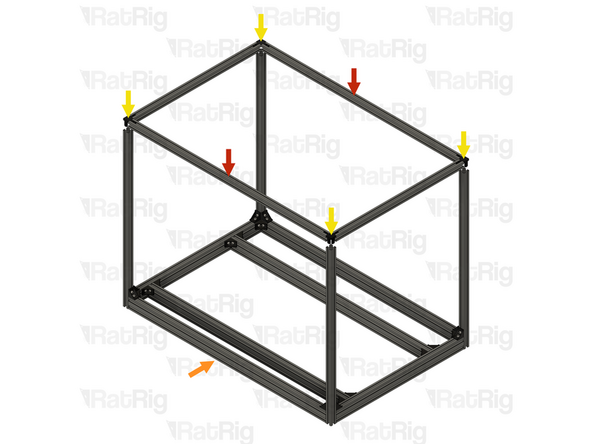

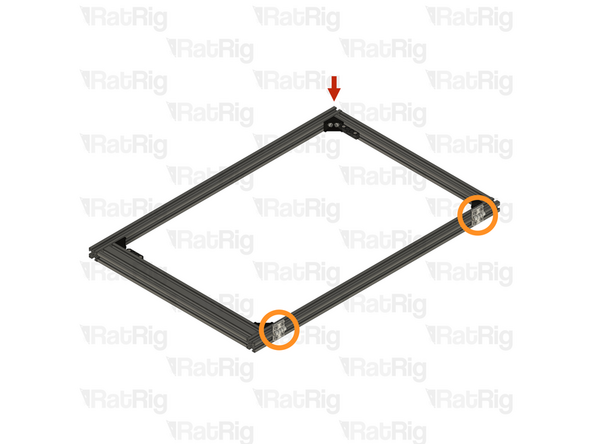

2x Bottom frame front & back assembly from Step 7

-

2x Bottom frame left & right assembly

-

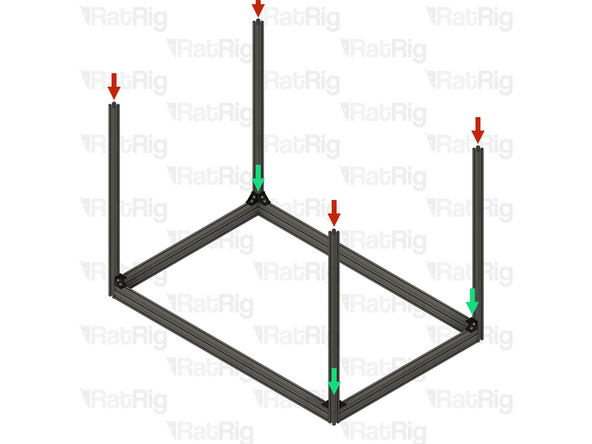

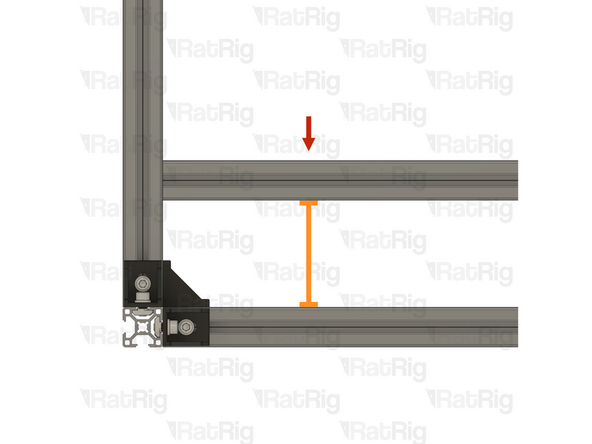

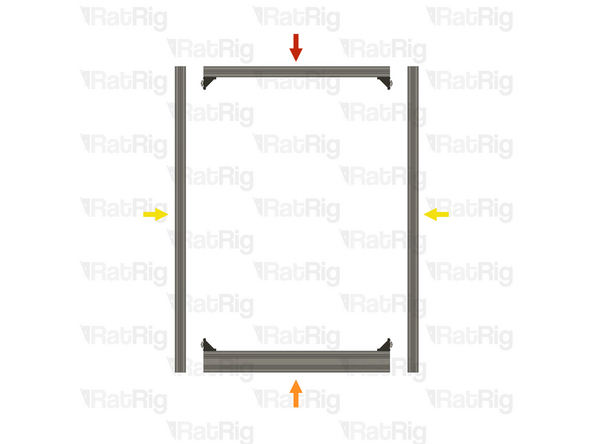

Position the bottom frame assemblies as shown

-

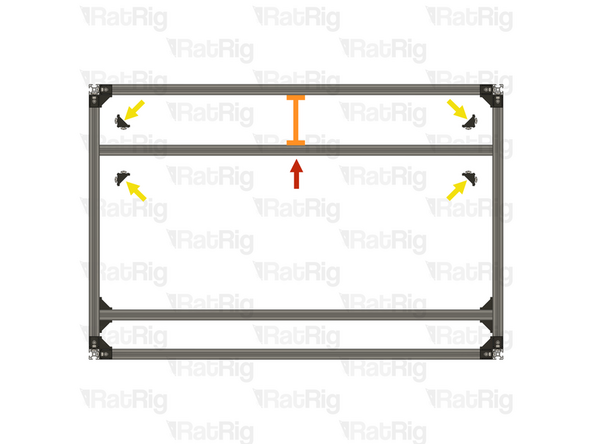

1x 850mm 3030 extrusion

-

Slot the 850mm 3030 extrusion into the corner of the bottom frame assemblies as shown, it will be secured in the next step

-

-

-

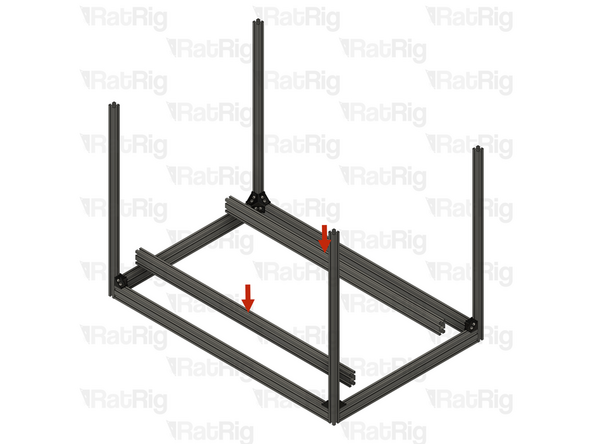

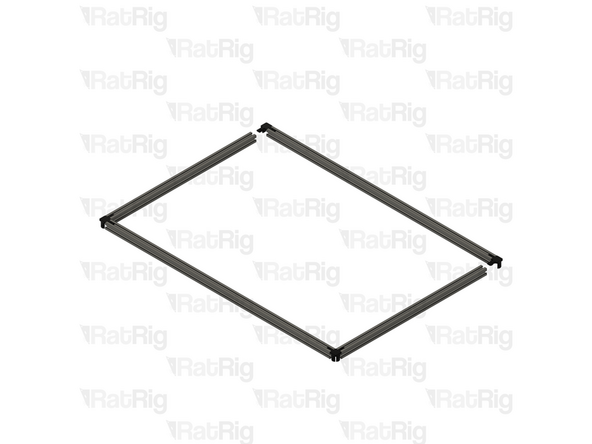

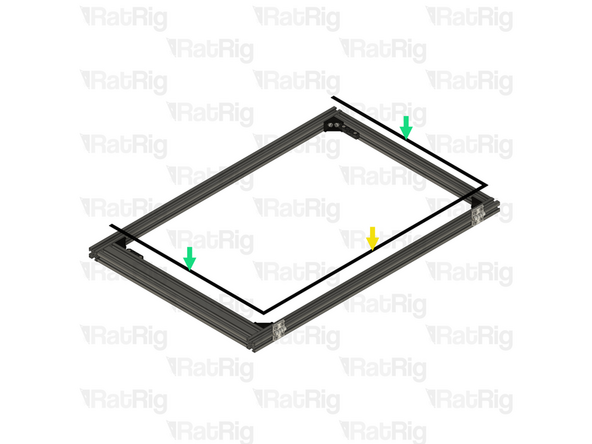

1x 850mm 3030 extrusion

-

Align the 850mm 3030 extrusion into the corner of the bottom frame assemblies as shown, make sure it is square

-

Make sure the end of the 850mm 3030 extrusion which has been tapped, faces downwards towards the bottom frame, otherwise you will be unable to install the feet in a later step

-

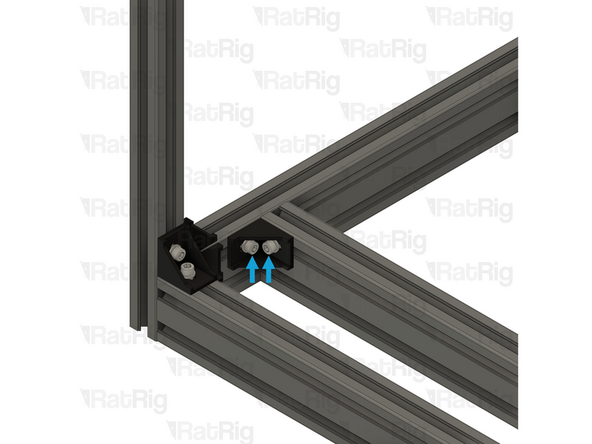

Tighten the marked M6x12 screws to secure the 850mm 3030 extrusion to the bottom frame

-

Repeat these instructions to install and secure the remaining 3x 850mm 3030 extrusions as shown

-

-

-

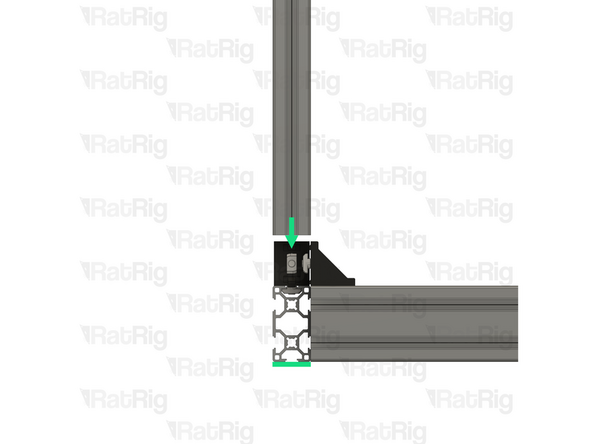

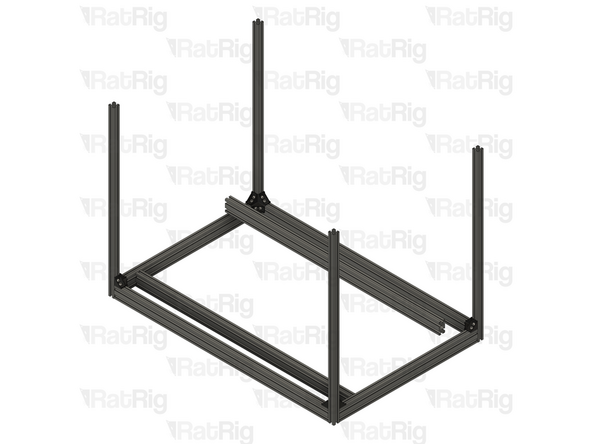

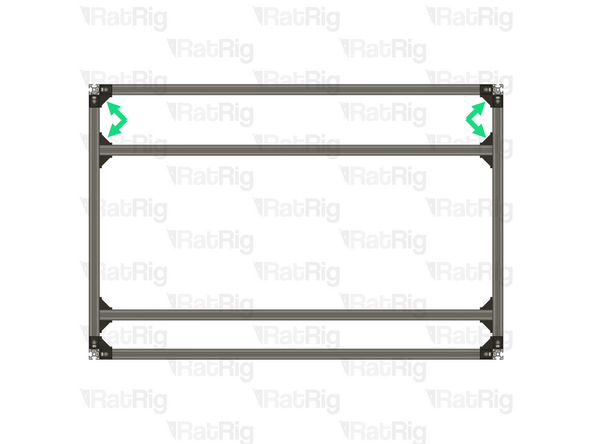

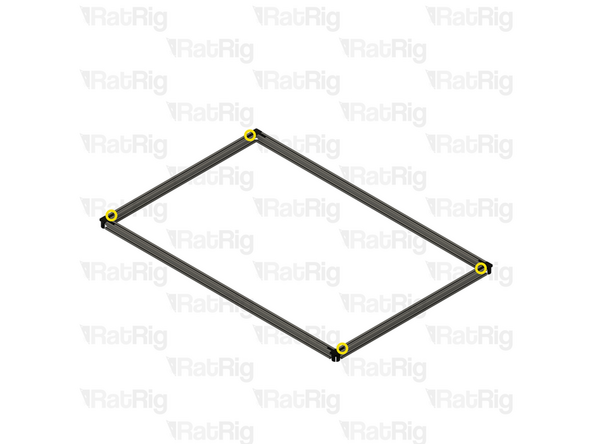

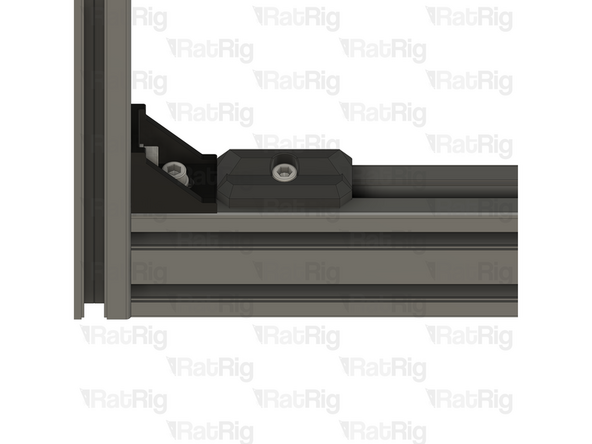

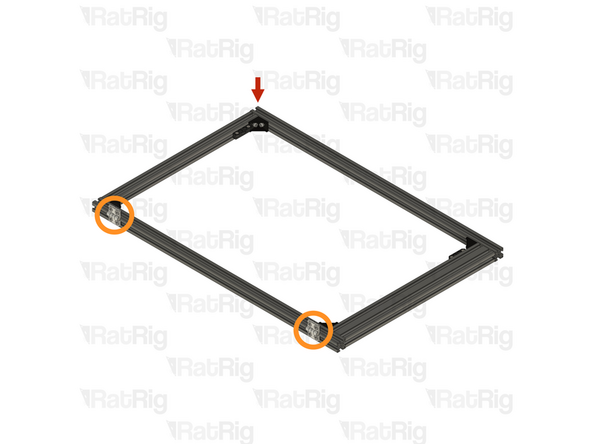

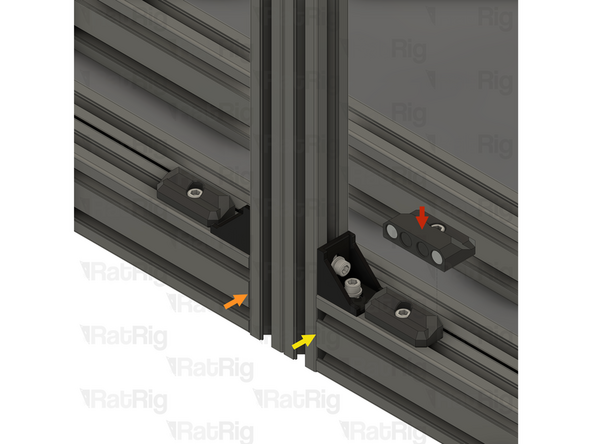

1x 3030 cast 90 degree corner assembly

-

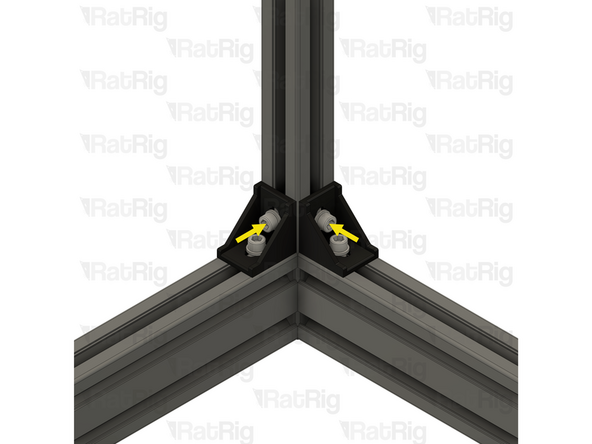

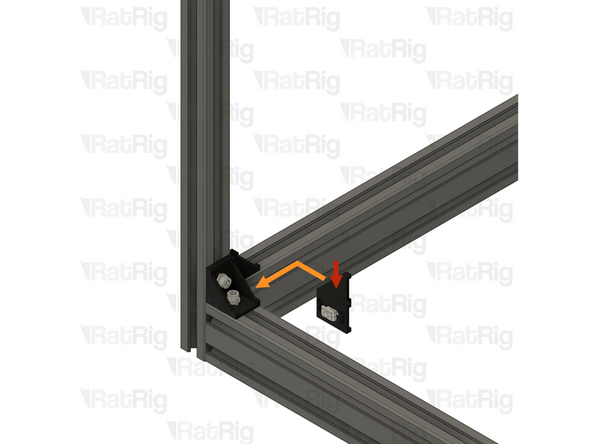

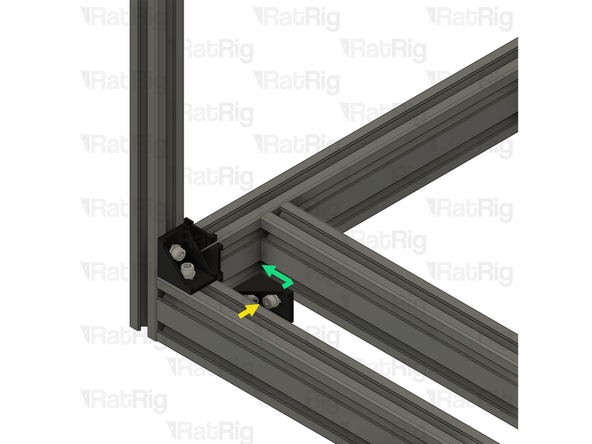

Install a 3030 cast 90 degree corner assembly into the inner corner as shown

-

Tighten both M6x12 screws to secure the cast 90 degree corner to the frame assembly

-

-

-

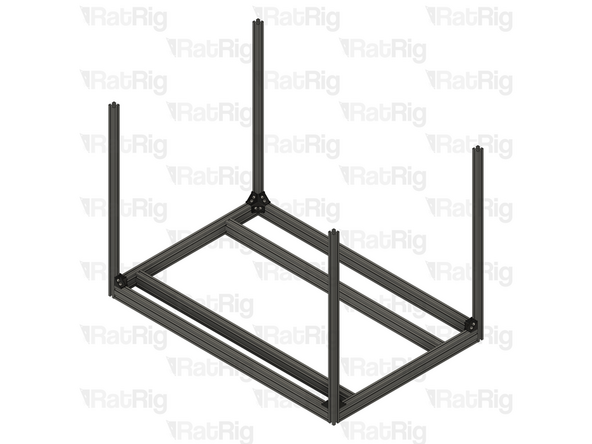

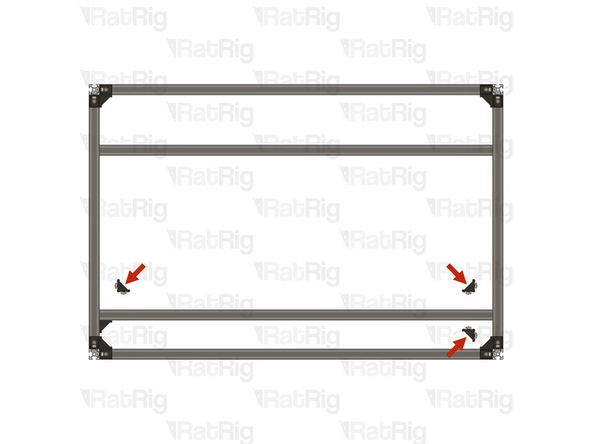

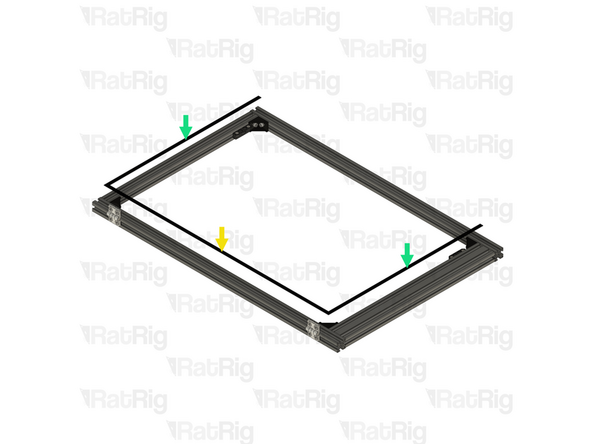

3x 3030 cast 90 degree corner assembly

-

Repeat the instructions in the previous step to install the remaining 3x 3030 cast 90 degree corner assemblies

-

-

-

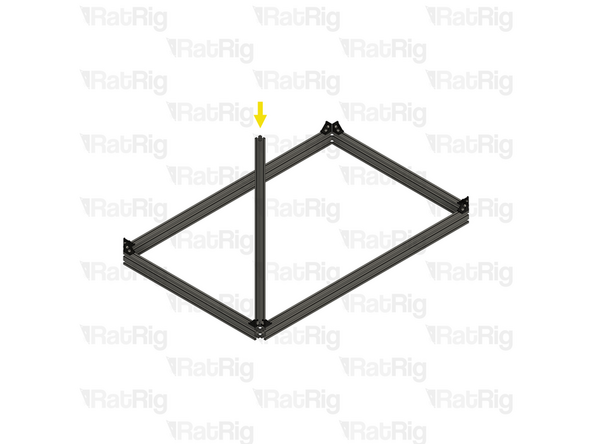

2x 1102mm 3060 extrusion

-

Place the 1102mm 3060 extrusions inside the bottom of the frame, they will be aligned and secured in the next steps

-

-

-

1x 1102mm 3060 extrusion

-

Position the extrusion so the marked gap measures 80mm

-

1x 3030 cast 90 degree corner assembly

-

Install a 3030 cast 90 degree corner assembly into the inner corner as shown

-

Tighten both M6x12 screws to secure corner assembly to the frame assembly

-

Double check the 80mm measurement once the 3030 cast 90 degree corner is secured

-

-

-

3x 3030 cast 90 degree corner assembly

-

Repeat the instructions in the previous step to install the remaining 3x 3030 cast 90 degree corner assemblies

-

-

-

1x 1102mm 3060 extrusion

-

Position the extrusion so the marked gap measures 140mm

-

4x 3030 cast 90 degree corner assembly

-

Install a 3030 cast 90 degree corner assembly into each inner corner as shown

-

Tighten both M6x12 screws on each corner assembly to secure the frame together

-

Double check the 140mm measurement once the 3030 cast 90 degree corners are secured

-

-

-

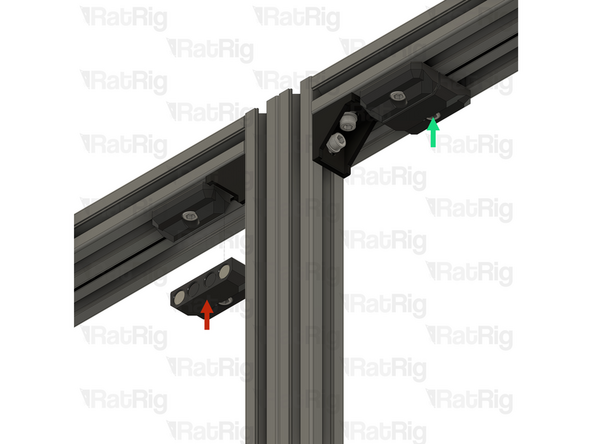

1x 1102mm 3030 extrusion

-

2x Inside hidden three way corner assemblies from Step 5

-

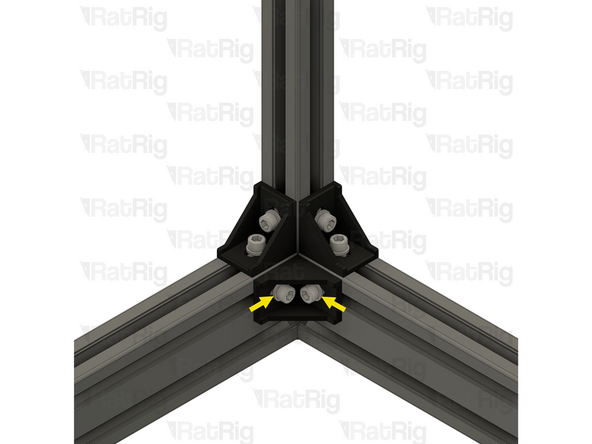

Tighten the M6x8 set screws to secure the corners to the extrusion

-

Ensure the extrusion is flush and square with the both hidden three way corner assemblies before and after tightening the set screws

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner

-

-

-

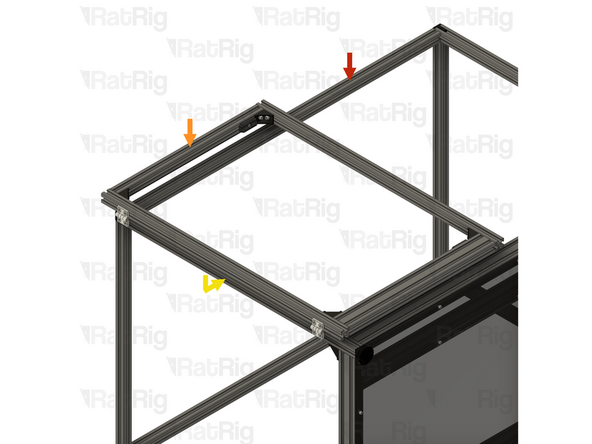

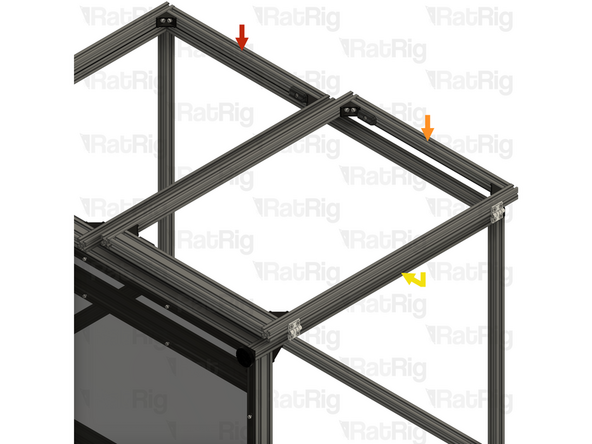

2x Assemblies from the previous step

-

2x 712mm 3030 extrusion

-

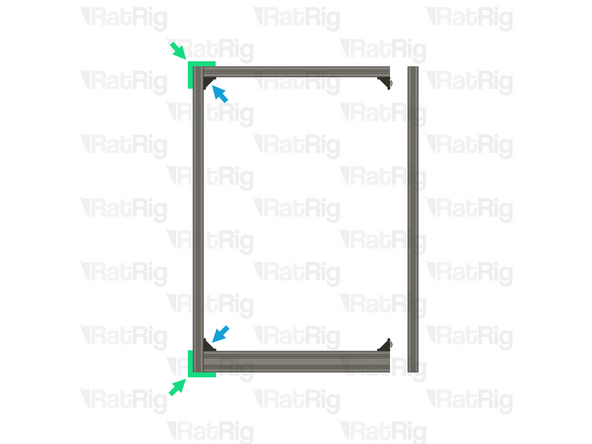

Assemble the enclosure top as shown, securing it together by tightening the M6x8 set screws

-

Ensure the extrusion is flush and square with the both hidden three way corner assemblies before and after tightening the set screws

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner

-

-

-

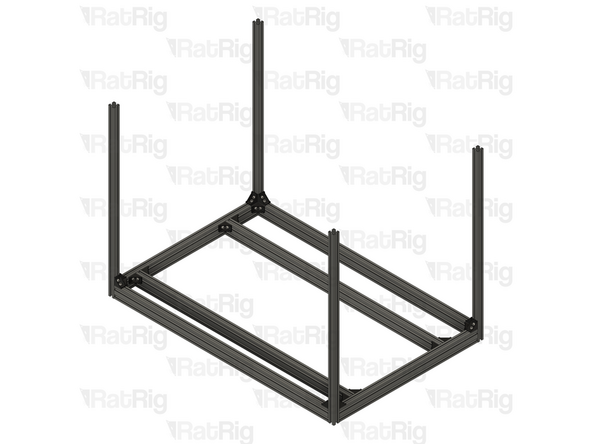

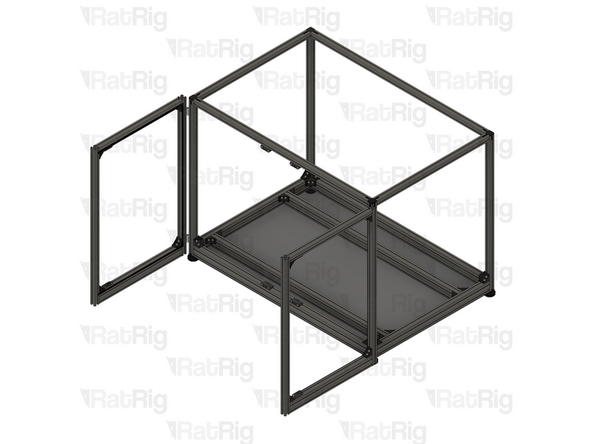

It is strongly recommended to have a second person assist with installing the upper frame, and also to manipulate the frame in the remaining steps. The enclosure weighs roughly 22KG without the panels installed

-

The enclosure is large and heavy and can cause injury if it were to fall

-

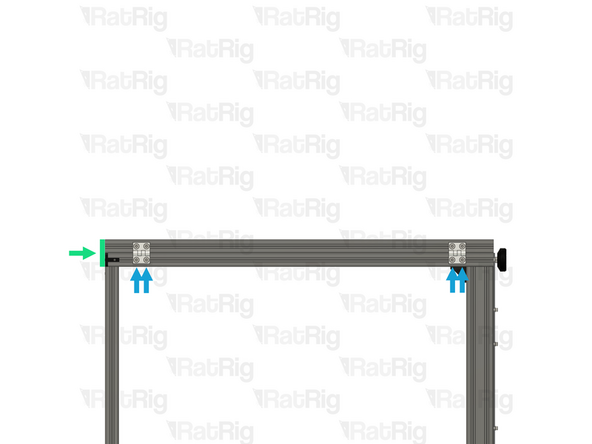

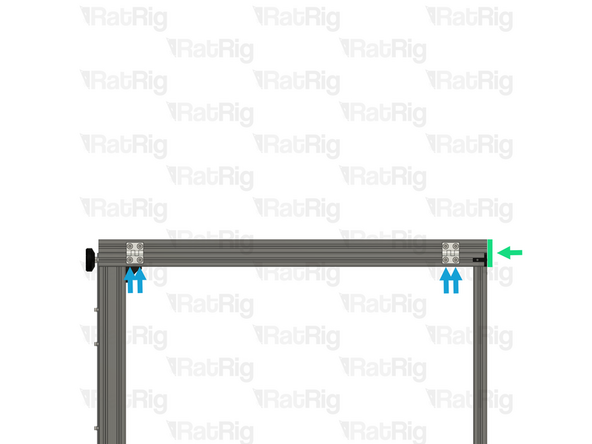

1x Enclosure top assembly from the previous step

-

1x Enclosure assembly

-

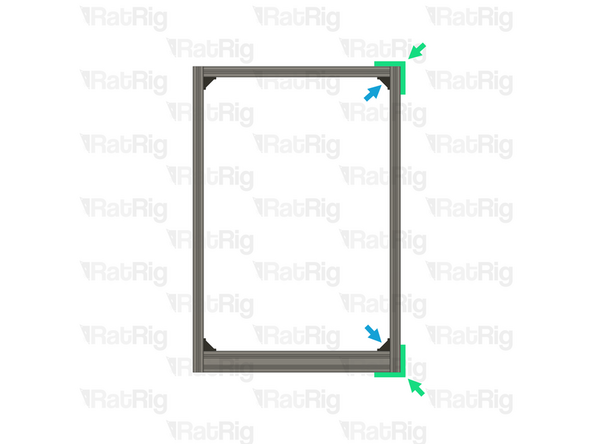

Align the inside hidden three way corner assemblies with the upright 3030 extrusions

-

Once fully aligned and situated, tighten all M6x8 set screws to secure the enclosure frame together

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner

-

-

-

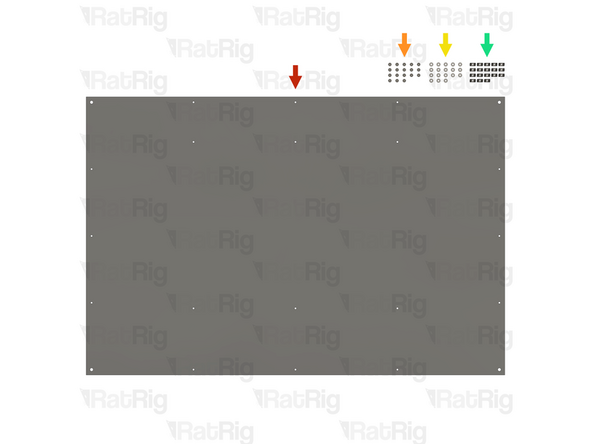

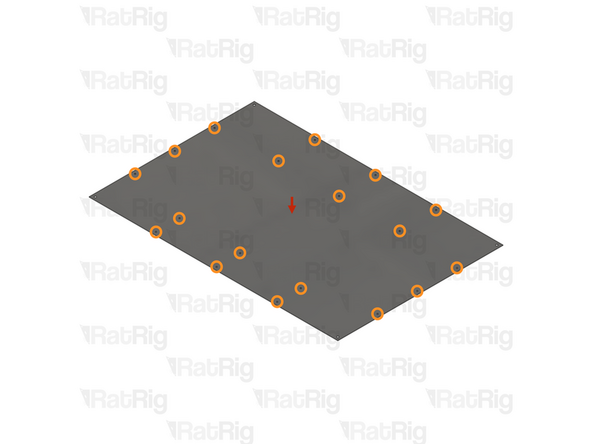

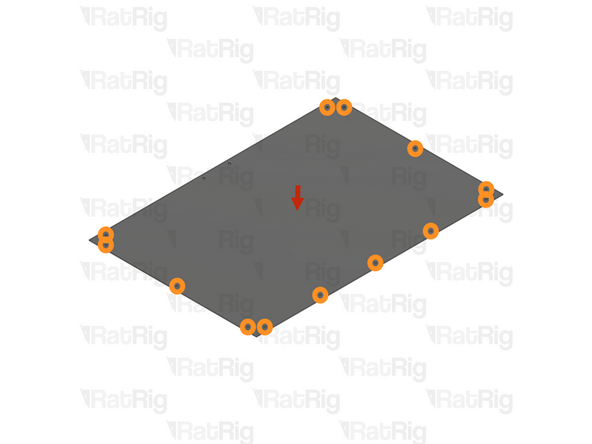

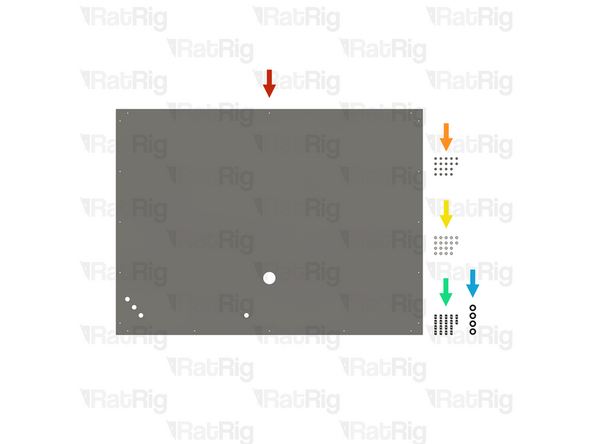

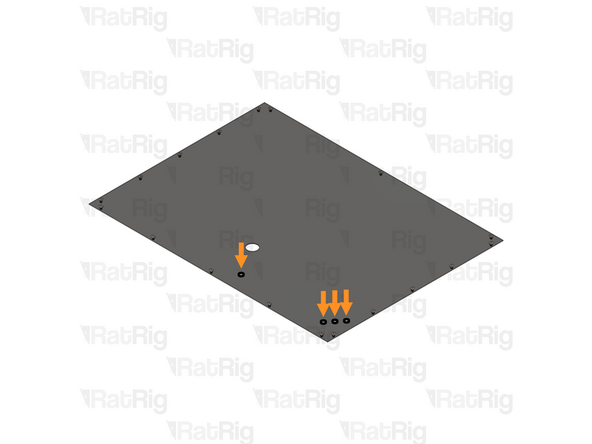

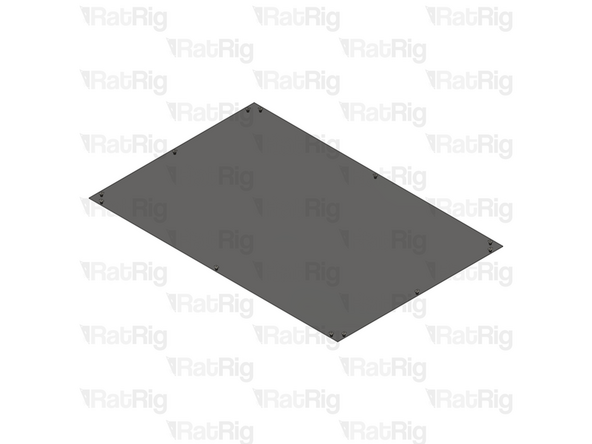

1x panel_enclosure_mill_base panel

-

18x M5x12 cap head screw

-

18x M5 washer

-

18x T-nut drop-in for 3030 - M5

-

-

-

1x panel_enclosure_mill_base panel

-

For each of the 18x marked holes, install the mounting hardware as shown in Step 22

-

-

-

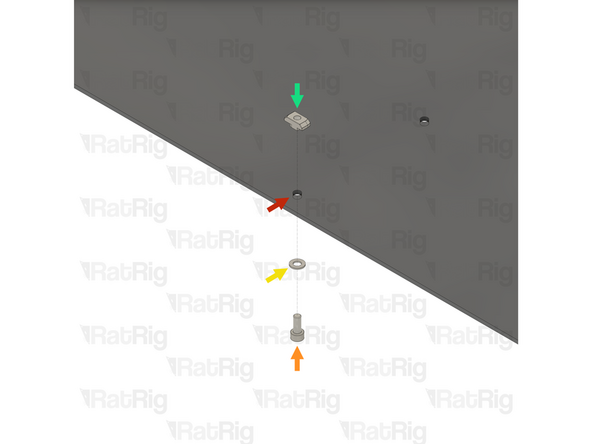

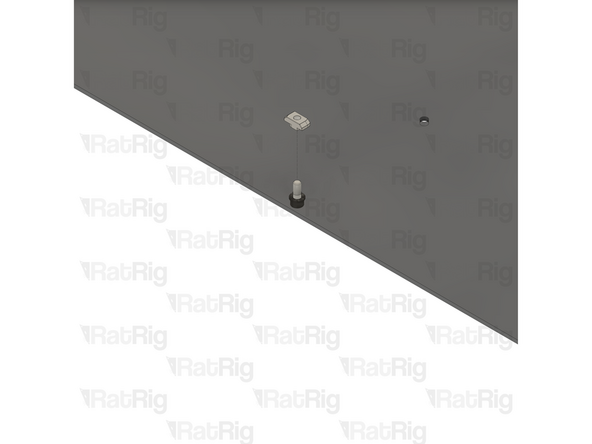

1x panel_enclosure_mill_base panel

-

1x M5x12 cap head screw

-

1x M5 washer

-

1x T-nut drop-in for 3030 - M5

-

Loosely thread the 3030 T-nuts onto the M5x12 screws. Do not tighten them at this point

-

-

-

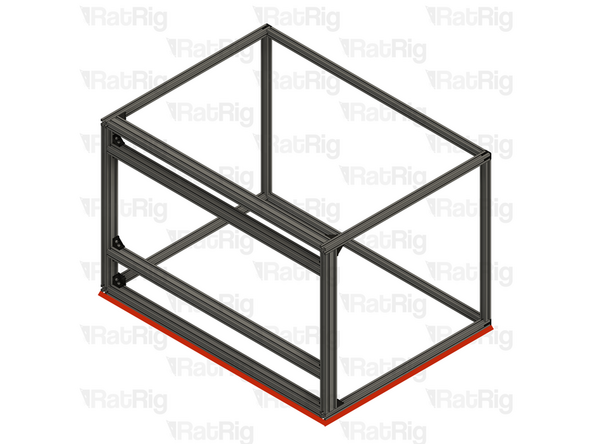

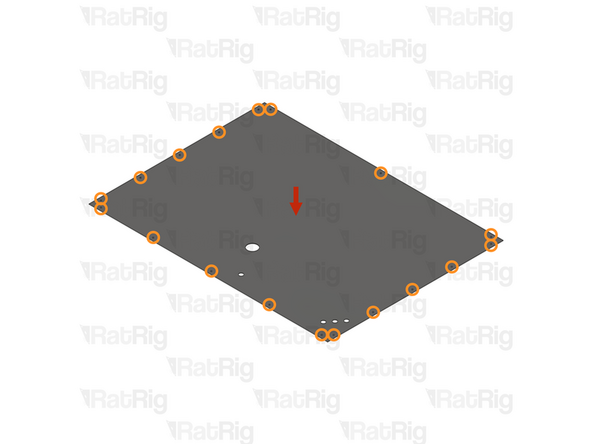

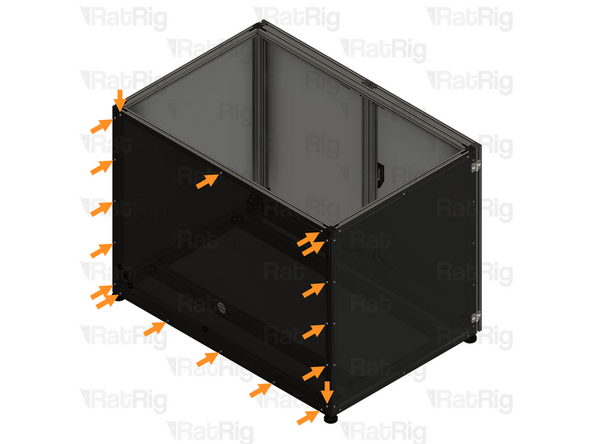

It is strongly recommended to have a second person assist with manipulating the frame in this step

-

The enclosure is large and heavy and can cause injury if it were to fall

-

Rotate the enclosure frame assembly so that it lays on its back as shown

-

1x Base panel assembly from the previous step

-

Align the panel assembly to the frame as shown

-

Secure the panel in place by fastening the eighteen M5x12 screws

-

-

-

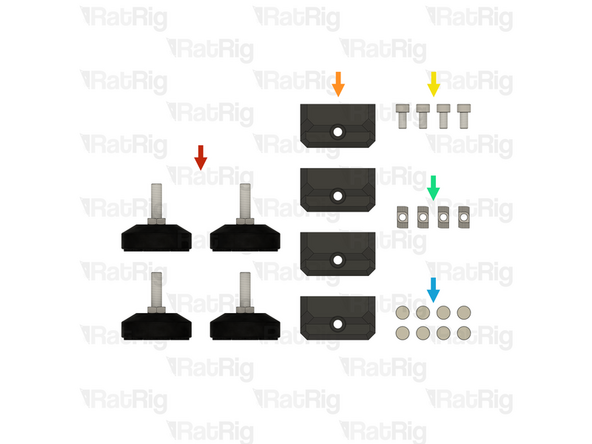

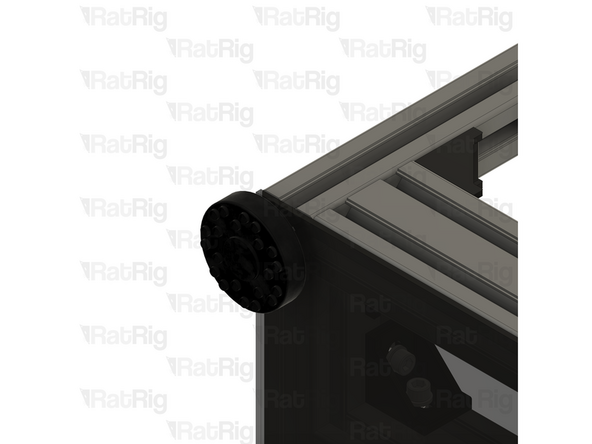

4x Leveling feet for 3030 - M8x30mm (Non-slip)

-

4x cnc_enclosure_magnet_frame_3030 printed part

-

4x M6x12 cap head screw

-

4x T-nut drop-in for 3030 - M6

-

8x Magnet - Neodymium disc - 10x4mm

-

-

-

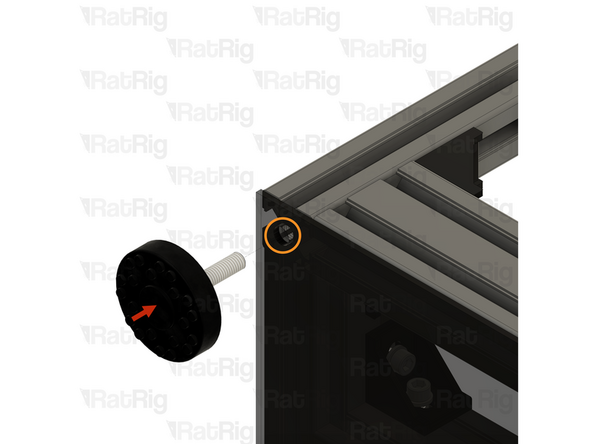

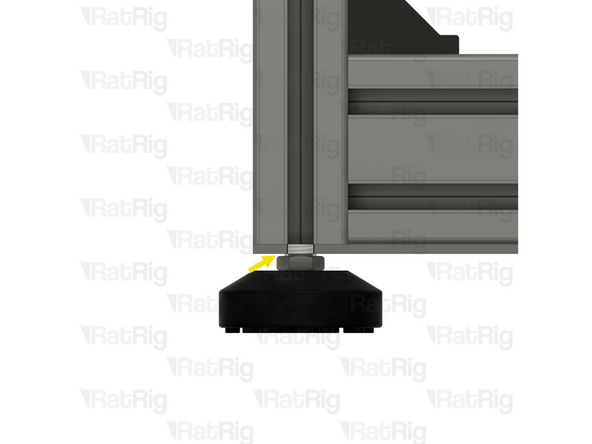

1x Leveling feet for 3030 - M8x30mm (Non-slip)

-

Install the foot by screwing the threaded section in to the tapped extrusion through the base panel as shown

-

Tighten the foot until the hex section nearly touches the panel

-

-

-

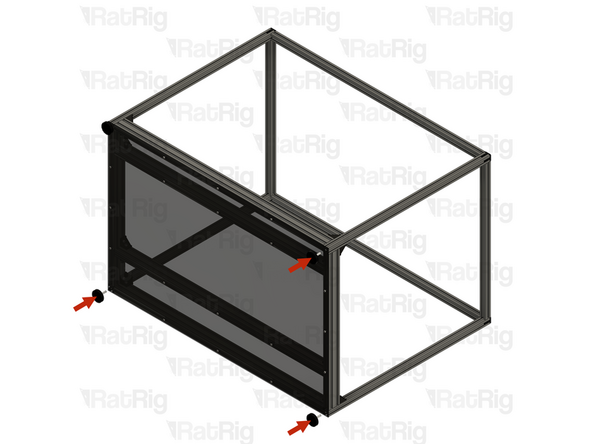

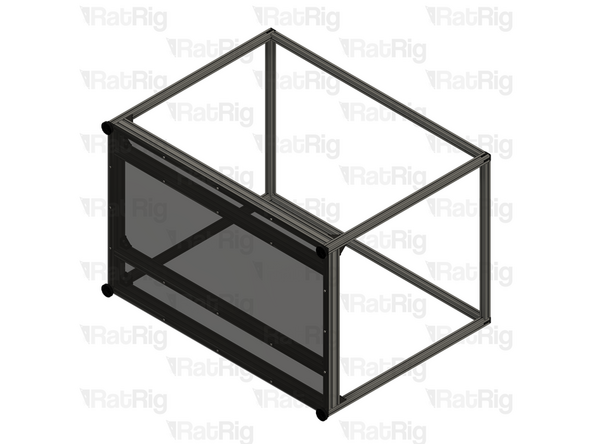

3x Leveling feet for 3030 - M8x30mm (Non-slip)

-

Install the remaining three feet into the frame assembly as shown

-

-

-

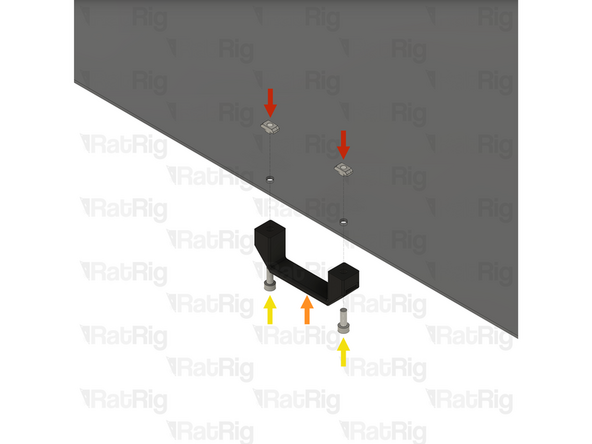

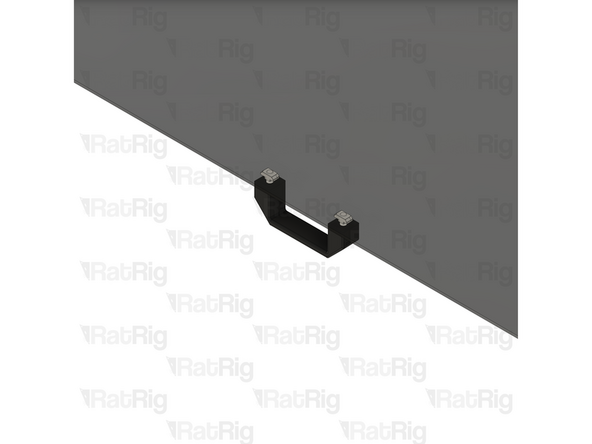

1x cnc_enclosure_magnet_frame_3030 printed part

-

2x Magnet - Neodymium disc - 10x4mm

-

Tip: Use a drop of super glue to prevent the magnets from coming loose over time

-

1x M6x12 cap head screw

-

1x T-nut drop-in for 3030 - M6

-

Loosely thread the 3030 T-nut onto the M6x12 screw. Do not tighten it at this point

-

-

-

4x 856mm 3030 extrusion

-

2x 521mm 3060 extrusion

-

2x 521mm 3030 extrusion

-

8x 3030 cast 90 degree corner assembly

-

-

-

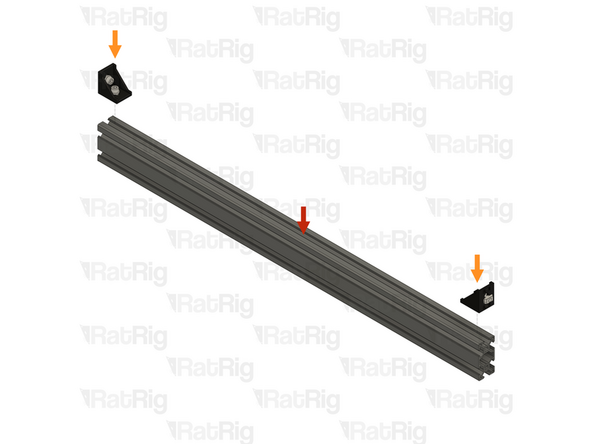

1x 521mm 3060 extrusion

-

2x 3030 cast 90 degree corner assemblies

-

Install one corner assembly onto each end of the 521mm 3060 extrusions as shown. Tighten the M6x12 screw to secure them

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

Set these assemblies aside until Step 31

-

-

-

1x 521mm 3030 extrusion

-

2x 3030 cast 90 degree corner assemblies

-

Install one corner assembly onto each end of the 521mm 3030 extrusions as shown. Tighten the M6x12 screw to secure them

-

Ensure the corner assemblies are flush and square with the ends of the extrusions after tightening the screws

-

-

-

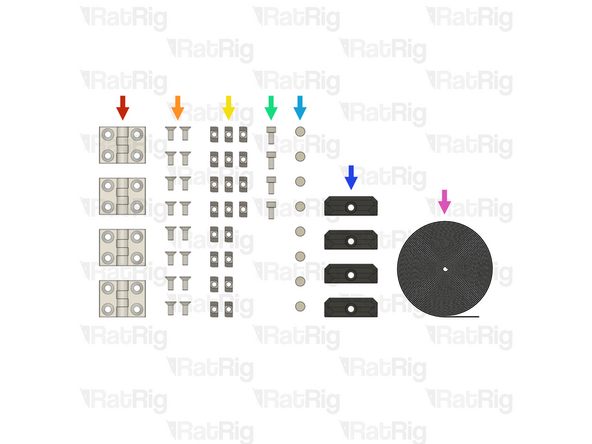

4x Hinge - metallic anodized for 3030

-

16x M6x14 countersink screw

-

20x T-nut drop-in for 3030 - M6

-

4x M6x12 cap head screw

-

8x Magnet - Neodymium disc - 10x4mm

-

4x V-Core 4 frame magnet holder - nylon

-

5.5M x Foam strip - 1x8mm - adhesive

-

-

-

-

1x V-Core 4 frame magnet holder - nylon

-

2x Magnet - Neodymium disc - 10x4mm

-

It is important to make sure the polarity of the magnets are correct. Use the assemblies from Step 27 to make sure the magnets do not repel each other

-

Tip: Use a drop of super glue to prevent the magnets from coming loose over time

-

1x M6x12 cap head screw

-

1x T-nut drop-in for 3030 - M6

-

Loosely thread the 3030 T-nut onto the M6x12 screw. Do not tighten it at this point

-

-

-

-

-

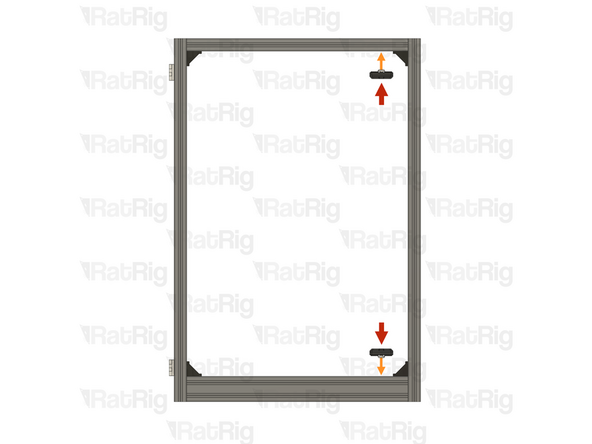

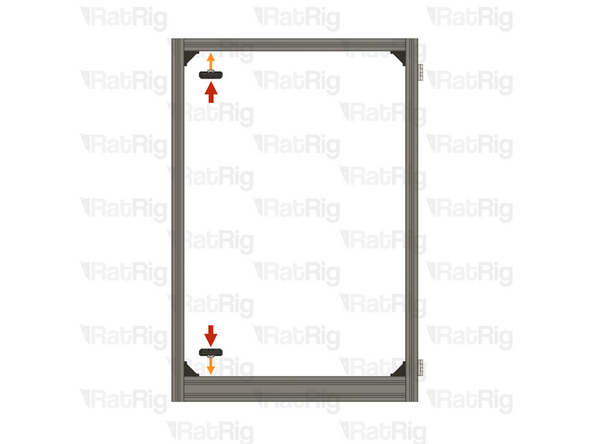

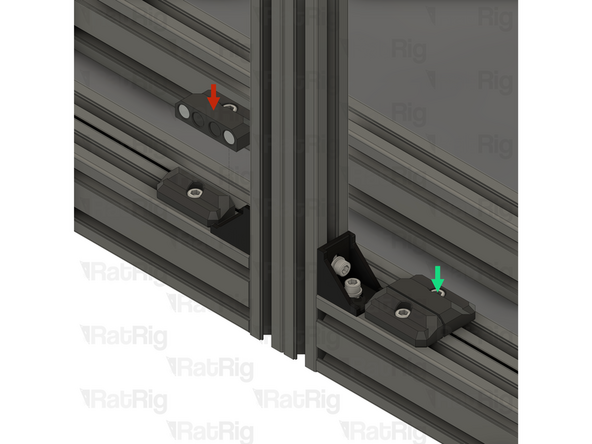

2x Door magnetic latch assembly from Step 34

-

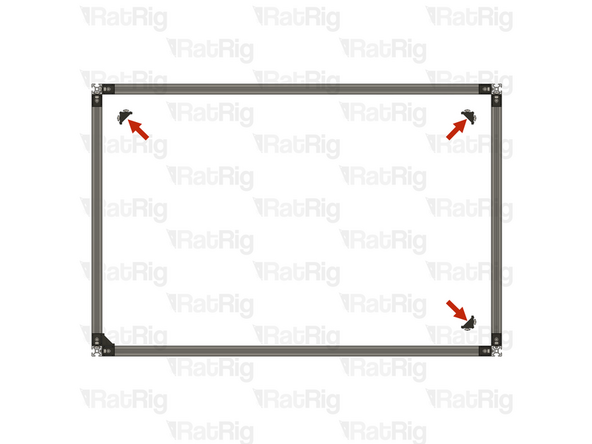

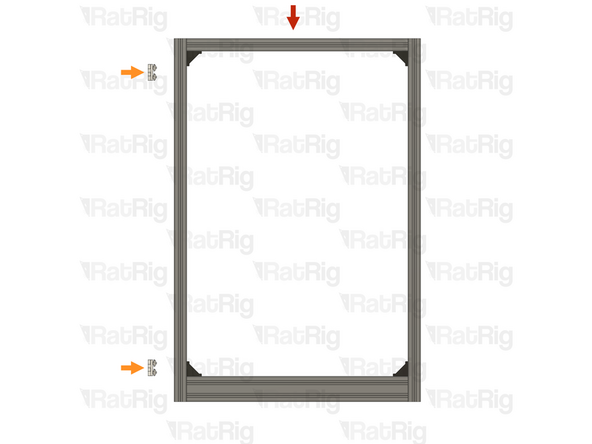

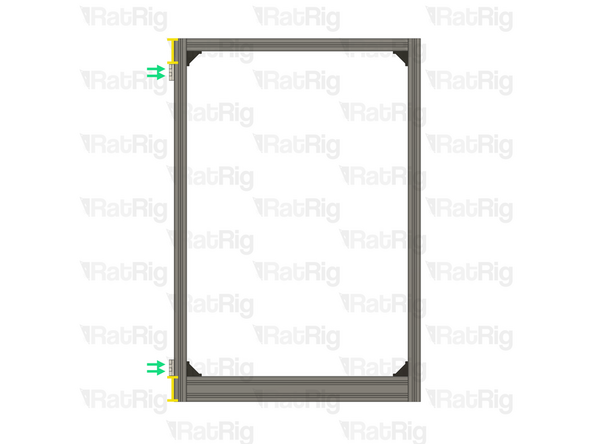

Position the magnetic latch assemblies onto the upper and lower extrusions as shown. They should touch the 3030 cast 90 degree corners

-

Tighten the M6x12 marked screws to secure the magnetic latches to the door

-

Take care not to over-tighten the M6x12 screws as you can damage the nylon part

-

Set this assembly aside until Step 40

-

-

-

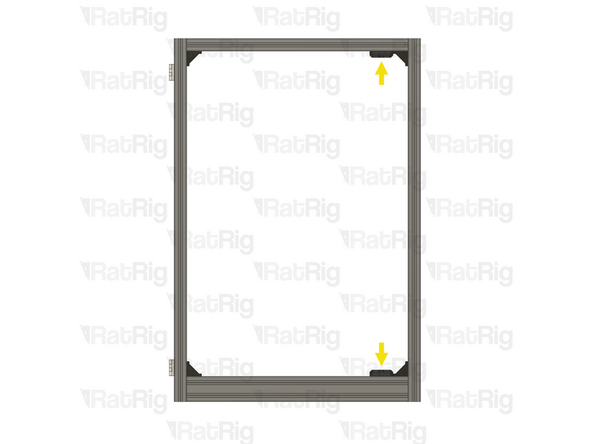

-

2x Door magnetic latch assembly from Step 34

-

Position the magnetic latch assemblies onto the upper and lower extrusions as shown. They should touch the 3030 cast 90 degree corners

-

Tighten the M6x12 marked screws to secure the magnetic latches to the door

-

Take care not to over-tighten the M6x12 screws as you can damage the nylon part

-

Set this assembly aside until Step 41

-

-

-

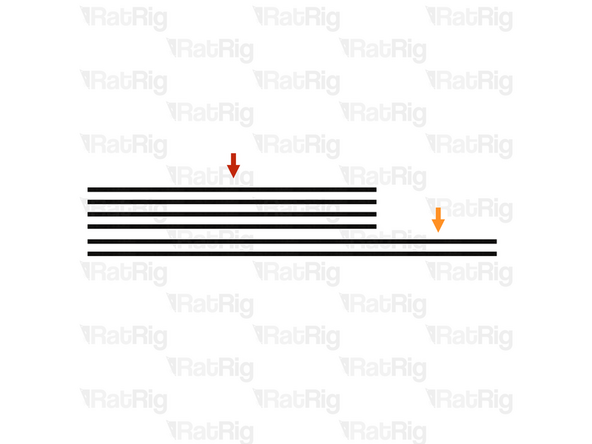

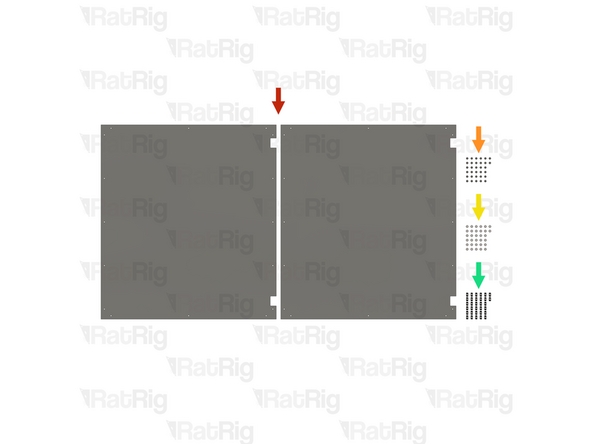

The 5.5 metres of foam strip needs to be cut into the following lengths:

-

4x 540mm lengths

-

2x 765mm lengths

-

The foam strip can easily be cut with regular scissors

-

Do not remove the backing from the foam strip lengths yet

-

-

-

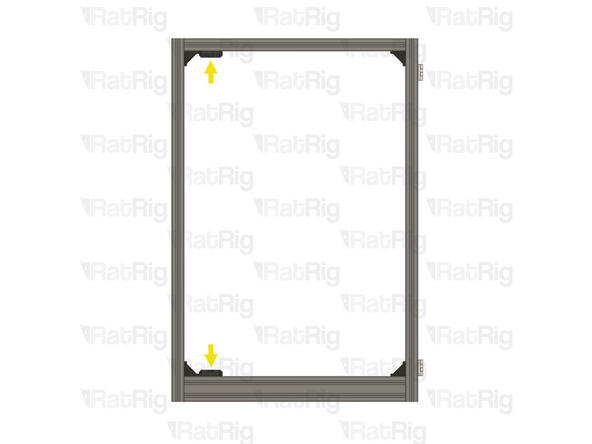

1x Left door assembly from Step 36

-

Orient the door assembly as shown. The foam strip must be installed on the inside of the door

-

1x 765mm length of foam strip

-

2x 540mm length of foam strip

-

The foam strip has a protective backing which covers the adhesive. Peel the backing off each strip and apply them to the door assembly as shown

-

-

-

1x Right door assembly from Step 38

-

Orient the door assembly as shown. The foam strip must be installed on the inside of the door

-

1x 765mm length of foam strip

-

2x 540mm length of foam strip

-

The foam strip has a protective backing which covers the adhesive. Peel the backing off each strip and apply them to the door assembly as shown

-

-

-

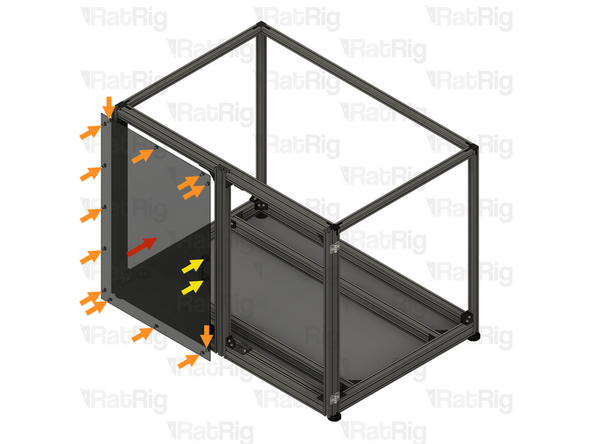

1x Enclosure assembly from Step 26

-

1x Left door assembly from Step 40

-

Place the left door assembly onto the enclosure as shown

-

Align the door assembly as shown, making sure the top of the door is level with the top of the enclosure

-

Tighten the four marked M6x14 countersink screws to fix the door assembly to the enclosure

-

-

-

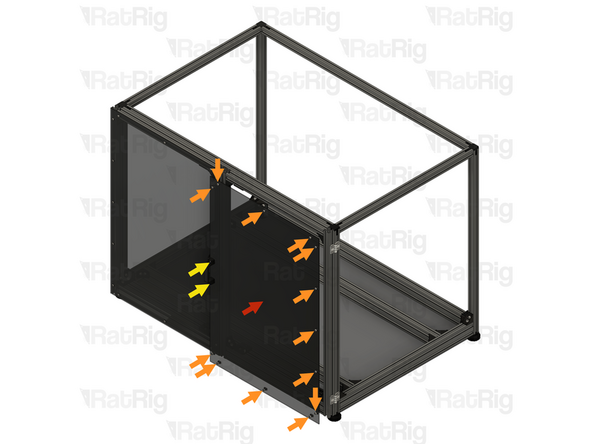

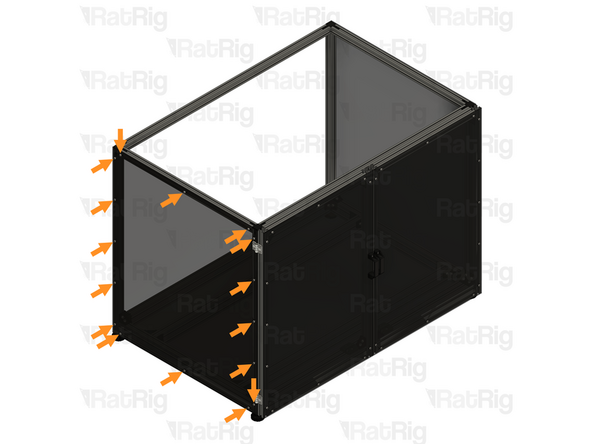

1x Enclosure assembly

-

1x Right door assembly from Step 42

-

Place the right door assembly onto the enclosure as shown

-

Align the door assembly as shown, making sure the top of the door is level with the top of the enclosure

-

Tighten the four marked M6x14 countersink screws to fix the door assembly to the enclosure

-

-

-

It is strongly recommended to have a second person assist with manipulating the frame in this step

-

The enclosure is large and heavy and can cause injury if it were to fall

-

Be careful as the doors can swing freely at this stage

-

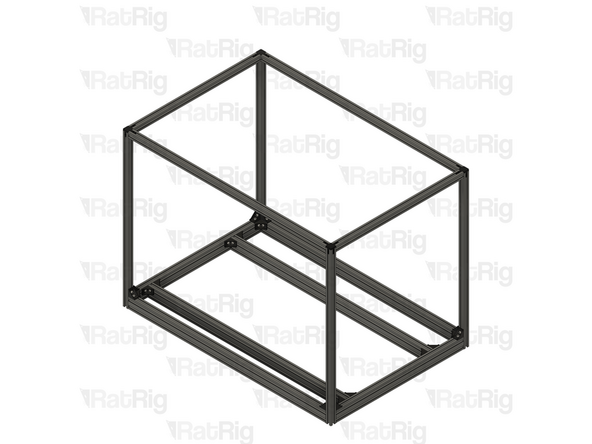

Rotate the enclosure frame assembly so that it stands on its feet as shown

-

-

-

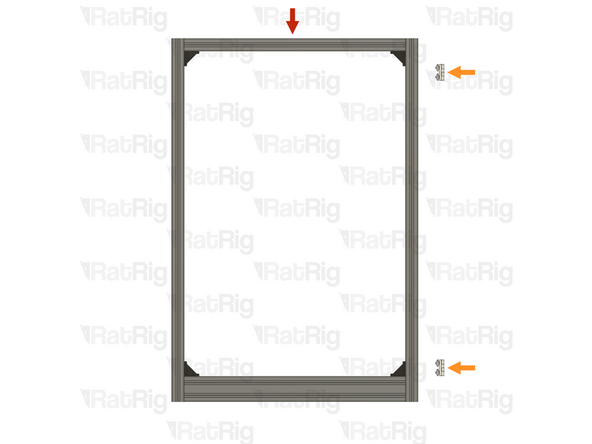

2x Frame magnetic latch assemblies from Step 27

-

Left door

-

Right door

-

Position the magnetic latch assemblies onto the enclosure assembly as shown, the magnets should help align them

-

Tighten the M6x12 marked screws to secure the magnetic latches to the enclosure

-

-

-

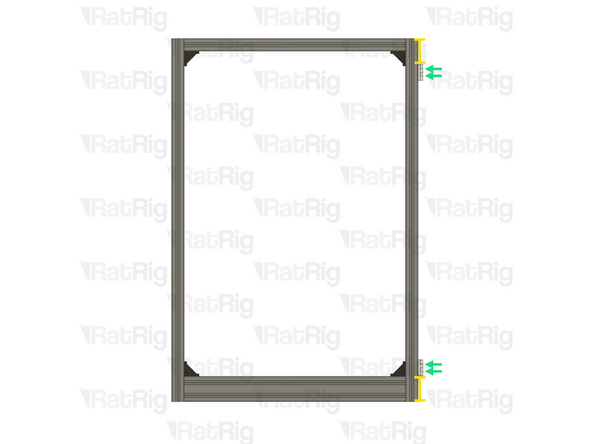

2x Frame magnetic latch assemblies from Step 27

-

Left door

-

Right door

-

Position the magnetic latch assemblies onto the enclosure assembly as shown, the magnets should help align them

-

Tighten the M6x12 marked screws to secure the magnetic latches to the enclosure

-

-

-

Test that both doors open and close without binding, and that the magnetic latches hold the doors closed

-

If the doors bind, make minor adjustments to the hinge positions until the doors move smoothly

-

If the magnetic latches do not hold the doors closed, adjust the position of the magnetic latches and check no magnets are repelling

-

-

-

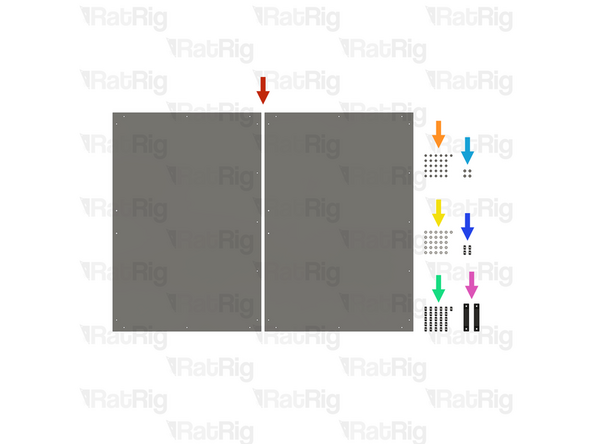

2x panel_enclosure_mill_door panel

-

26x M5x12 cap head screw

-

26x M5 washer

-

26x T-nut drop-in for 3030 - M5

-

4x M6x16 cap head screw

-

4x T-nut drop-in for 3030 - M6

-

2x V-slot door handle

-

-

-

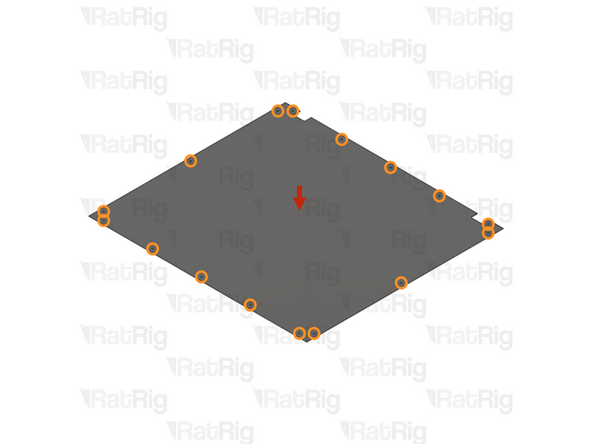

1x panel_enclosure_mill_door panel

-

For each of the 13x marked holes, install the mounting hardware as shown in Step 22

-

Loosely thread the 3030 T-nuts onto the M5x12 screws. Do not tighten them at this point

-

The door panels are identical for left and right, assemble both the same

-

-

-

2x T-nut drop-in for 3030 - M6

-

1x V-slot door handle

-

2x M6x16 cap head screw

-

Loosely thread the 3030 T-nuts onto the M6x16 screws. Do not tighten them at this point

-

The door panels are identical for left and right, assemble both the same

-

-

-

2x Door panel assembly from the previous step

-

Align the panel assembly to the door as shown

-

Secure the panel in place by fastening the thirteen M5x12 screws

-

Tighten the two M6x16 screws in the handle

-

-

-

2x panel_enclosure_mill_side panel

-

32x M5x12 cap head screw

-

32x M5 washer

-

32x T-nut drop-in for 3030 - M5

-

-

-

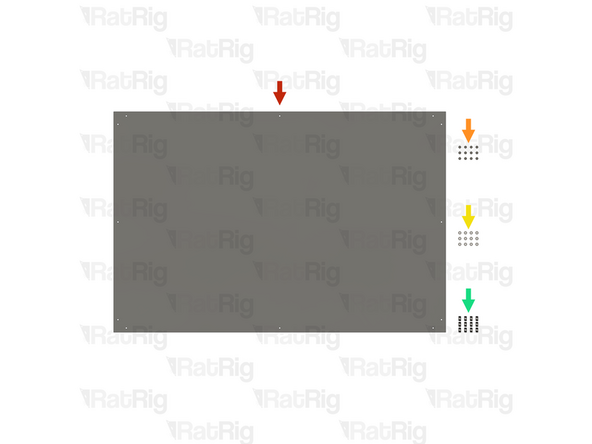

1x panel_enclosure_mill_side panel

-

For each of the sixteen marked holes, install the mounting hardware as shown in Step 22

-

Loosely thread the 3030 T-nuts onto the M5x12 screws. Do not tighten them at this point

-

The side panels are identical for left and right, assemble both the same

-

-

-

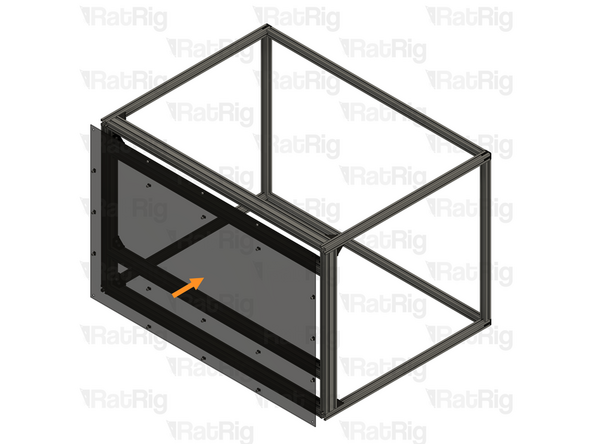

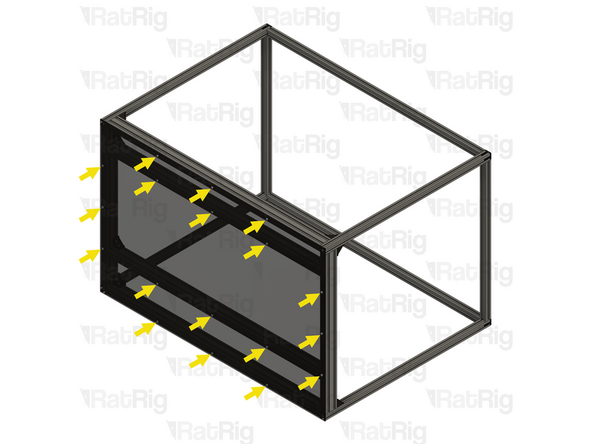

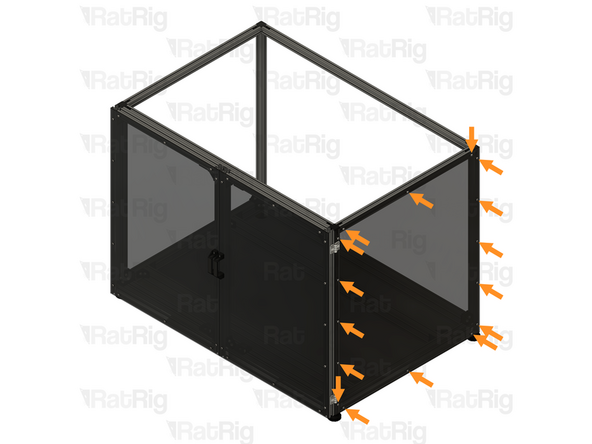

2x Side panel assembly from the previous step

-

Align the panel assembly to the enclosure as shown

-

Secure the panel in place by fastening the sixteen M5x12 screws

-

Repeat for the second side panel assembly

-

-

-

1x panel_enclosure_mill_back panel

-

18x M5x12 cap head screw

-

18x M5 washer

-

18x T-nut drop-in for 3030 - M5

-

4x Grommet - 18x14x7mm

-

-

-

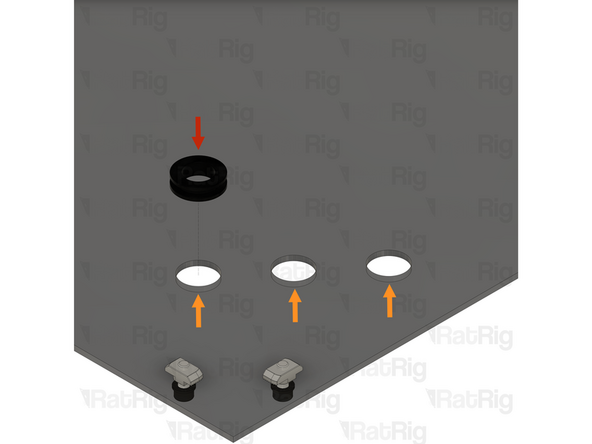

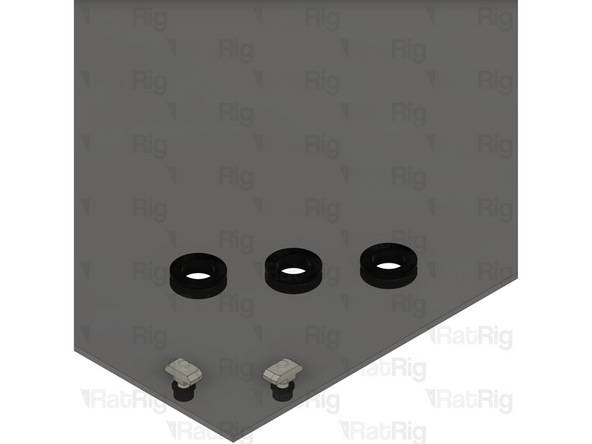

1x panel_enclosure_mill_back panel

-

For each of the eighteen marked holes, install the mounting hardware as shown in Step 22

-

Loosely thread the 3030 T-nuts onto the M5x12 screws. Do not tighten them at this point

-

-

-

4x Grommet - 18x14x7mm

-

Install a grommet into each of the four marked holes

-

-

-

1x Back panel assembly from the previous step

-

Align the panel assembly to the enclosure as shown

-

Secure the panel in place by fastening the eighteen M5x12 screws

-

-

-

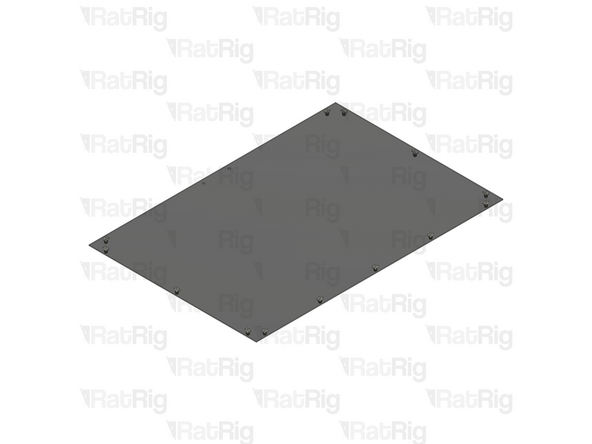

1x panel_enclosure_mill_lid panel

-

12x M5x12 cap head screw

-

12x M5 washer

-

12x T-nut drop-in for 3030 - M5

-

-

-

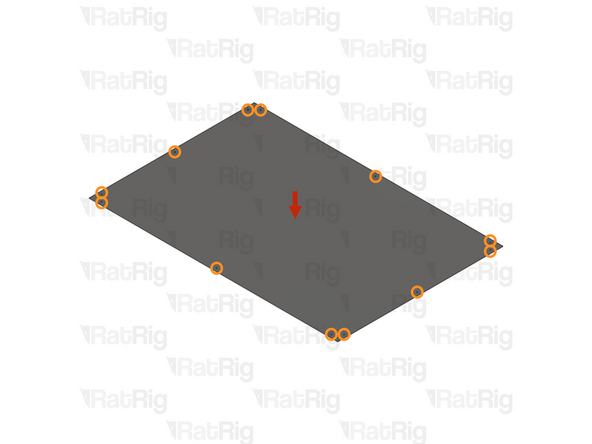

1x panel_enclosure_mill_lid panel

-

For each of the twelve marked holes, install the mounting hardware as shown in Step 22

-

Loosely thread the 3030 T-nuts onto the M5x12 screws. Do not tighten them at this point

-

-

-

1x Lid panel assembly from the previous step

-

Align the panel assembly to the enclosure as shown

-

Secure the panel in place by fastening the twelve M5x12 screws

-

-

-

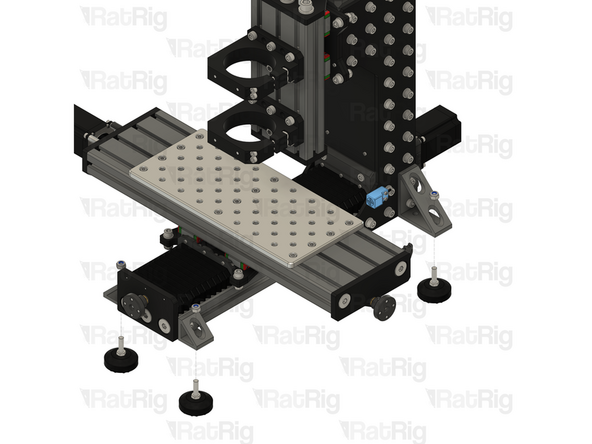

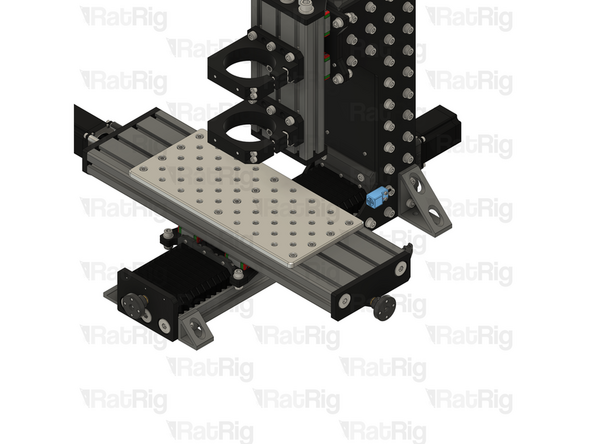

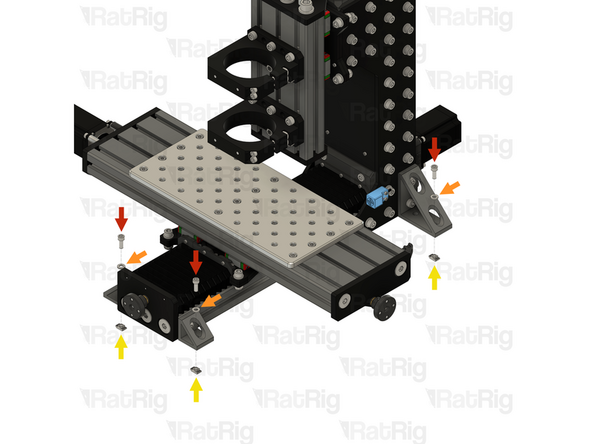

1x Rat Rig Mill assembly

-

4x M6x16 cap head screw

-

4x M6 washer

-

4x T-nut drop-in for 3030 - M6

-

-

-

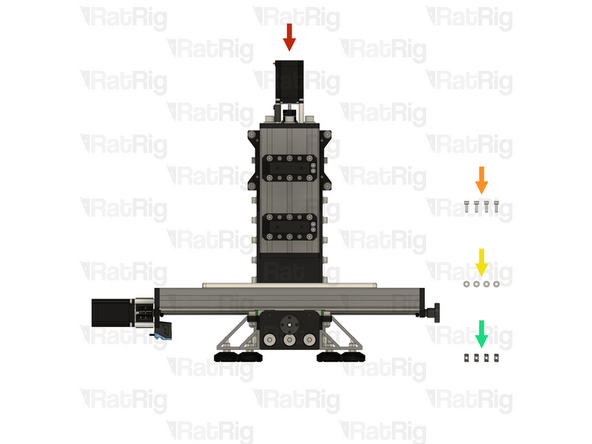

1x Rat Rig Mill assembly

-

4x Leveling feet for 3030 - M8x30mm (Non-slip)

-

4x M6 hex locking nut

-

Unscrew and remove all four levelling feet, and their locking hex nuts, from the Mill assembly

-

Store the feet and locking hex nuts so they can be used in the future if needed

-

-

-

4x M6x16 cap head screw

-

4x M6 washer

-

4x T-nut drop-in for 3030 - M6

-

Loosely thread the 3030 T-nuts onto the M6x16 screws. Do not tighten them at this point

-

-

-

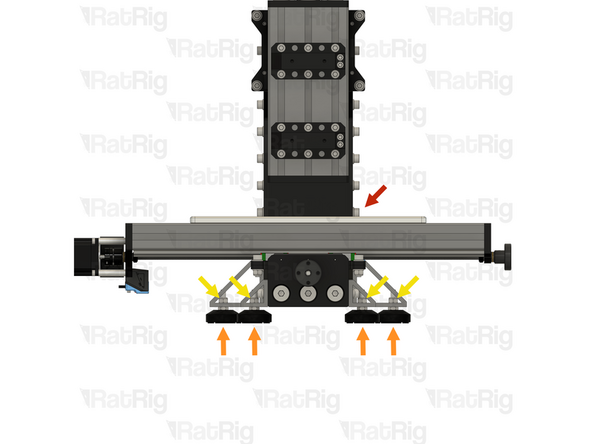

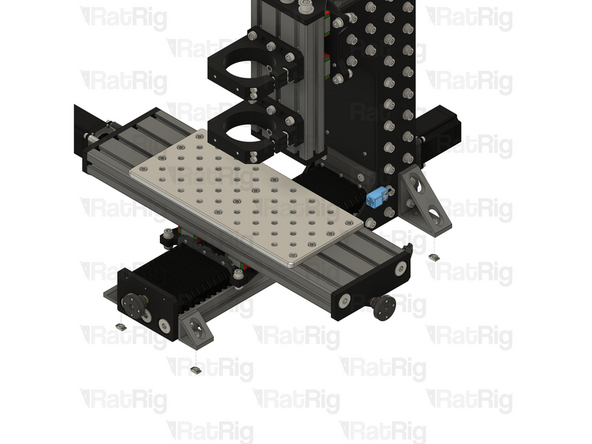

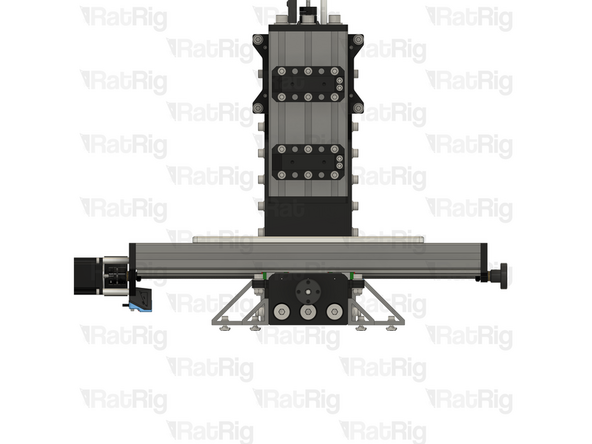

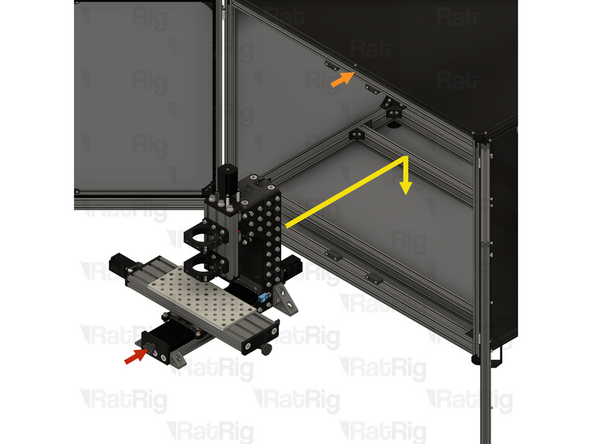

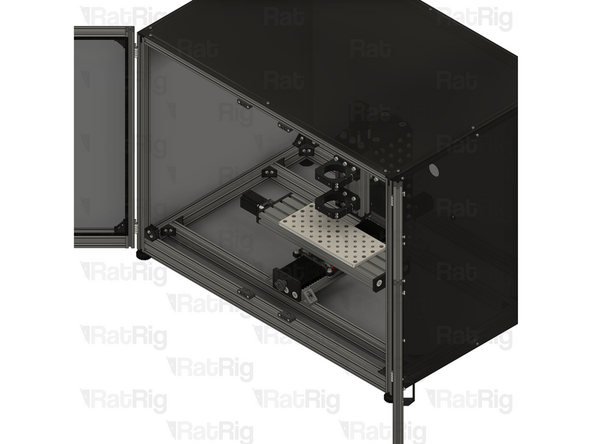

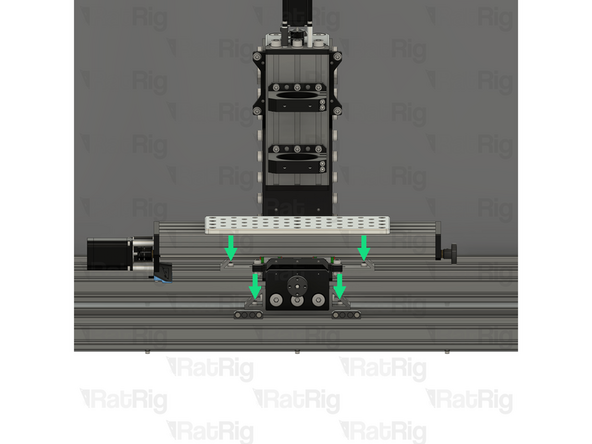

1x Rat Rig Mill assembly

-

1x Enclosure Assembly

-

Carefully lift the Mill into the enclosure. Align the brackets with the horizontal 3060 extrusions making sure the T-nuts drop into the extrusion slot

-

4x M6x16 cap head screw

-

Fully tighten the M6x16 screws to secure the Rat Rig Mill to the enclosure

-