-

-

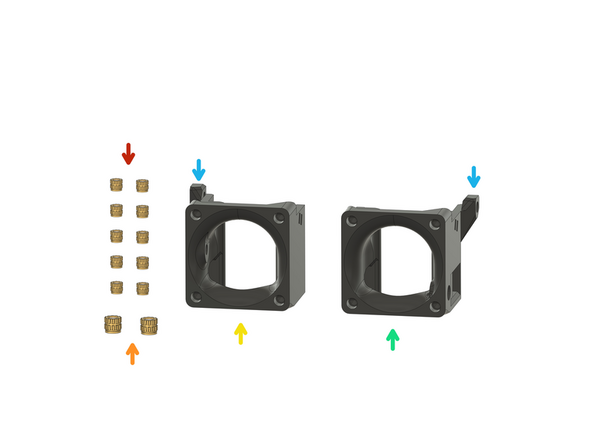

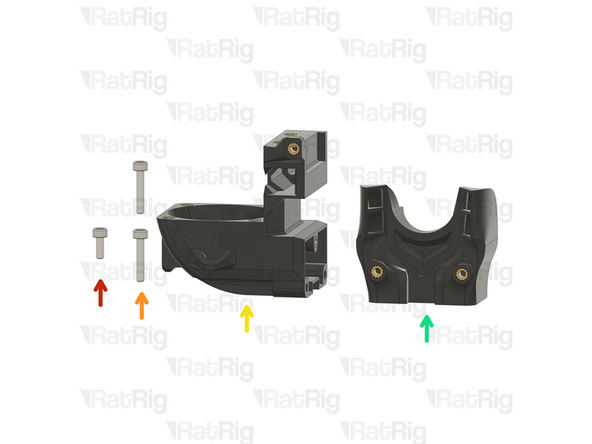

16x Heat Insert M3

-

rr_toolhead_vc4_back_idex_t0

-

rr_toolhead_vc4_back_idex_t1

-

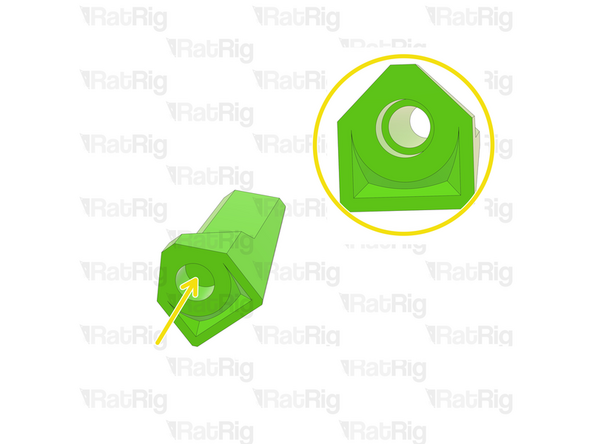

Remove the AGAD parts (Anti Gravity Assistance Device)

-

Rat Rig avoids supports at all costs, so we're introducing the AGAD as this printed part needs to have a very precise overhang.

-

-

-

rr_toolhead_vc4_back_idex_t0

-

rr_toolhead_vc4_back_idex_t1

-

16x Heat Insert M3

-

-

-

10x Heat Insert M3

-

2x Heat Insert M4

-

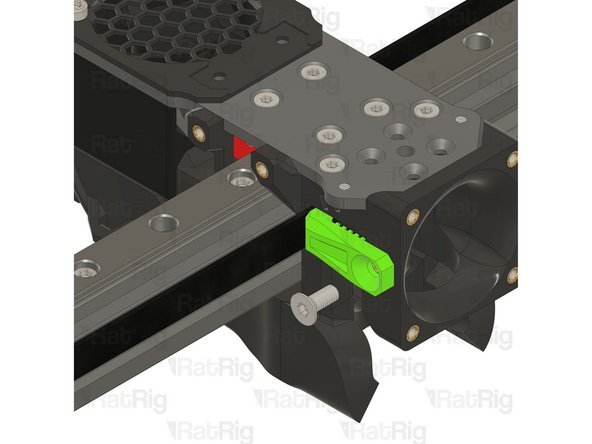

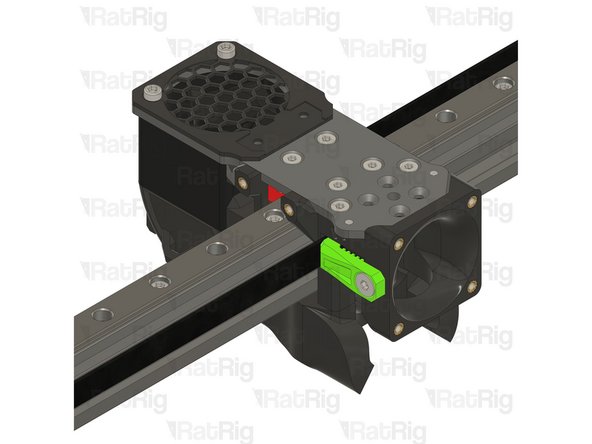

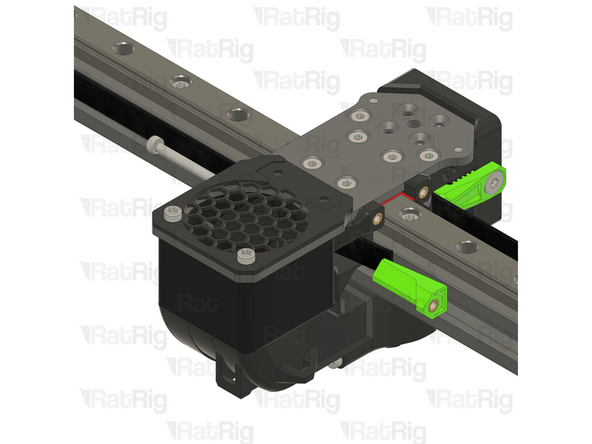

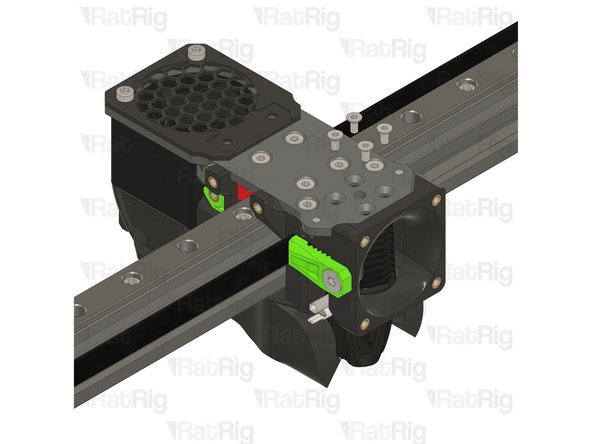

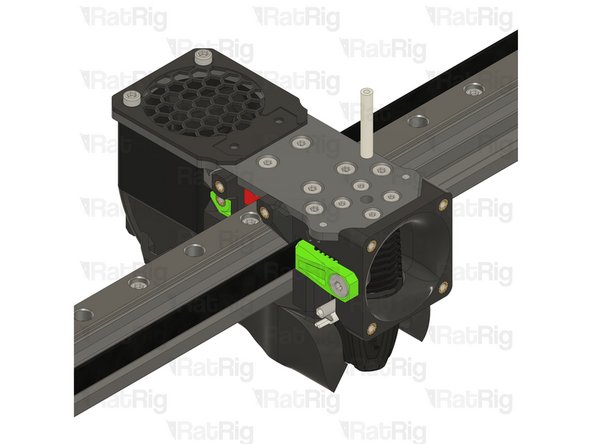

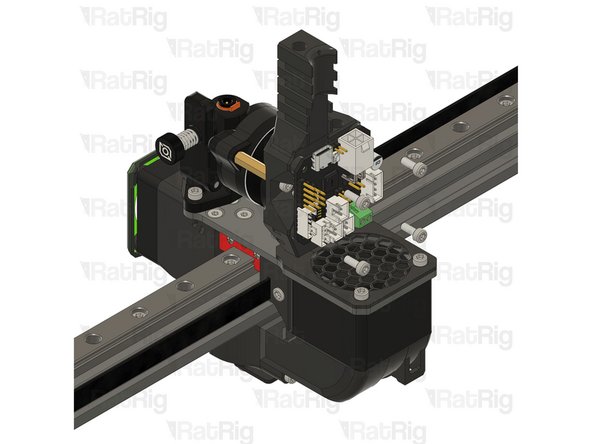

rr_toolhead_vc4_idex_idex_t0

-

rr_toolhead_vc4_idex_idex_t1

-

The only differences between the two printed parts are the endstop location and the M4 belt clamp heat insert. For T0, these elements are positioned on the left, while for T1, they are positioned on the right.

-

-

-

8x Heat Insert M3

-

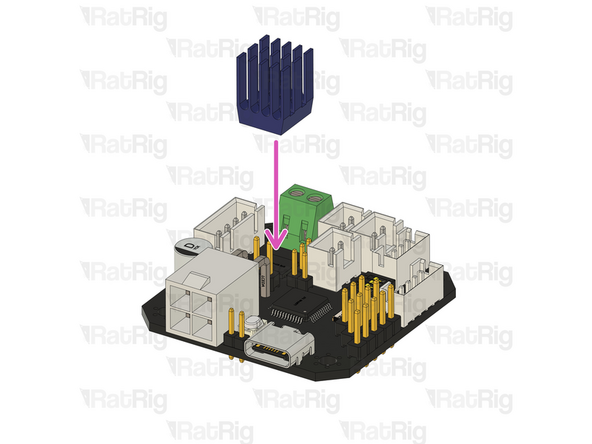

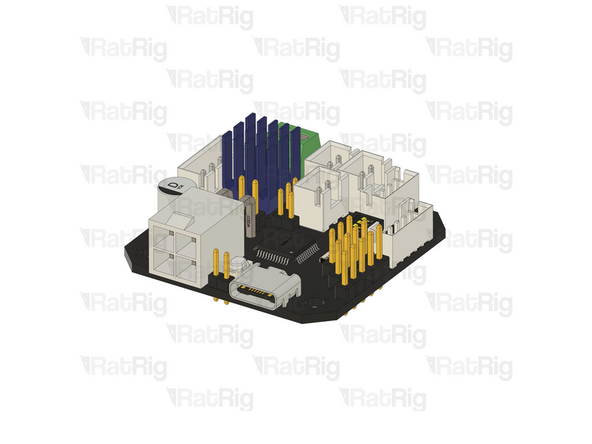

2x rr_vc4_toolhead_toolboard_vertical

-

-

-

10x Heat insert M3

-

2x rr_toolhead_vc4_duct_idex

-

-

-

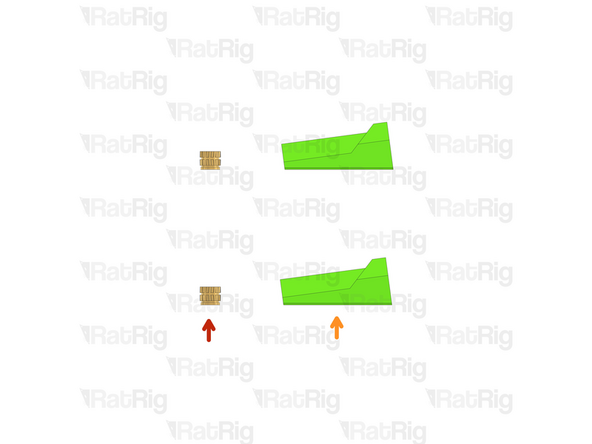

2x Heat Insert M3

-

2x rr_toolhead_vc4_back_clamp

-

Clean the sacrificial layers on the rr_vc4_toolhead_back_clamp parts, obtaining a clean passthrough hole.

-

-

-

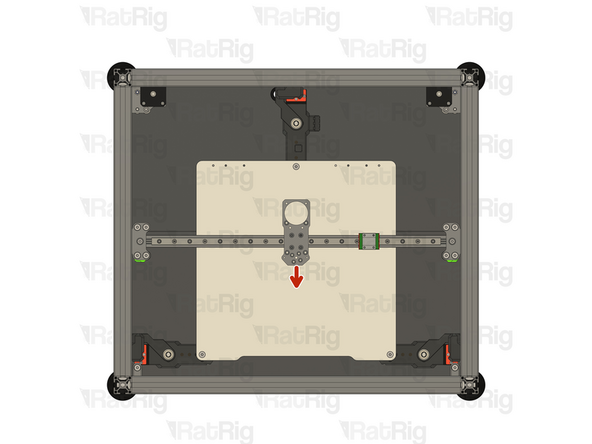

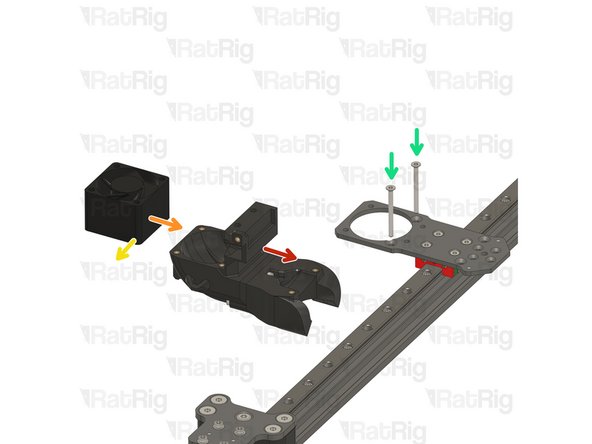

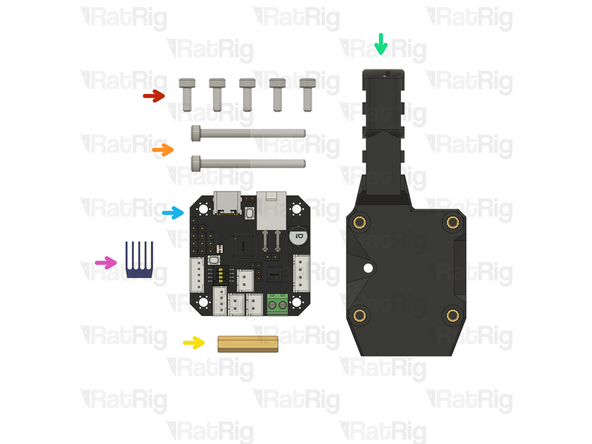

1x Rat Rig toolhead plate

-

4x M3x6 Countersink Screw with applied thread locker

-

-

-

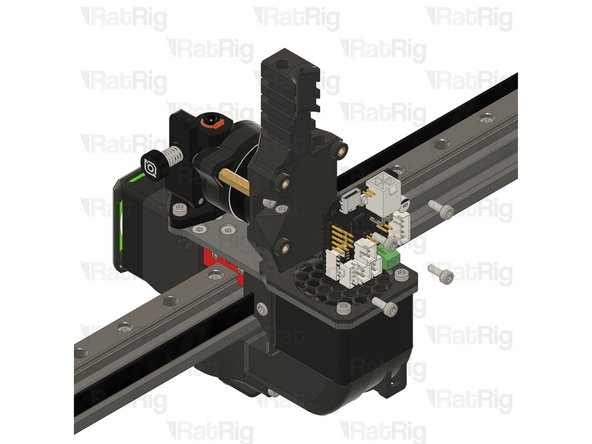

Rat Rig toolhead plate

-

4x M3x6 Countersink Screw

-

Tighten the M3x6 Countersink Screws to secure the plate to the carriage.

-

Pay attention to the orientation of the metal plate, having the pointy side towards the front of the printer, chamfered holes up.

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

After tightening the screws, it is essential to verify that the X carriage retains its free movement. Excessive tightening of the screws may lead to the binding of the carriage.

-

-

-

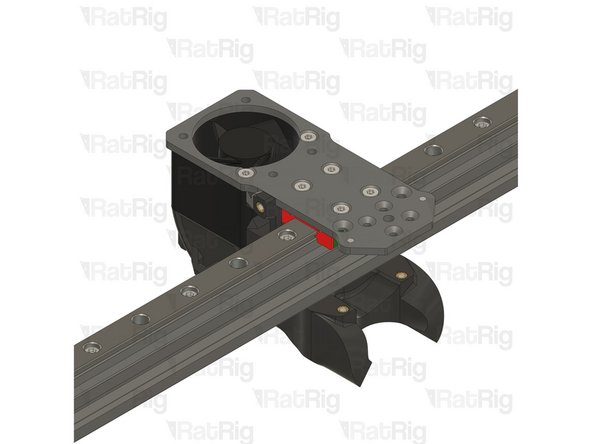

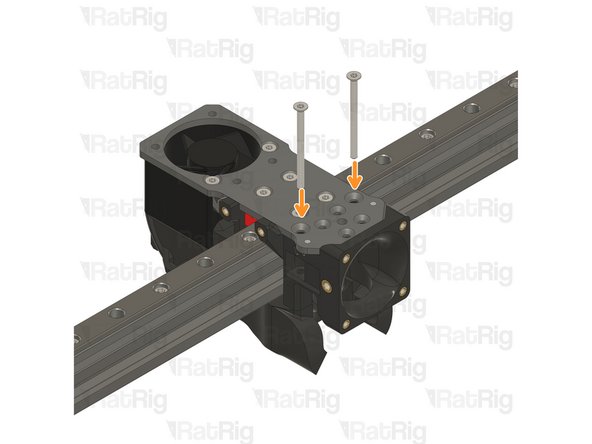

1x M3x8 Cap Head Screw

-

2x M3x16 Cap Head Screw

-

1x rr_toolhead_vc4_back_idex_t0 assembly

-

1x rr_toolhead_vc4_duct_idex assembly

-

-

-

Join the two assemblies together, ensuring they are flush.

-

2x M3x16 Cap Head Screw

-

Insert the M3x16 screws through the back part and tighten them into the duct.

-

M3x8 Cap Head Screw

-

Feed the M3x8 screw from the opposite side and secure the parts together.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

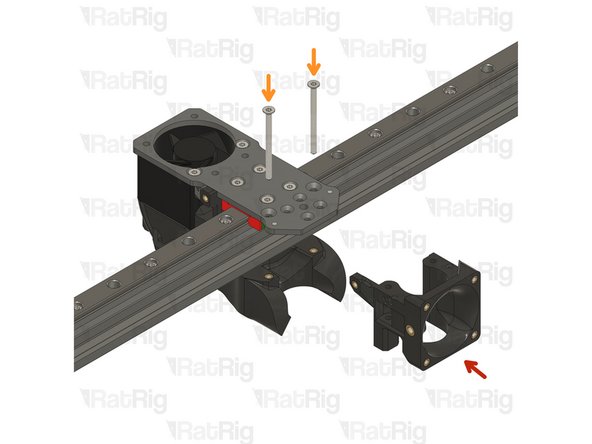

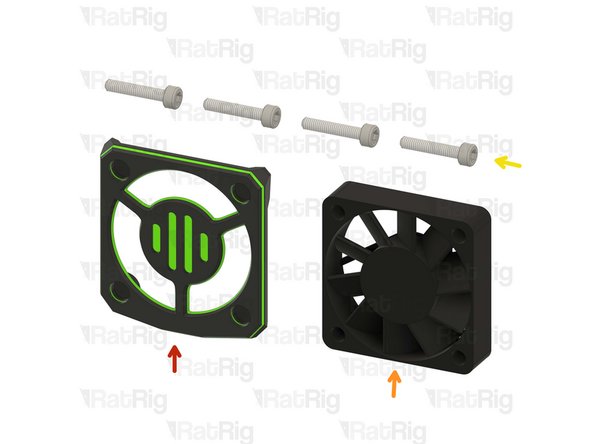

4028 Cooling fan

-

Remove the four rubber spacers on the 4028 Part Cooling Fan

-

-

-

rr_vc4_toolhead_fan_grille

-

rr_vc4_toolhead_front_idex_t0 assembly

-

M4x10 Countersink Screw

-

3x M3x35 Cap Head Screw

-

2x M3x40 Countersink Screw

-

2x rr_vc4_toolhead_front_clamp

-

rr_toolhead_vc4_back_clamp assembly

-

-

-

Back part & duct sub-assembly

-

4028 Part Cooling Fan

-

Pay special attention to the fan airflow, it should blow the air towards the cooling duct. Most fans have a small arrow indicating the airflow.

-

Point the fan wires to this side.

-

2x M3x35 Countersink Screw

-

Feed the M3x35 screws into the toolhead plate, through the 4028 part cooling fan and tighten them into the printed sub-assembly.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

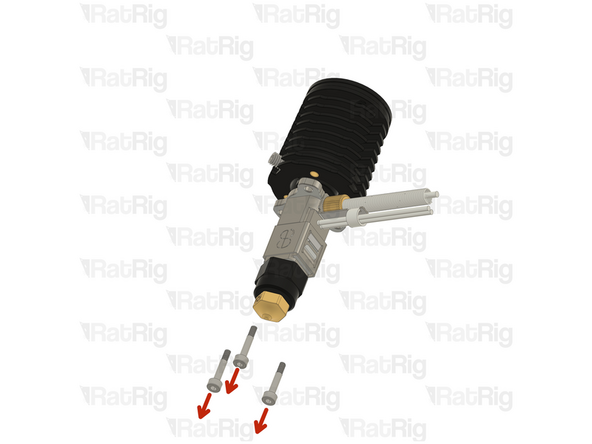

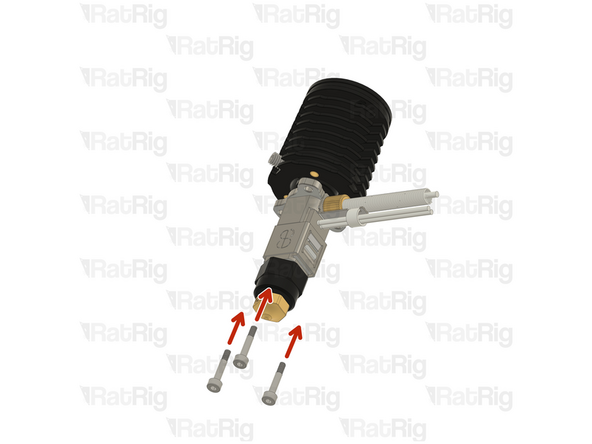

Phaetus Rapido V2 UHF Hotend

-

4x M2.5x6 Countersink Screw

-

PTFE tube - 24.5mm

-

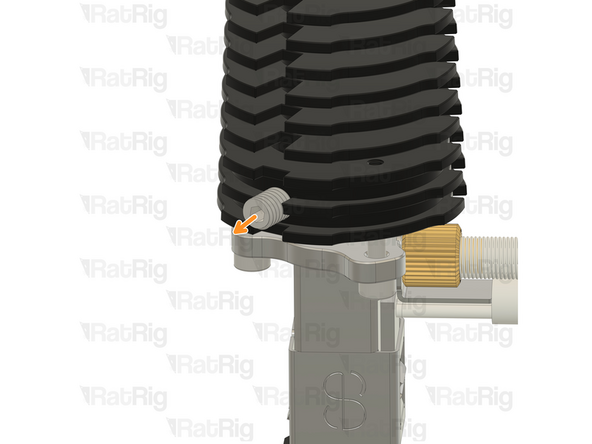

Remove the two countersink screws on top of the rapido

-

Remove the V6-style adapter, it is not required for the RatRig toolhead

-

-

-

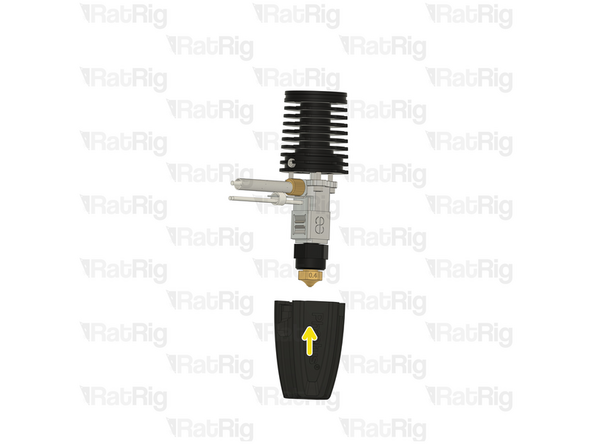

If the cables of your Rapido 2 hotend don't align perfectly with the toolhead slot, please follow the next steps:

-

Push down on the silicone sock to remove it

-

Loosen the set screw on the heatsink

-

Do not remove it completely to avoid losing it

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

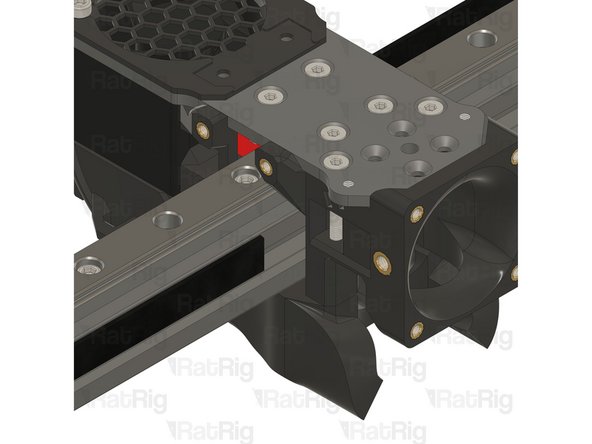

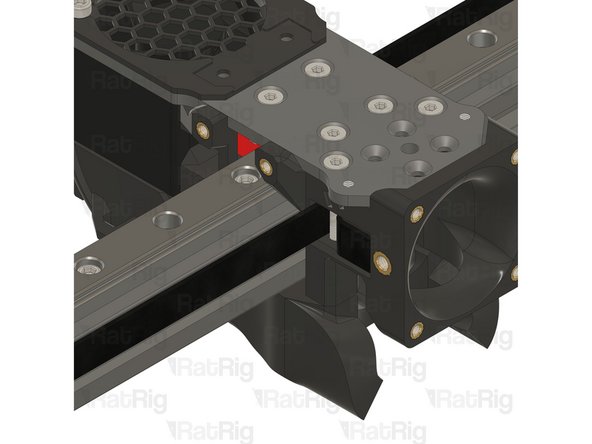

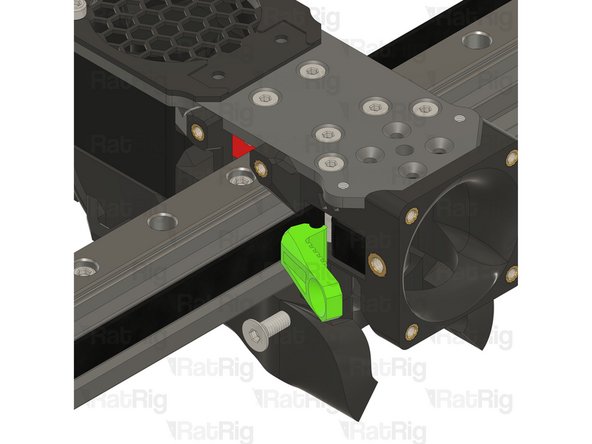

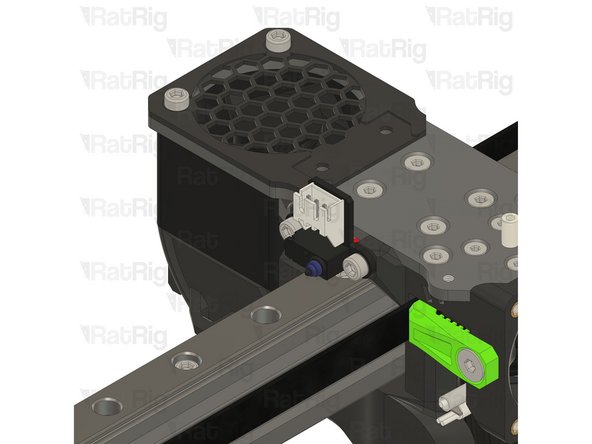

1x Rat Rig Endstop

-

2x M3x6 Cap Head Screw

-

-

-

Insert wisdom here

-

-

-

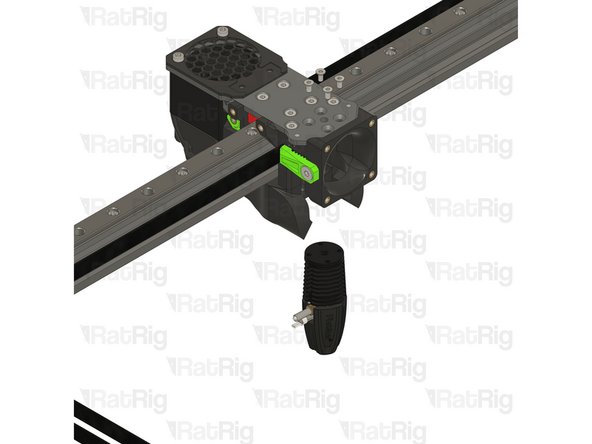

1x rr_vc4_toolhead_shroud

-

40x10mm 24V Axial Fan

-

4x M3x16 Cap Head Screw

-

Remove the sacrificial layers from the back of the rr_vc4_toolhead_shroud

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-

-

-

Insert wisdom here

-