Introduction

Please note: All measurements provided in this guide are based on building a 300x300 V-Core 4.

If you are building a machine of a different size, the following adjustments can be made to the stated extrusion and linear rail lengths:

- 400x400: Add 100mm

- 500x500: Add 200mm

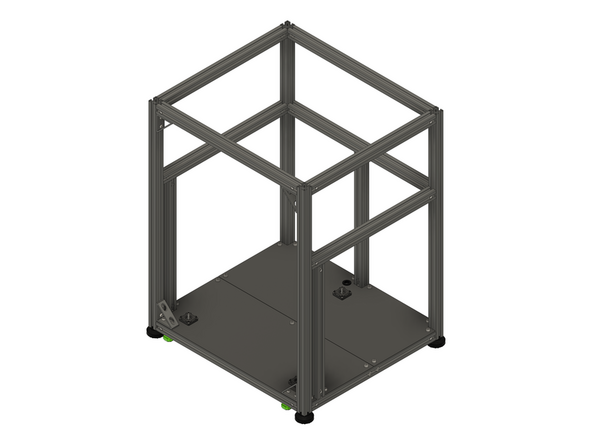

It is strongly recommended to assemble the frame on a known flat surface (such as a solid table, work surface or similar). Assembling the frame on a carpeted floor, tile floor or other non-flat surface can cause the finished frame to not be square. This can cause issues with print quality and performance.

-

-

The following tools are required for this section of the guide:

-

Allen key / hex wrenches in the following sizes: 4mm & 5mm

-

Avoid using ball end hex wrenches on the Quick Connectors as they are more prone to damaging the heads of the Set Screws

-

Spanners / wrenches in the following size: 13mm

-

A pair of scissors

-

The following tools are recommended for this guide:

-

A tape measure

-

An engineer square

-

-

-

The following steps show how the aluminium extrusion quick connectors are prepared and installed. The V-Core 4.0 frame assembly begins on step 7

-

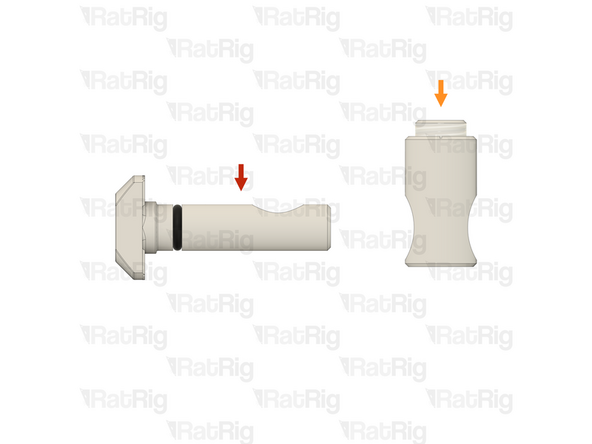

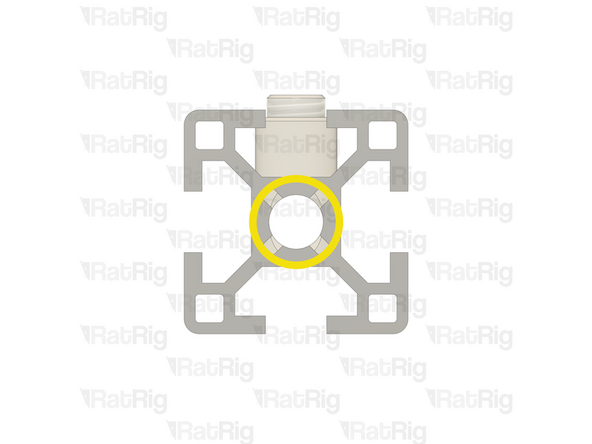

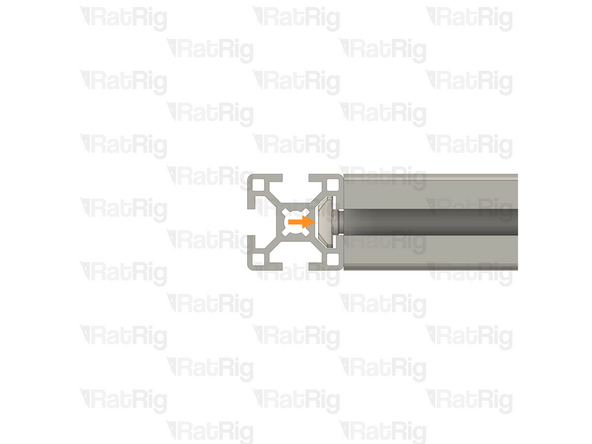

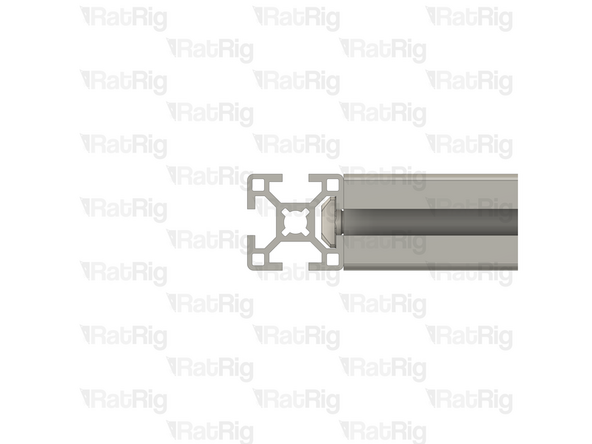

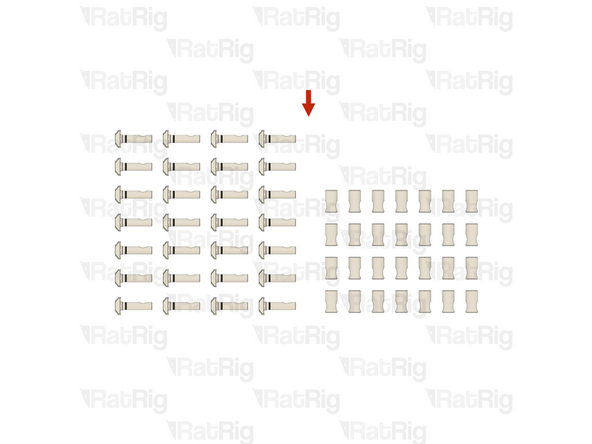

The Quick Connectors are supplied in two parts:

-

Quick Connector T-Nut Pin with the O-Ring pre-installed

-

Quick Connector Housing with the Set Screw pre-installed

-

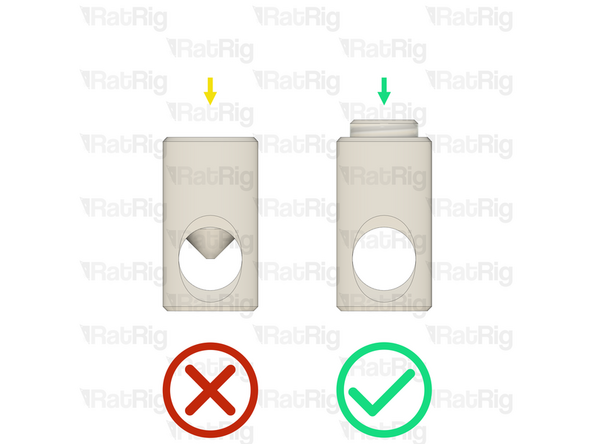

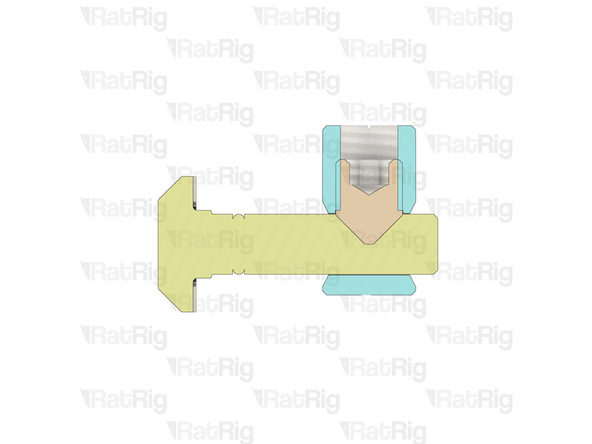

Before trying to install a Quick Connector Housing into an extrusion, check that the Set Screw is not blocking the hole in the Quick Connector Housing

-

If the Set Screw is blocking the hole in the Quick Connector Housing, slightly unscrew it to achieve the necessary clearance

-

-

-

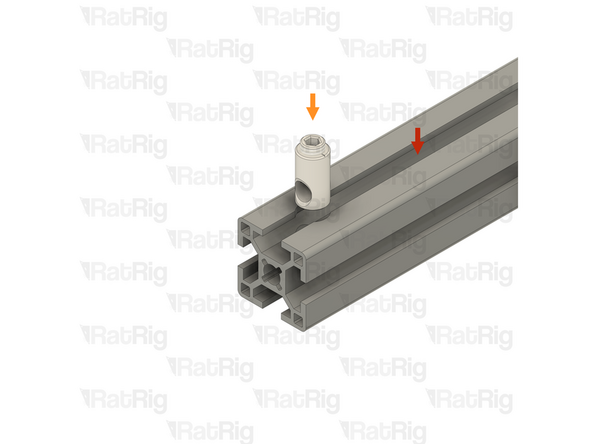

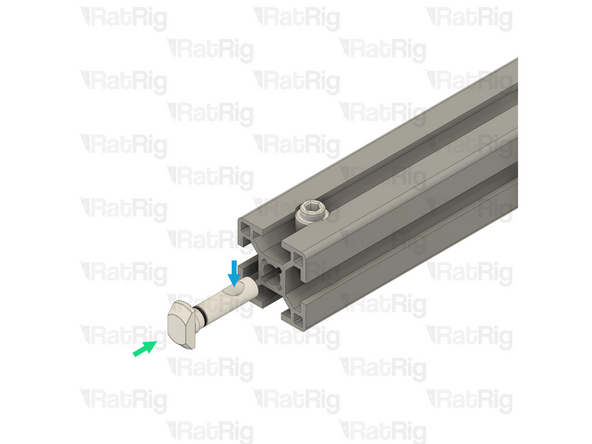

Example extrusion

-

Quick Connector Housing

-

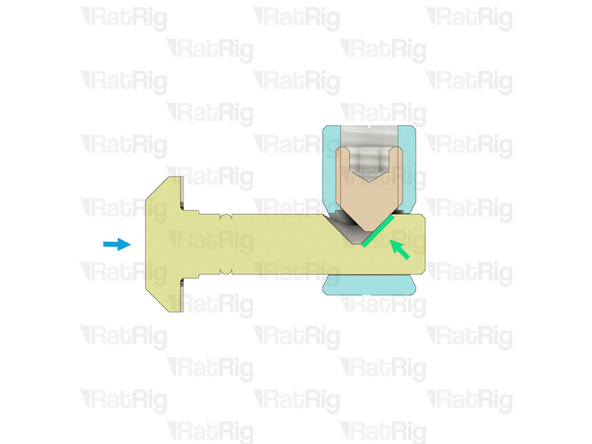

Insert the Quick Connector Housing into the hole on the aluminium extrusion

-

Please note: If the Quick Connector Housing is difficult to insert into the aluminium extrusion, try inserting it from the opposite side

-

Make sure that the Quick Connector Housings all face the same direction

-

Make sure that the hole in the Quick Connector Housing is aligned with the central hole on the aluminium extrusion as shown

-

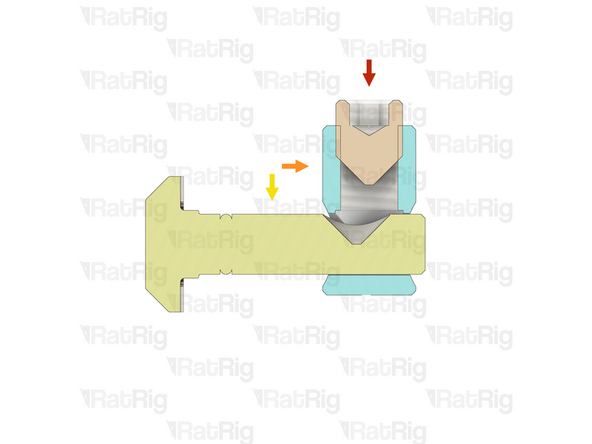

Insert the Quick Connector T-Nut pin into the central hole on the extrusion slot

-

Make sure the "notch" in the pin is facing towards the Set Screw

-

-

-

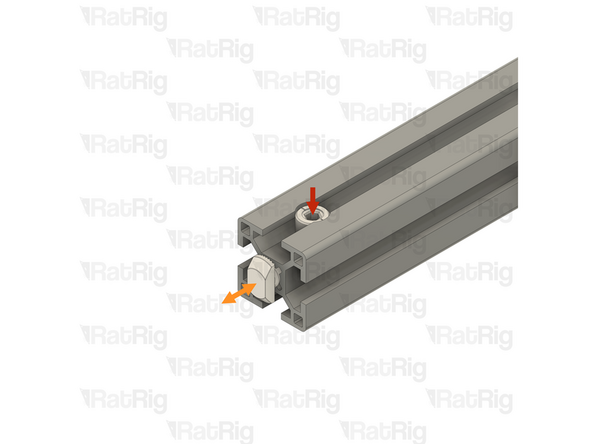

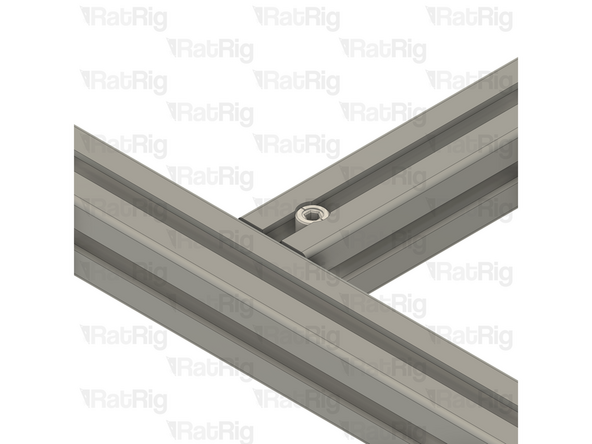

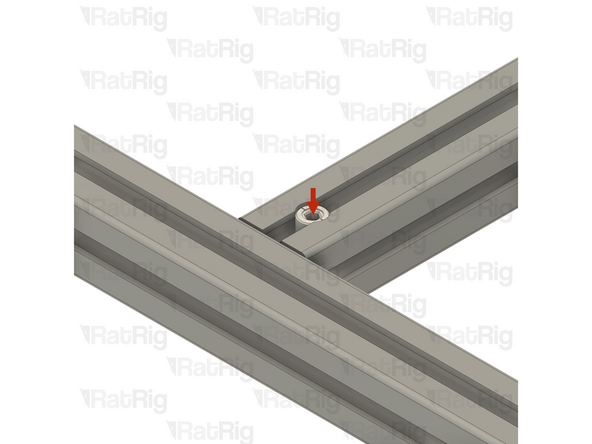

Quick Connector Set Screw

-

Using a 4mm hex key, tighten the Set Screw just enough to hold the Quick Connector T-Nut Pin inside the extrusion

-

If correctly tightened, the Quick Connector T-Nut Pin should still move slightly backwards and forwards, but should not come loose

-

Slide the second aluminium extrusion into position, aligning the Quick Connector T-Nut Pin into the slot of the second aluminium extrusion

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

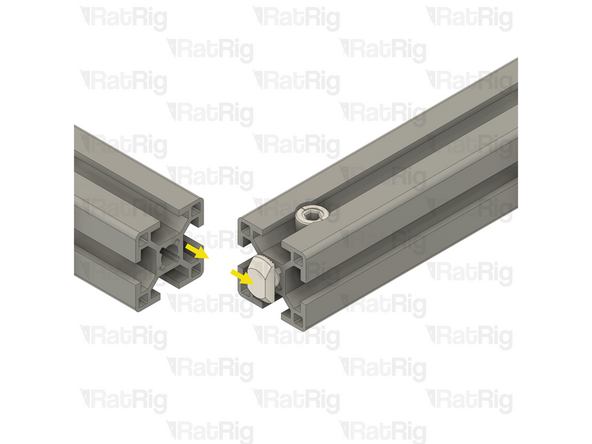

Quick Connector Housing Set Screw

-

Fully tighten the Set Screw to secure the extrusions together

-

The Set Screw will cause the Quick Connector T-Nut Pin to pull tight against the second extrusion, securing them together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

Set Screw

-

Quick Connector Housing

-

Quick Connector T-Nut Pin

-

The Set Screw within the Quick Connector Housing engages with the "notch" in the Quick Connector T-Nut Pin

-

As the Set Screw is fastened, the T-Nut Pin is pulled inwards, causing the extrusions to lock together

-

-

-

As mentioned in the introduction, all extrusion and linear rail measurements in this guide are given based on a V-Core 4.0 in the 300 size

-

If you are building a machine of a different size, the following adjustments can be made to the stated extrusion and linear rail lengths:

-

V-Core 4.0 - 400: Add 100mm to all measurements

-

V-Core 4.0 - 500: Add 200mm to all measurements

-

-

-

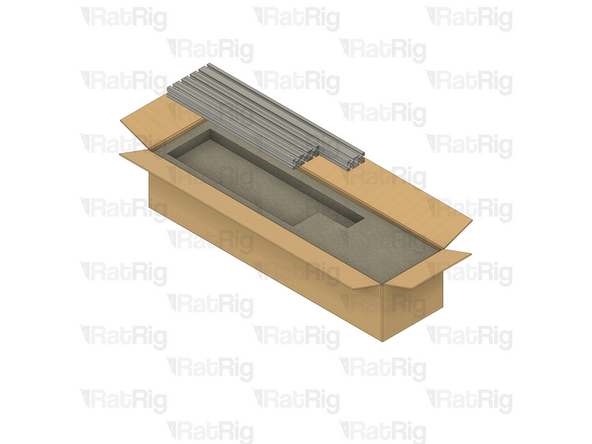

All of the extrusions for the V-Core 4.0 are provided packed in the same box. The SKU varies depending on the size being assembled:

-

V-Core 4.0 - 300: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 300 (SKU: HW3984MK)

-

V-Core 4.0 - 400: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 400 (SKU: HW3985MK)

-

V-Core 4.0 - 500: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 500 (SKU: HW3986MK)

-

Be careful when opening the package. Do not use a long blade to cut the box open as you can damage the extrusions

-

Unpack each layer carefully, placing the extrusions to the side for now

-

There are four layers of extrusions to unpack

-

The 2020 V-Slot extrusion will be used in a later guide. All others are used in the construction of the frame

-

-

-

If you are building a machine of a different size, add 100mm to all listed extrusion lengths for the V-Core 4.0 400 or 200mm for the V-Core 4.0 500

-

28x Quick Connector for 30 series B-Type - 0º (SKU: HW3347GC)

-

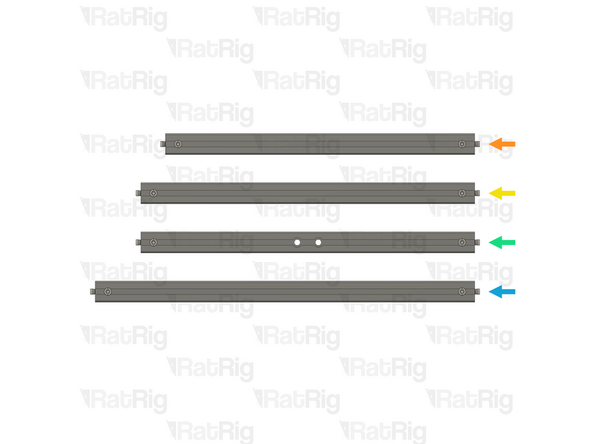

Install Quick Connectors into both ends of the following extrusions:

-

3x T-Slot 3030 Milled Extrusion - 440mm

-

4x T-Slot 3030 Milled Extrusion - 475mm

-

2x T-Slot 3030 Milled Extrusion - 475mm with two M8 holes

-

Make sure the Quick Connector Set Screws are facing the same side as the counterbores for the M8 screw holes

-

5x T-Slot 3030 Milled Extrusion - 540mm

-

-

-

If you are building a machine of a different size, add 100mm to all listed extrusion lengths for the V-Core 4.0 400 or 200mm for the V-Core 4.0 500

-

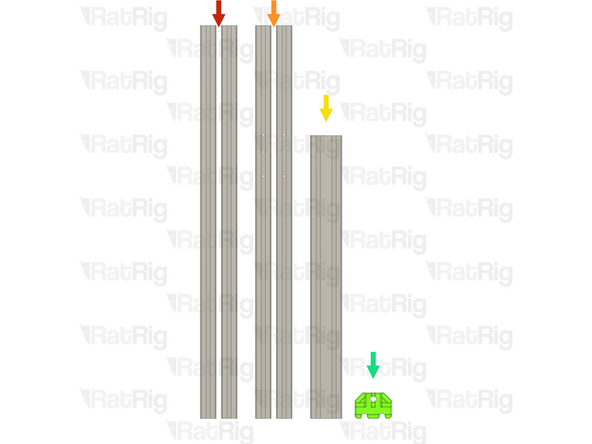

In addition to the extrusions prepared in the previous step, the following extrusions are needed to assemble th frame:

-

2x T-Slot 3030 Milled Extrusion - 750mm

-

2x T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

1x T-Slot 3060 Milled Extrusion - 540mm

-

1x vc4_frame_jig Printed Part (SKU: PP000279)

-

Please note: The V-Core 4 frame jig may be have been printed in green or black. The design is the same regardless of colour

-

-

-

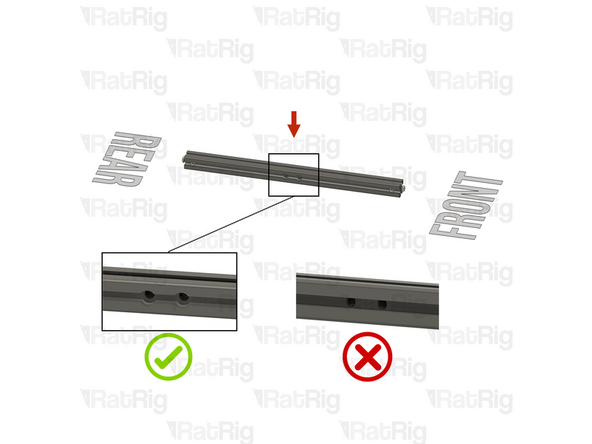

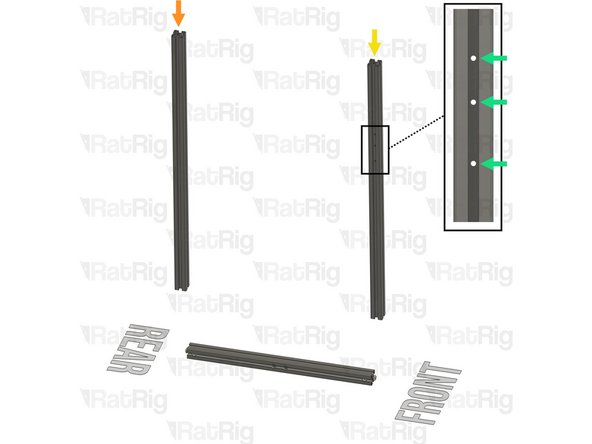

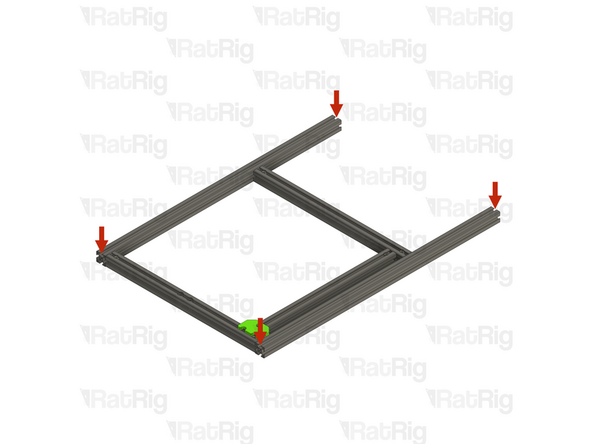

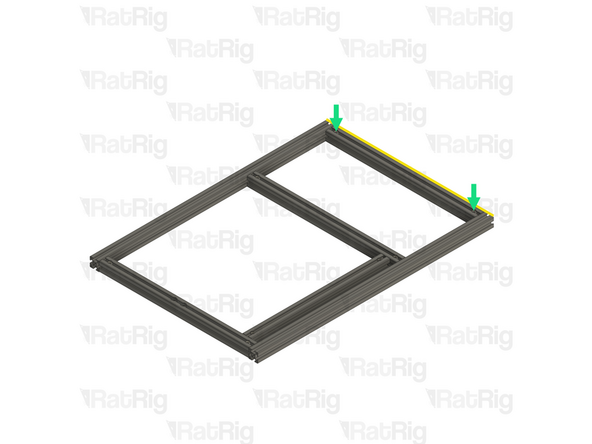

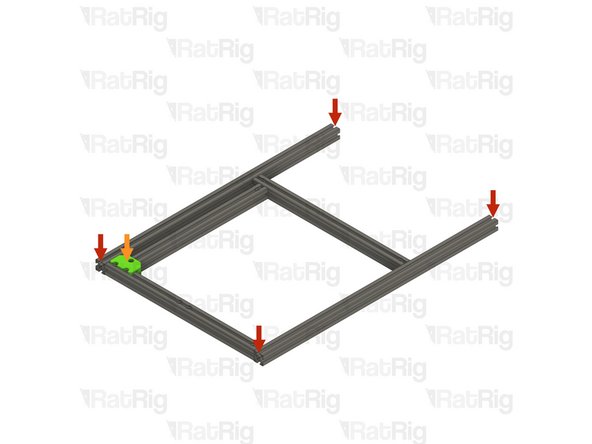

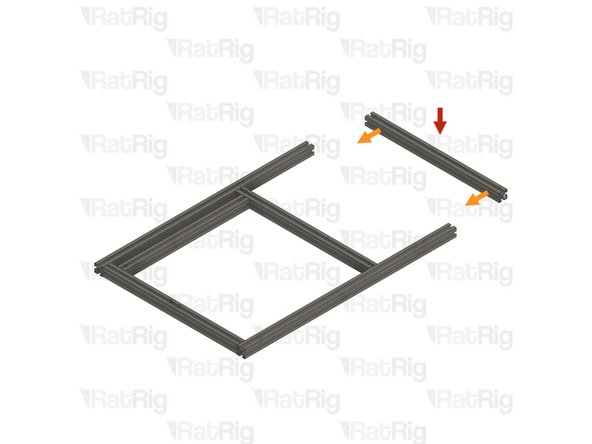

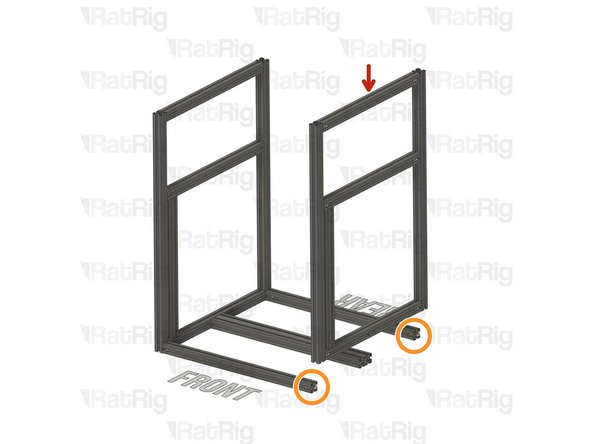

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors and two M8 holes from step 9

-

Make sure that the counterbores for the M8 holes are oriented as shown

-

T-Slot 3030 Milled Extrusion - 750mm

-

T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

Make sure this extrusion is installed as shown. It should be at the front, with the three M4 holes at the top and facing to the side

-

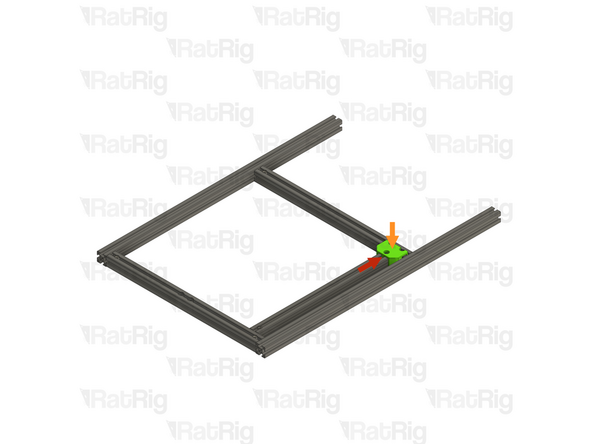

Assemble the extrusions as shown but do not fasten them together yet

-

Be careful when sliding the extrusions into position as you can scratch the black anodising

-

-

-

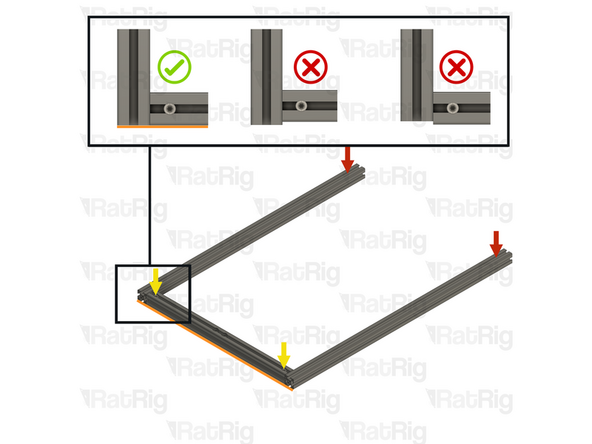

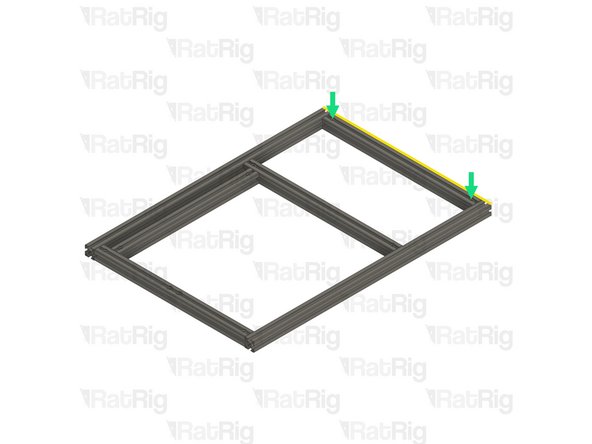

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Good surfaces: Poured self-levelled concrete, glass, or a stone countertop

-

Bad surfaces: Carpeted floor, a tile floor, or rough concrete

-

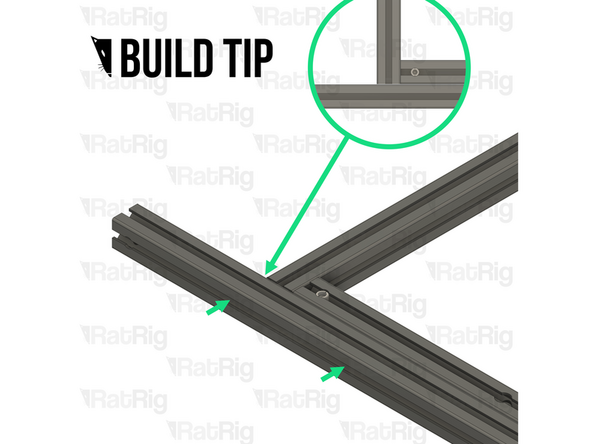

Align the extrusions as shown - making sure the ends are flush

-

Build Tip: You can use a spare 3030 extrusion or an Engineer Square to help align the assembly

-

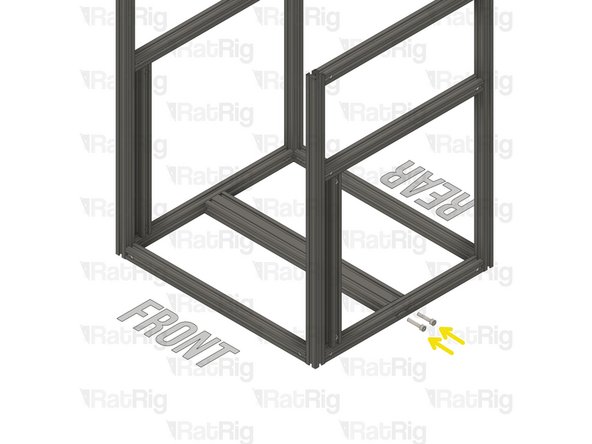

Fasten the Set Screws in both of the Quick Connectors to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

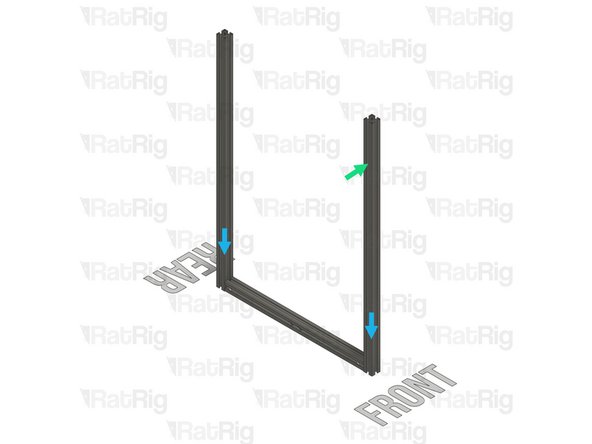

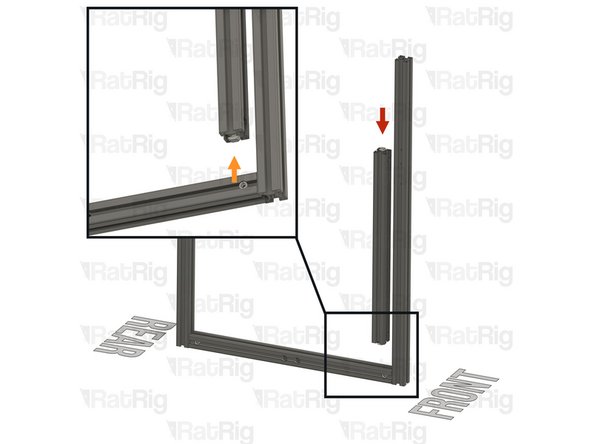

T-Slot 3030 Milled Extrusion - 440mm with Quick Connectors from step 9

-

Align the Quick Connector T-Nut Pin with the bottom extrusion slot

-

Insert the Quick Connector T-Nut Pin into the bottom extrusion slot

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

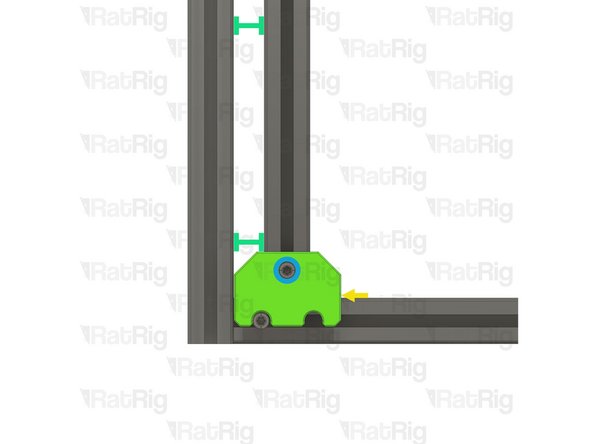

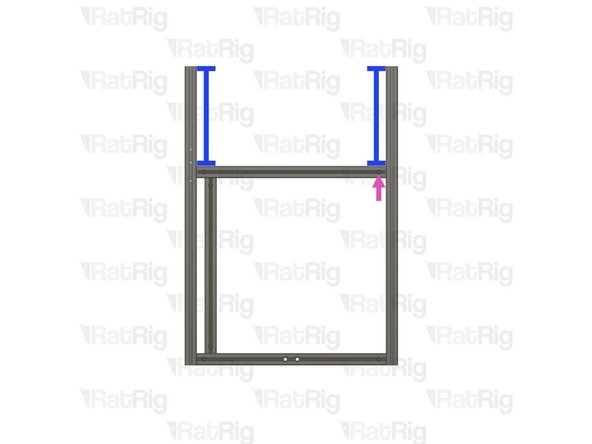

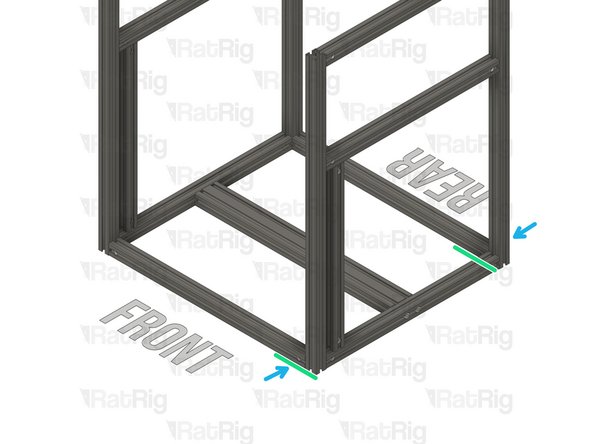

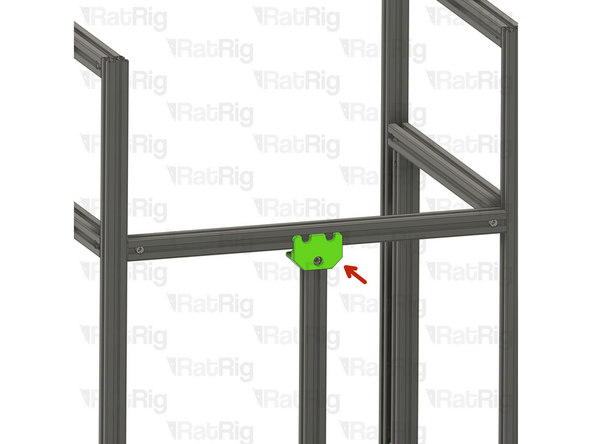

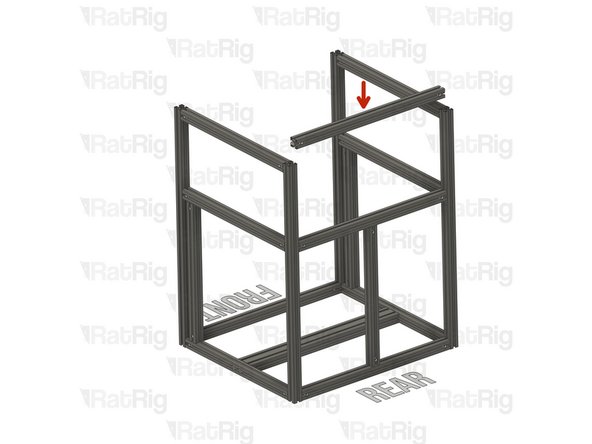

Slide the marked extrusion downwards, making sure the Quick Connector T-Nut Pin on the 440mm extrusion fits inside the extrusion slot

-

Carefully rotate the marked extrusion 90 degrees so that the Quick Connector Set Screws face outwards as shown

-

Look into the extrusion slots and make sure that both the upper and lower Quick Connector T-Nut Pins have rotated correctly

-

Be careful not to scratch the aluminium extrusions when assembling them

-

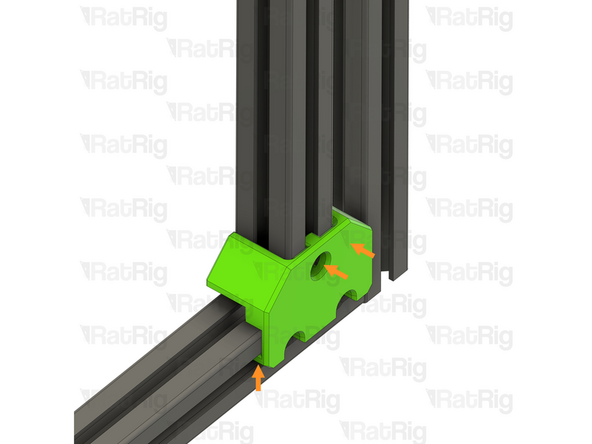

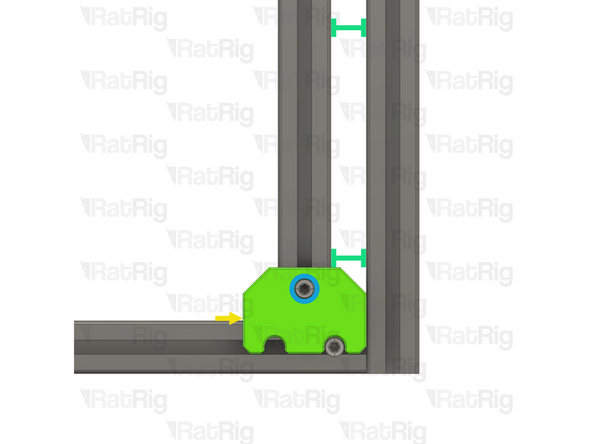

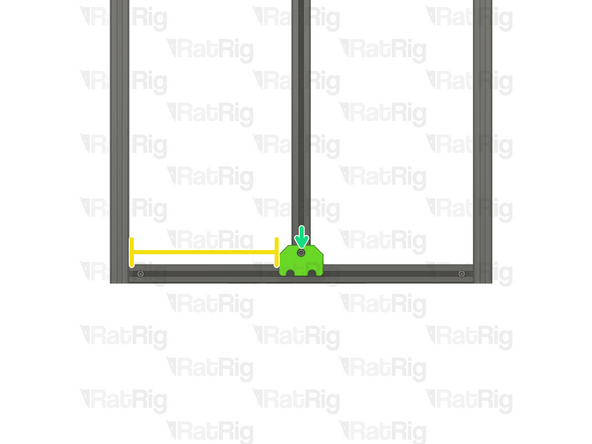

V-Core 4.0 Frame Jig

-

Install the Frame Jig onto the assembly as shown

-

-

-

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the right to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm

-

Build Tip: You can use the 2020 V-Slot extrusion to verify the gap but be careful not to scratch the aluminium extrusions

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

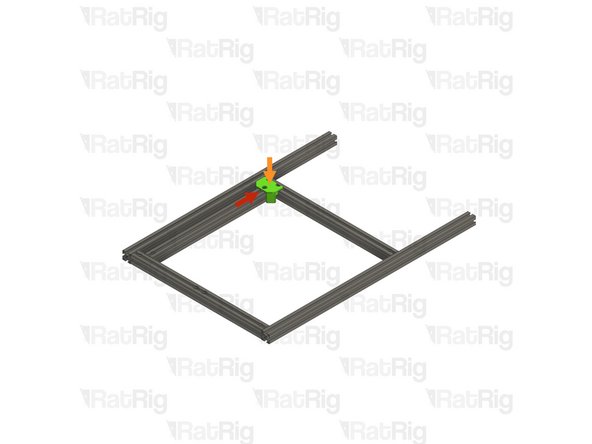

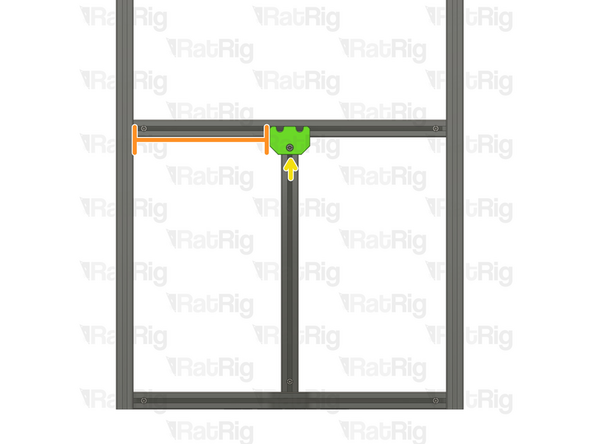

Move the Frame Jig to the marked position

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the right to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

Double check that the marked distance is 250mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

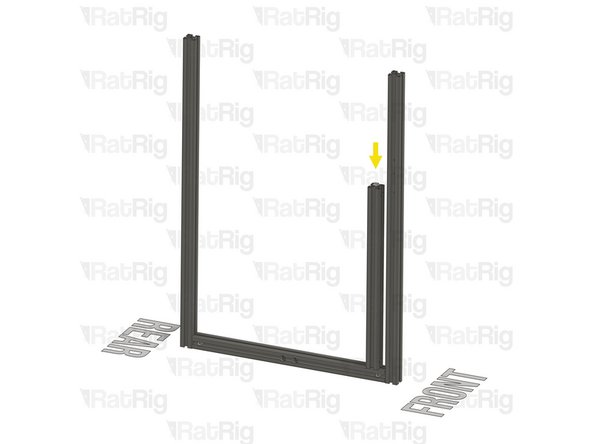

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors and two M8 holes from step 9

-

Make sure that the counterbores for the M8 holes are oriented as shown

-

T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

T-Slot 3030 Milled Extrusion - 750mm

-

Make sure this extrusion is installed as shown. It should be at the front, with the three M4 holes at the top and facing to the side

-

Assemble the extrusions as shown but do not fasten them together yet

-

-

-

T-Slot 3030 Milled Extrusion - 440mm with Quick Connectors from step 9

-

Align the Quick Connector T-Nut Pin with the bottom extrusion slot and insert it

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut pins are aligned with the side extrusion slots

-

Slide the extrusion downwards, making sure the Quick Connector T-Nut Pin on the 440mm extrusion fits inside the extrusion slot

-

Carefully rotate the marked extrusion 90 degrees so that the Quick Connector Set Screws face outwards as shown

-

Look into the extrusion slots and make sure that both the upper and lower Quick Connector T-Nut Pins have rotated correctly

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

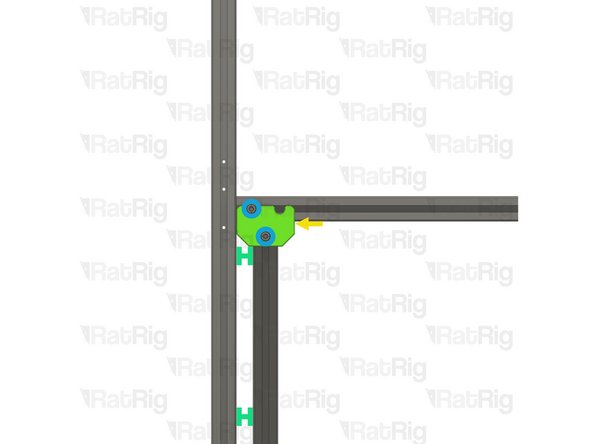

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Install the Frame Jig onto the assembly as shown

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the left to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm

-

Build Tip: You can use the 2020 V-Slot extrusion to verify the gap but be careful not to scratch the aluminium extrusions

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

Move the Frame Jig to the marked position

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the left to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

Double check that the marked distance is 250mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

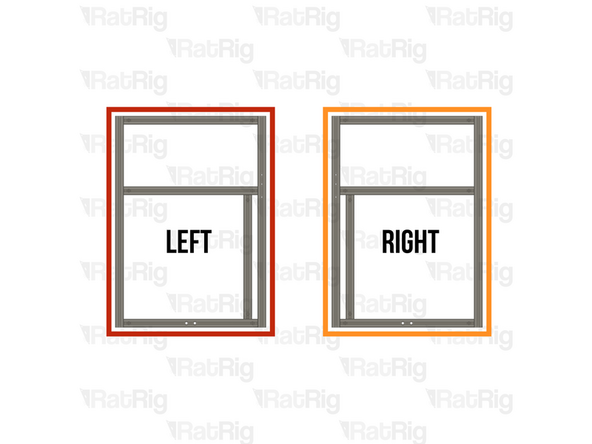

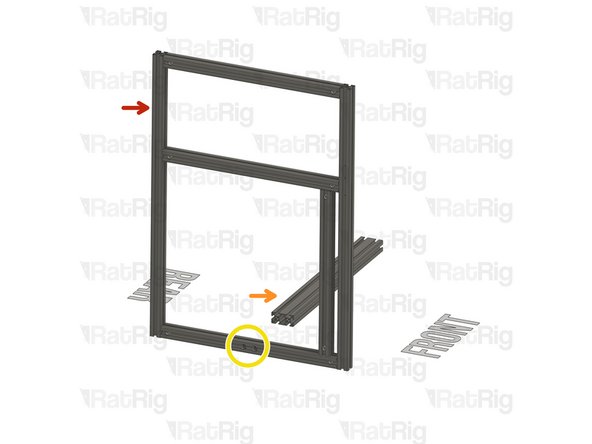

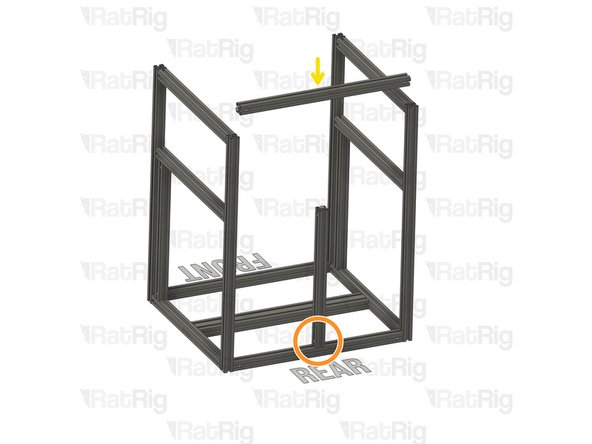

Left Side frame sub-assembly

-

T-Slot 3060 extrusion - 540mm

-

Align the extrusion with the two holes on the side frame sub-assembly bottom extrusion

-

2x M8x40 Cap Head screw

-

Insert them into the sub frame assembly and tighten them to the T-Slot 3060 extrusion - 540mm

-

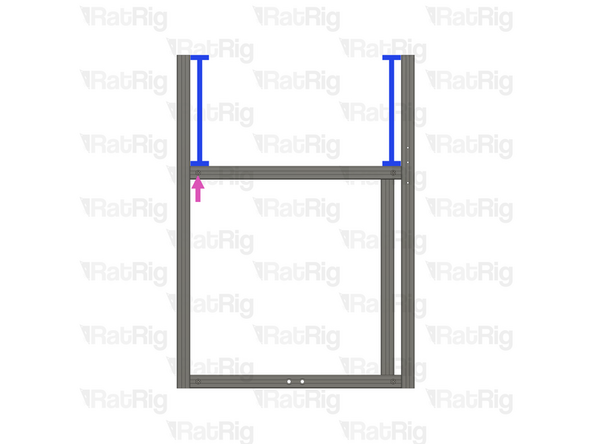

2x T-Slot 3030 Milled extrusion - 540mm

-

Insert the extrusion on the assembly, making sure the T-nut pins are aligned with the side extrusion slots.

-

When sliding the extrusion to the right place, be careful, and take it slowly so as to not damage the extrusion coating.

-

-

-

Place the assembly on a flat surface, as to ensure all extrusions are correctly aligned.

-

Tighten the quick connectors to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

-

-

Right Side frame sub-assembly

-

Insert the extrusion on the assembly, making sure the T-nut pins are aligned with the side extrusion slots.

-

When sliding the extrusion to the right place, be careful, and take it slowly so as to not damage the extrusion coating.

-

Align the extrusion with the two holes on the side frame sub-assembly bottom extrusion

-

Insert 2x M8x40 Cap Head screw into the sub frame assembly and tighten to the T-Slot 3060 extrusion - 540mm

-

Place the assembly on a flat surface, as to ensure all extrusions are correctly aligned.

-

Tighten the quick connectors to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

-

-

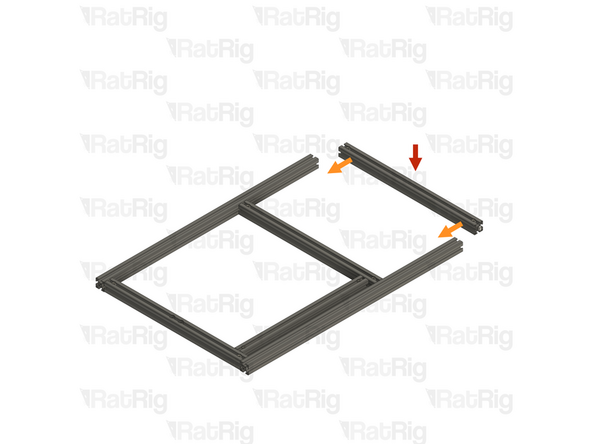

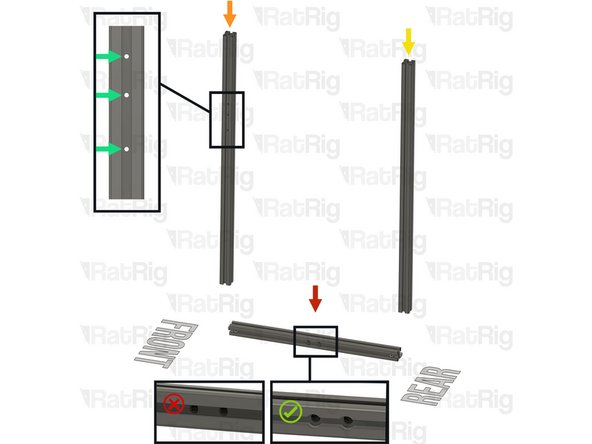

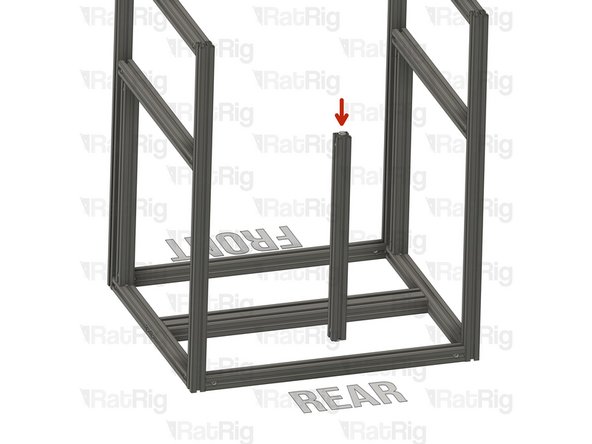

T-Slot 3030 Milled extrusion - 440mm

-

Align the T-nut pin with the bottom extrusion slot

-

Insert the T-nut pin in the bottom extrusion slot.

-

T-Slot 3030 Milled extrusion - 540mm

-

Insert the extrusion on the assembly, making sure the T-nut pins are aligned with the side extrusion slots.

-

When sliding the extrusion to the right place, be careful, and take it slowly so as to not damage the extrusion coating.

-

-

-

Carefully rotate the T-Slot 3030 Milled extrusion - 440mm 90º so the quick connectors face the side shown in the picture.

-

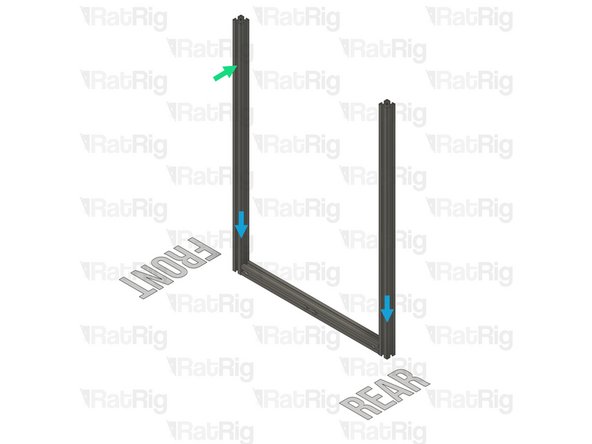

Insert the frame jig on the assembly, make sure the frame jig is inserted all the way and completely flush with the extrusion

-

Ensure the distance between the frame jig side wall and the frame extrusion is 235mm

-

It should be 285mm for the V-Core 4 400 and 335mm for the V-Core 4 500

-

Tighten the quick connector to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

-

-

Insert the frame jig on the assembly, make sure the frame jig is inserted all the way and completely flush with the extrusion

-

Ensure the distance between the frame jig side wall and the frame extrusion is 235mm

-

Add 50mm for the V-Core 4 400 and 100mm for the V-Core 4 500

-

Tighten the quick connector to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

-

-

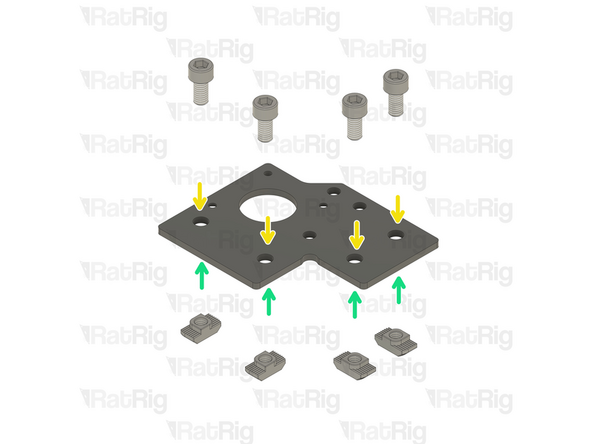

In this step, you will prepare two stepper motor plates with screws and T-nuts, although they will only be used to align the frame.

-

Rat Rig V-Core 4.0 - Motor Plate - Lower Left v1.0

-

Rat Rig V-Core 4.0 - Motor Plate - Lower Right v1.0

-

8x M6x12 Cap Head Screw

-

8x 3030 Drop In T-Nut M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Please notice: The t-nuts should be on the same side as the countersink holes.

-

-

-

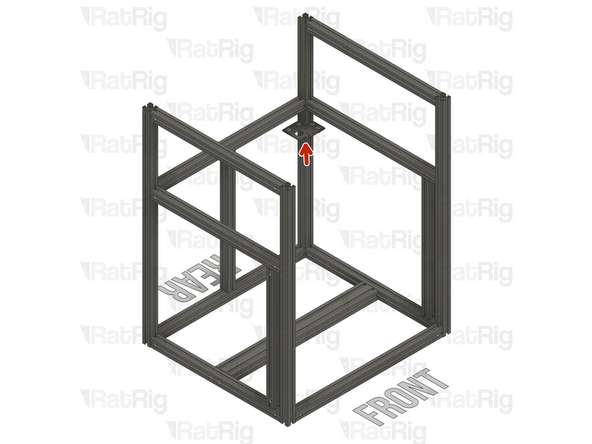

Install the Rat Rig V-Core 4.0 - Motor Plate - Lower Right v1.0 Assembly to the frame as shown

-

Tighten the M6x12 Cap Head Screws to secure the plate and guarantee the extrusions are perfectly aligned.

-

Tighten the quick connector to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

Remove the Rat Rig V-Core 4.0 - Motor Plate - Lower Right v1.0 Assembly and set it aside, it will be used later in the guide.

-

Repeat the Steps above for the other end of the extrusion, using the Rat Rig V-Core 4.0 - Motor Plate - Lower Left v1.0 Assembly

-

-

-

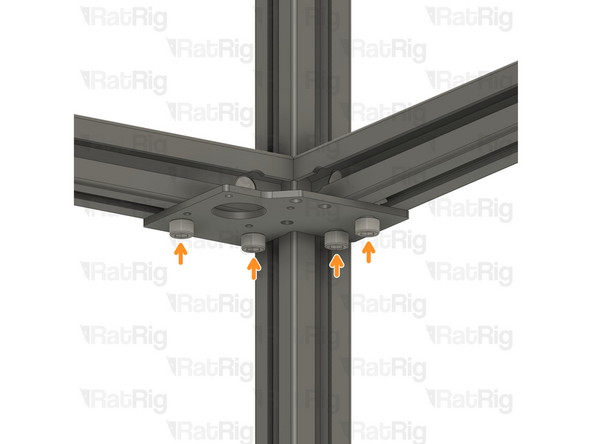

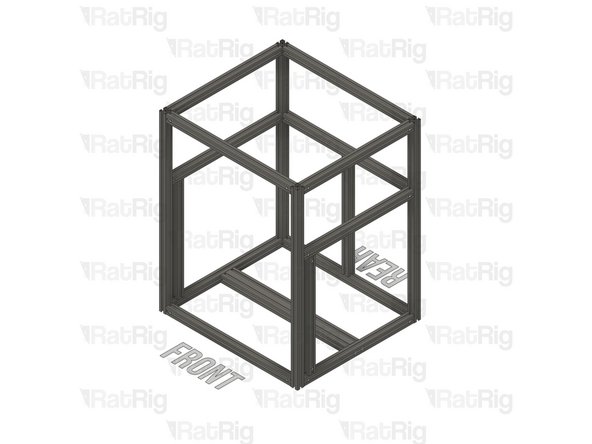

Make sure the front side extrusions have the 3xM3 holes facing the sides. Be aware of the extrusion orientation, the small spacing between the M3 holes must be upwards.

-

-

-

T-Slot 3030 Milled extrusion - 540mm

-

Insert the extrusion on the assembly, making sure the T-nut pins are aligned with the side extrusion slots.

-

Ensure the two extrusions are perfectly aligned

-

Refer to Step 10 on how to accurately align the extrusions.

-

Tighten the quick connectors to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

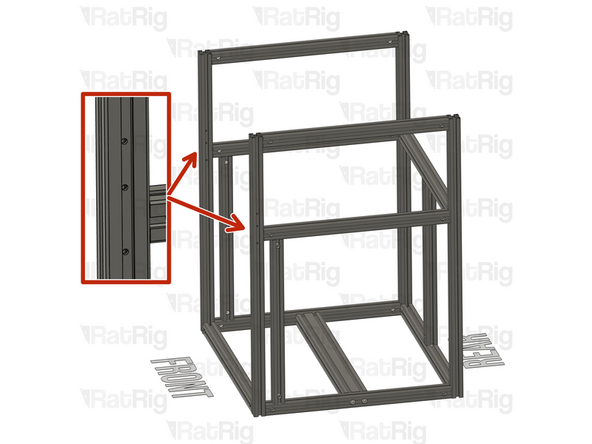

T-Slot 3030 Milled extrusion - 540mm

-

Insert the extrusion on the assembly, making sure the T-nut pins are aligned with the side extrusion slots.

-

-

-

Ensure the two extrusions are perfectly aligned

-

Refer to Step 10 on how to accurately align the extrusions.

-

Tighten the quick connectors to secure the extrusions together.

-

Always verify the strength of the connection between the extrusions. If the connection is not strong, loosen the set screw, ensure that the T-nut pin groove is positioned below the set screw, and reconnect the extrusions.

-

-

-

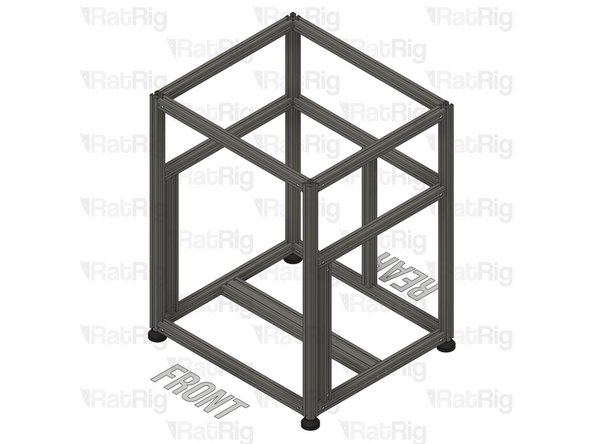

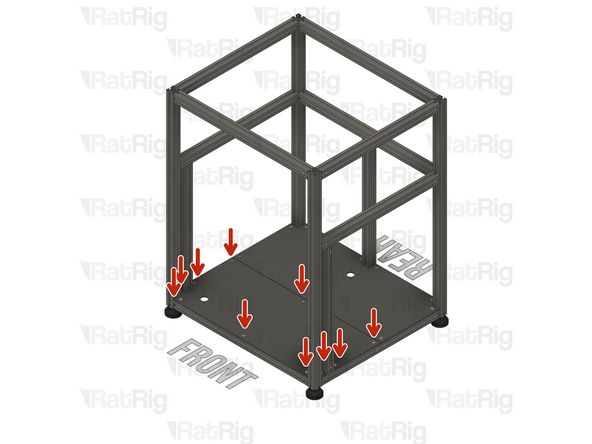

4 x V-Core 4 rubber feet

-

Tighten the four V-Core 4 rubber feet to the frame assembly

-

-

-

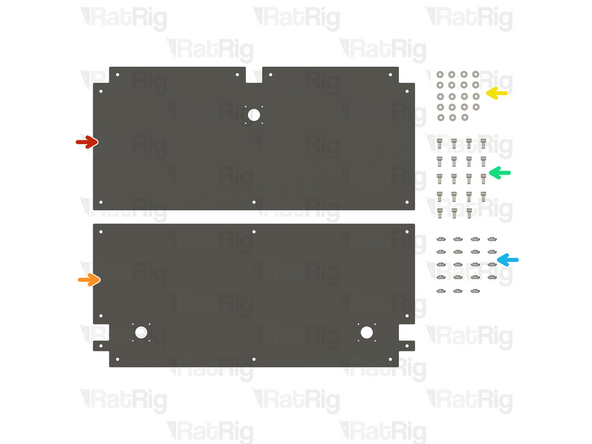

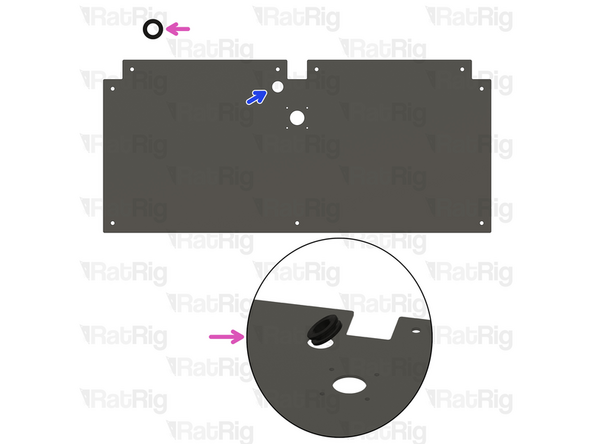

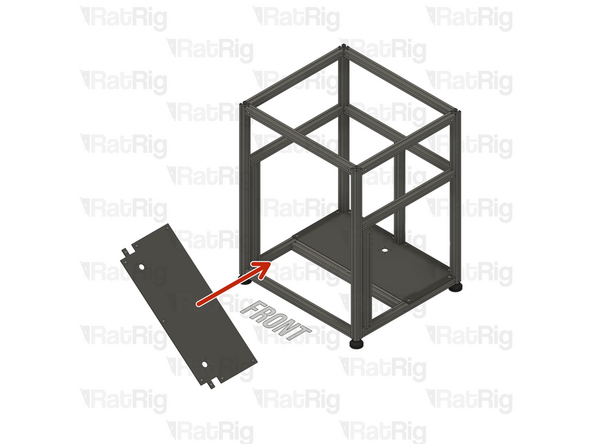

1x Rear base plate

-

The rear plate has been recently updated. If you purchased your kit recently, your rear plate may feature a new hole for the Z stepper motor cable management. Refer to the second picture for more details.

-

1x Front base plate

-

19x M6 Washer

-

19x M6x12 Cap Head Screws

-

19x 3030 M6 Drop in T-Nut

-

Updated rear base plate with Z cable passthrough.

-

Rubber grommet. Insert the grommet in the designated hole.

-

-

-

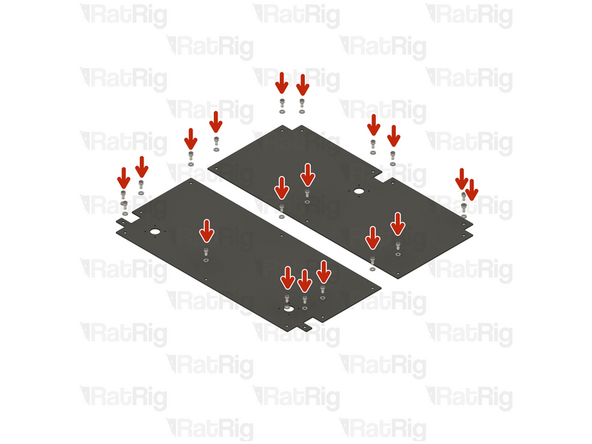

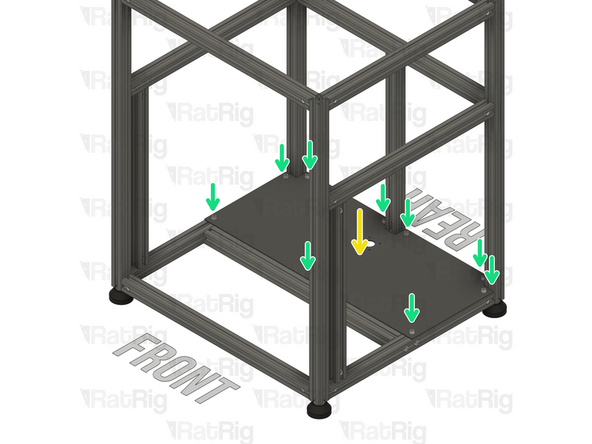

Inset a M6x12 Cap Head Screw + M6 washer on every 6mm hole on the base plates.

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

-

-

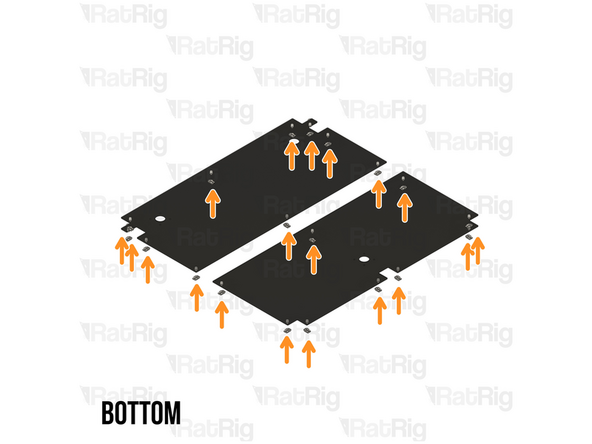

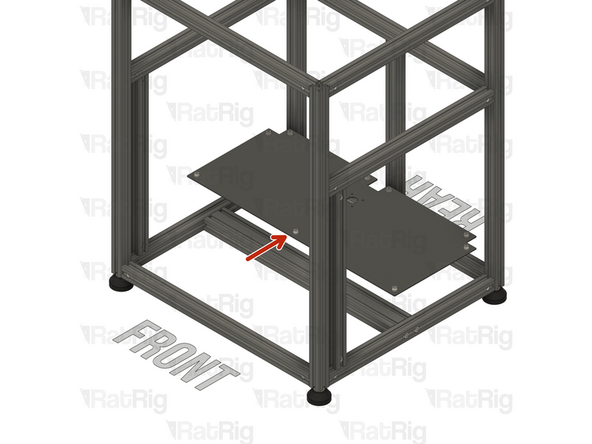

Rear base plate assembly

-

Carefully place it inside the frame. The Z cable passthrough should be on the left side when facing the front of the printer.

-

Ensure the base plate assembly is pushed all the way to the back and aligned with the rear extrusions.

-

When sliding the base plate assembly to the right place, be careful, and take it slowly so as to not damage the extrusion coating.

-

Place the base plate assembly on the bottom of the frame

-

Make sure every 3030 Drop In T-nut aligns with the extrusion slots

-

Tighten the M6x12 Cap Head Screws to secure the base plate assembly to the frame.

-

-

-

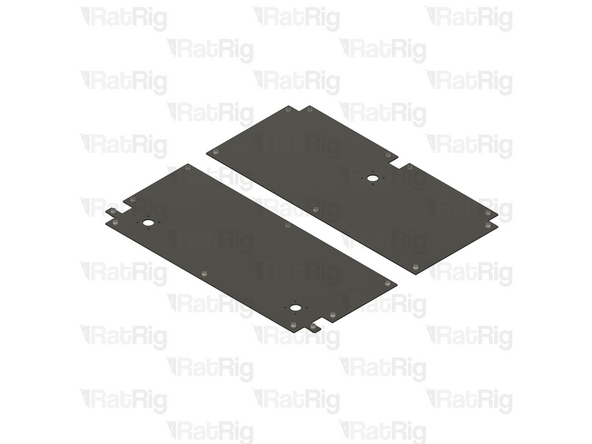

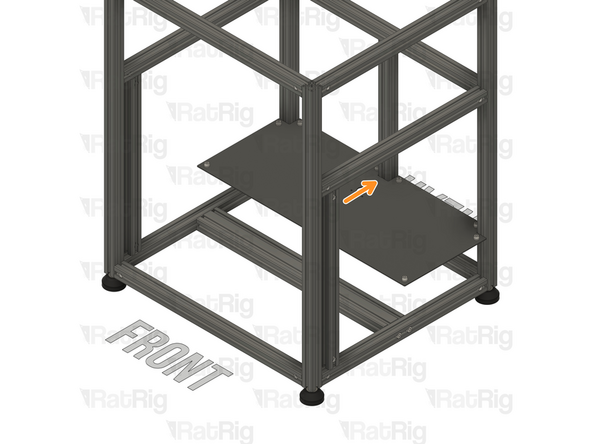

Insert the front base plate inside the frame assembly, at an angle so it can be rotated into place.

-

When sliding the base plate assembly to the right place, be careful, and take it slowly so as to not damage the extrusion coating.

-

Carefully rotate the front base panel towards the side of the frame, as shown.

-

Align the base panel with the extrusions

-

Rotate the front base plate assembly into position.

-

-

-

Tighten the M6x12 Cap Head Screws to secure the base plate assembly to the frame.

-

-

-

Continue with the next guide: 02. Z-Axis Assembly

-