Introduction

Please note: All measurements and component counts provided in this guide are based upon building a 300x300 V-Core 3.

If you are building a machine of a different size, please refer to the following list for the linear rail length, 2020 extrusion length, and required number of fasteners:

- 200x200: 300mm Linear Rail, 322mm 2020 Extrusion, 6x M3x8 Screw & 2020 T-Nuts

- 300x300: 400mm Linear Rail, 422mm 2020 Extrusion, 8x M3x8 Screw & 2020 T-Nuts

- 400x400: 500mm Linear Rail, 522mm 2020 Extrusion, 10x M3x8 Screw & 2020 T-Nuts

- 500x500: 600mm Linear Rail, 622mm 2020 Extrusion, 12x M3x8 Screw & 2020 T-Nuts

-

-

1x xy_joiner_left_3.1 Printed Part

-

1x xy_joiner_right_3.1 Printed Part

-

4x 695ZZ Ball Bearing

-

8x F695ZZ Ball Bearing

-

12x Mini Precision Shim

-

8x 6mm Aluminium Spacer

-

4x M5x55 Cap Head Screw

-

-

-

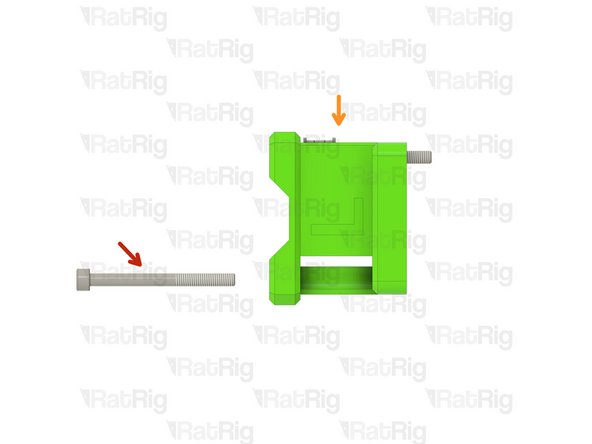

M5x55 Cap Head Screw

-

xy_joiner_left_3.1 Printed Part

-

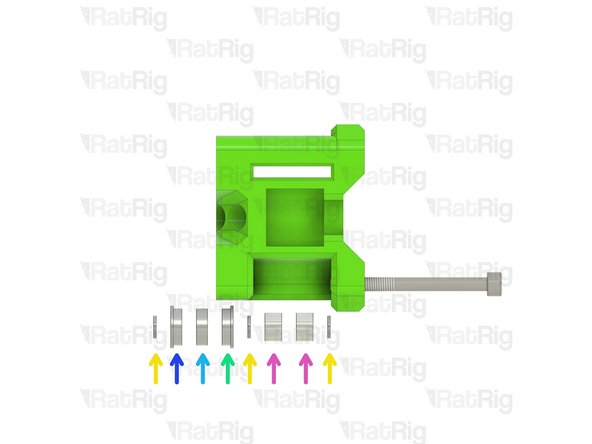

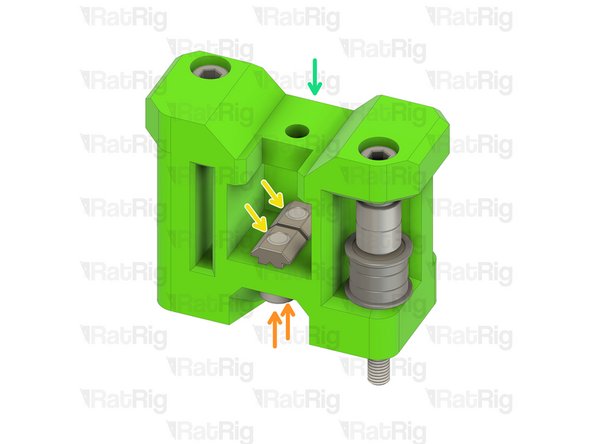

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the top)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the bottom)

-

6mm Aluminium Spacer

-

-

-

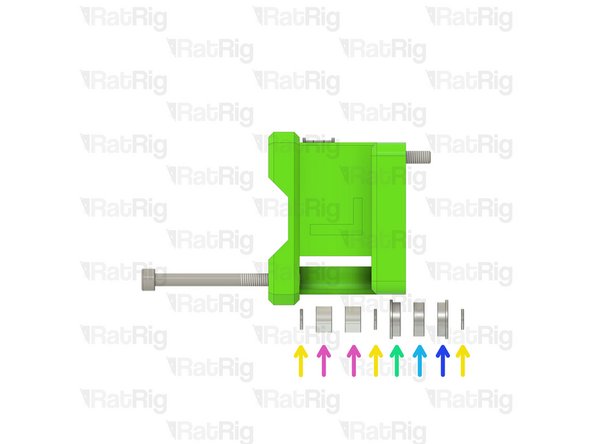

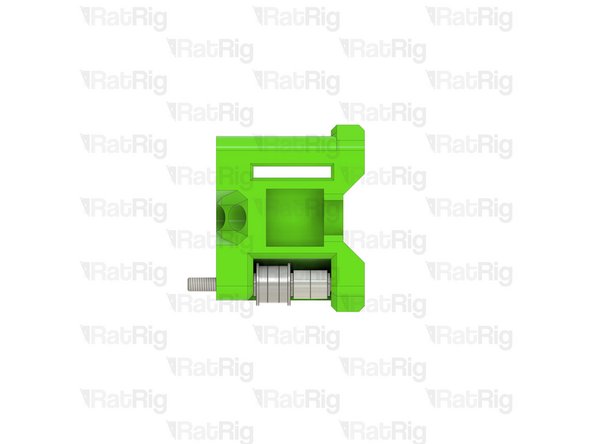

M5x55 Cap Head Screw

-

Assembly from the previous step

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the top)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the bottom)

-

6mm Aluminium Spacer

-

-

-

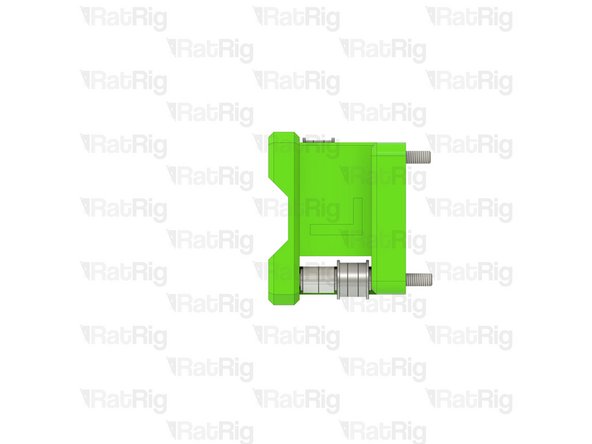

M5x55 Cap Head Screw

-

xy_joiner_right_3.1 Printed Part

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the top)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the bottom)

-

6mm Aluminium Spacer

-

-

-

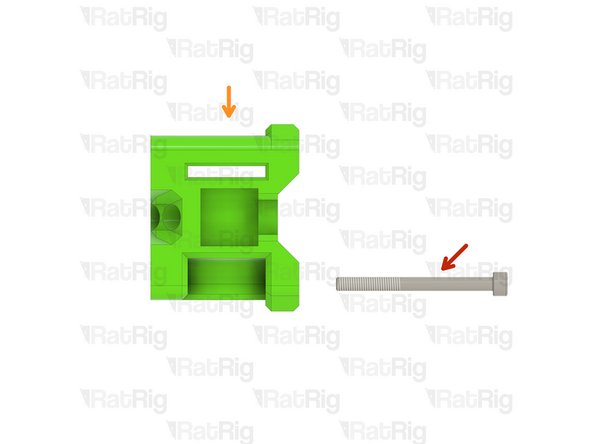

M5x55 Cap Head Screw

-

Assembly from the previous step

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the top)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the bottom)

-

6mm Aluminium Spacer

-

-

-

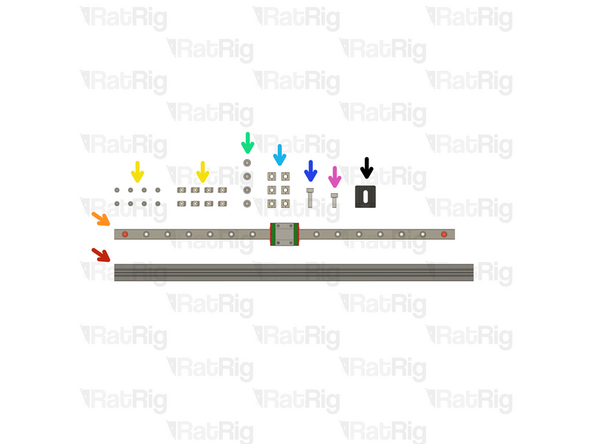

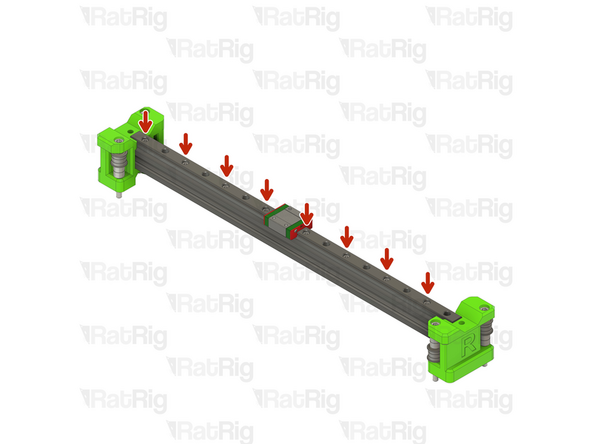

1x 422mm 2020 Extrusion

-

1x 400mm MGN12 Linear Rail

-

8x M3x8 Cap Head Screw & 2020 Drop-in T-Nut - M3

-

4x M5x10 Cap Head Screw

-

6x 2020 Square T-Nut - M5

-

1x M5x18 Cap Head Screw

-

1x M5x12 Cap Head Screw

-

1x x_endstop_block_3.1 Printed Part

-

-

-

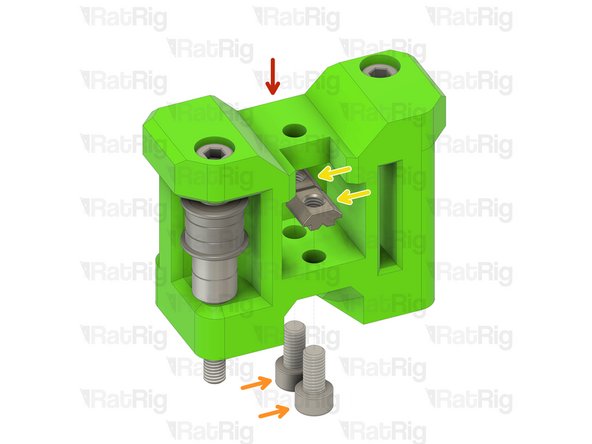

Assembly from Step 3

-

M5x10 Cap Head Screw

-

2020 Square T-Nut - M5

-

Loosely thread a 2020 Square T-Nut onto each of the M5x10 screws

-

Assembly from Step 5

-

-

-

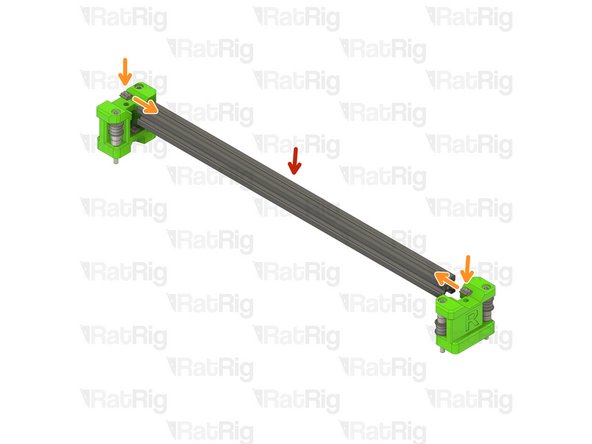

422mm 2020 Extrusion

-

2020 Square T-Nut - M5

-

Install one 2020 Square T-Nut into the top slot on each end of the 2020 extrusion

-

Install the left x-axis end onto one end of the 2020 Extrusion

-

Install the right x-axis end onto the other end of the 2020 Extrusion

-

Make sure the x-axis ends are fully installed on the 2020 extrusion before proceeding

-

-

-

Tighten the marked M5x10 screws to secure the x-axis ends to the 2020 extrusion

-

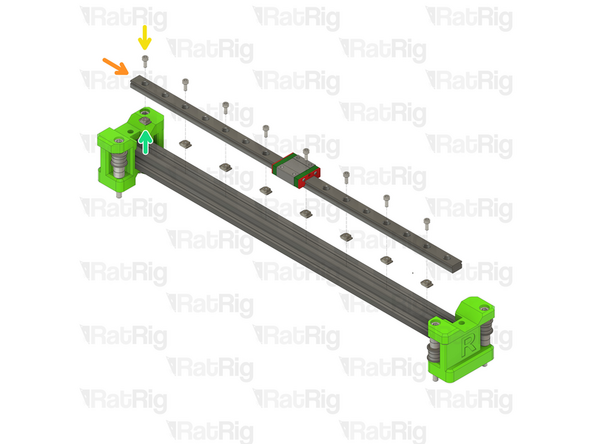

400mm MGN12 Linear Rail

-

Insert an M3x8 screw into every other hole in the linear rail

-

Loosely thread a 2020 T-Nut onto each of the M3x8 screws

-

Install the linear rail into the 2020 extrusion as shown

-

-

-

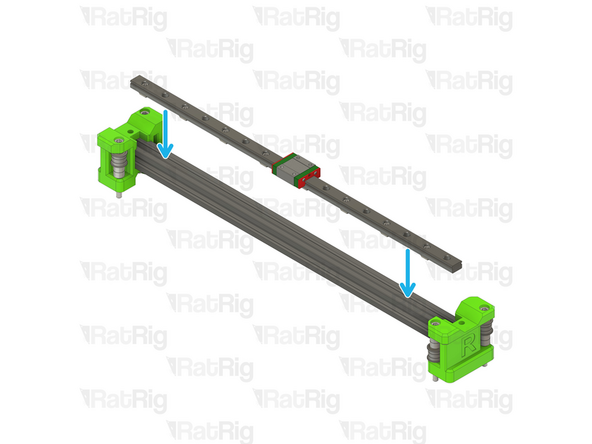

Fasten the marked M3x8 screws, starting from the left

-

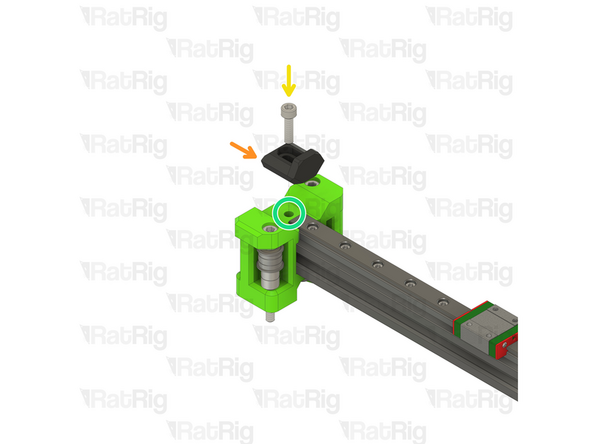

x_endstop_block_3.1 Printed Part

-

M5x18 Cap Head Screw

-

Make sure the previously installed 2020 square T-Nut is aligned with the marked hole. A small screwdriver or hex key can be used to help position it correctly

-

The correct positioning for the x_endstop_block will be set when building the EVA3 assembly at a later point

-

Take care not to over tighten the M5x18 screw as you can damage the printed parts

-

-

-

M5x12 Cap Head Screw

-

Make sure the previously installed 2020 square T-Nut is aligned with the marked hole. A small screwdriver or hex key can be used to help position it correctly

-

Take care not to over tighten the M5x12 screw as you can damage the printed parts

-

-

-

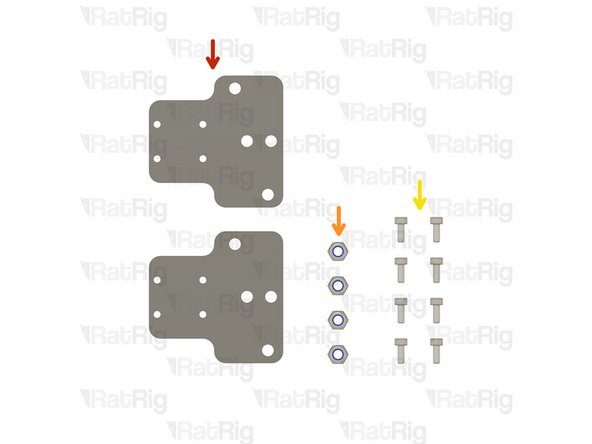

2x xy_joiner_plate

-

4x M5 Nylon Locking Hex Nut

-

8x M3x8 Cap Head Screw

-

-

-

xy_joiner_plate

-

Check that the xy_joiner_plate is installed in the correct orientation. It should be flush with the xy_joiner printed part. If it is not, flip the plate upside down and check again

-

M5 Nylon Locking Hex Nut

-

Tighten the M5x55 screws into the M5 nylon locking hex nuts to secure the plate to the printed part

-

Repeat these steps for the right hand side

-

-

-

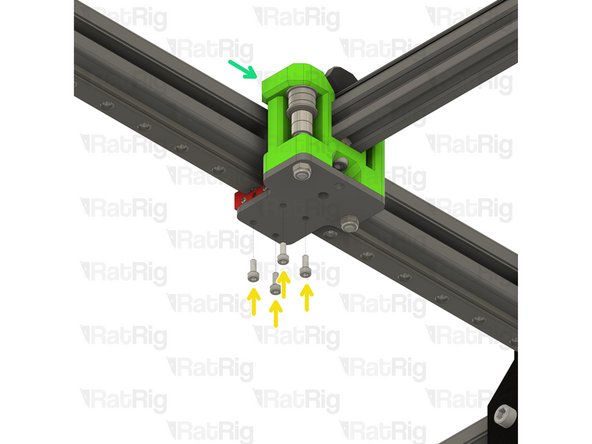

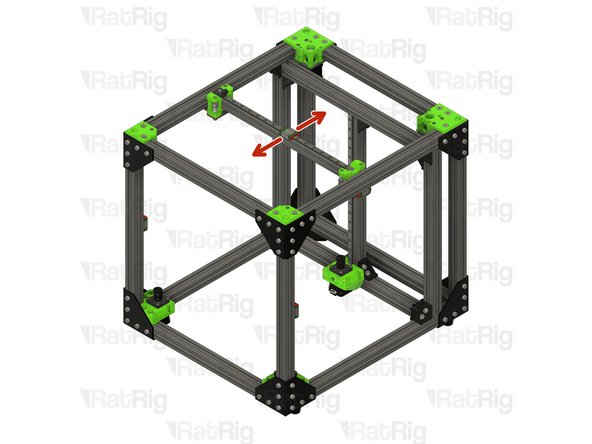

V-Core 3.1 Frame Assembly

-

X-axis Assembly (Right side)

-

M3x8 Cap Head Screw

-

Secure the right side of the x-axis to the right y-axis linear rail as shown

-

X-axis Assembly (Left side)

-

Secure the left side of the x-axis to the left y-axis linear rail as shown

-

-

-

Test the movement of the y-axis over the full travel distance

-

Small changes in resistance are normal, but becoming much harder to push, or binding completely are not

-

-

-

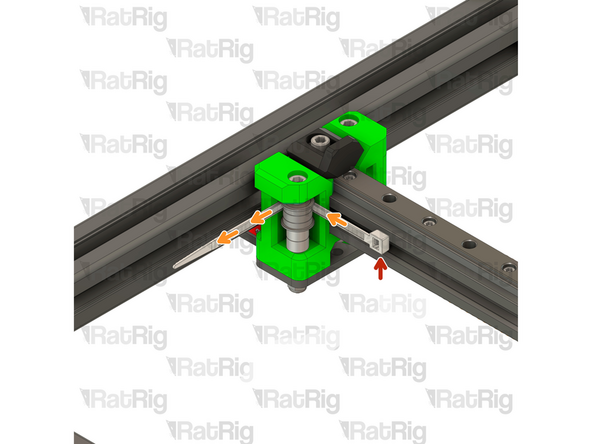

This step is not mandatory, it's just a Rat Rig tip on how to feed the belts on the idlers.

-

Zip Tie

-

The wider the zip tie is, the easier the process will be

-

Bend the tip of the zip tie a little bit and feed it between the printed part and the idler, as shown

-

Insert the belt between the zip tie and the idler

-

Slowly feed the belt and pull the zip tie at the same time

-

-

-

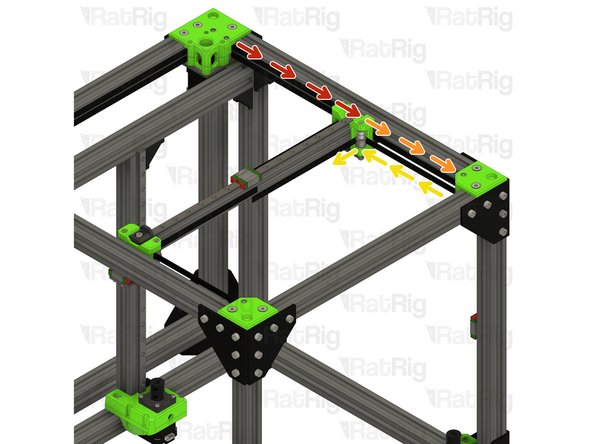

Take the loose end of the top CoreXY belt on the left hand side:

-

Feed the belt behind the left xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the left xy_joiner

-

Take the loose end of the bottom CoreXY belt on the left hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-

-

-

Take the loose end of the bottom CoreXY belt on the right hand side:

-

Feed the belt behind the right xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the right xy_joiner

-

Take the loose end of the top CoreXY belt on the right hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-

Cancel: I did not complete this guide.

29 other people completed this guide.

One Comment

The correct positioning for the x_endstop_block will be set when building the EVA3 assembly at a later point

The rest of the guide never goes into detail of how to set the x and y endstops position correctly? The EVA section doesn't have it nor the last section after it. which it goes over tensioning of the belt.