-

-

T-Slot extrusion 40120 - 502mm

-

Rat Rig StrongHold ONE CNC - Z-Axis Bottom 10mm

-

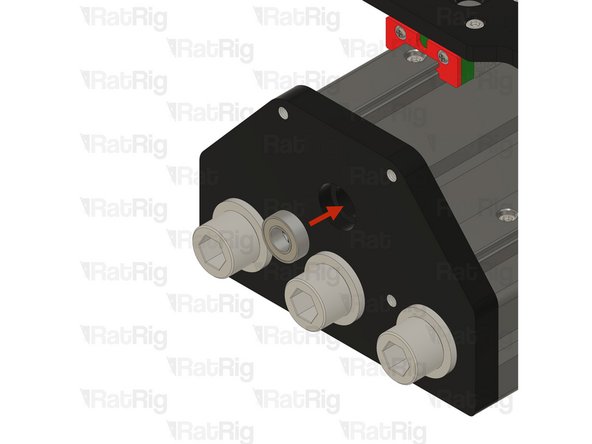

3x M12x25 Countersink screws

-

Both plates must be facing upwards.

-

Rat Rig StrongHold ONE CNC - Z-Axis Top 10mm

-

3x M12 Washer

-

3x M12x25 Cap Head Screw

-

-

-

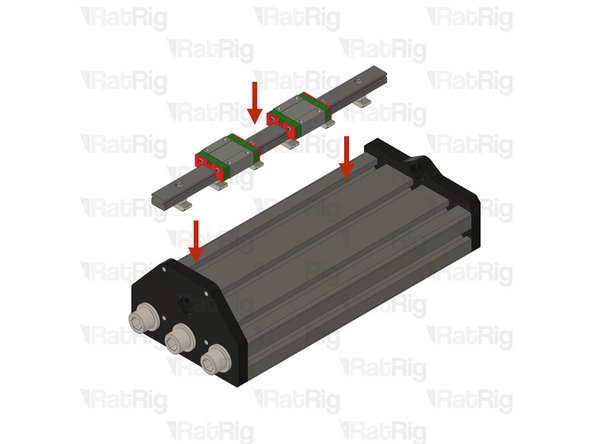

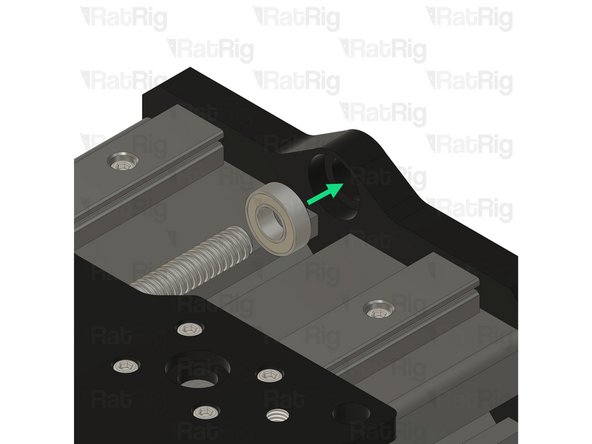

Place one Z linear rail assembly on the designated T-slot.

-

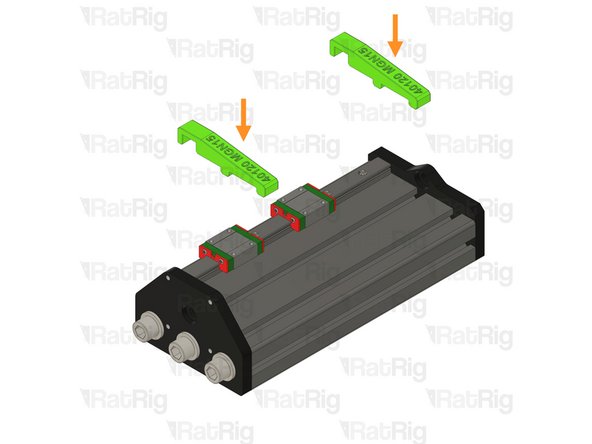

Insert the two align_40120_mgn15 printed jigs in the T-Slot and rail.

-

Make sure the align_40120_mgn15 printed jigs are correctly placed and centering the rail on the T-slot

-

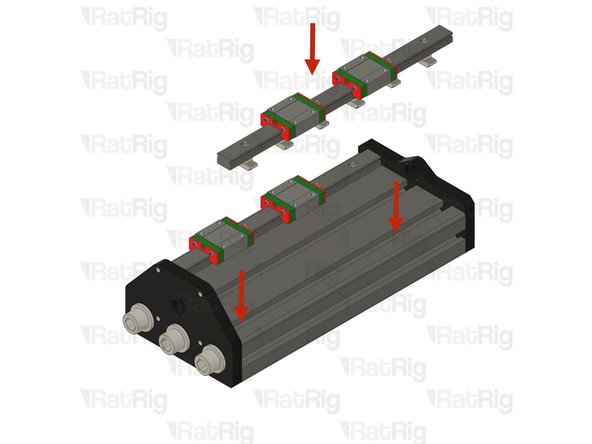

Tighten the linear rails screws one at a time starting from the front and making your way towards the back, one by one.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

-

-

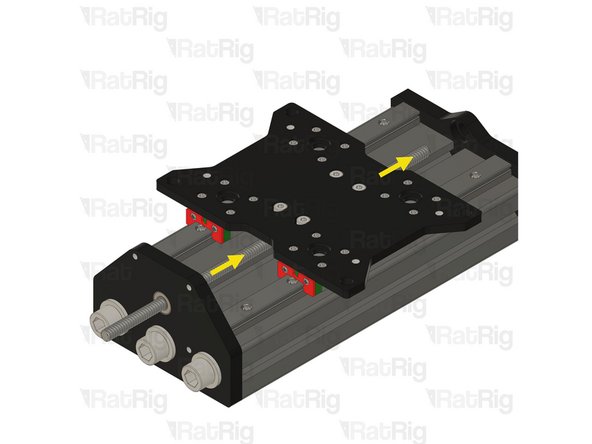

Place the second Z linear rail assembly on the T-slot but DO NOT tighten the screws.

-

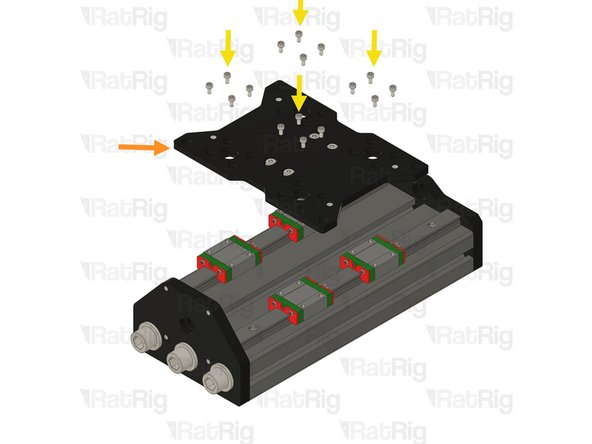

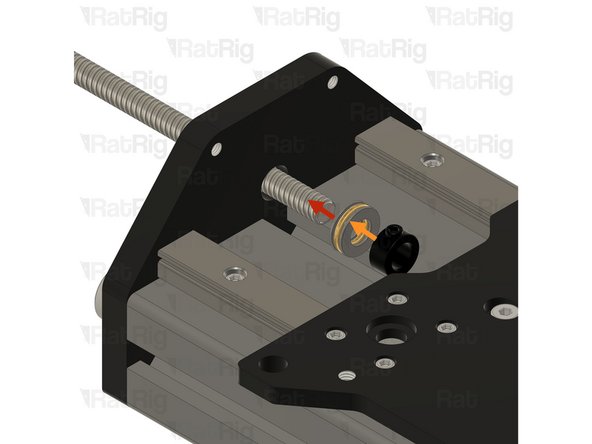

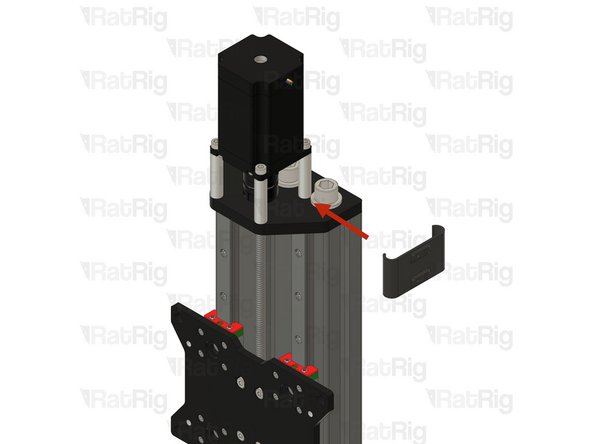

Install the Z Joiner assembly on the linear rails.

-

Using the 16x M3x6 Cap Head screws, fasten the XY joiner plate assembly to the mgn15 carriages.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

Tip: Blue thread lock can be added to the thread of the M3x6 Cap Head screws.

-

-

-

While the second linear rail remains loose, the Z plate should move smoothly without resistance. If you experience any binding or drag, slightly loosen the carriage screws, as they may be overtightened.

-

Be careful to ensure that the Z joiner plate carriages do not detach from the linear rail during the process.

-

Move the Z joiner fully to the front as demonstrated. Then, gradually move it toward the back, exposing one linear rail screw at a time, and tighten each screw as you progress.

-

Ensure that all linear rail screws are tightened from front to back. Avoid overtightening, as this may cause binding and restrict movement.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-