-

-

4x T-Slot extrusion 3030 - 160mm

-

4x T-Slot extrusion 3030 - 400mm

-

4x T-Slot extrusion 3030 - 480mm

-

8x Hidden three way corners + 32 M6x8 Set Screws

-

4x vc4_magnet_frame

-

4x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

4x Magnet - Neodymium disc 10x4mm

-

-

-

4x M6x8 Set Screw

-

Hidden Three Way Corner

-

Insert the set screws into the part's threads.

-

-

-

2x Hidden three-way corner assembly from the last step

-

1x T-Slot extrusion 3030 - 160mm

-

Ensure the extrusions are flush and square with the hidden three way corner assembly before and after tightening the screws.

-

Tighten the M6x8 set screws.

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner.

-

Prepare two assemblies

-

2x T-Slot extrusion 3030 - 400mm

-

Assemble the parts as shown.

-

-

-

Tighten the M6x8 set screws.

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner.

-

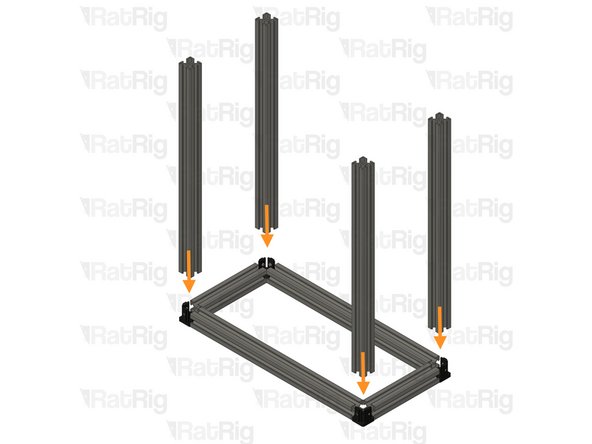

4x T-Slot extrusion 3030 - 448mm

-

Insert the T-slot Exstrusions in the three way hidden corner as shown.

-

Tighten the M6x8 set screws.

-

Ensure the extrusions are flush and square with the hidden three way corner assembly before and after tightening the screws.

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner.

-

-

-

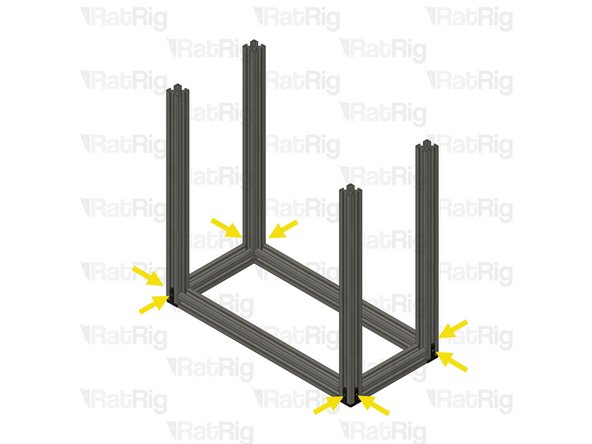

Fram assembly from Step 2

-

Insert the T-slot Exstrusions in the three way hidden corner as shown.

-

Tighten the M6x8 set screws.

-

Ensure the extrusions are flush and square with the hidden three way corner assembly before and after tightening the screws.

-

Be careful while tightening the set screws, extreme force may break the three way hidden corner.

-

-

-

vc4_magnet_frame

-

Magnet - Neodymium disc 10x4mm

-

3030 Drop-in T-Nut - M6

-

M6x12 Cap Head Screw

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Please verify the magnet polarity in relation to the magnets on the door panel. If the polarity is inverted, the magnets will repel each other instead of attracting.

-

Prepare 4 assemblies

-

-

-

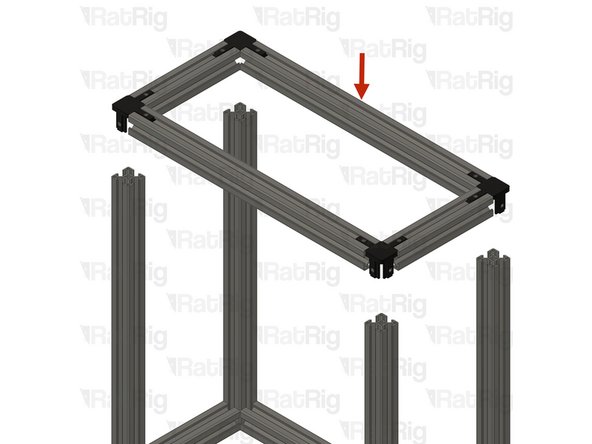

Position the magnet mount assembly as shown.

-

Push it down so it sits flush with both extrusions.

-

Position the remaining magnet mount assemblies as shown.

-

-

-

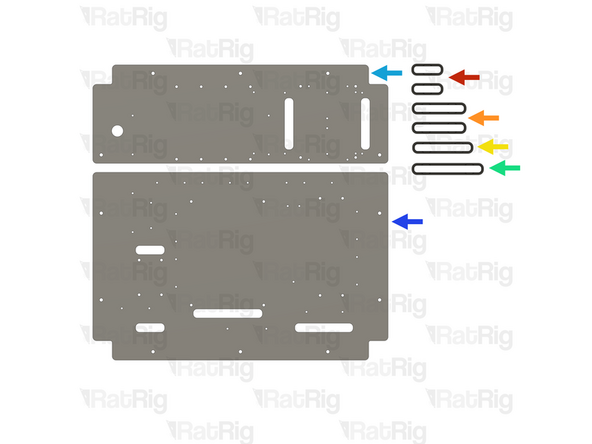

2x ucee_grommet_45mm

-

2x ucee_grommet_80mm

-

ucee_grommet_90mm

-

ucee_grommet_107mm

-

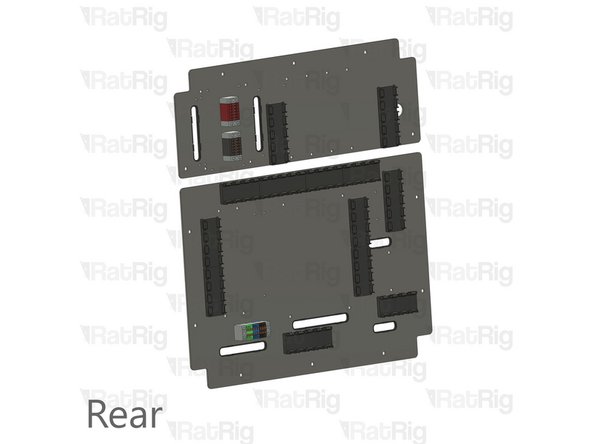

Rat Rig Universal CNC Electronics Enclosure - Components Upper

-

Rat Rig Universal CNC Electronics Enclosure - Components Lower

-

Insert the grommets into place, they should click in place.

-

-

-

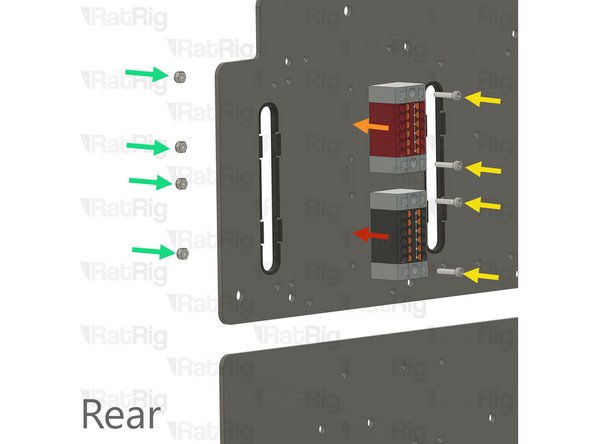

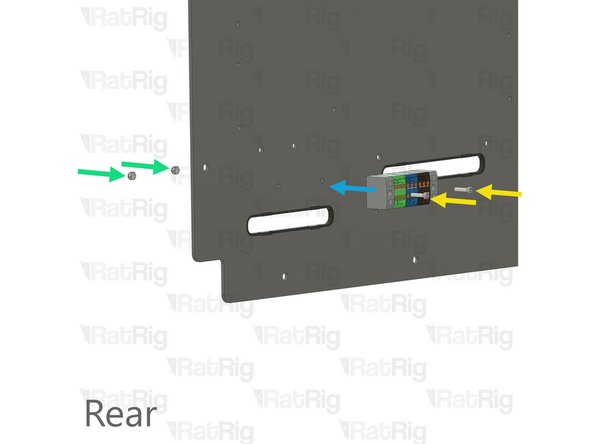

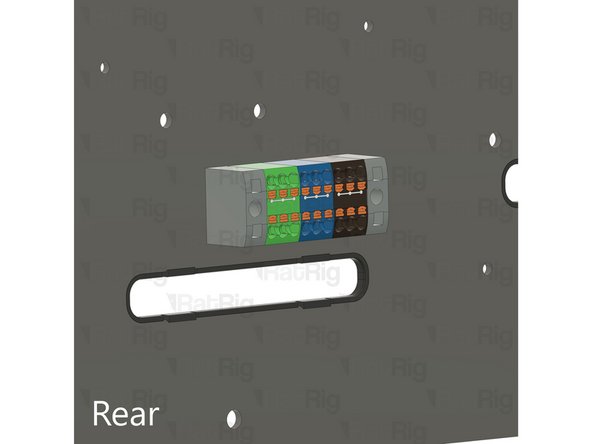

GND PTFix block

-

+24V PTFix block

-

4x M2.5 Cap Head Screw

-

4x M2.5 Nylon Locking Nut

-

Mains volatage PTFix block

-

2x M2.5 Cap Head Screw

-

2x M2.5 Nylon Locking Nut

-

Using the Screws and Nylon Locking Nuts secure the PTFix blocks to the rear of the electronics panels.

-

-

-

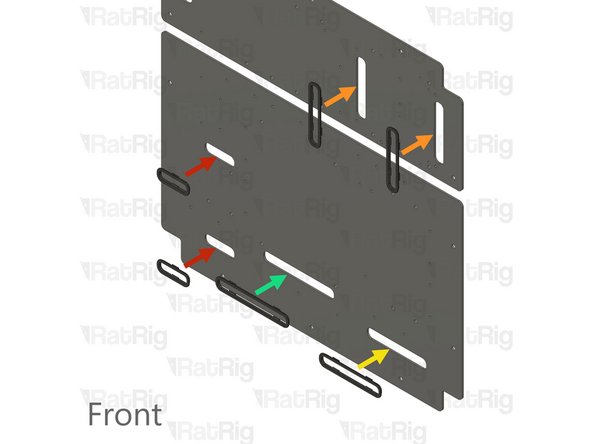

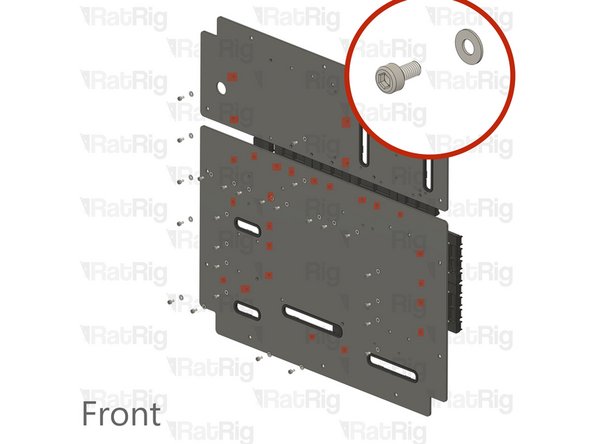

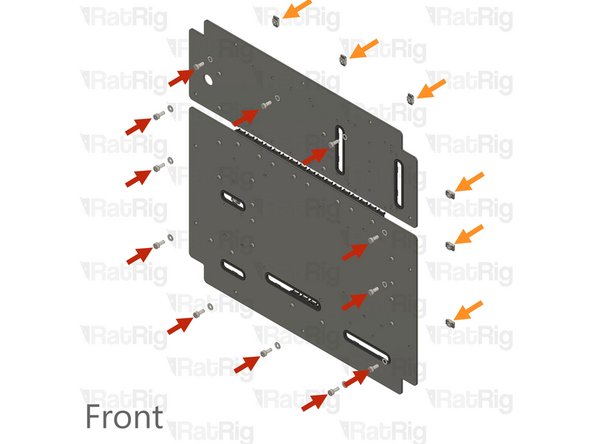

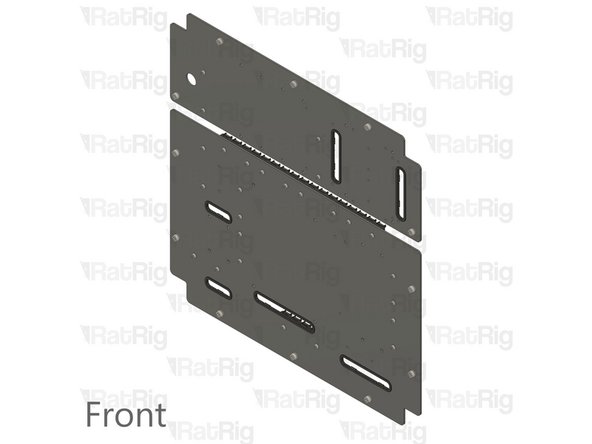

(26x) M3x6 Cap Head Screw + M3 Washer

-

Insert a screw and washer from the front of the plate in every marked hole

-

Secure the eight vc4_cable_guide_4 assembly using M3x6 screws and heat inserts in the back at the designated locations.

-

Secure the five vc4_cable_guide_5 assembly using M3x6 screws and heat inserts in the back at the designated locations.

-

-

-

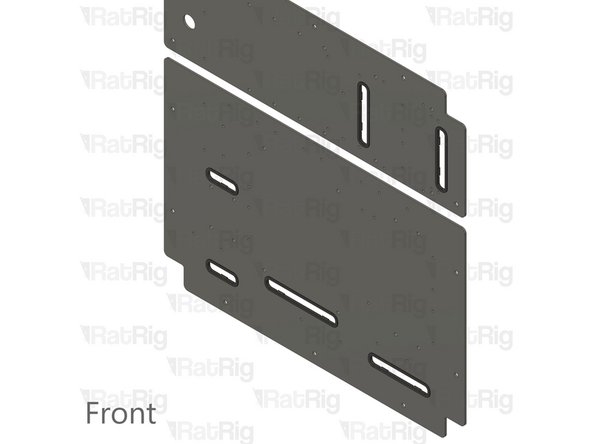

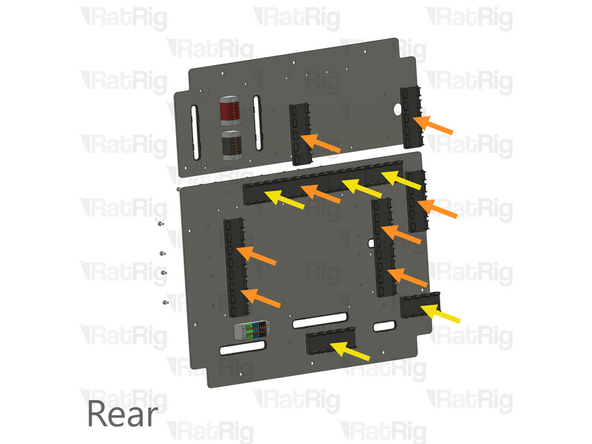

12x M5x12 Cap Head Screws

-

12x 3030 Drop-in T-Nut - M5

-

Insert a Screw and T-nut on every marked hole

-

-

-

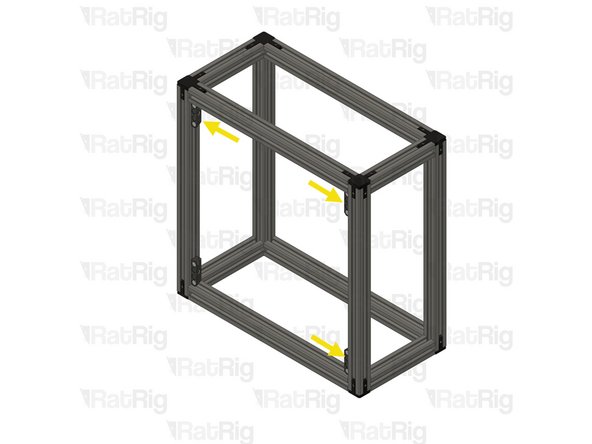

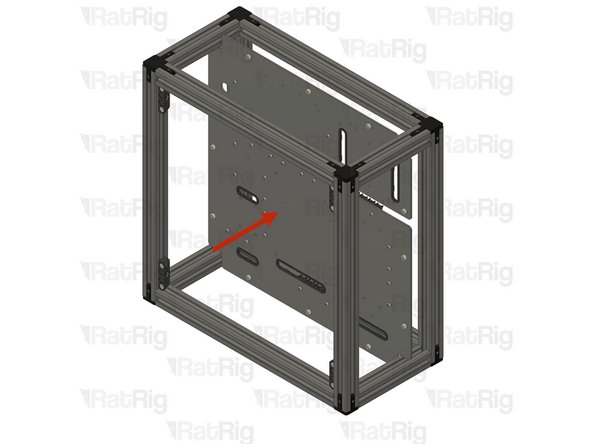

Insert the panels into the frame as shown.

-

Ensure the lower panel is aligned flush with the bottom extrusion, then securely tighten the screws.

-

Ensure the top panel is aligned flush with the top extrusion, then securely tighten the screws.

-

Almost done!

Finish Line