-

-

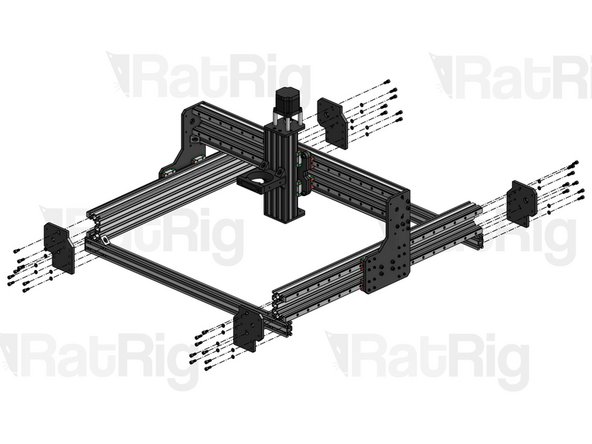

Lay the Y Axis C-Beam profiles on top of the X-Base 2040 profiles. You're about to mount the XZ Axis on the XY Carriages. Either ask for a friend's help or get a couple of boxes as temporary support for your XZ Axis.

-

X Base 2040 profiles (they are 5mm shorter than your X Axis)

-

XY Carriages

-

XZ Axis

-

-

-

Cap Head Screw M5x12mm

-

Washer M5 Black

-

Cap Head Screw M5x16mm

-

Repeat step on the opposite XY carriage

-

-

-

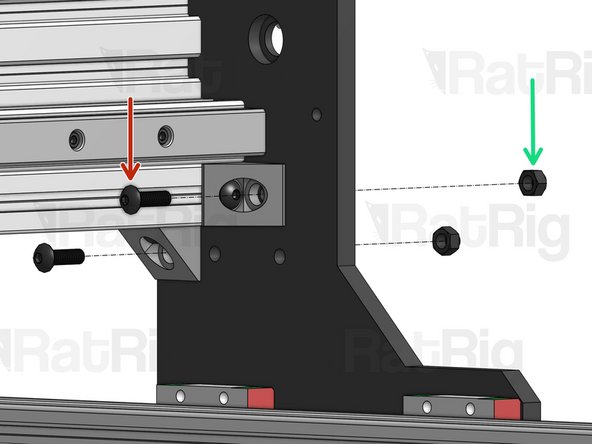

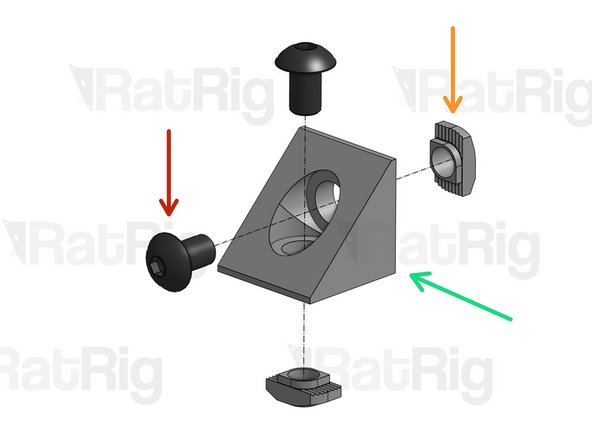

Button Head Screw M5x16mm

-

Hex Locking Nut M5

-

Repeat step on the Angle Corners on the opposite XY carriage.

-

-

-

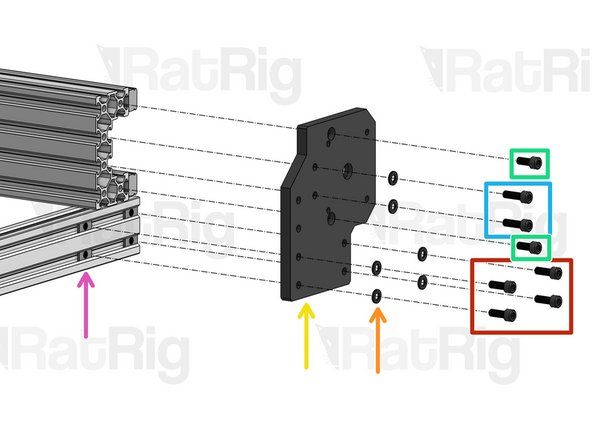

Set the 4 Y Plates in position, aligning them so they are flush with the ends of the 2040 profiles, but don't give the final tightening just yet.

-

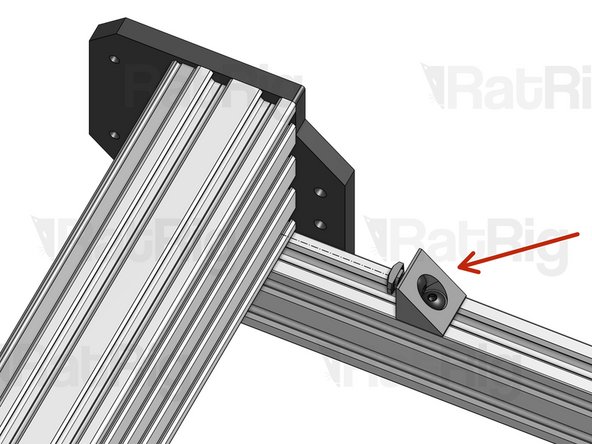

Flat T-Nut M5. Slide it inside the slot through the opening at the end.

-

These are different from the Drop-in T-Nuts you've used until now.

-

Y Plate

-

Washer M5 Black

-

Cap Head Screw M5x12mm

-

Cap Head Screw M5x16mm

-

Cap Head Screw M5x14mm

-

-

-

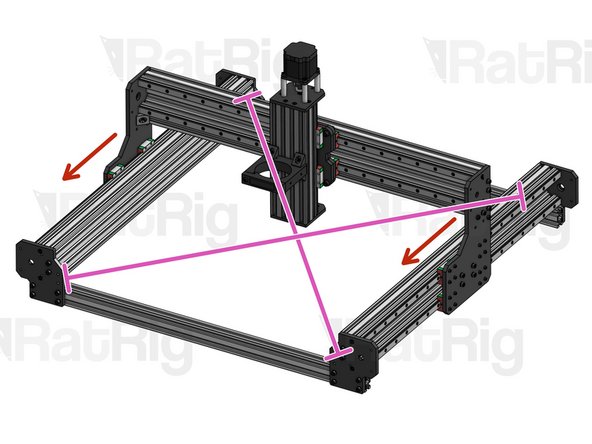

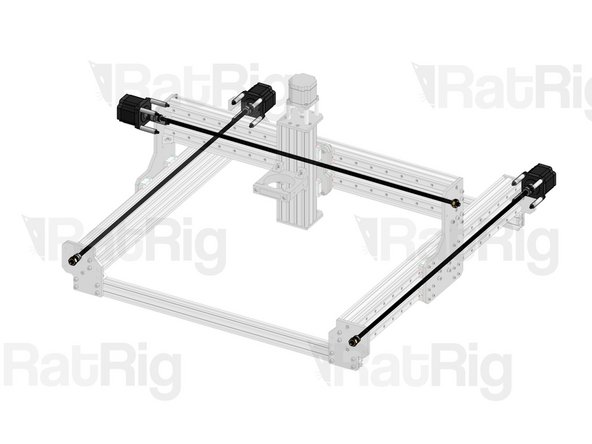

We can't overstate how important this step is. Take your time to get it right or your machine's performance and lifespan will be affected.

-

Measure the diagonals of the square formed by the machine's frame. They need to be exactly the same length.

-

To make a precise measurement, get 2 pointy sticks. Each stick needs to have more than half of the diagonal length. Position each stick on opposite corners of the diagonal. They will meet in the middle, overlapping each other.

-

Mark the position where they overlap, remove the sticks from the frame, and measure their combined length.

-

Move the XZ Gantry back and forth across the entire range of movement, so the Y plates settle in the right positions.

-

Move the gantry all the way to the front and give the final tightening on the front Y plates.

-

Move the gantry all the way to the back and give the final tightening on the back Y plates.

-

-

-

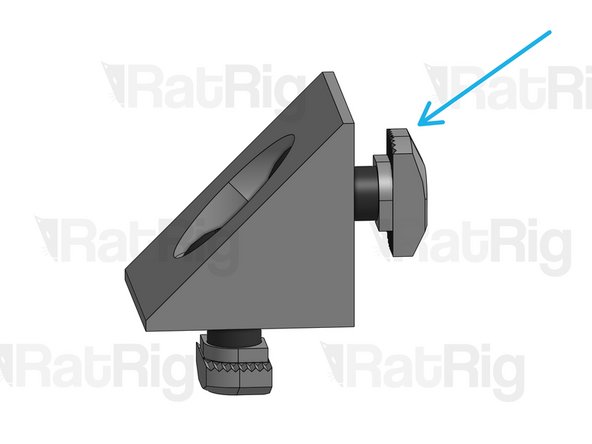

Repeat step for 4 Angle Corners

-

Button Head Screw M5x8mm

-

Angle Corner

-

Drop-in T-Nut M5

-

Do not tighten the T-Nuts. Screw them in just enough so they don't fall.

-

-

-

Repeat this step on each of the 4 corners of the frame.

-

Fit the Angle Corners you set up on the last step inside the profile slots and tighten them.

-

Cancel: I did not complete this guide.

5 other people completed this guide.

One Comment

Managed to do the first part alone…. it’s really easyer to dot it with help ! We were 3 : 2 holding the X axes, on screwing all :)

Flamand Laurent - Resolved on Release Reply