Video Overview

-

-

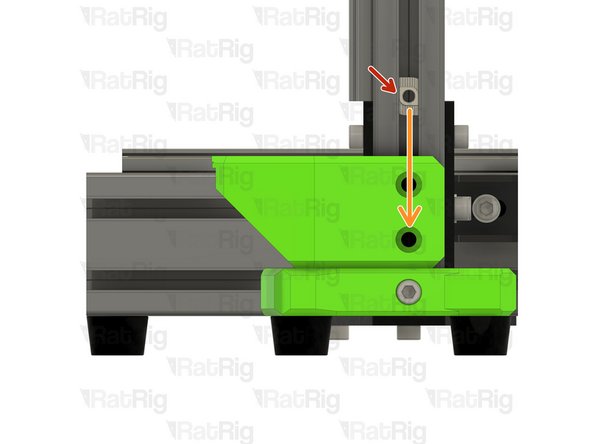

z_motor_cage printed part

-

4x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

-

-

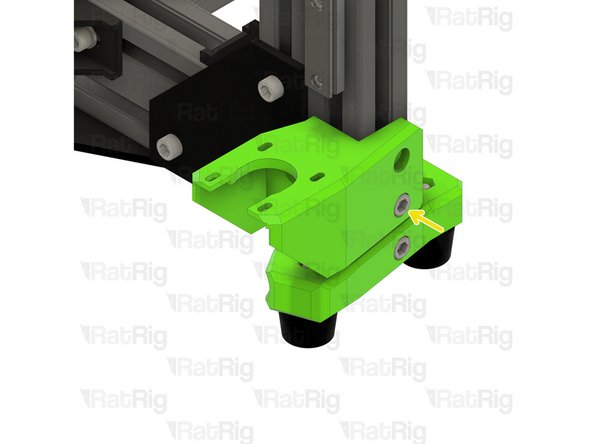

z_motor_cage printed part

-

2x M6x12 Cap Head Screw

-

2x 3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Position the Z-axis motor mount as shown. The base should rest on the rear feet

-

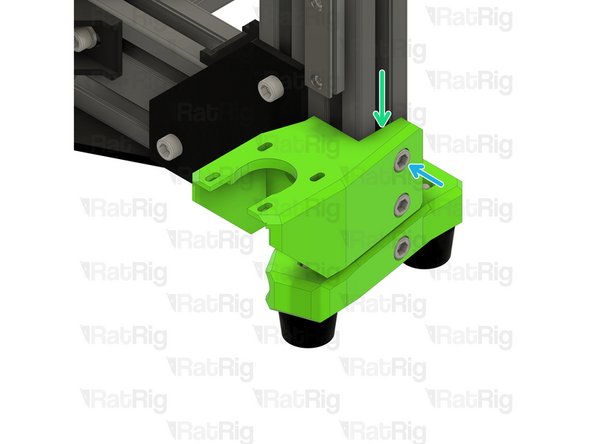

Fasten both M6x12 screws to secure the mount to the frame

-

Take care not to over tighten the M6x12 screws as you can damage the printed part.

-

-

-

3030 Drop In T-Nut M6

-

Slide the 3030 T-Nut behind the lower screw hole on the Z-axis motor mount as shown

-

Fasten the M6x12 screw into the 3030 T-Nut

-

Take care not to over tighten the M6x12 screw as you can damage the printed part

-

Slide the 3030 T-Nut behind the upper screw hole on the Z-axis motor mount as shown

-

Fasten the M6x12 screw into the 3030 T-Nut

-

Take care not to over tighten the M6x12 screw as you can damage the printed part

-

-

-

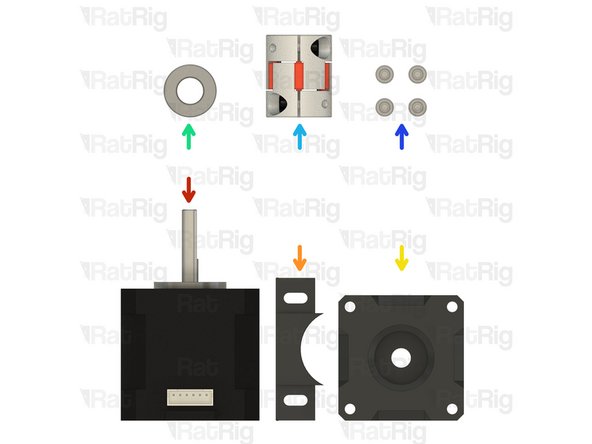

1x 40mm NEMA17 Stepper Motor

-

z_motor_cage_plug printed part

-

pillow_block printed part

-

1x Axial Thrust Bearing

-

1x Spider Coupler

-

4x M3x18 Cap Head Screw

-

-

-

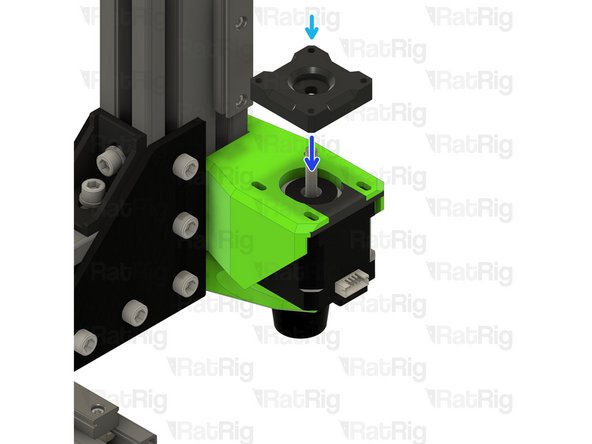

40mm NEMA17 Stepper Motor

-

Slide the stepper motor into the mount as shown

-

z_motor_cage_plug printed part

-

Insert the z_motor_cage_plug to fill the gap after the motor is installed

-

pillow_block printed part

-

Place the pillow_block printed part on top of the motor mount. The stepper motor shaft should pass through the middle

-

-

-

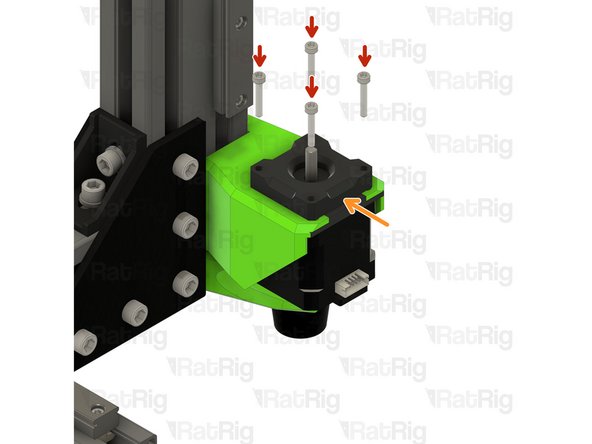

4x M3x18 Cap Head Screw

-

The holes in the Z-axis motor mount are slotted to allow adjustment. This will be performed at a later step. For now, push the motor as far back (towards the frame) as possible and fasten all four M3x18 screws

-

Take care not to over tighten the M3x18 screws as you can damage the printed parts

-

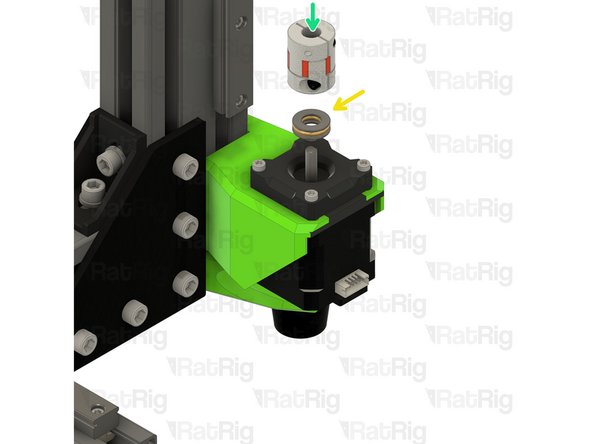

Install the axial thrust bearing over the shaft of the stepper motor. It should sit within the pillow_block printed part

-

Spider Coupler

-

Apply downwards pressure on the spider coupler to compress the axial thrust bearing

-

Tighten the lower screw on the spider coupler whilst applying downwards force as stated above

-

Cancel: I did not complete this guide.

20 other people completed this guide.