-

-

1x T-Slot extrusion 40120 - 250mm

-

3x M12x25 Countersink screws

-

3x M12 Washer

-

3x M12x25 Cap Head Screw

-

Rat Rig StrongHold ONE CNC - Z-Axis Bottom 10mm

-

Rat Rig StrongHold ONE CNC - Z-Axis Top 10mm

-

-

-

T-Slot extrusion 40120 - 502mm

-

Rat Rig StrongHold ONE CNC - Z-Axis Bottom 10mm

-

3x M12x25 Countersink screws

-

Both plates must be facing upwards.

-

Rat Rig StrongHold ONE CNC - Z-Axis Top 10mm

-

3x M12 Washer

-

3x M12x25 Cap Head Screw

-

-

-

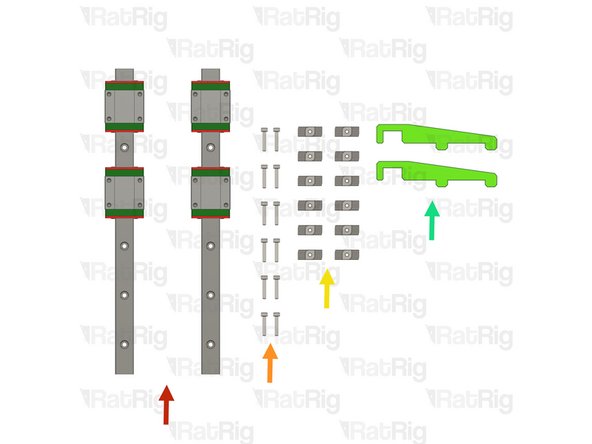

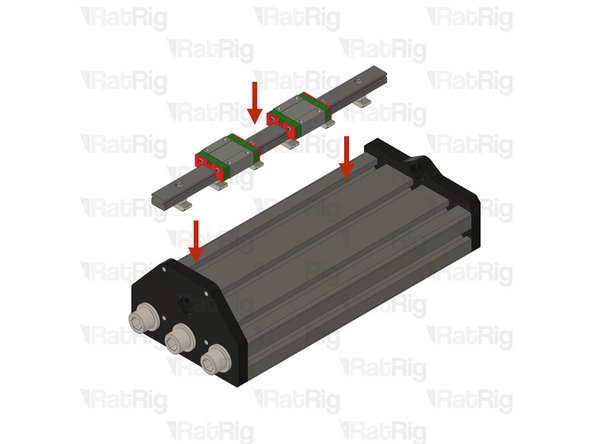

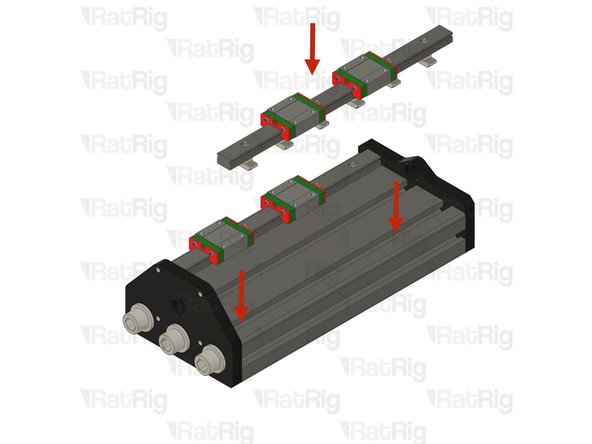

2x Linear Rail - MGN15 250mm + 2 x MGN15C carriage

-

12x M3x16 Cap Head screws

-

12x 4040 Drop-in T-Nut - M3

-

2x align_40120_mgn15 printed part

-

-

-

The linear rails are supplied with a protective oil coating on them. It is strongly recommended to prepare your work surface with paper towels and to wear disposable gloves.

-

Paper Towels

-

Linear Rail

-

With the rail still on the absorbent paper towels, carefully and slowly move the carriage from one end of the rail to the other

-

Small changes in resistance are normal, but the carriage becoming very hard to push, or binding completely are not

-

If the carriage does not move smoothly, or binds completely, refer to the Linear Rail Troubleshooting Guide

-

The linear rail carriages are not interchangeable. Do not try to use a carriage on a different linear rail than the one it was supplied with.

-

Check this guide if one or more carriages don't move smoothly.

-

-

-

Do not allow the linear rail carriages to leave the end of the rail at any point

-

MGN15 Linear Rail

-

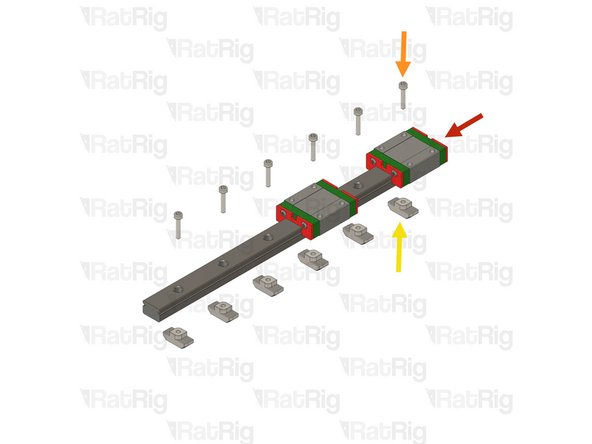

Insert an M3x16 cap head screw in each of the holes on the linear rail

-

Loosely thread a 4040 T-Nut on to each of the M3x16 screws

-

Repeat these instructions for the second linear rail

-

-

-

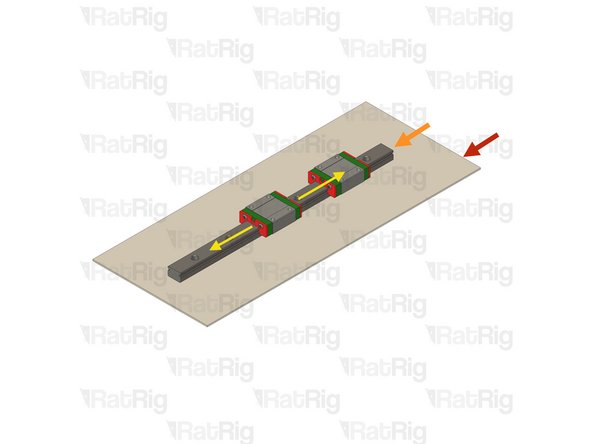

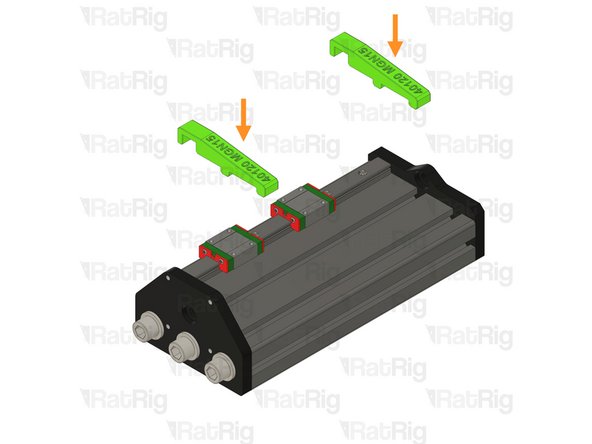

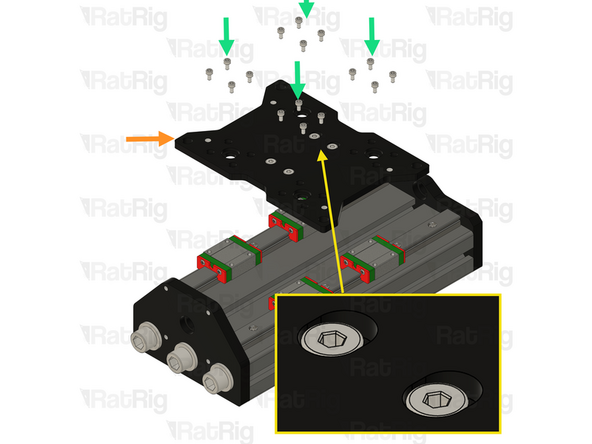

Place one Z linear rail assembly on the designated T-slot.

-

Insert the two align_40120_mgn15 printed jigs in the T-Slot and rail.

-

Make sure the align_40120_mgn15 printed jigs are correctly placed and centering the rail on the T-slot

-

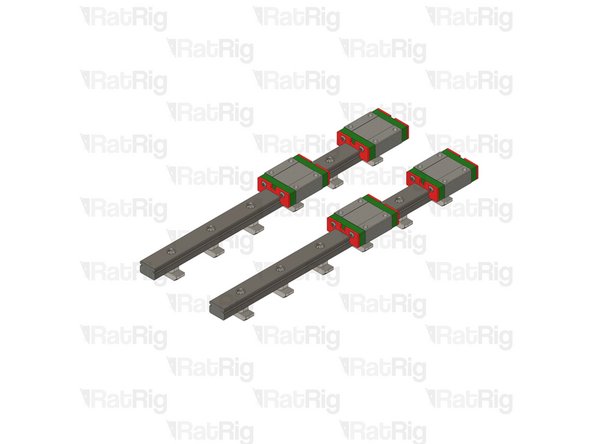

Tighten the linear rails screws one at a time starting from the front and making your way towards the back, one by one.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

-

-

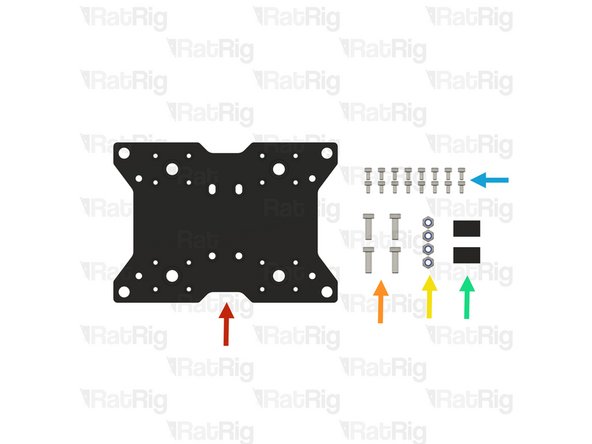

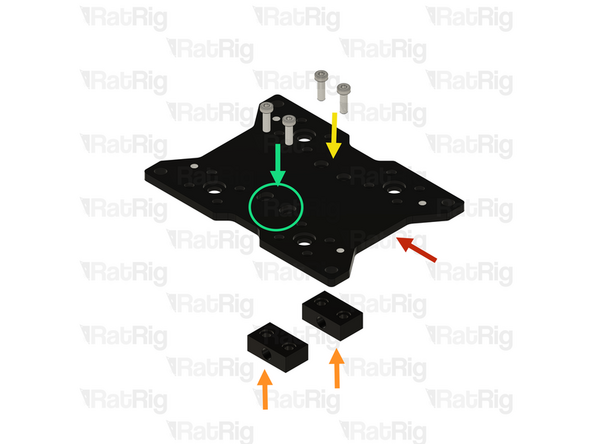

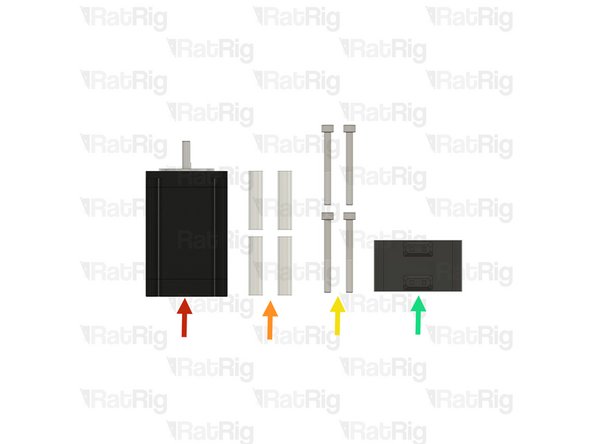

Rat Rig Mill - Z Plate

-

4x M5x16 Low Head Screw

-

4x M5 Nylon Locking Hex Nuts

-

2x Nut Block for TR8x4

-

16x M3x6 Cap Head Screws

-

-

-

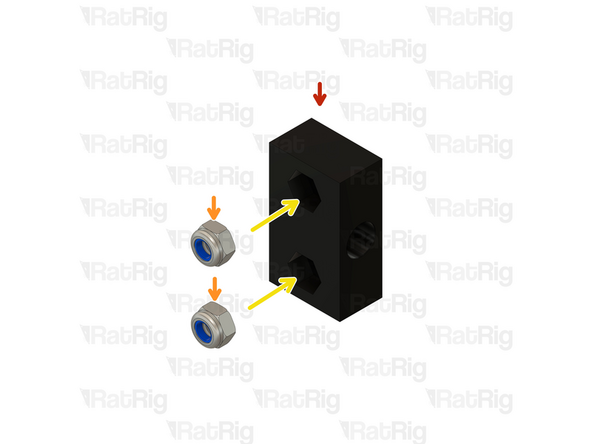

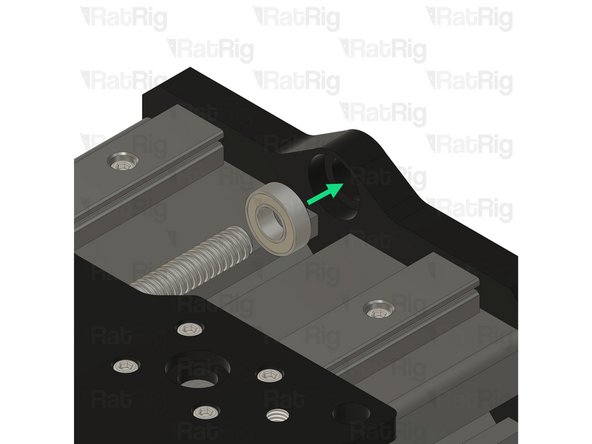

Nut Block for TR8x8

-

M5 Nylon Locking Hex Nut

-

Insert the M5 Locking Hex Nuts in to the Nut Block

-

Prepare two assemblies.

-

-

-

Rat Rig Mill - Z Plate

-

Nut Block for TR8x4 assembly from the last step.

-

The M5 Nylon Locking Hex Nuts, must be facing away from the Y gantry plate.

-

Gently tighten the M5x16 Low Head Screws on the designated holes.

-

Do not overtighten the screws as it will cause binding in the lead screw. Tighten until the nut block is flush with the plate and add half a turn on the screws.

-

Thread the M5x16 Low Head Screws on the designated slot, Do not tighten this Nut Block, it will be adjusted later.

-

-

-

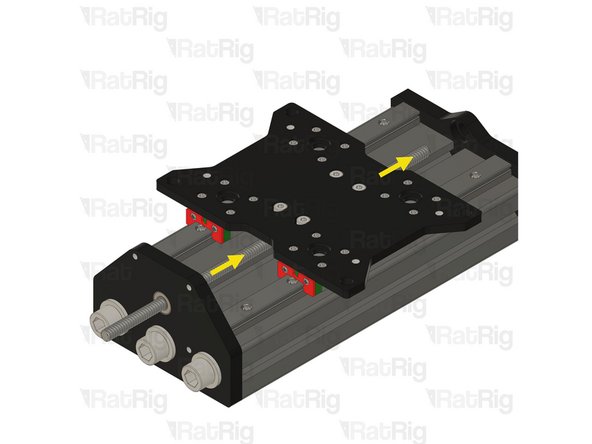

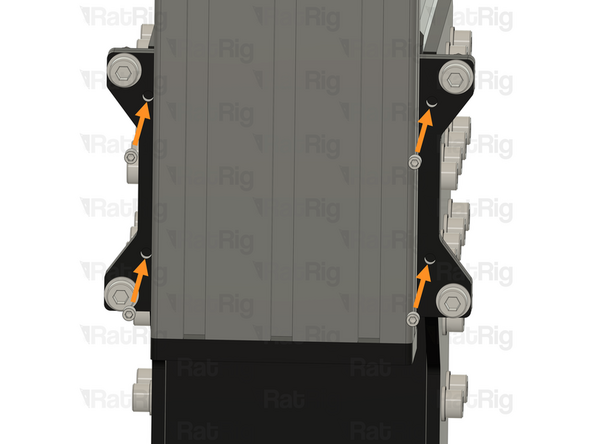

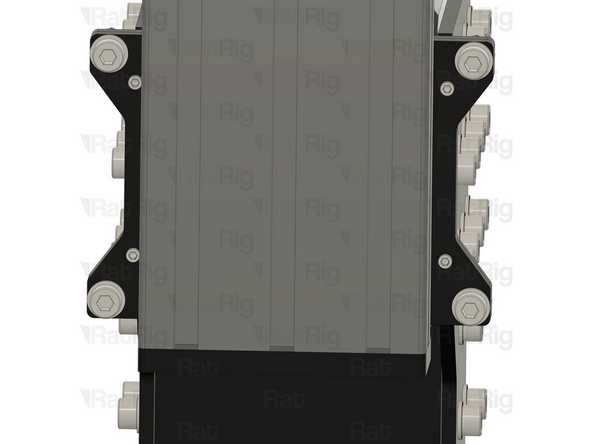

Place the second Z linear rail assembly on the T-slot but DO NOT tighten the screws.

-

Install the Z Joiner assembly on the linear rails.

-

Ensure the M5 screw slots are facing the Rat Rig StrongHold ONE CNC - Z-Axis Bottom 10mm side as shown.

-

Using the 16x M3x6 Cap Head screws, fasten the XY joiner plate assembly to the mgn15 carriages.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

Tip: Blue thread lock can be added to the thread of the M3x6 Cap Head screws.

-

-

-

While the second linear rail remains loose, the Z plate should move smoothly without resistance. If you experience any binding or drag, slightly loosen the carriage screws, as they may be overtightened.

-

Be careful to ensure that the Z joiner plate carriages do not detach from the linear rail during the process.

-

Move the Z joiner fully to the front as demonstrated. Then, gradually move it toward the back, exposing one linear rail screw at a time, and tighten each screw as you progress.

-

Ensure that all linear rail screws are tightened from front to back. Avoid overtightening, as this may cause binding and restrict movement.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

-

-

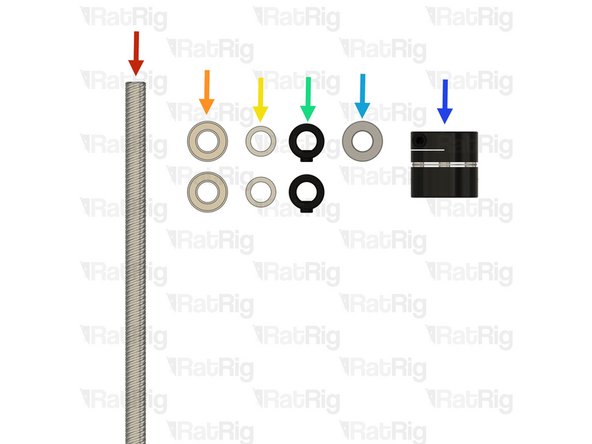

Leadscrew - TR8x4 Metric - 281mm

-

2x Ball Bearing 688ZZ

-

2x Shim - 12 x 8 x 1mm

-

2x Lock Collar

-

Thrust Bearing F8-16M

-

Coupler - Disc Type

-

-

-

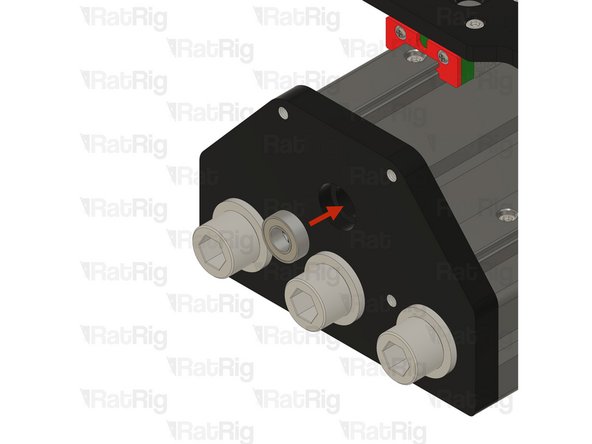

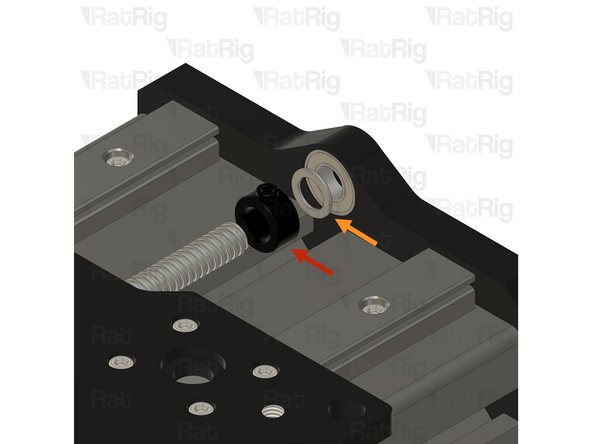

688ZZ Ball bearing

-

Push the ball bearing against the inner side of the plate, ensuring it stays inside the designated groove.

-

Push the Lead Screw through the hole in the ball bearing

-

-

-

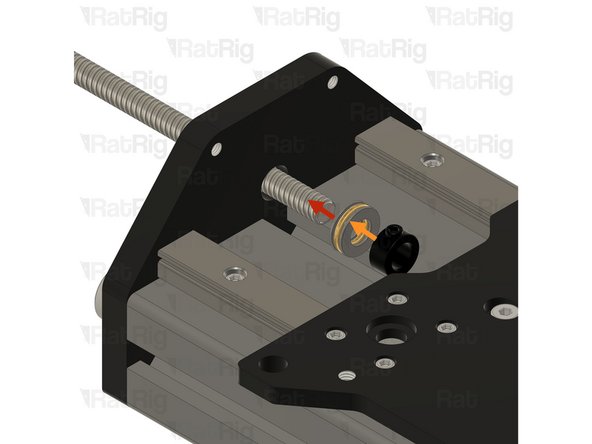

Thrust Bearing F8-16M

-

Install the Thrust Bearing on to the exposed end of the Lead Screw as shown

-

Lock Collar

-

The Precision Shim 12x8x1mm should be in between the 688ZZ Ball bearing and the Lock Collar

-

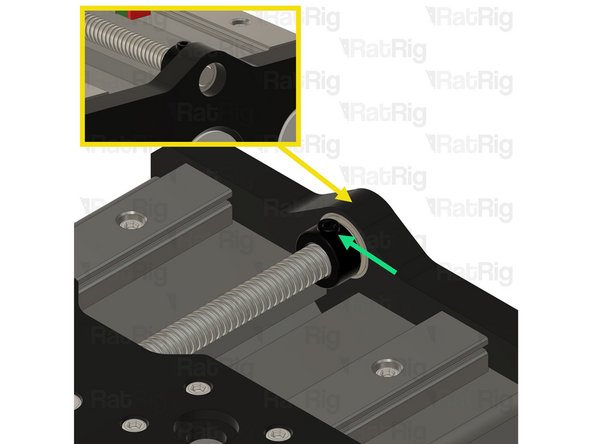

Screw the Lead Screw through both Nut Blocks under the Y joiner plate.

-

-

-

Precision Shim 12x8x1mm

-

Slide the Precision Shim on to the Lead Screw

-

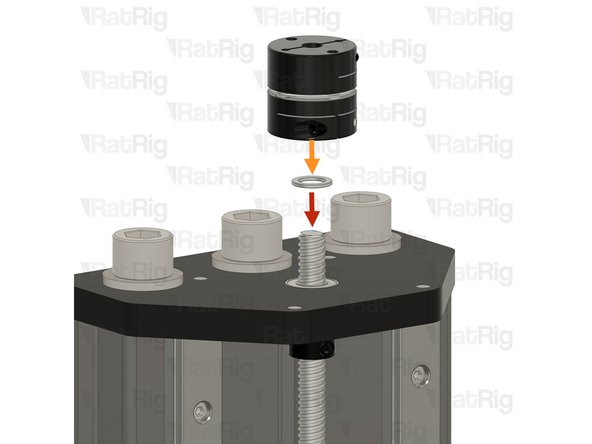

Coupler - Disk Type

-

Install the Coupler on to the exposed end of the Lead Screw.

-

Push the coupler against the metal plate and tighten the set screw.

-

Push the lock collar against the axial bearing to ensure the axial bearing is making full contact with both surfaces.

-

Tighten the set screw on the lock collar.

-

-

-

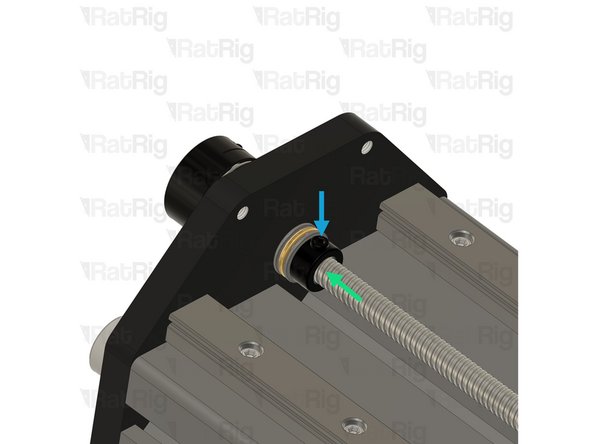

Nema 23 Stepper Motor High Torque

-

4x 40mm Aluminium Spacer

-

4x M5x50 Cap Head Screw

-

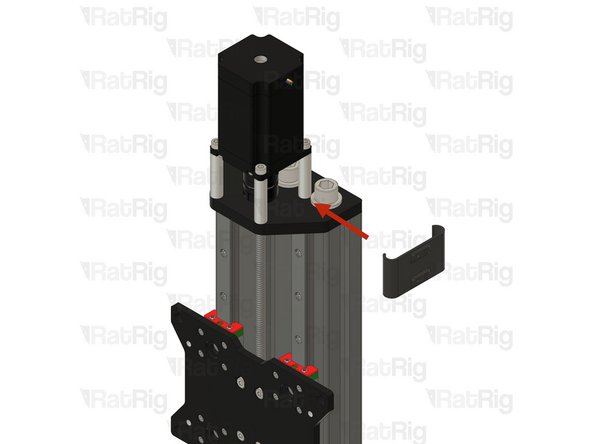

mill_stepper_cable_management printed part

-

-

-

4x 40mm Aluminium Spacer

-

Nema 23 Stepper Motor High Torque

-

4x M5x50 Cap Head Screw

-

Tighten the set screw on the coupler, to secure the stepper motor shaft to it.

-

-

-

Insert the mill_stepper_cable_management printed part as shown.

-

-

-

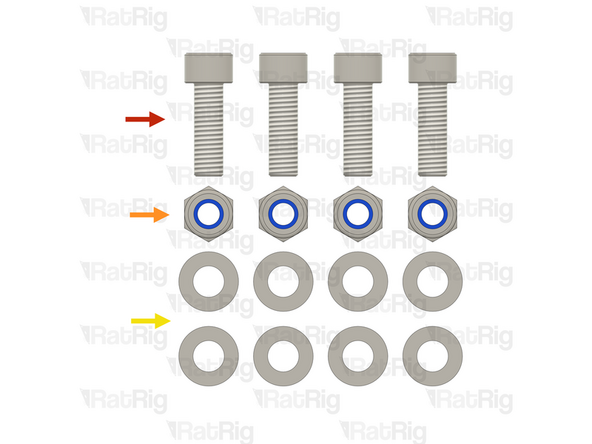

4x M8x25 Cap Head Screw

-

4x M8 Nylon Locking Hex Nut

-

8x M8 Washer

-

-

-

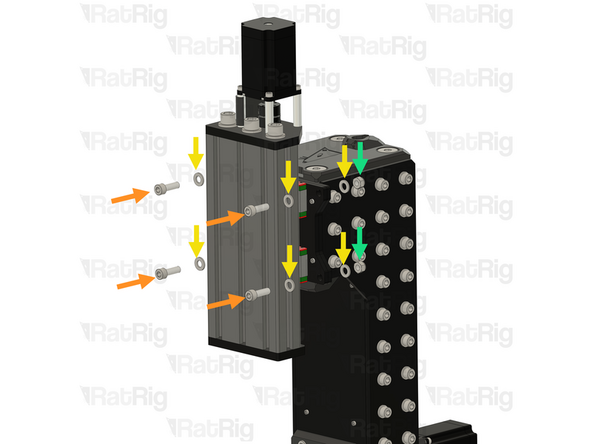

Place the Z-axis assembly on the Z tower, ensuring the M8 Low Head

-

The Z-axis is heavy and difficult to manage alone. Please request assistance from another person to hold the Z-axis while you tighten the screws.

-

Assemble the M8x25 cap head screws by inserting them through the M8 washers and the Z plates. Then, place an M8 washer on the rear and secure everything with an M8 nylon locking nut.

-

4x M8x25 Cap Head Screw

-

8x M8 Washer

-

4x M8 Nylon Locking Hex Nut

-

-

-

4x M6x8 Set screws

-

Look through the threaded holes; there should be no light visible on the other side. If you see light, it indicates that one of the Z plates is installed upside down. Visit this 02. Z Tower Assembly and flip the Z plate upside down.

-

Lightly thread the set screws into the designated holes. Once they reach the rear Z plate, stop tightening.

-

These screws are intended to assist the user in tramming the spindle during the commissioning process.

-

-

-

Select your work tool to continue with the next guide:

-

2.2KW Spindle - 05. Spindle

-

Rat Rig Router - 06. Rat Rig Router

-

Almost done!

Finish Line