Introduction

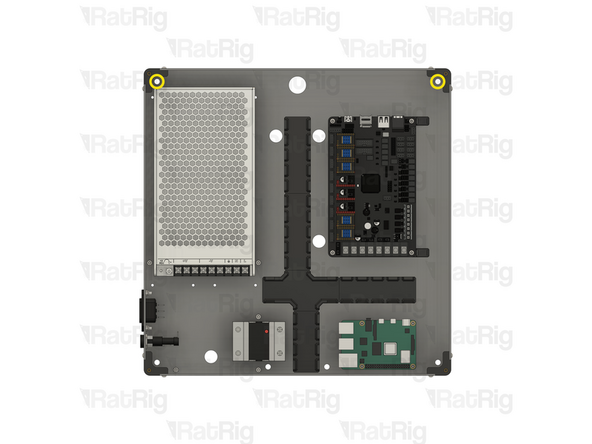

This section of the guide will step you through preparing and assembling all of the components used in the V-Core 4.0 electronics enclosure.

-

-

The following tools are required for this guide:

-

Allen key / hex wrenches in the following sizes: 2mm, 2.5mm & 5mm

-

Spanners / wrenches in the following sizes: 5.5mm, 7mm, 10mm & 15mm

-

The following tools are recommended for this guide:

-

A slim 7mm hex socket and ratchet, or 7mm socket driver

-

-

-

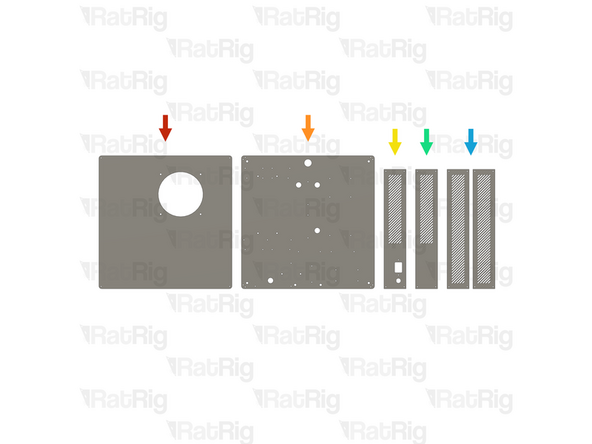

The six panels for the V-Core 4.0 aluminium electronics enclosure are provided as a single pack (SKU: HW3944GC)

-

1x Lid panel

-

1x Base panel

-

1x IEC inlet panel

-

1x Bottom vent panel

-

2x Top / Side vent panels

-

-

-

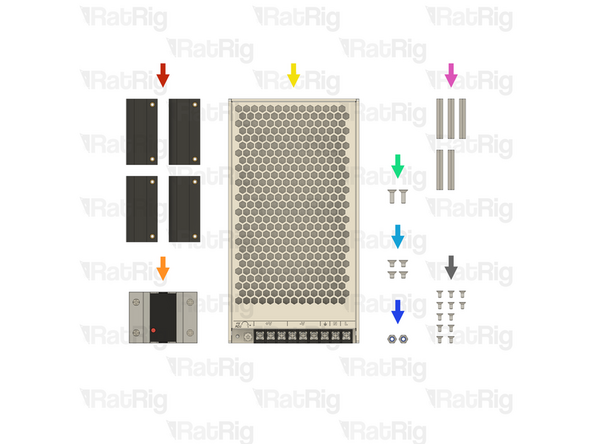

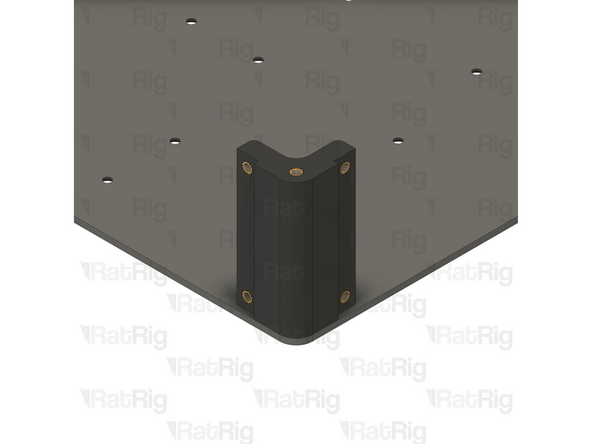

4x vc4_electronics_1.2_corner assemblies (SKU: PP000352)

-

1x 40A Solid State Relay (SKU: HW1733EC)

-

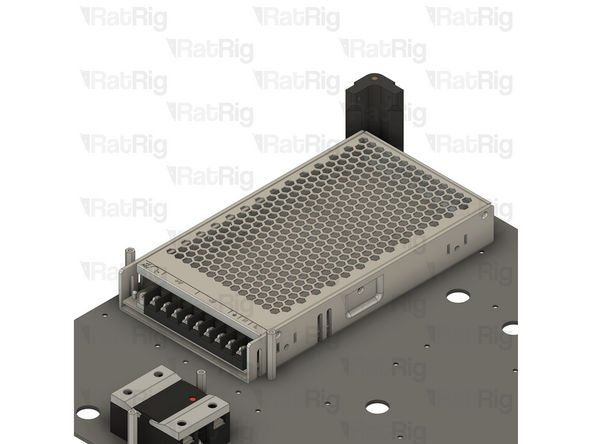

1x 250W 24V Fanless Power Supply (SKU: HW1351EC)

-

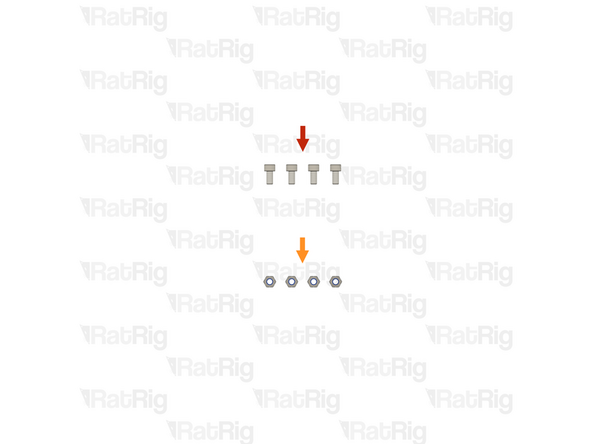

2x M4x12 Countersink Screw (SKU: HW3259SC)

-

4x M4x6 Countersink Screw (SKU: HW3777SC)

-

2x M4 Locking Hex Nut (SKU: HW1374NC)

-

5x M3 Hex Standoff - 35mm (SKU: HW3935NC)

-

13x M3x6 Countersink Screw (SKU: HW3414SC)

-

-

-

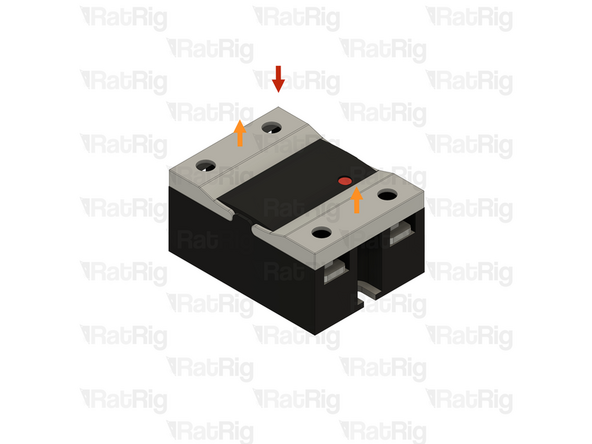

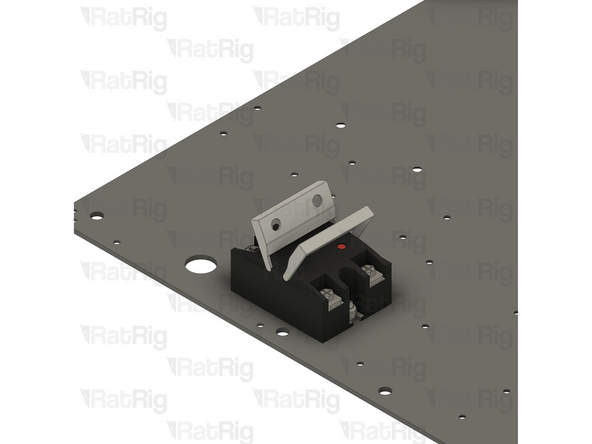

1x 40A Solid State Relay

-

The Solid State Relay has a plastic guard on each end. These must be rotated upwards as shown

-

-

-

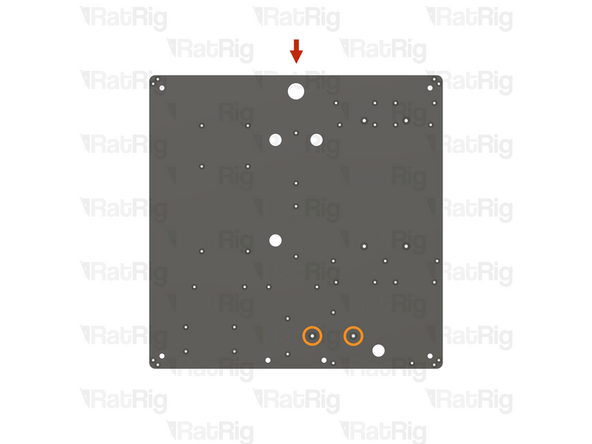

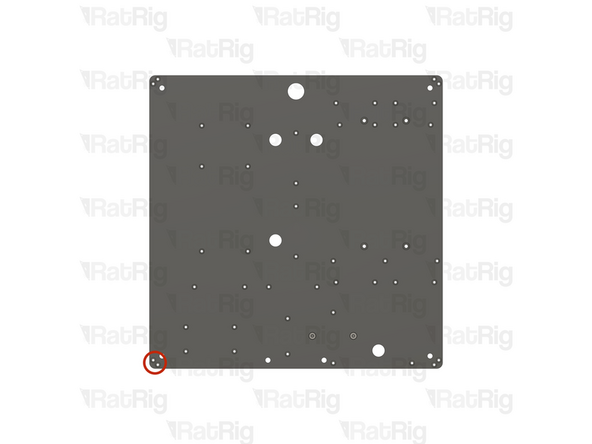

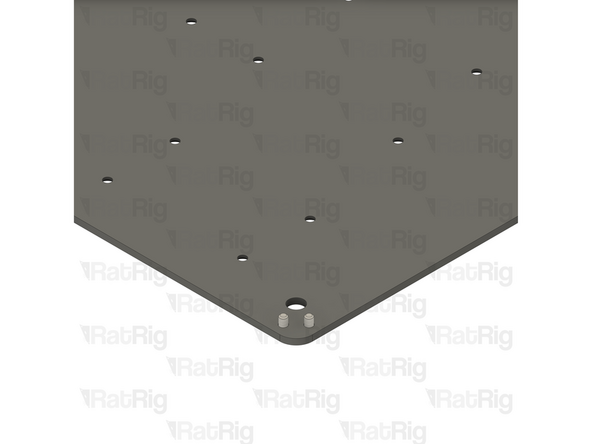

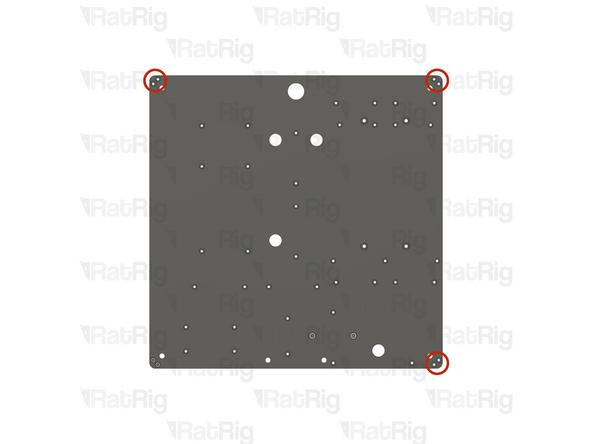

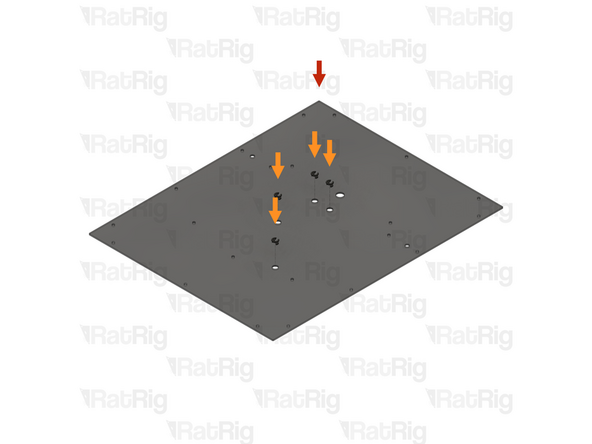

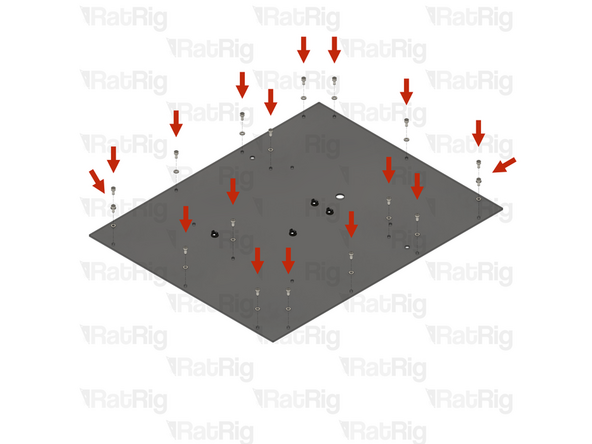

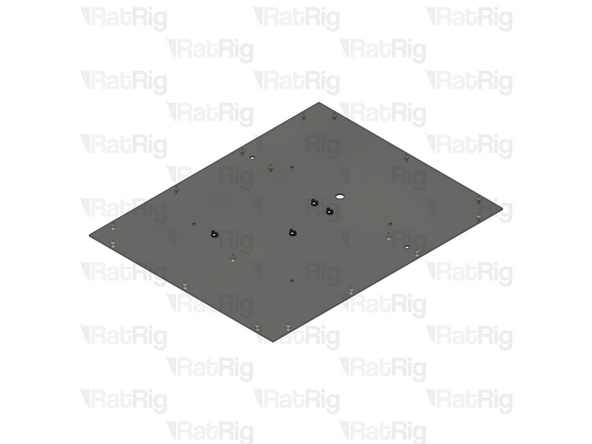

1x Electronics enclosure base panel

-

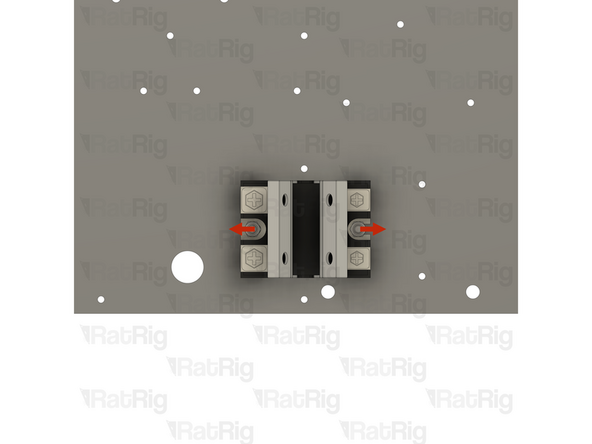

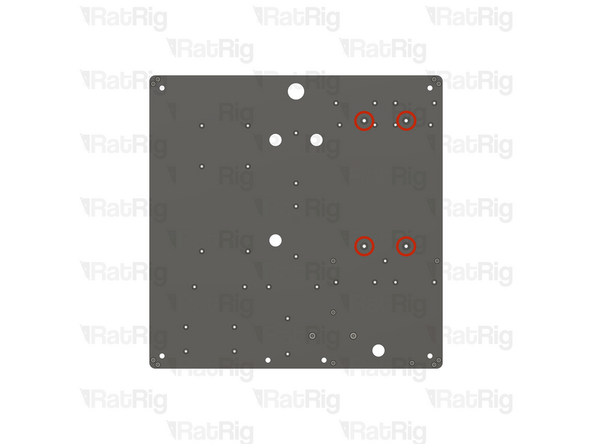

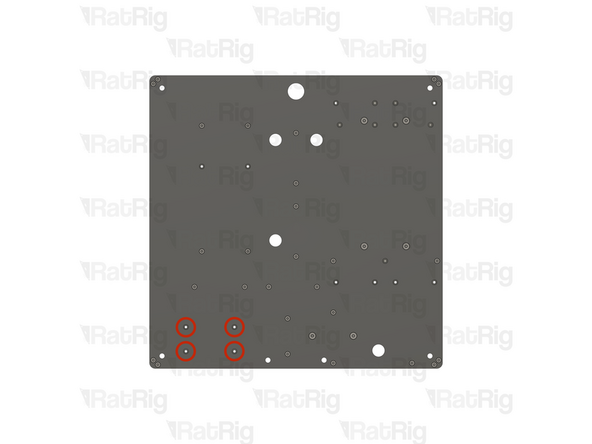

Locate the two marked holes in the base panel

-

2x M4x12 Countersink Screw

-

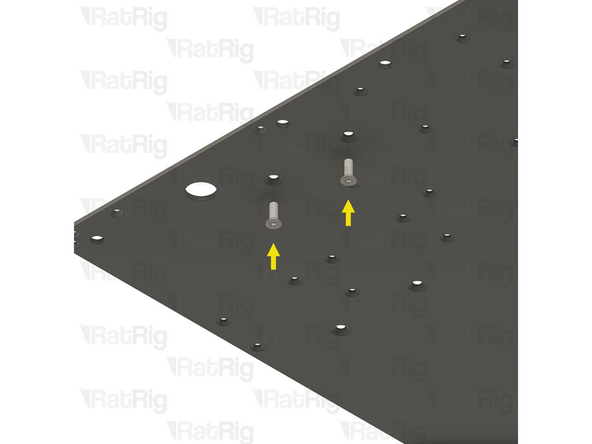

Insert an M4x12 Countersink Screw into each marked hole

-

When correctly installed, the screw heads should be flat with the panel

-

-

-

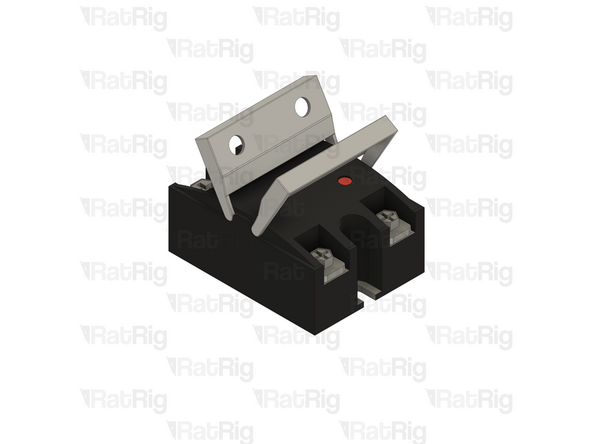

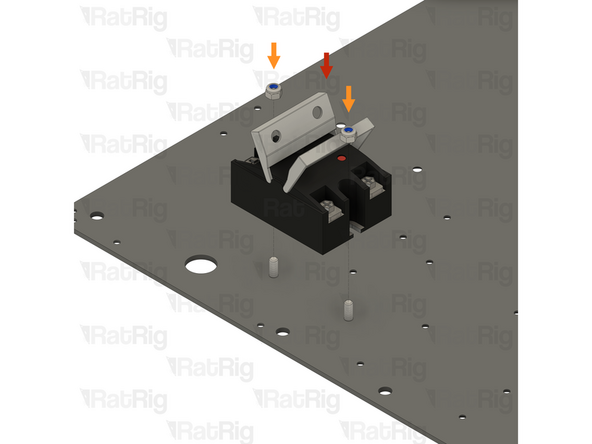

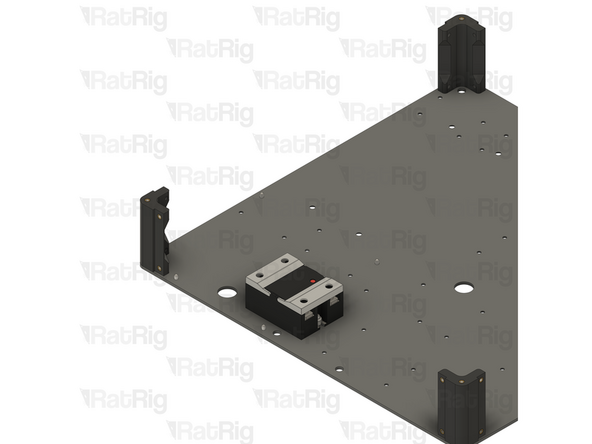

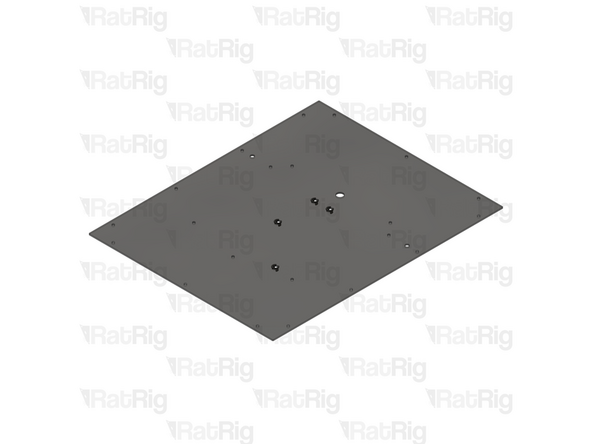

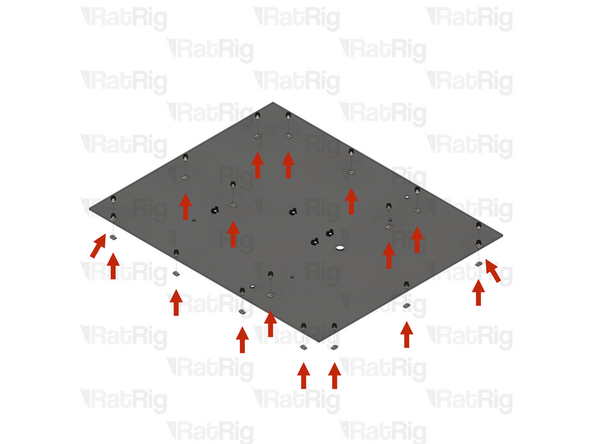

1x 40A Solid State Relay

-

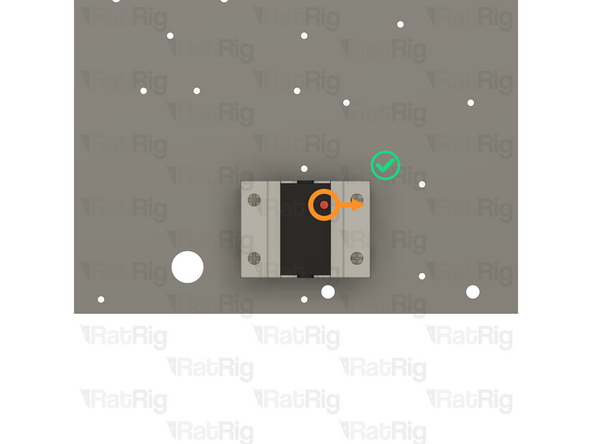

The Solid State Relay has a high voltage and low voltage side, and needs to be oriented correctly

-

Make sure that the red LED indicator on the Solid State Relay faces towards the right hand side of the panel

-

2x M4 Locking Hex Nut

-

Install an M4 Locking Hex Nut onto each M4x12 screw as shown

-

It is recommended, and easier, to use a 7mm socket driver or a slim 7mm hex socket and ratchet to tighten the M4 Locking Hex Nuts

-

It is also possible to use a flat head screwdriver, or needle-nose pliers, to prevent the nut from turning whilst tightening the screws

-

-

-

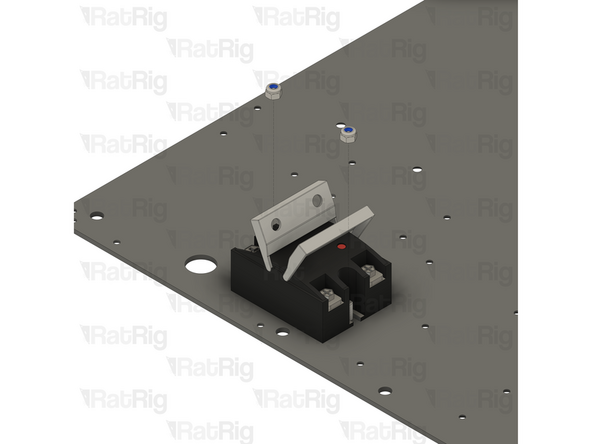

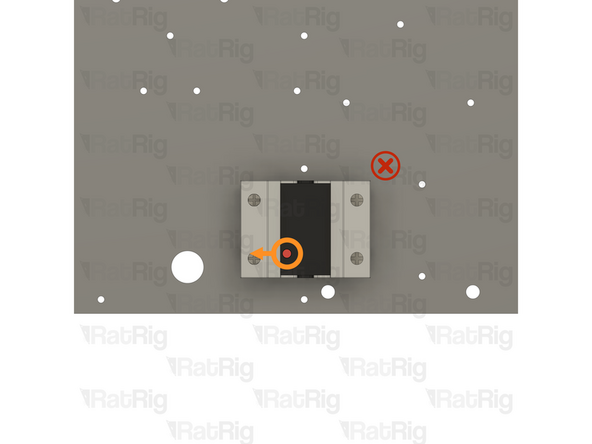

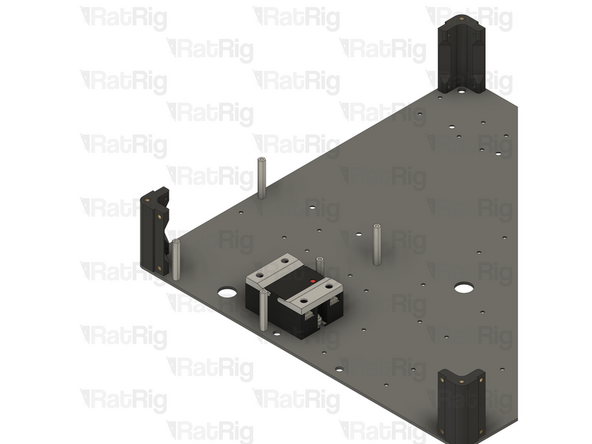

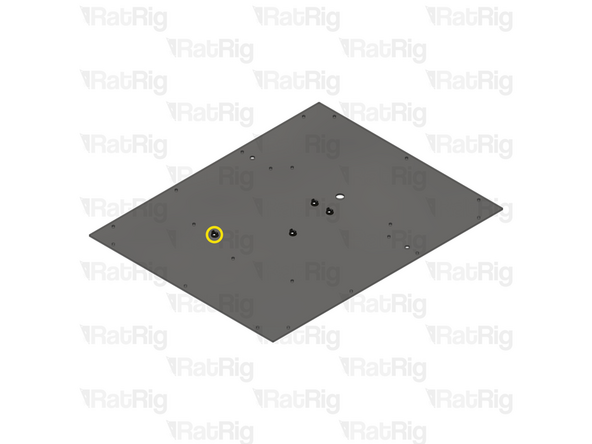

Close the plastic guards on the Solid State Relay

-

Verify the orientation of the Solid State Relay before continuing

-

Make sure that the red LED indicator on the Solid State Relay faces towards the right hand side of the panel

-

-

-

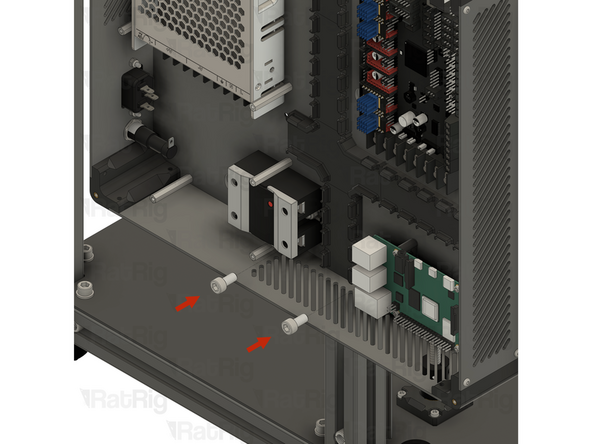

Locate the two marked holes in the base panel

-

2x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

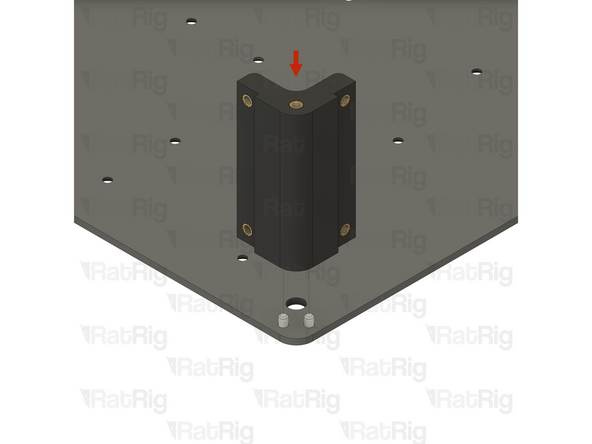

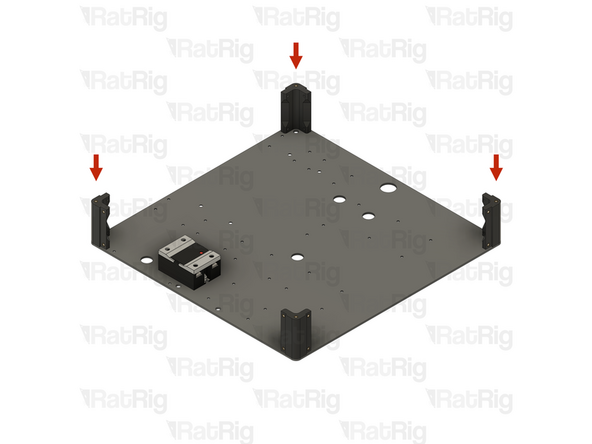

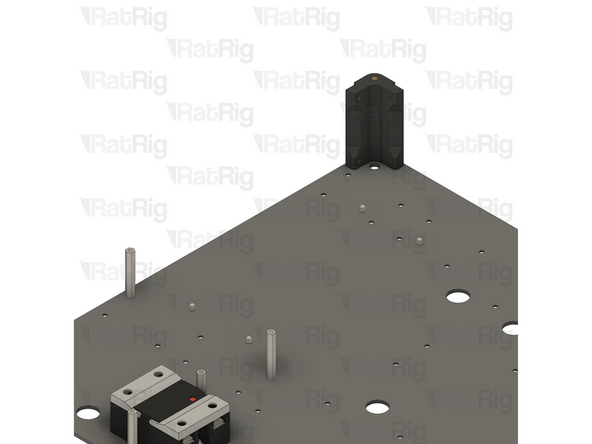

1x vc4_electronics_1.2_corner assembly

-

Tighten both M3x6 Countersink Screws to secure the corner assembly to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

-

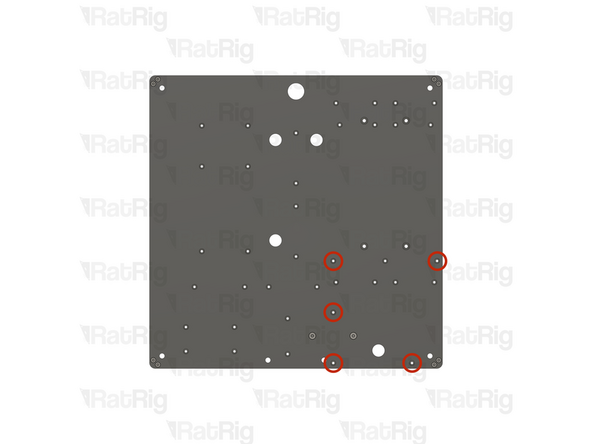

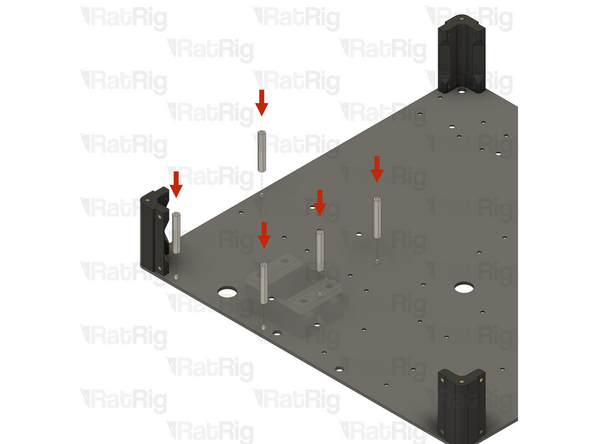

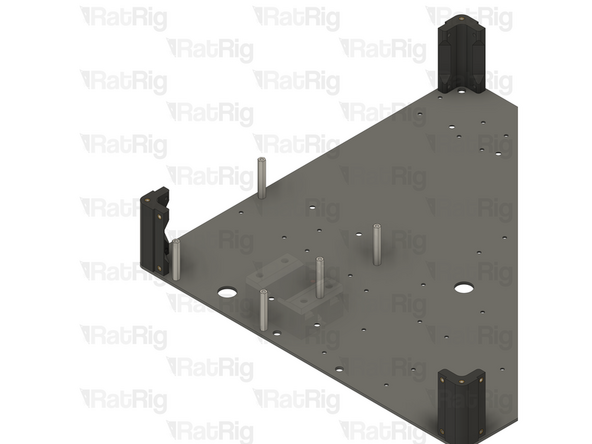

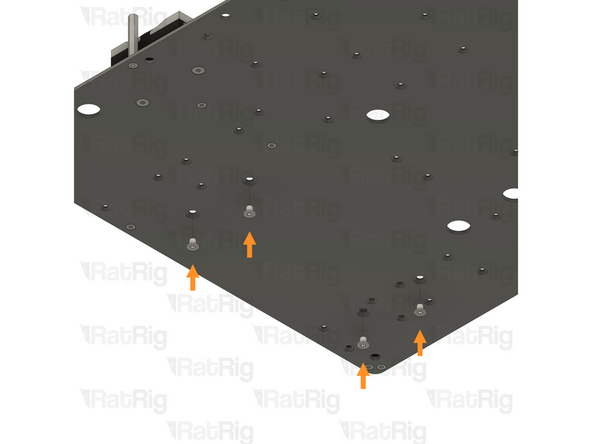

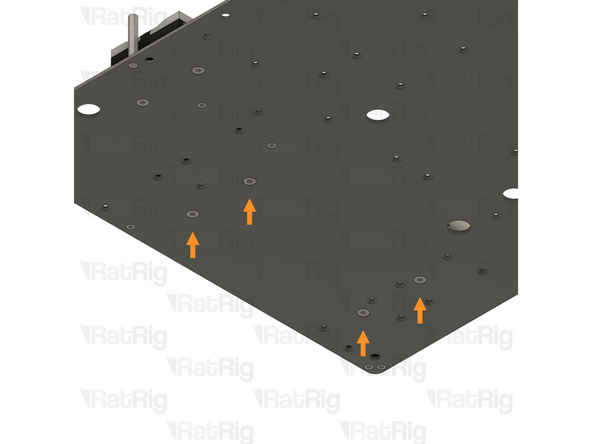

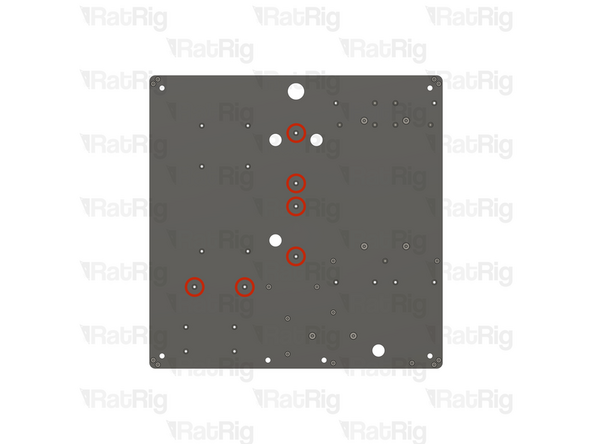

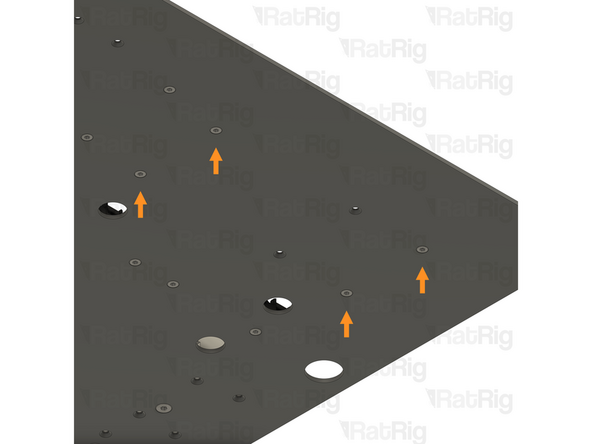

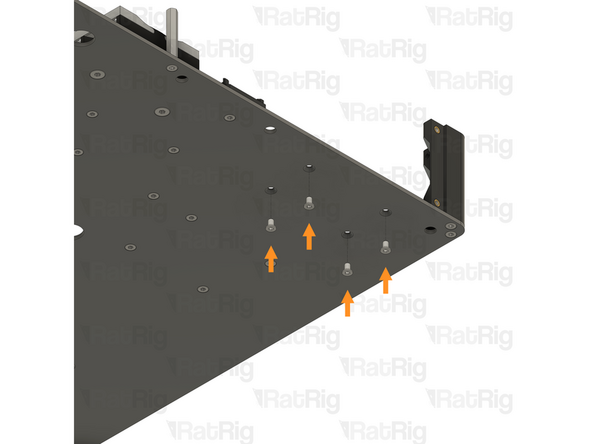

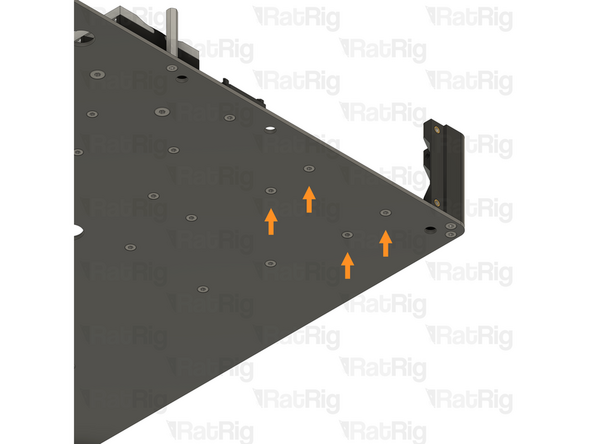

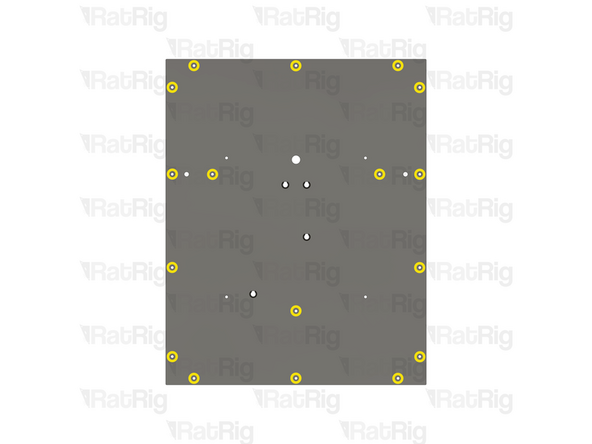

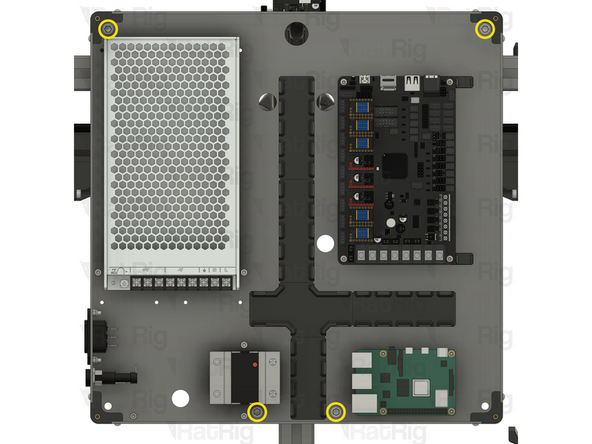

Locate the five marked holes in the base panel

-

5x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

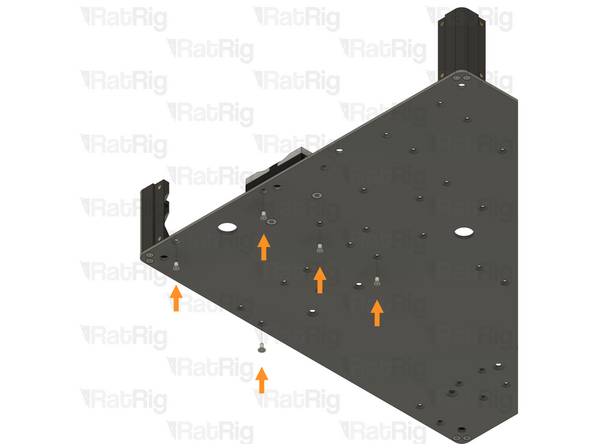

In this step, the Solid State Relay has been faded out to avoid obscuring the instructions

-

5x M3 Hex Standoff - 35mm

-

Thread a Hex Standoff onto each of the five M3 Countersink Screws as shown and tighten them

-

-

-

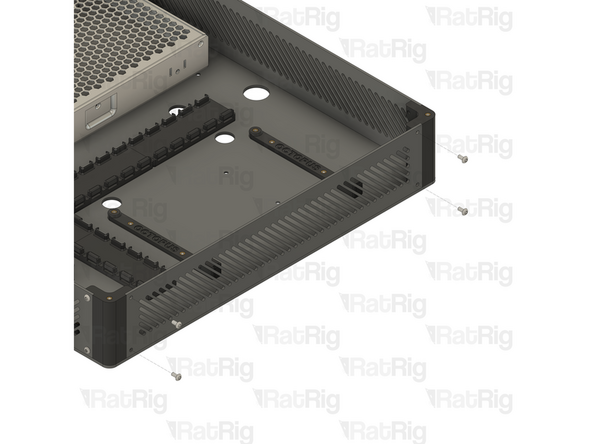

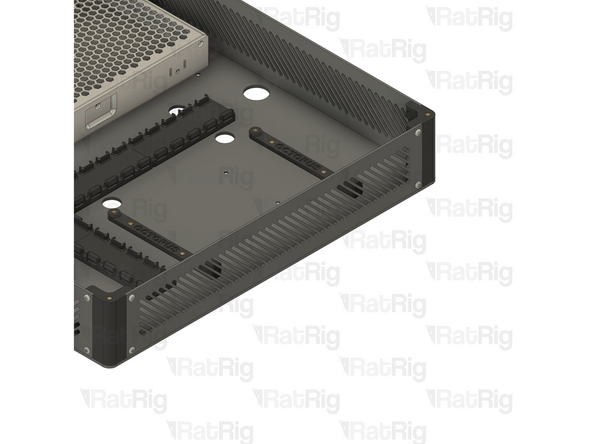

Locate the four marked holes in the base panel

-

4x M4x6 Countersink Screw

-

Insert an M4x6 Countersink Screw into each of the marked holes

-

-

-

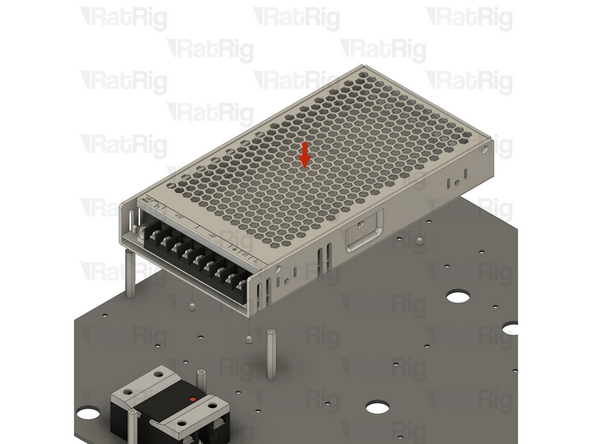

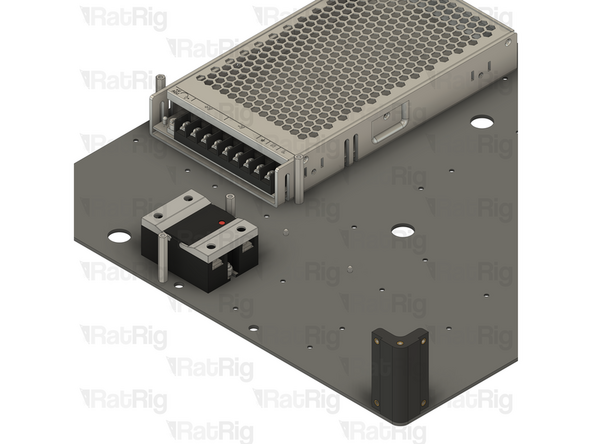

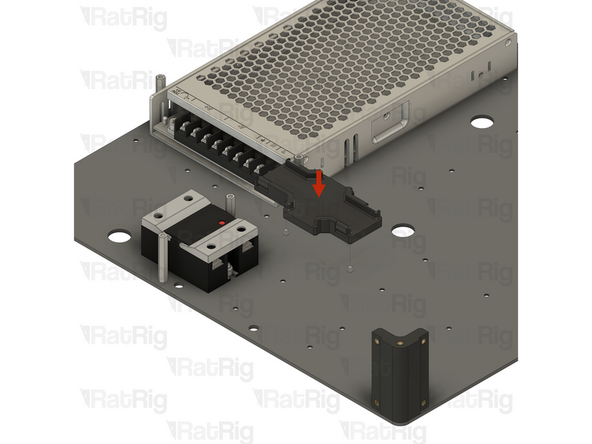

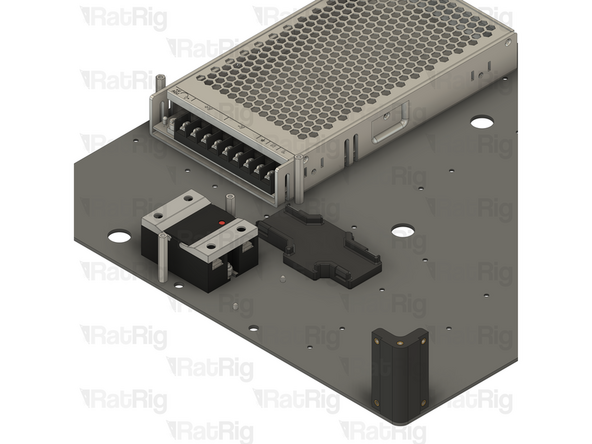

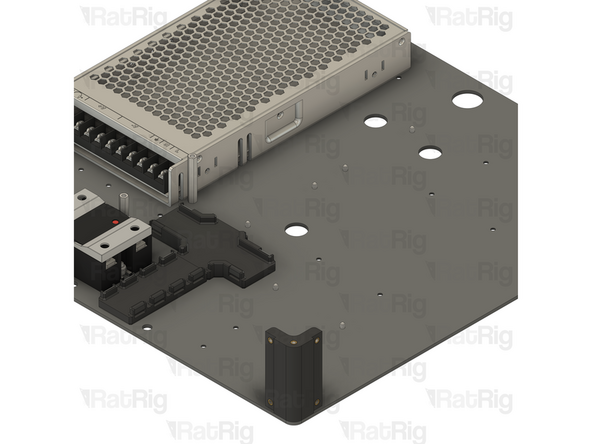

1x 250W 24V Fanless power supply

-

Tighten all four M4x6 Countersink Screws to secure the power supply to the base panel

-

-

-

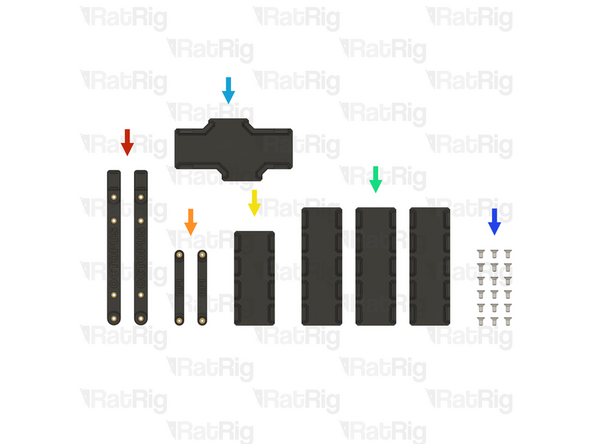

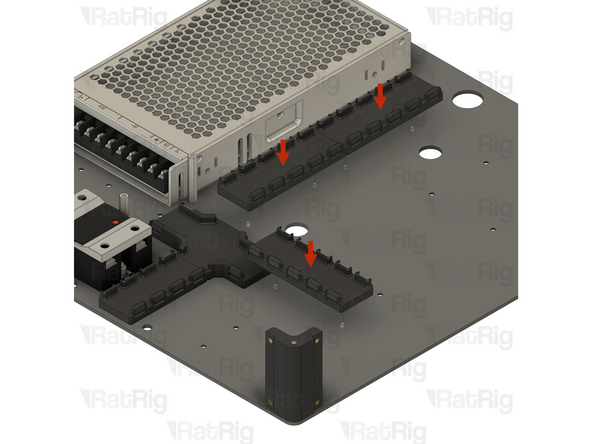

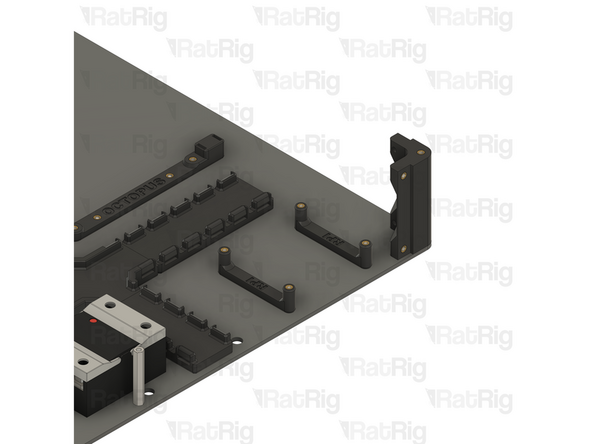

2x vc4_adapter_octopus (SKU: PP000301)

-

2x vc4_adapter_rpi (SKU: PP000302)

-

1x vc4_cable_guide_4 (SKU: PP000304)

-

3x vc4_cable_guide_5 (SKU: PP000305)

-

1x vc4_cable_guide_cross (SKU: PP000306)

-

18x M3x6 Countersink Screw (SKU: HW3414SC)

-

-

-

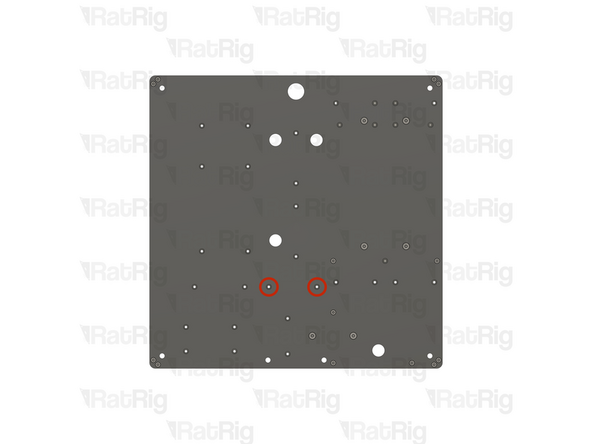

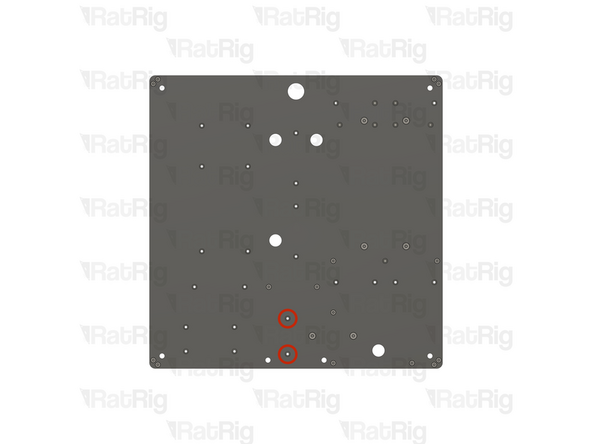

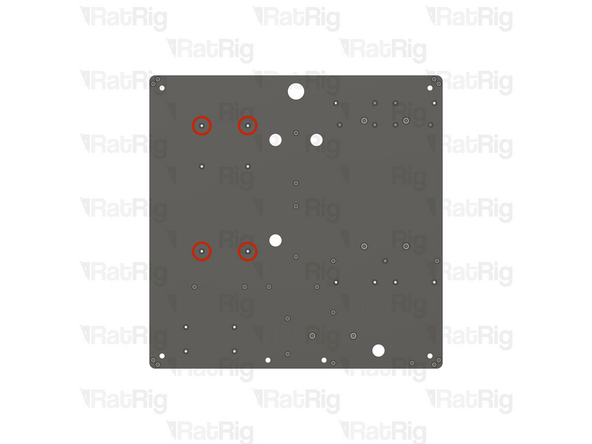

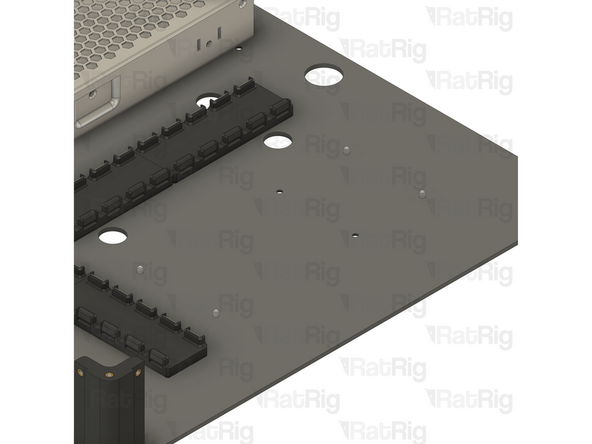

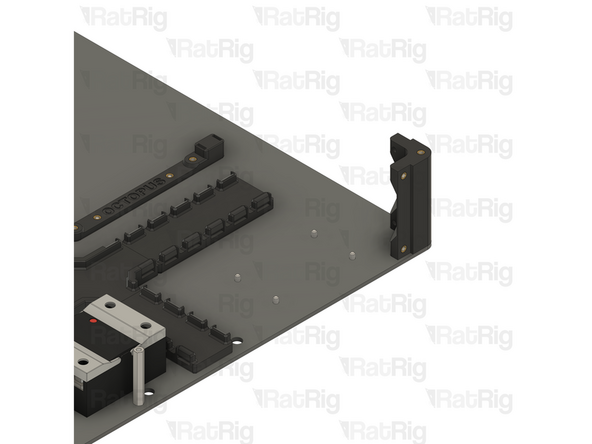

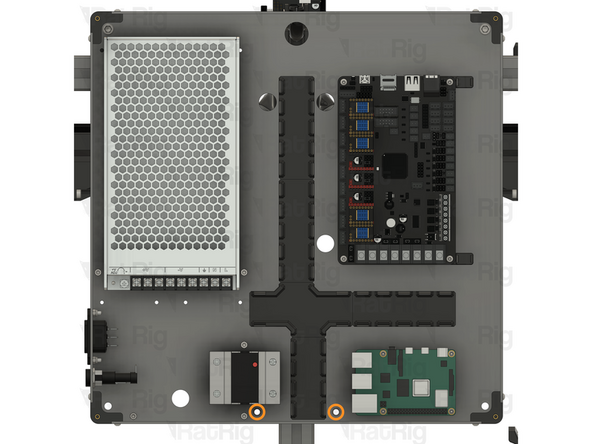

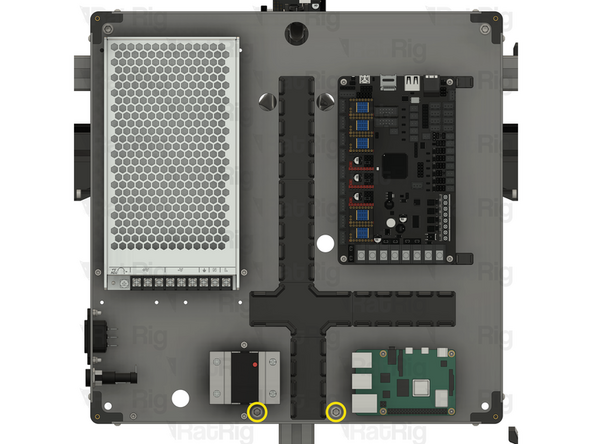

Locate the two marked holes in the base panel

-

2x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

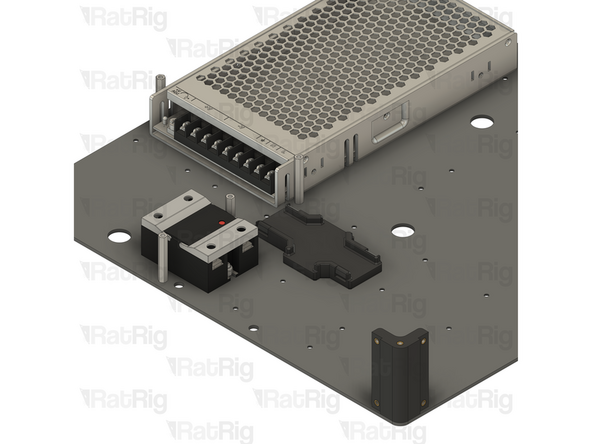

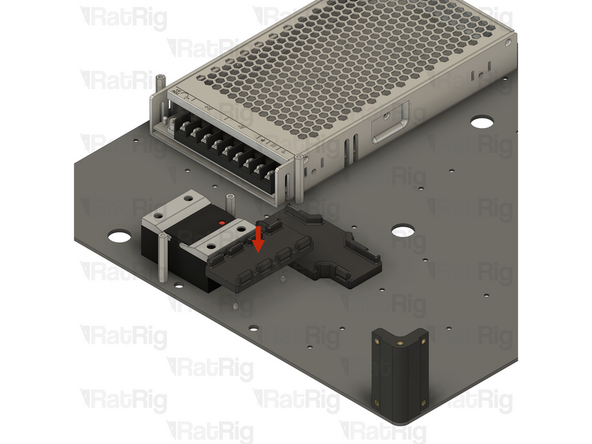

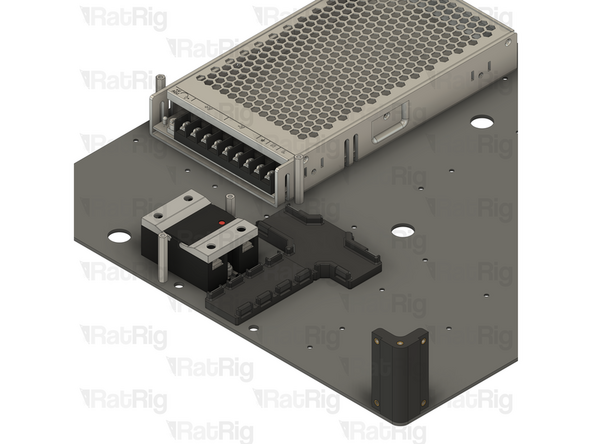

1x vc4_cable_guide_cross

-

Tighten both M3x6 Countersink Screws to secure the cable guide to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

Locate the two marked holes in the base panel

-

2x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

1x vc4_cable_guide_4

-

Tighten both M3x6 Countersink Screws to secure the cable guide to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

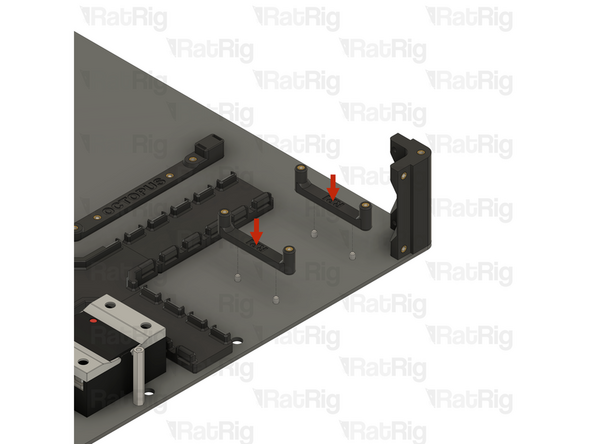

Locate the six marked holes in the base panel

-

6x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

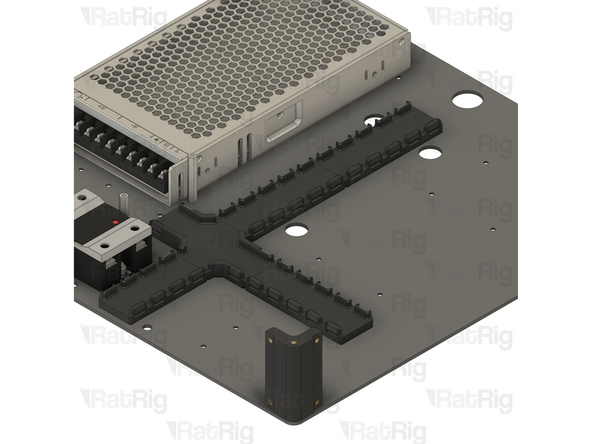

3x vc4_cable_guide_5

-

Tighten all six M3x6 Countersink Screws to secure the cable guides to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

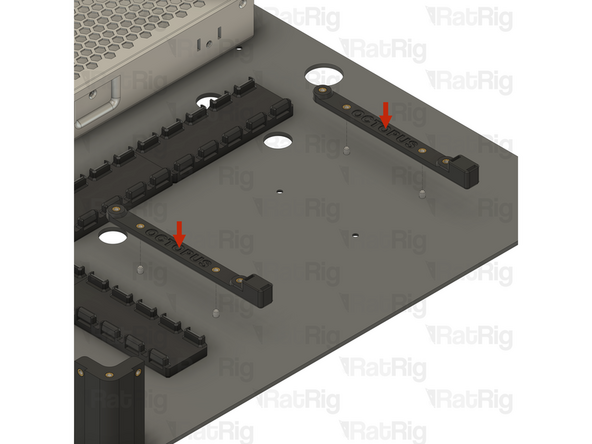

Locate the four marked holes in the base panel

-

4x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

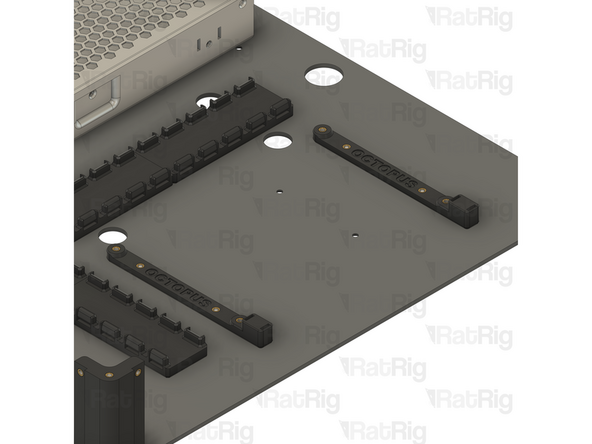

2x vc4_adapter_octopus

-

Tighten all four M3x6 Countersink Screws to secure the cable guides to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

Locate the four marked holes in the base panel

-

4x M3x6 Countersink Screw

-

Insert an M3x6 Countersink Screw into each of the marked holes

-

-

-

2x vc4_adapter_rpi

-

Tighten all four M3x6 Countersink Screws to secure the cable guides to the base panel

-

Be careful not to overtighten the screws as you can damage the printed parts

-

Set this assembly aside until step 34

-

-

-

1x IEC Socket - Schurter 6100.3200 (SKU: HW3957EC)

-

1x Fuse Holder - EATON BK2-HTJ-608I (SKU: HW3958EC)

-

1x Fuse - 6.3x32mm Time-Lag 15A (SKU: HW3959EC)

-

2x M3x12 Countersink Screw (SKU: HW1874SC)

-

2x M3 Locking Hex Nut (SKU: HW1251NC)

-

16x M3x6 Button Head Screw (SKU: HW1337SC)

-

-

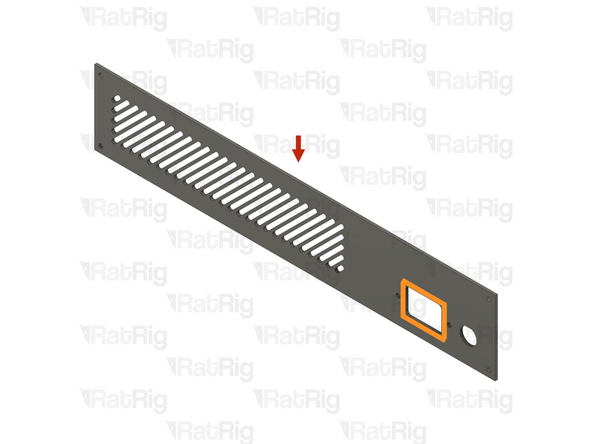

-

-

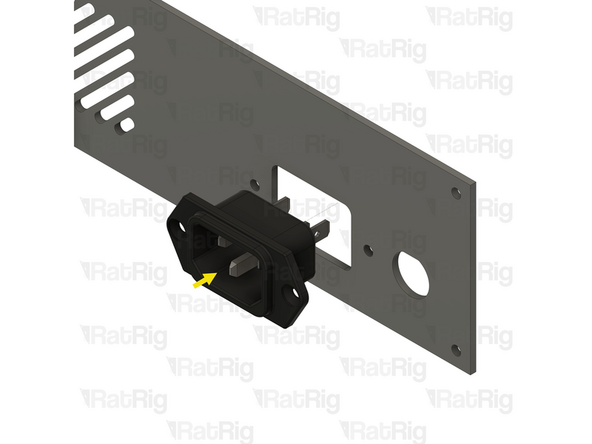

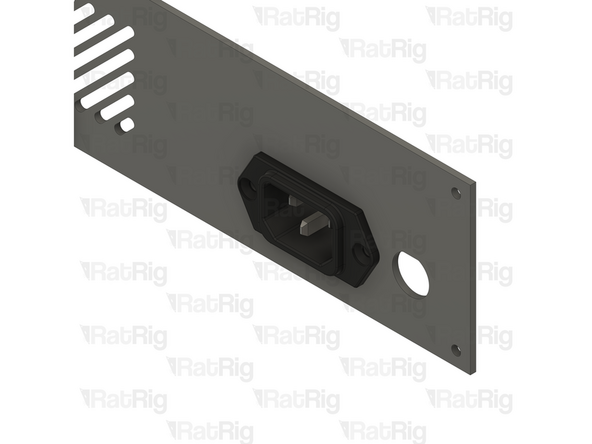

1x IEC inlet panel from step 2

-

Make sure the panel is oriented as shown, with the rectangular hole at the bottom

-

1x IEC Socket - Schurter 6100.3200

-

Insert the IEC socket into the panel as shown

-

Make sure that the middle pin of the IEC socket is at the bottom

-

-

-

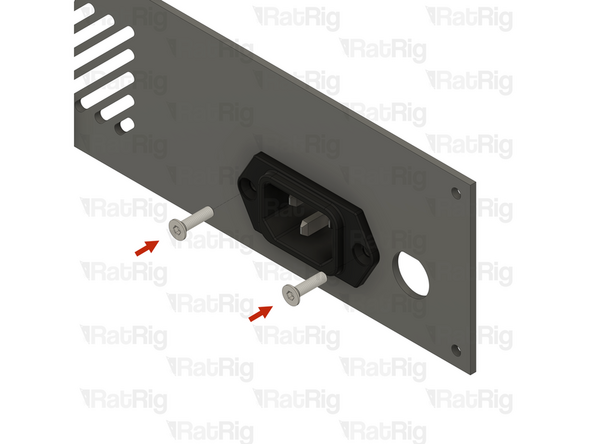

2x M3x12 Countersink Screw

-

Insert an M3x12 Countersink Screw into each of the holes on the IEC socket and through the panel

-

2x M3 Locking Hex Nut

-

Install an M3 Locking Hex Nut onto each of the M3x12 screws and tighten them to secure the IEC socket to the panel

-

The M3 Locking Hex Nuts can be held with a 5.5mm spanner, wrench or socket

-

-

-

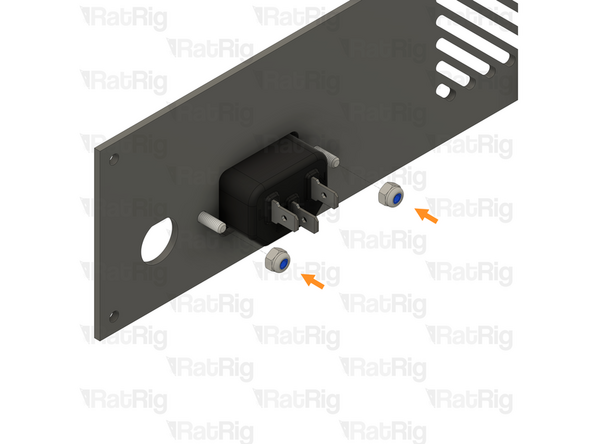

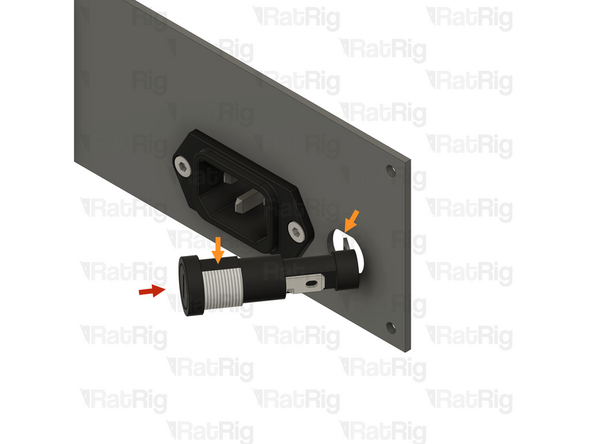

1x Prepared Fuse Holder from step 27

-

Rotate the fuse holder, so the flat surface is aligned with the flat on the panel cutout

-

Angle the fuse holder and insert it into the panel as shown

-

-

-

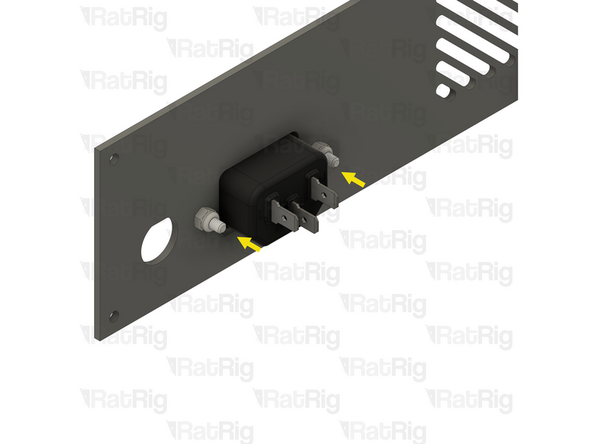

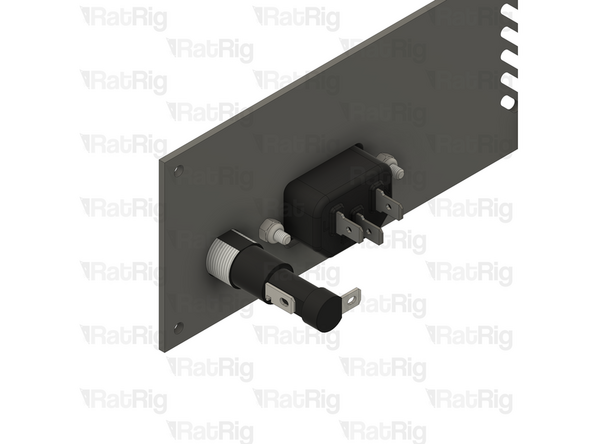

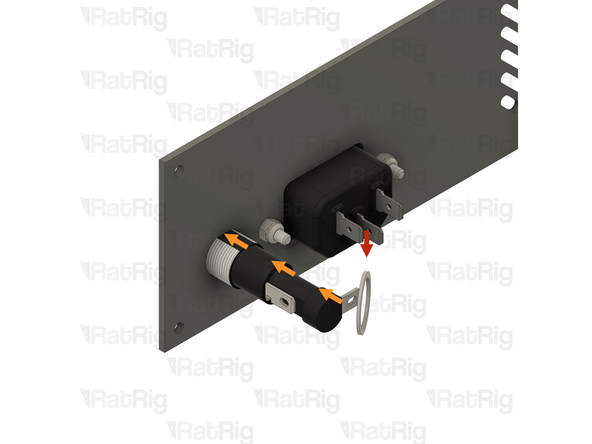

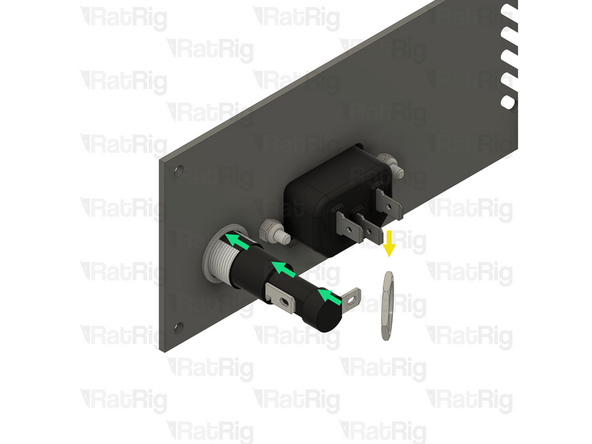

1x Fuse Holder Washer from step 27

-

Slide the washer back onto the fuse holder body, positioning it next to the panel as shown

-

1x Fuse Holder Retaining Nut from step 27

-

Slide the retaining nut back onto the fuse holder body as shown

-

Holding the fuse holder, to prevent it from spinning, tighten the retaining nut onto the threaded section to secure the fuse holder to the panel

-

Using excessive force to tighten the retaining nut can damage the plastic threads on the fuse holder

-

-

-

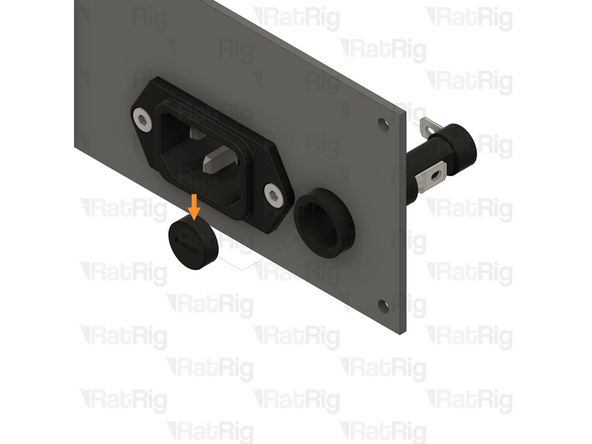

1x Fuse Holder Cap

-

Use a flat head screwdriver to open the fuse holder by turning it a quarter turn counterclockwise

-

Set the cap aside for the next step

-

-

-

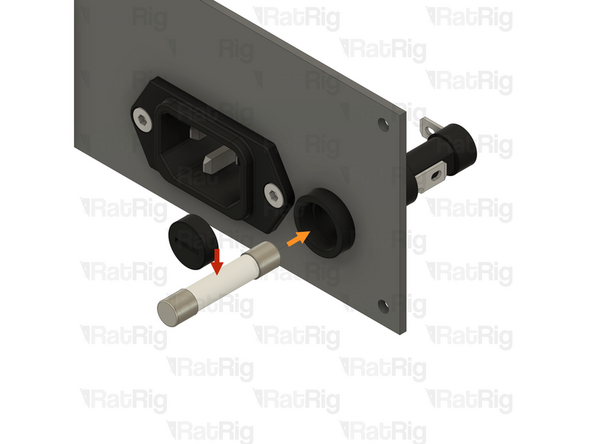

1x Fuse - 6.3x32mm time-lag 15A

-

Insert the fuse fully into the holder, as shown

-

1x Fuse Holder Cap

-

Insert the cap into the fuse holder and secure it by turning it a quarter turn clockwise with a flat head screwdriver

-

Set this assembly aside until step 35

-

-

-

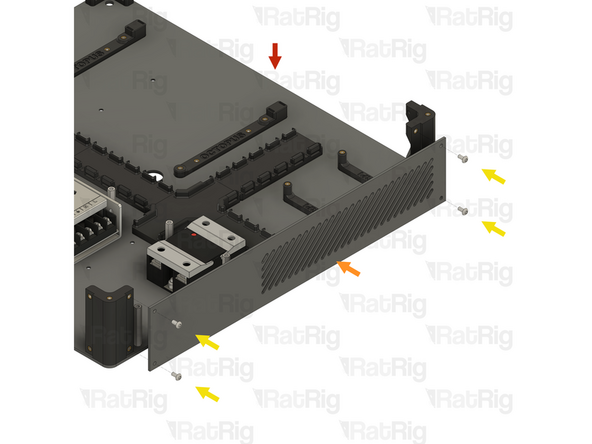

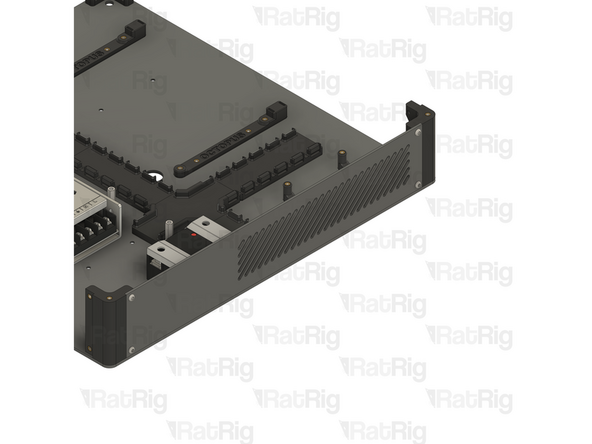

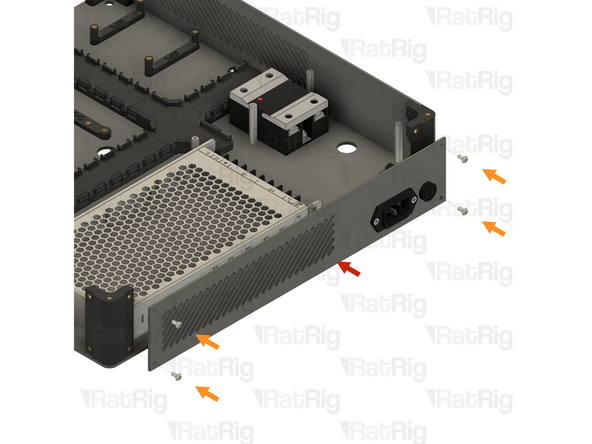

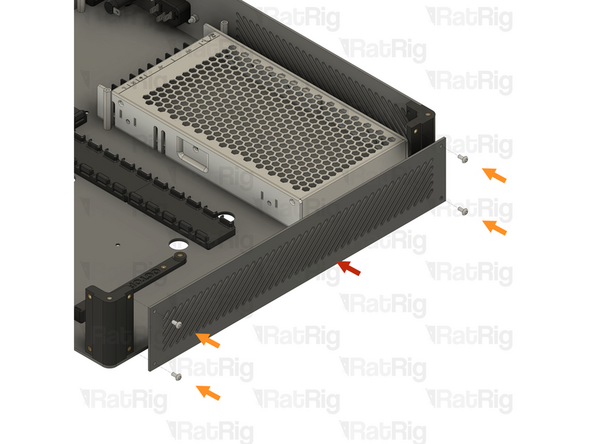

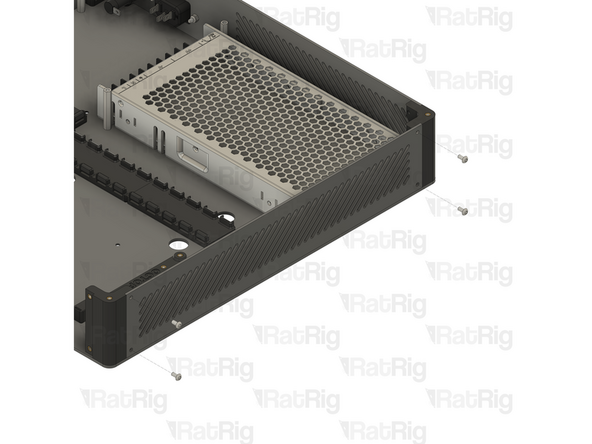

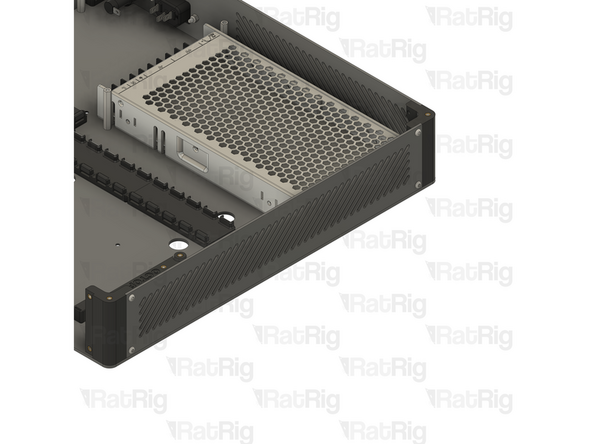

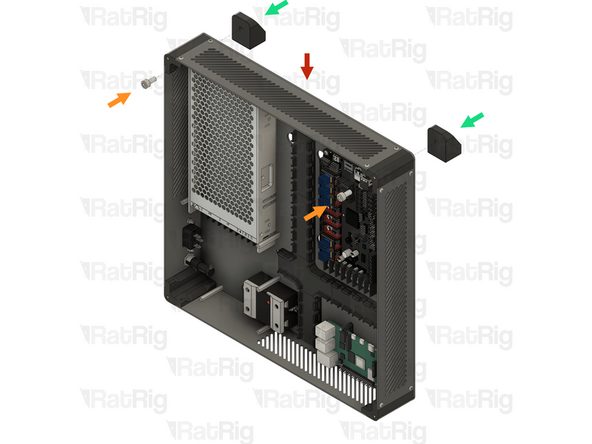

1x Electronics enclosure assembly from step 25

-

1x Bottom vent panel from step 2

-

Align the bottom vent panel as shown, making sure the vented section is on the right hand side

-

4x M3x6 Button Head Screw

-

Tighten all four M3x6 Button Head Screws to secure the panel to the base enclosure assembly

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

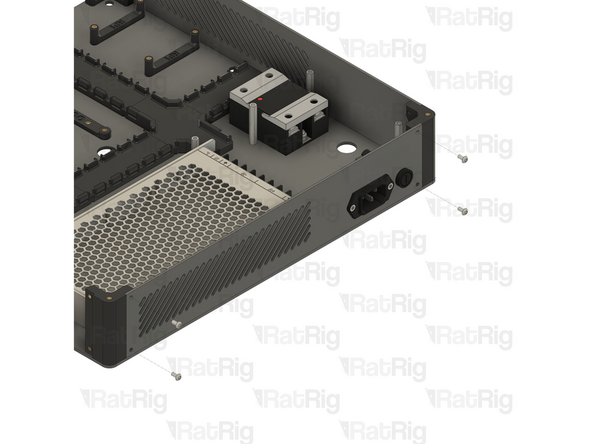

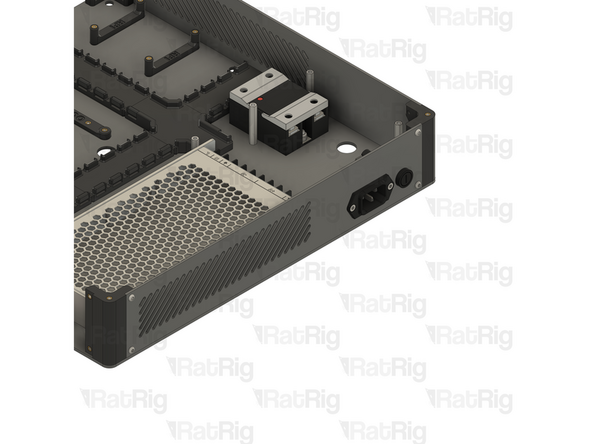

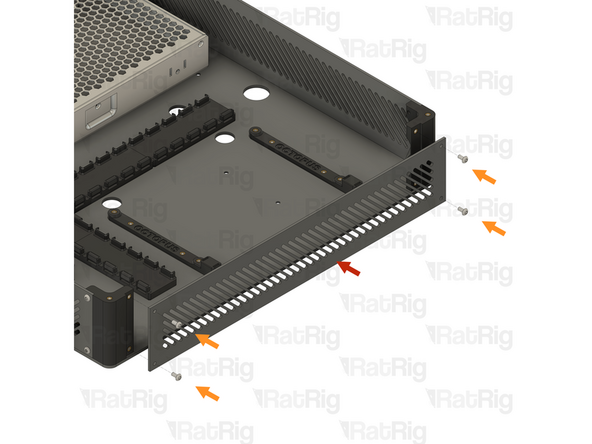

1x IEC inlet panel assembly from step 33

-

Align the IEC inlet panel as shown, making sure the IEC inlet is on the right-hand side

-

4x M3x6 Button Head Screw

-

Tighten all four M3x6 Button Head Screws to secure the panel to the base enclosure assembly

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

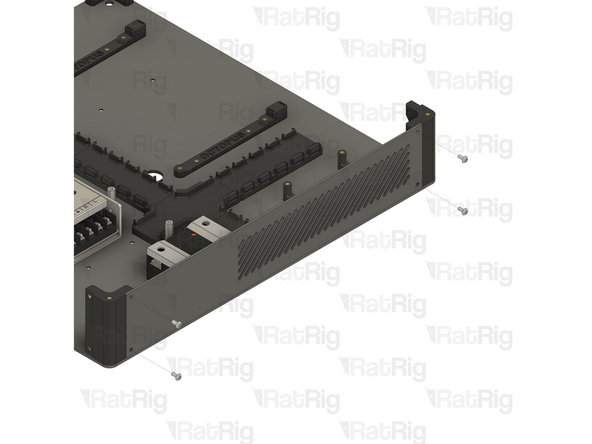

1x Top / side vent panel from step 2

-

Align the top vent panel as shown

-

4x M3x6 Button Head Screw

-

Tighten all four M3x6 Button Head Screws to secure the panel to the base enclosure assembly

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

1x Top / side vent panel from step 2

-

Align the top vent panel as shown

-

4x M3x6 Button Head Screw

-

Tighten all four M3x6 Button Head Screws to secure the panel to the base enclosure assembly

-

Be careful not to overtighten the screws as you can damage the printed parts

-

Set the electronics enclosure assembly aside until step 48

-

-

-

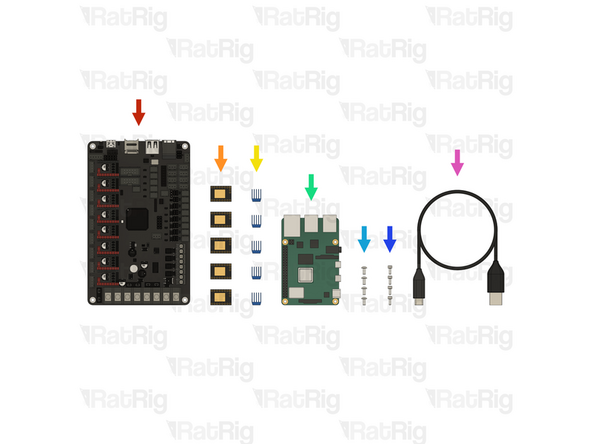

1x BIGTREETECH Octopus v1.1 motherboard (SKU: HW2832EC)

-

5x BIGTREETECH TMC2209 Stepper driver (SKU: HW2052EC)

-

5x Blue anodised heatsink (Included in the stepper driver box)

-

If you are building a Hybrid or IDEX variant of the V-Core 4.0, you need seven drivers and heatsinks instead of five

-

1x Raspberry Pi model 4B - 1GB (SKU: HW3790EC)

-

4x M3x6 Button Head Screw (SKU: HW1337SC)

-

4x M2.5x6 Cap Head Screw (SKU: HW3775SC)

-

1x USB-A to USB-C cable (Included in the Octopus v1.1 box)

-

-

-

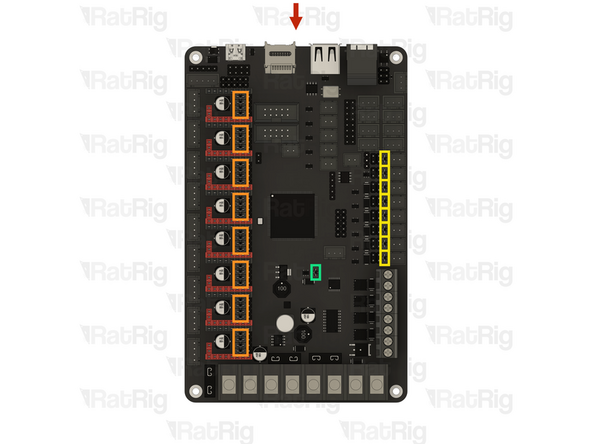

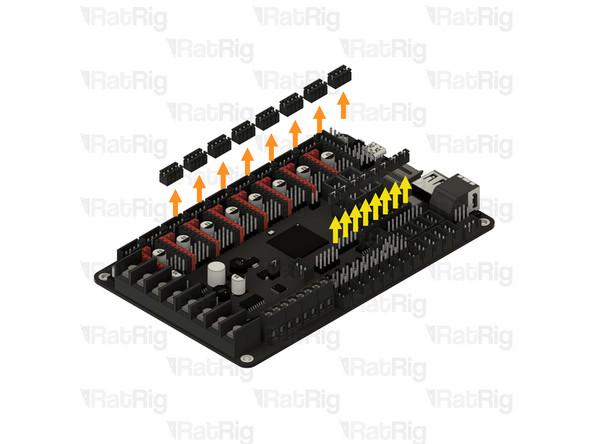

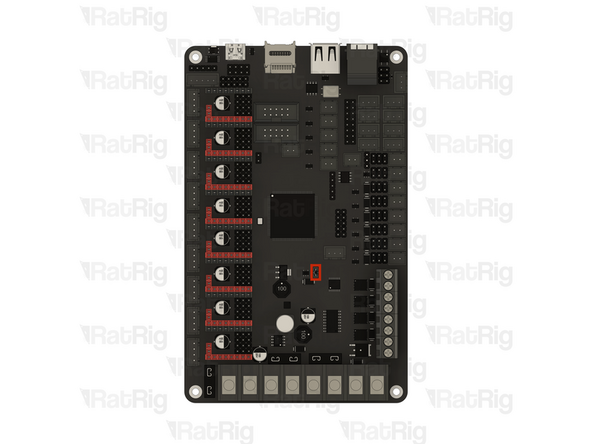

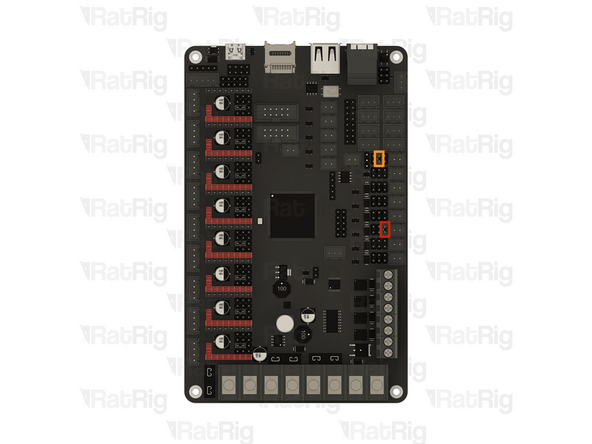

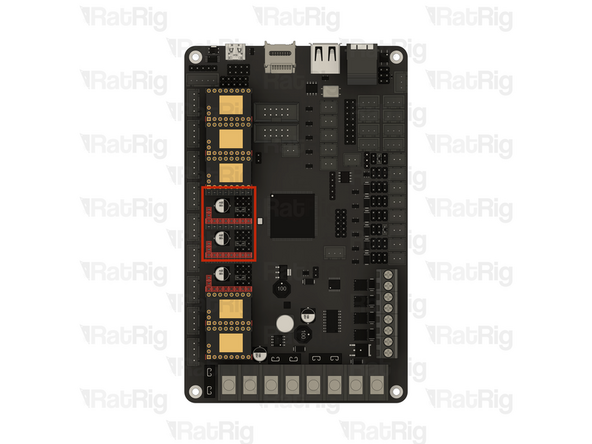

1x BIGTREETECH Octopus v1.1 motherboard

-

The Octopus motherboard is provided with jumpers preinstalled which need to be removed

-

Stepper driver configuration jumpers

-

Remove all thirty-two jumpers and set them aside

-

Fan voltage configuration jumpers

-

Remove all eight jumpers and set them aside

-

V-USB jumper

-

Leave this jumper installed (or install one if it is not present already)

-

-

-

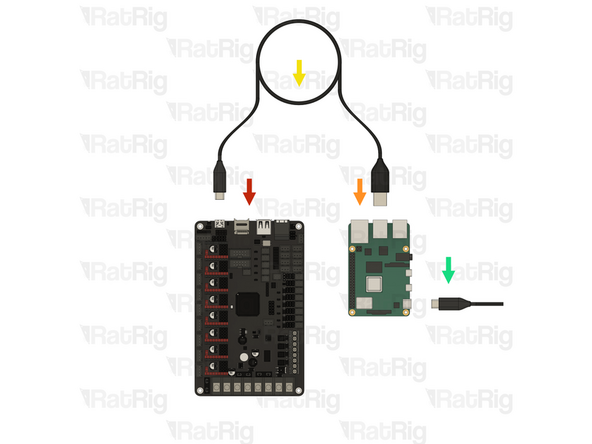

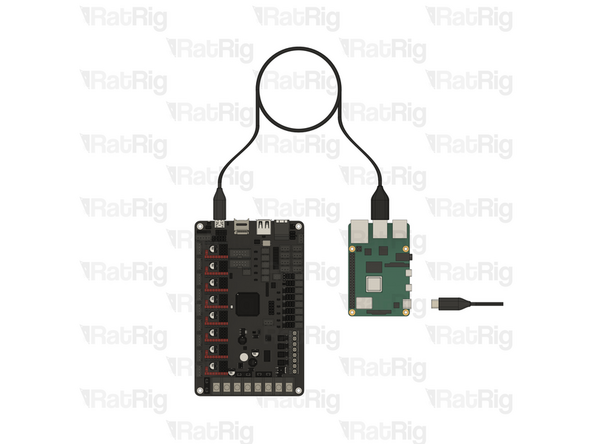

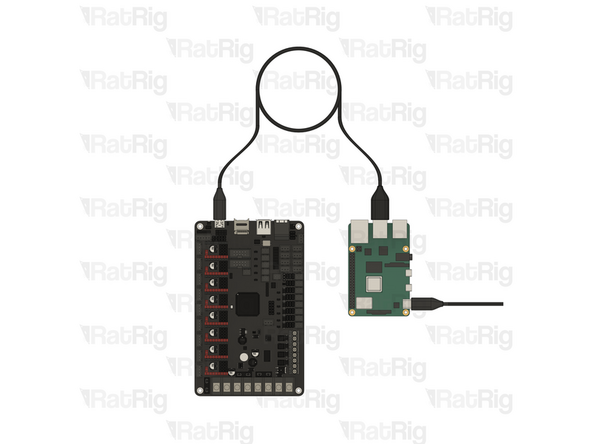

It is highly recommended to flash the Octopus motherboard and ensure the board is detected in RatOS before proceeding

-

1x BIGTREETECH Octopus v1.1 motherboard

-

1x Raspberry Pi model 4B - 1GB

-

1x USB-A to USB-C cable

-

1x 5V power supply with a USB-C connector

-

The power supply is not included in the V-Core kit, but common mobile phone chargers will work as long as it can deliver at least 2.5A

-

Connect the USB-C end of the cable to the Octopus motherboard and the USB-A end to any USB port on the Raspberry Pi

-

Follow the installation instructions on the RatOS website until you reach step 2 of "Setting up your printer". Then power down RatOS and the Raspberry Pi before continuing

-

-

-

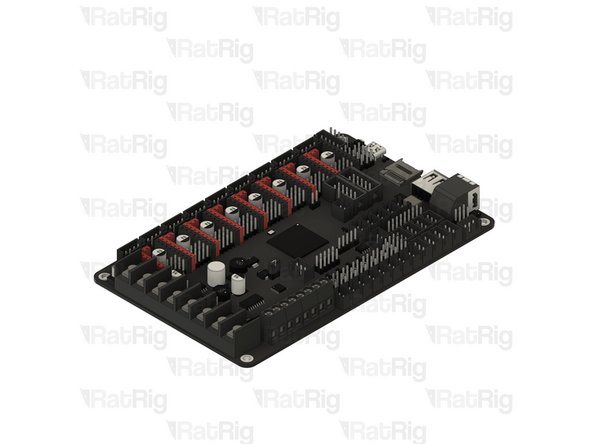

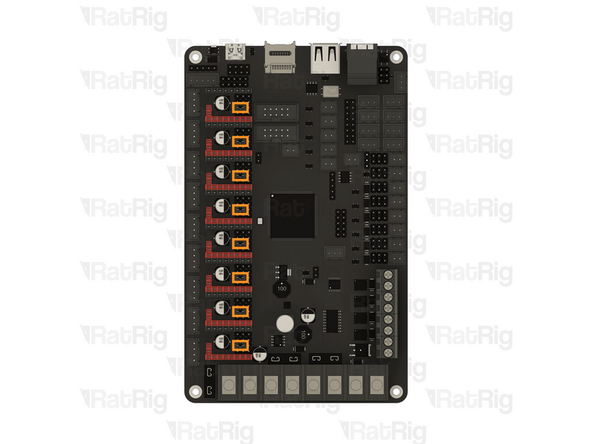

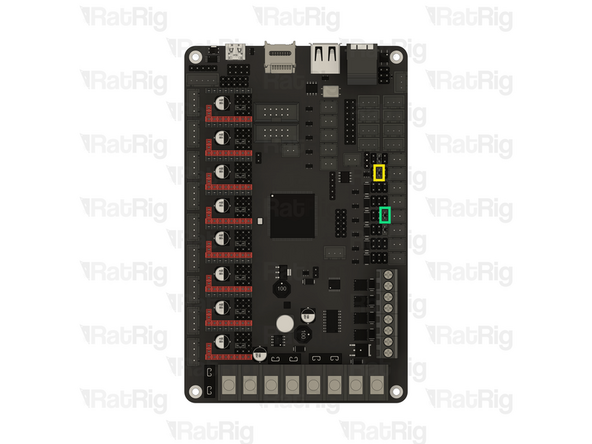

The following jumper configurations are intended for the electronics kit provided by Rat Rig. Do not blindly follow these instructions if using different hardware

-

Before proceeding, make sure the Raspberry Pi is powered down and unplugged and the USB cable between the Octopus motherboard and Raspberry Pi has been disconnected

-

V-USB jumper

-

Remove this jumper and set it aside

-

Stepper driver configuration jumpers

-

Install one jumper onto each position shown

-

This configures the stepper drivers in UART mode, allowing RatOS to tune and control them directly

-

Double-check the positions of all jumpers before continuing, failure to do so can lead to damage to the electronics

-

-

-

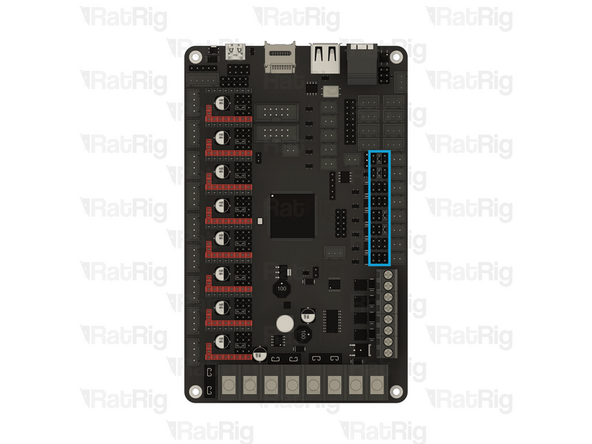

The following jumper configurations are intended for the electronics kit provided by Rat Rig. Do not blindly follow these instructions if using different hardware

-

Fan voltage configuration jumpers

-

24V - Electronics enclosure fan

-

12V - Toolhead part cooling fan

-

12V - Second toolhead part cooling fan (IDEX only)

-

24V - VAOC cooling fan (IDEX only)

-

Double-check the positions of all jumpers before continuing, failure to do so can lead to damage to the electronics

-

Store any remaining jumpers somewhere safe for future use

-

-

-

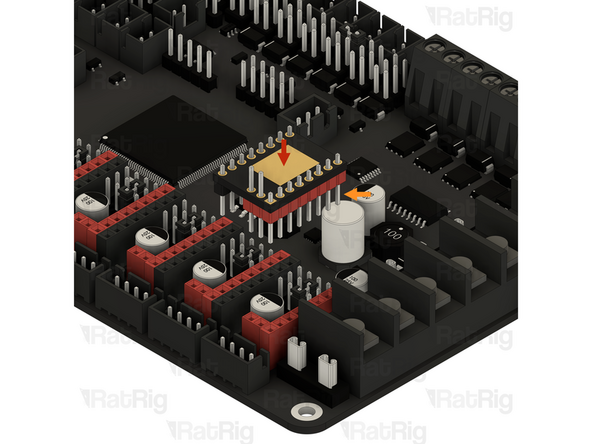

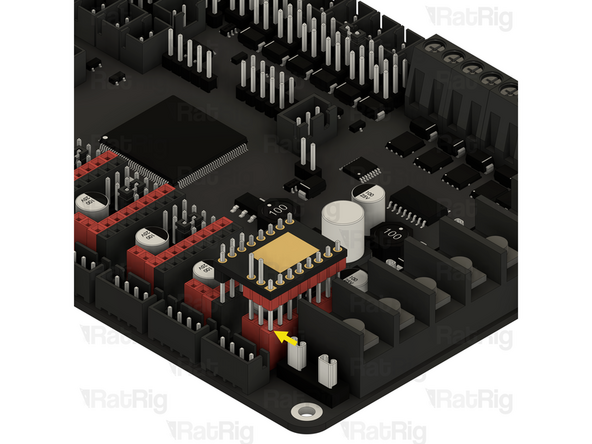

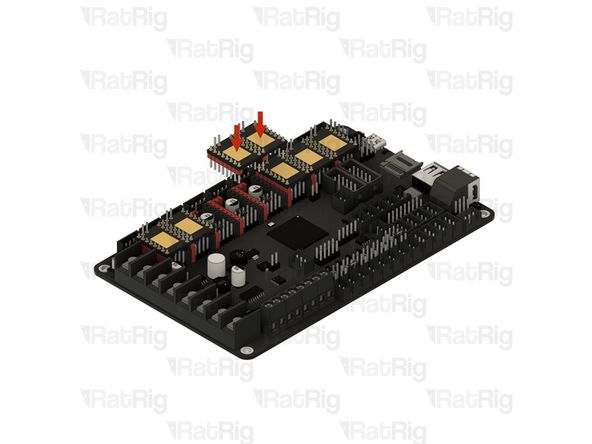

This step shows how to correctly install a stepper driver into the Octopus motherboard

-

1x BIGTREETECH TMC2209 Stepper driver

-

Align the stepper driver as shown with the longest pins facing downwards

-

Line up the pins of the stepper driver with the socket on the motherboard as shown

-

Once aligned, push the stepper driver down to fully seat it into the socket

-

-

-

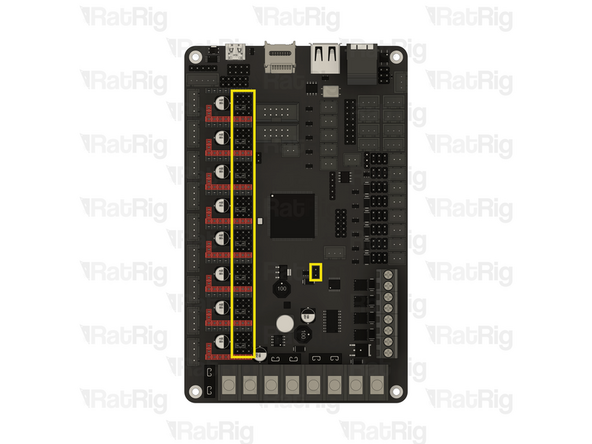

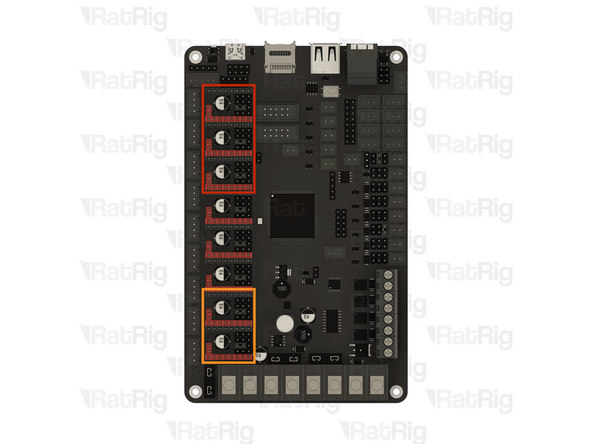

The following stepper driver configuration is intended for the electronics kit provided by Rat Rig. Do not blindly follow these instructions if using different hardware

-

Install a stepper driver into each marked socket

-

3x BIGTREETECH TMC2209 Stepper driver

-

These stepper drivers control the Z-axis

-

2x BIGTREETECH TMC2209 Stepper driver

-

These stepper drivers control the X and Y axes

-

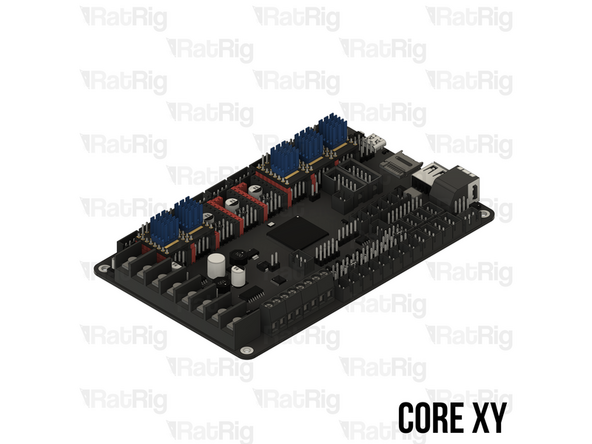

If you are building a CoreXY variant of the V-Core 4.0, then please skip to step 46

-

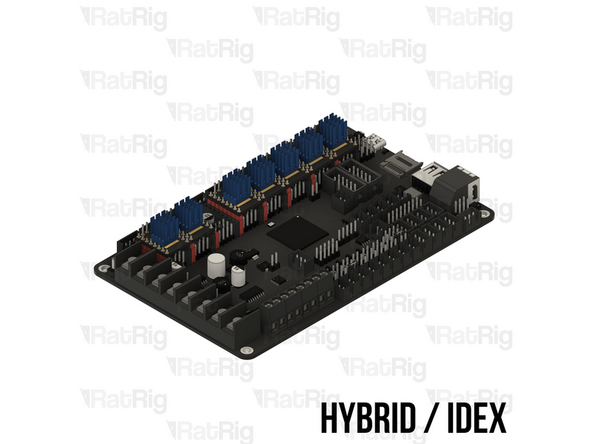

If you are building a Hybrid or IDEX variant of the V-Core 4.0, then please continue following the next steps

-

-

-

The following stepper driver configuration is intended for the electronics kit provided by Rat Rig. Do not blindly follow these instructions if using different hardware

-

Install a stepper driver into each marked socket

-

2x BIGTREETECH TMC2209 Stepper driver

-

These stepper drivers control the additional stepper motors for the Hybrid or IDEX variants of the V-Core 4.0

-

-

-

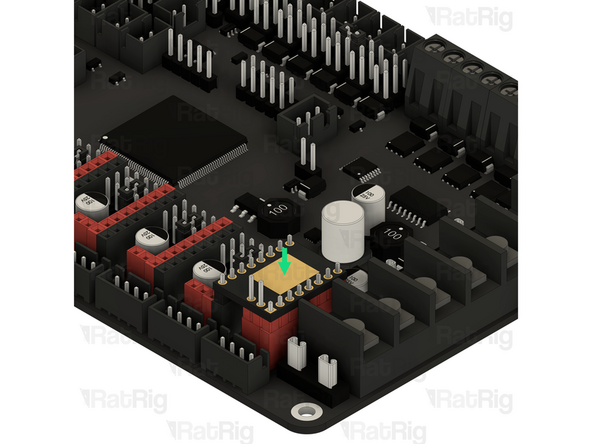

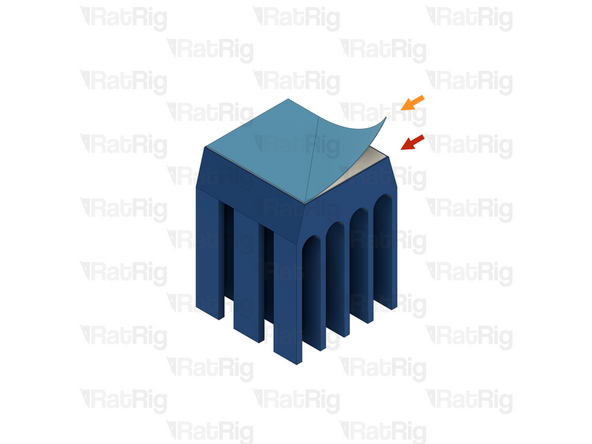

This step shows how to correctly install a stepper driver heatsink

-

1x Blue anodised heatsink

-

Adhesive pad cover

-

The adhesive to secure the heatsink to the stepper driver has a thin, blue, plastic cover, this needs to be peeled off

-

1x BIGTREETECH TMC2209 Stepper driver

-

Align the heatsink with the centre of the stepper driver as shown

-

The orientation of the heatsink does not matter, but they look better when all oriented the same way

-

Press the heatsink down gently for 5–10 seconds to make sure it adheres well

-

-

-

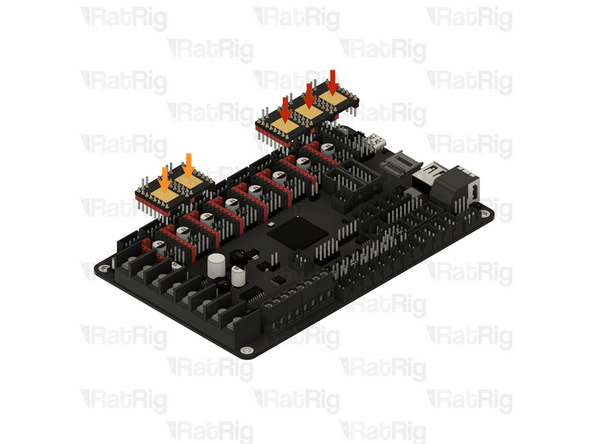

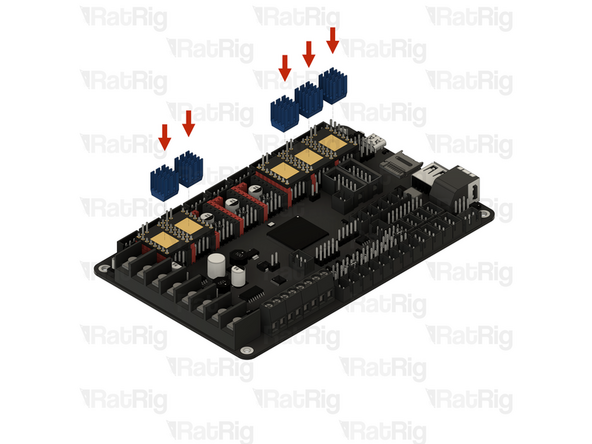

Install a heatsink onto each stepper driver

-

5x Blue anodised heatsink

-

You will need one heatsink per driver — for the Hybrid or IDEX variants of the V-Core 4.0, this means seven heatsinks instead of five

-

-

-

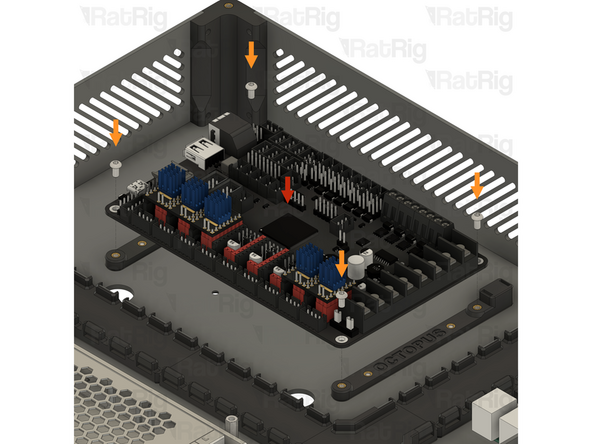

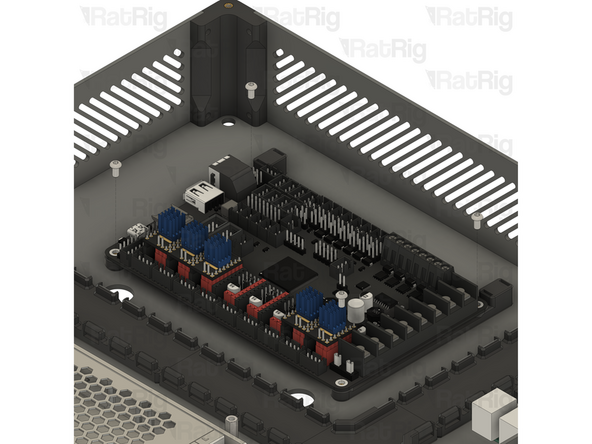

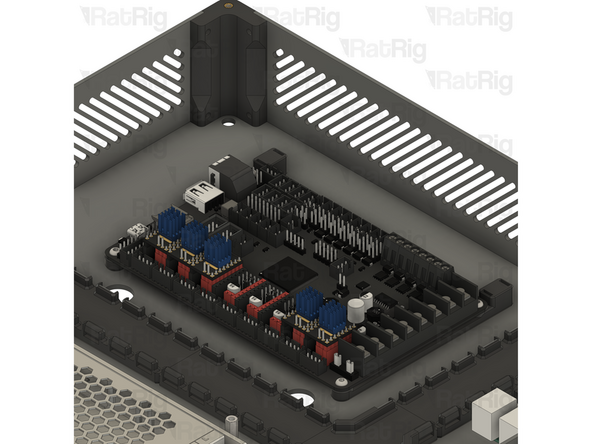

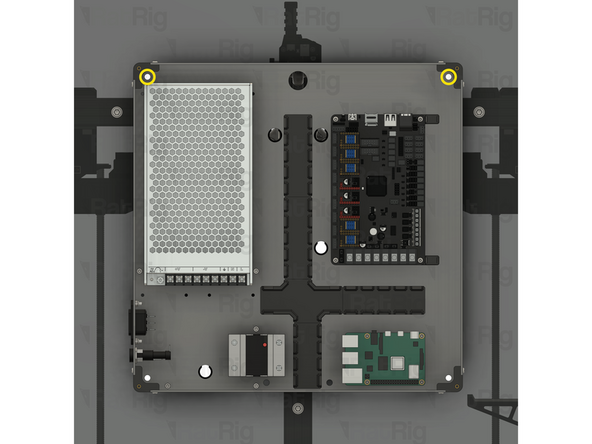

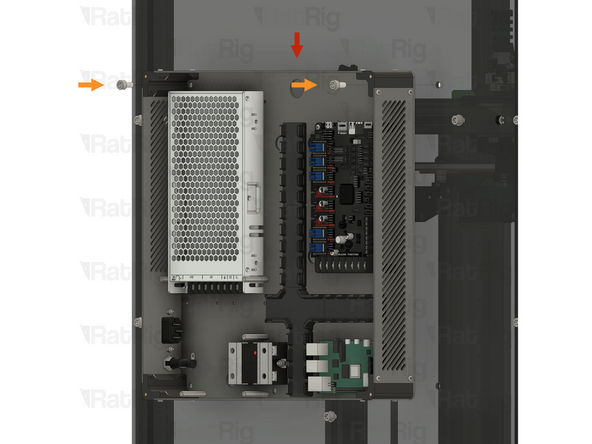

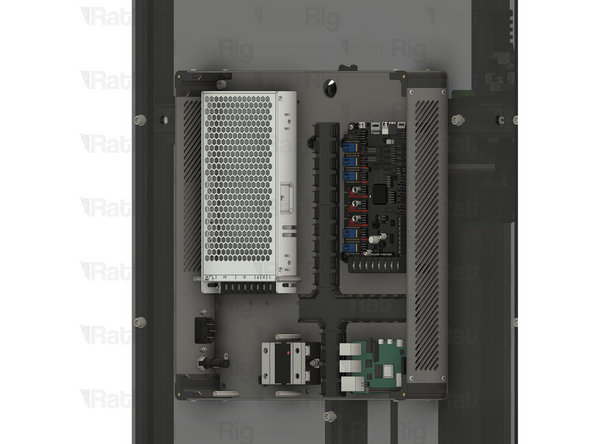

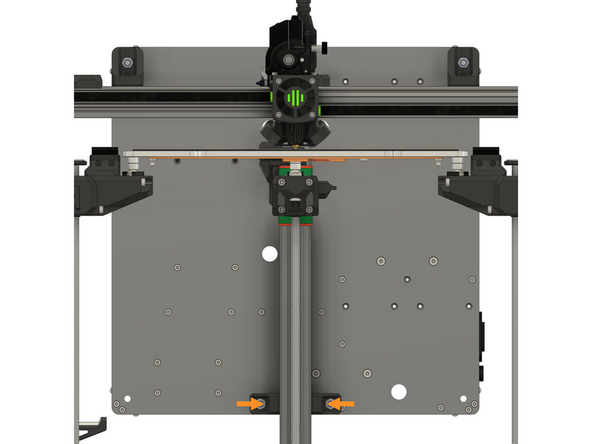

Prepared BIGTREETECH Octopus v1.1 motherboard

-

Align the Octopus motherboard with the printed mount as shown

-

4x M3x6 Button Head Screw

-

Tighten all four M3x6 Button Head Screws to secure the Octopus motherboard to the printed mount

-

Be careful not to overtighten the screws as you can damage the Octopus motherboard or the printed parts

-

-

-

If you are building a CoreXY or Hybrid variant of the V-Core 4.0, then please continue following the next steps

-

If you are building an IDEX variant of the V-Core 4.0, then please skip to step 51

-

-

-

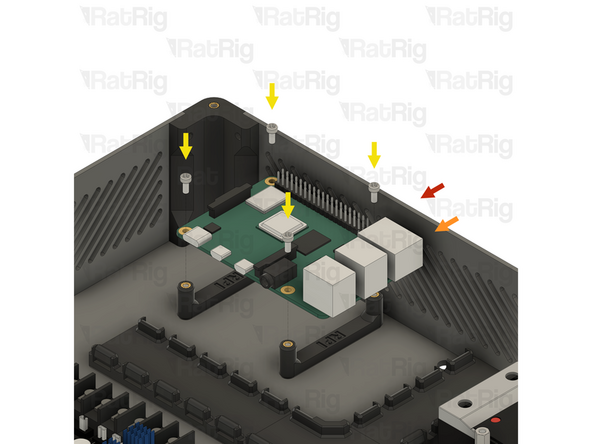

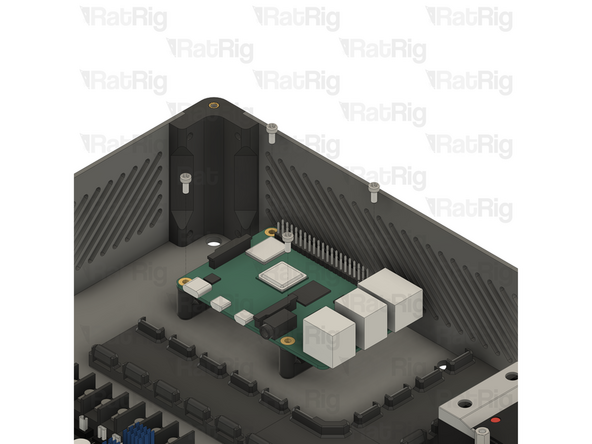

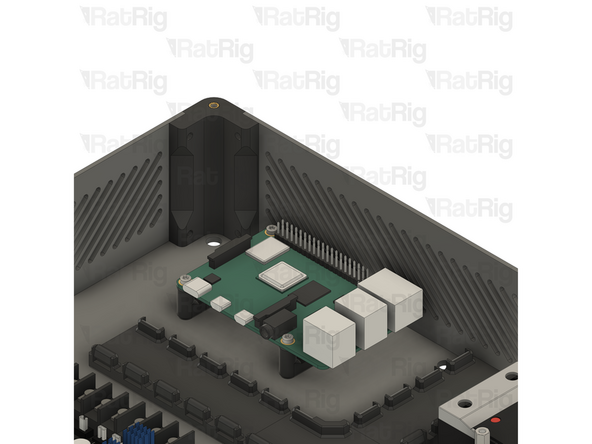

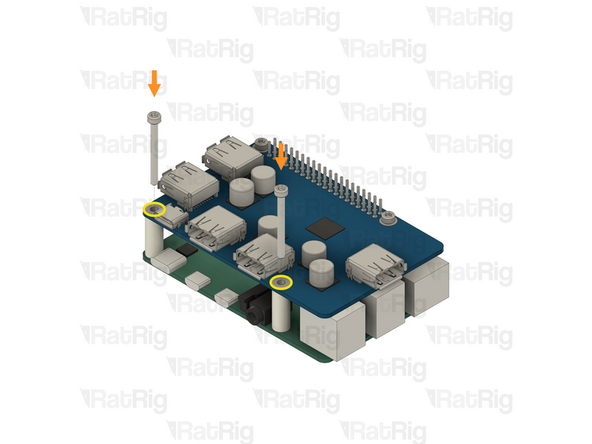

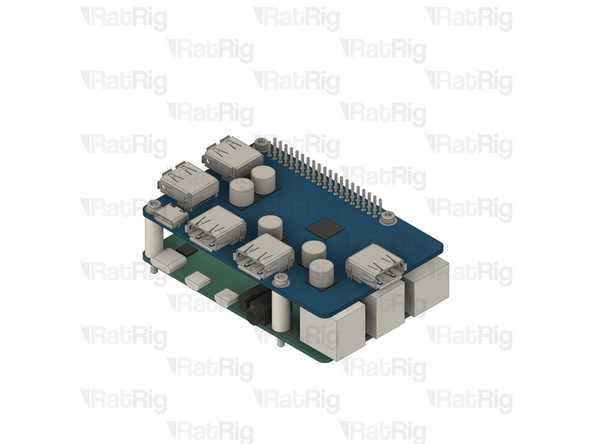

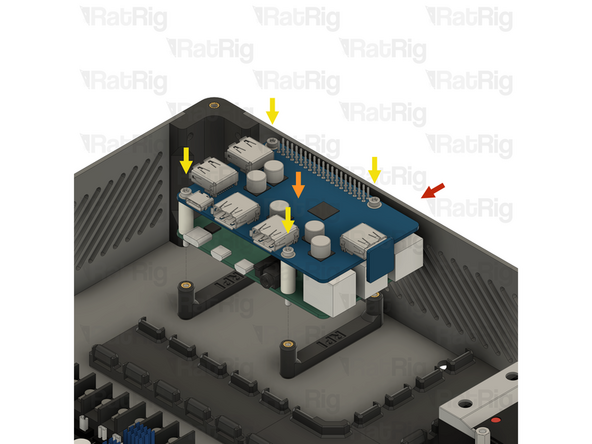

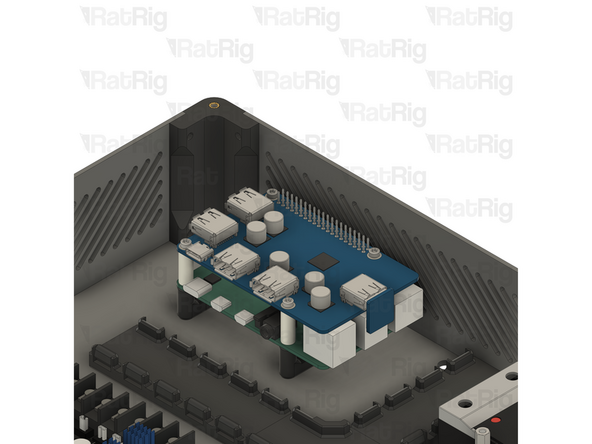

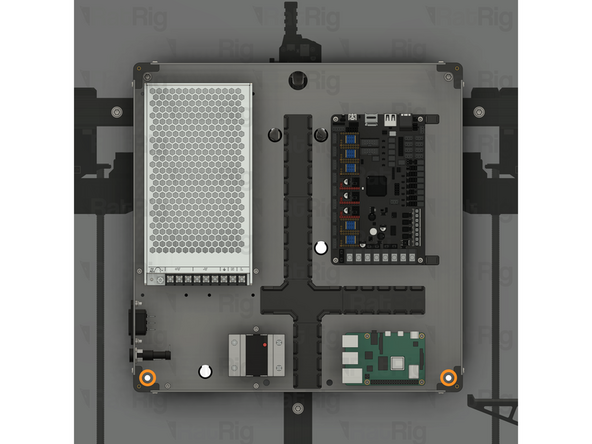

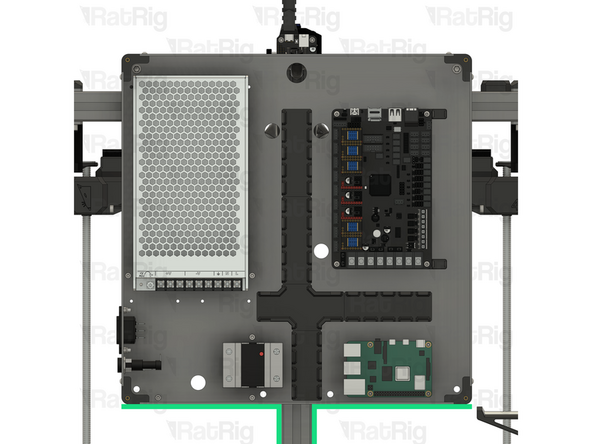

Electronics enclosure assembly

-

1x Raspberry Pi model 4B

-

Align the Raspberry Pi with the printed mount as shown

-

4x M2.5x6 Cap Head Screw

-

Tighten all four M2.5x6 Cap Head Screws to secure the Raspberry Pi to the printed mount

-

Be careful not to overtighten the screws as you can damage the Raspberry Pi or the printed parts

-

Set the electronics enclosure assembly aside until later in the guide

-

The next few steps are specific to the IDEX variant. If you are building the CoreXY or Hybrid variant, please skip to step 57

-

-

-

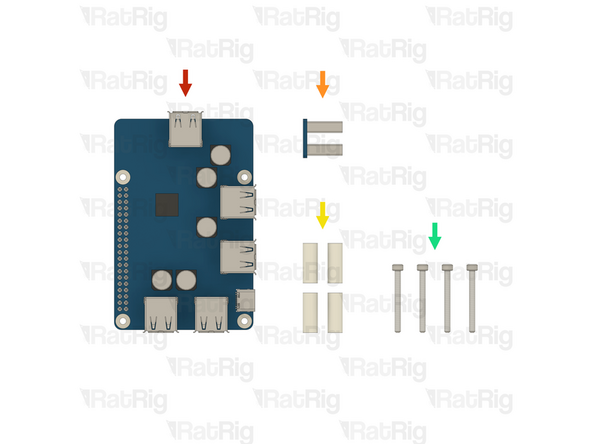

1x Waveshare USB 3.2 Raspberry Pi Hub (SKU: HW4002EC)

-

1x Waveshare USB Hub-to-Pi connector (Included in the usb hub box)

-

4x Nylon spacer - 3.2x6x16mm (SKU: HW4006NC)

-

4x M2.5x25 Cap Head Screw (SKU: HW4005SC)

-

-

-

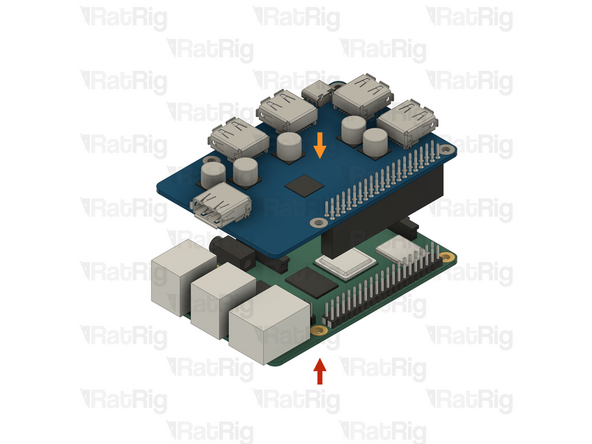

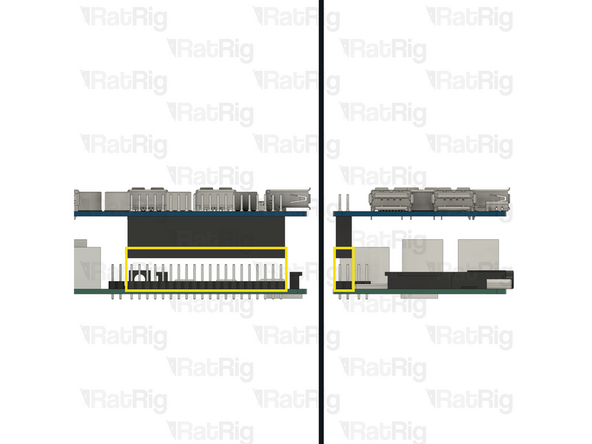

1x Raspberry Pi model 4B - 1GB

-

1x Waveshare USB 3.2 Raspberry Pi Hub

-

Align the female socket with the GPIO pins on the Raspberry Pi as shown

-

Apply gentle downwards force to install the USB hub onto the Raspberry Pi

-

-

-

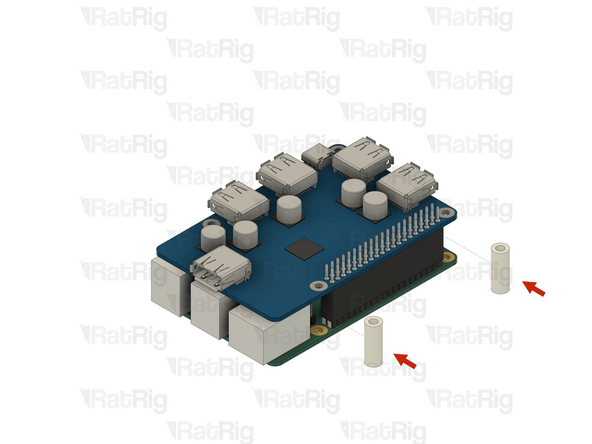

2x Nylon spacer - 3.2x6x16mm

-

Insert each of the nylon spacers into the gap, aligned with the screw holes as shown

-

2x M2.5x25 Cap Head Screw

-

Insert an M2.5x25 Cap Head Screw into each of the marked screw holes, passing through the nylon spacer and out the bottom of the Raspberry Pi

-

-

-

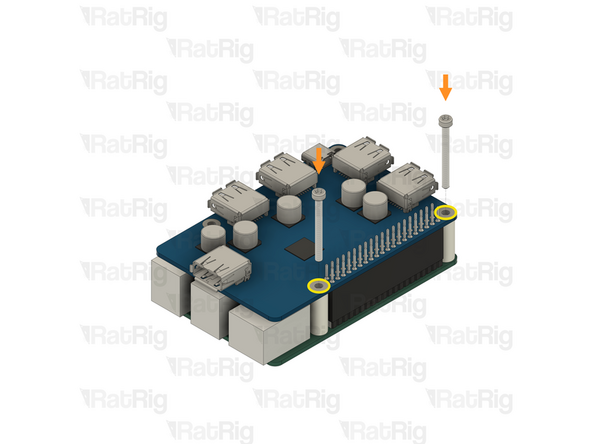

2x Nylon spacer - 3.2x6x16mm

-

Insert each of the nylon spacers into the gap, aligned with the screw holes as shown

-

2x M2.5x25 Cap Head Screw

-

Insert an M2.5x25 Cap Head Screw into each of the marked screw holes, passing through the nylon spacer and out the bottom of the Raspberry Pi

-

-

-

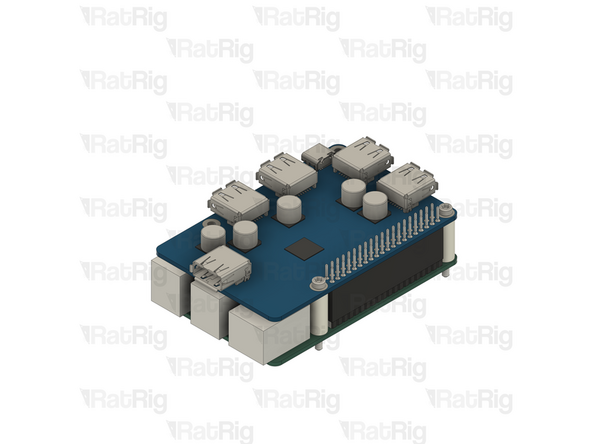

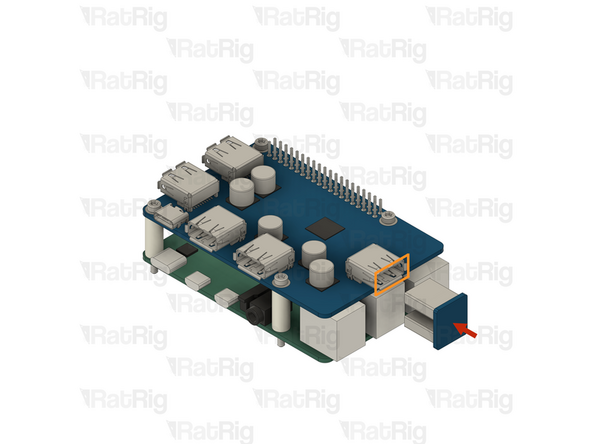

1x Waveshare USB Hub-to-Pi connector

-

Install the Hub-to-Pi connector into the marked USB port on the hub, and the USB port on the Raspberry Pi below

-

-

-

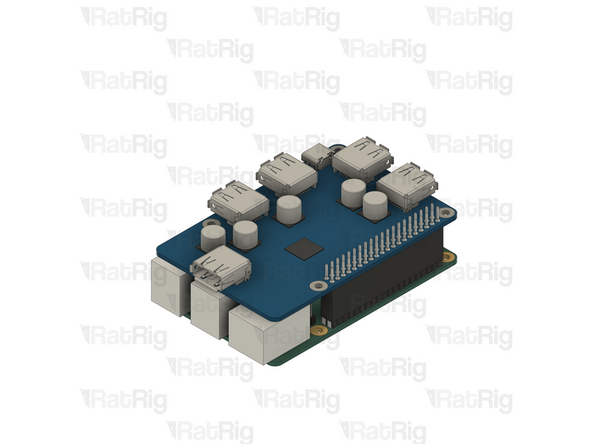

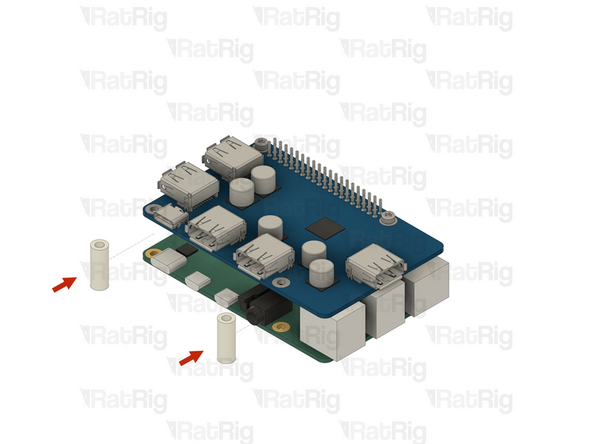

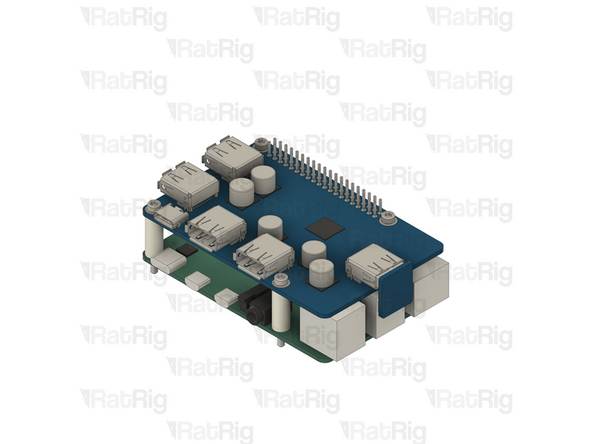

Electronics enclosure assembly from step 48

-

1x Raspberry Pi and USB hub assembly

-

Align the Raspberry Pi assembly with the printed mount as shown

-

4x M2.5x25 Cap Head Screw

-

Tighten all four M2.5x25 Cap Head Screws to secure the Raspberry Pi assembly to the printed mount

-

Be careful not to overtighten the screws as you can damage the Raspberry Pi or the printed parts

-

Set the electronics enclosure assembly aside until later in the guide

-

-

-

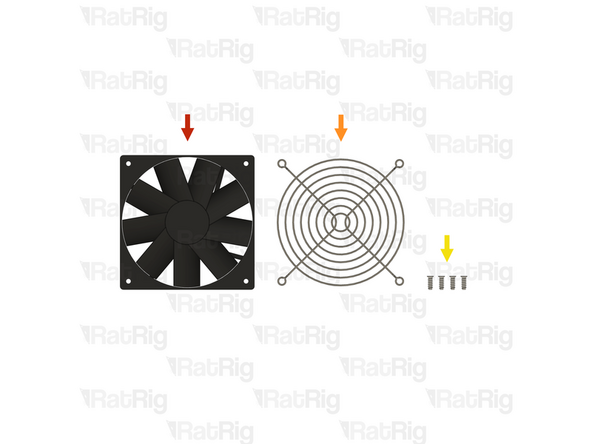

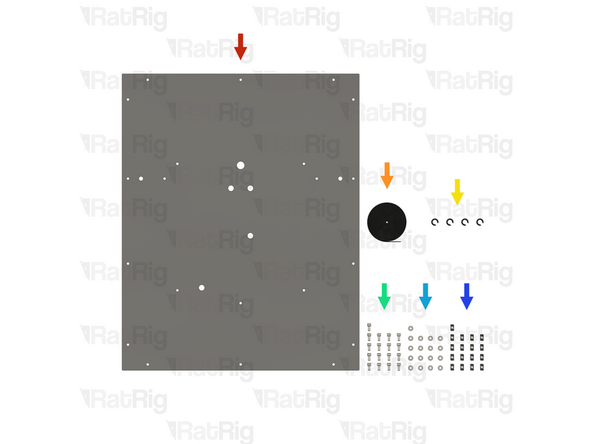

1x Fan - 120x15 Axial 24V (SKU: HW3945EC)

-

1x Fan Grille - 120mm - Black (SKU: HW3937GC)

-

4x Self-tapping Screw - Plastic fan - 12mm (SKU: HW3892SC)

-

-

-

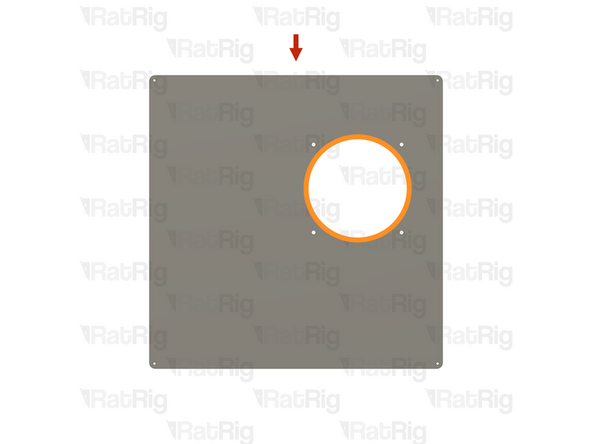

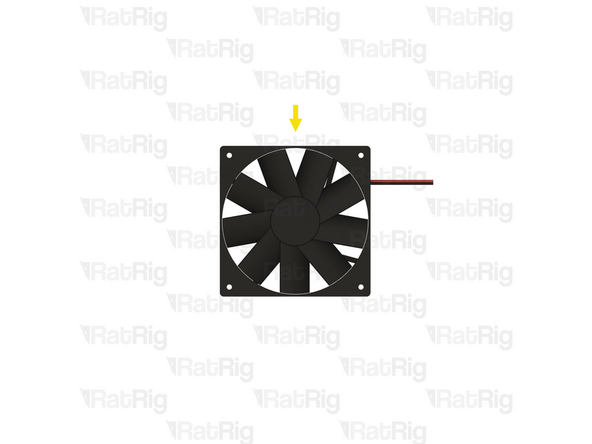

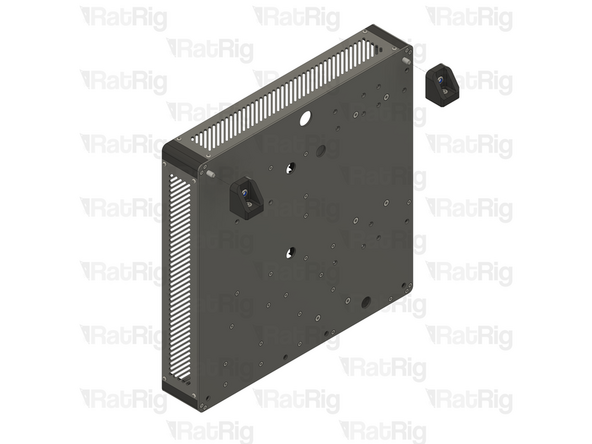

1x Lid panel from step 2

-

Make sure the panel is oriented as shown, with the large circular hole closest to the top right corner

-

1x Fan - 120x15 Axial 24V

-

Orient the fan so that the label on the fan faces away from the lid panel and the cable exits the right-hand side

-

Slide the fan under the panel, aligning it with the hole as shown

-

-

-

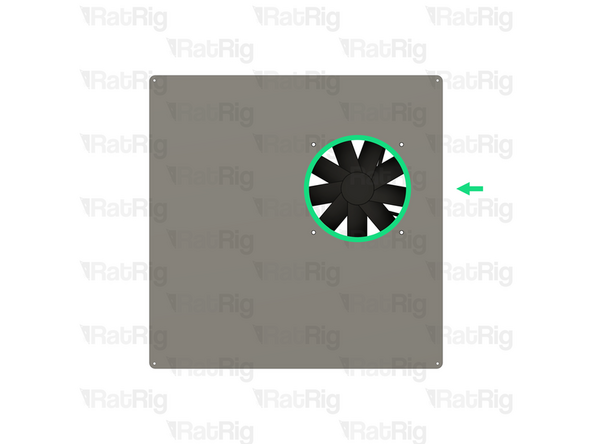

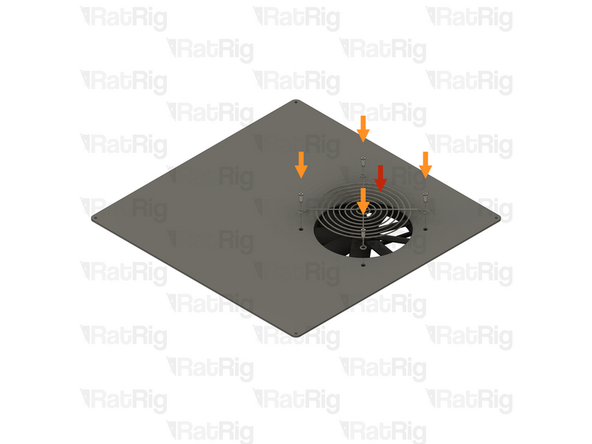

1x Fan Grille - 120mm - Black

-

Position the fan grille over the fan as shown

-

4x Self-tapping Screw - Plastic fan - 12mm

-

Tighten all four self-tapping screws to secure the fan grille and fan to the panel

-

The self-tapping screws will cut a thread into the plastic of the fan and may take some effort to fasten

-

Set the lid assembly aside for now, it will be needed after the wiring guide is complete

-

-

-

1x Rear V-Core 4.0 panel

-

Please note: The V-Core 4.0 panels are not included in the kit and must be sourced separately

-

The V-Core 4.0 is designed to use 4mm thick panels in either polycarbonate or acrylic

-

1x Foam Strip - 1mm x 8mm (SKU: HW2943GC)

-

4x vc4_grommet (SKU: PP000286)

-

17x M6x12 Cap Head Screw (SKU: HW1836SC)

-

17x M6 Washer (SKU: HW2746NC)

-

17x T-Nut Drop-in for 30 series - M6 (SKU: HW1361NC)

-

-

-

1x Rear V-Core 4.0 panel

-

Orient the panel as shown, making sure the bottom offset hole is to the right

-

4x vc4_grommet

-

Install a printed grommet into each of the marked holes

-

Flip the panel over so that the bottom offset hole is now on the left

-

-

-

17x M6x12 Cap Head Screw

-

17x M6 Washer

-

Install an M6 washer onto each of the M6x12 Cap Head Screws, and then insert the screw into each of the marked holes

-

-

-

17x T-Nut Drop-in for 30 series - M6

-

Loosely thread a 3030 T-nut onto each of the M6x12 screws. Do not tighten them at this point

-

Set the assembled panel aside until step 66

-

-

-

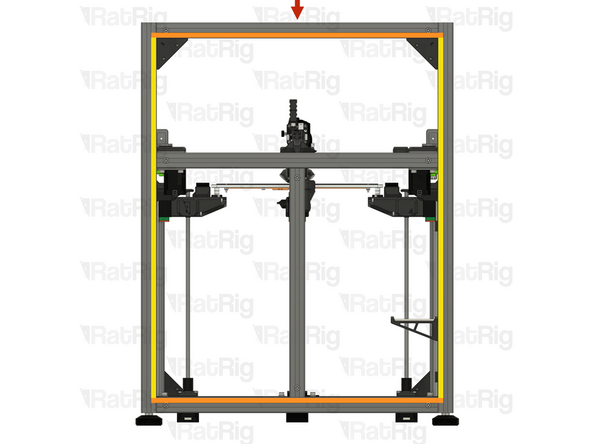

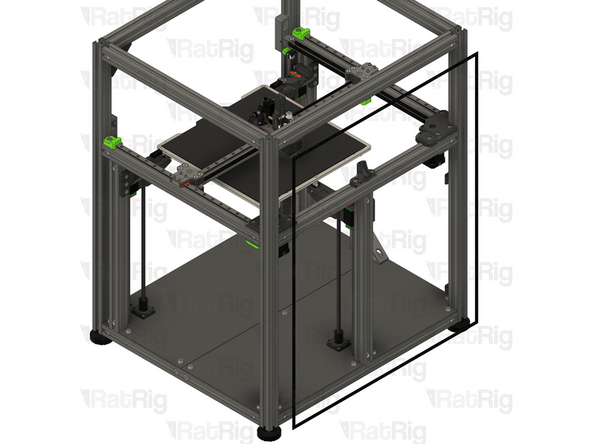

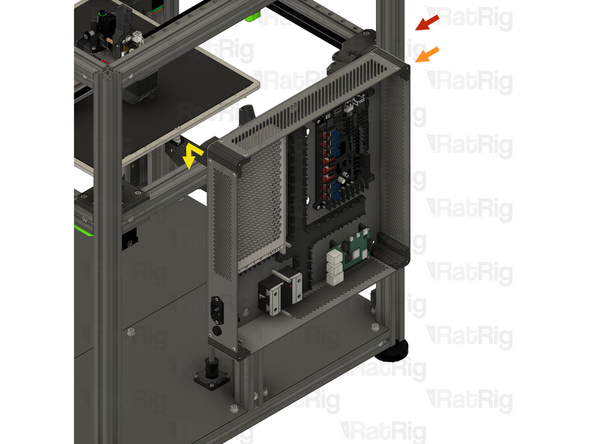

V-Core 4.0 Assembly - Rear side

-

Cut the following lengths of the 8mm x 1mm foam strip depending on the V-Core 4.0 size:

-

V-Coro 4.0 300: 2x 560mm, 2x 694mm

-

V-Coro 4.0 400: 2x 660mm, 2x 794mm

-

V-Coro 4.0 500: 2x 760mm, 2x 894mm

-

Peel the protective backing from the back of the foam strip and apply the shorter lengths to the top and bottom extrusions as shown

-

Peel the protective backing from the back of the foam strip and apply the longer lengths to the side extrusions as shown

-

-

-

1x V-Core 4.0 rear panel assembly from step 64

-

Align the rear panel with the frame, making sure all T-nuts slot into the extrusion slots

-

Secure the panel to the frame by tightening all seventeen M6x12 screws

-

Do not overtighten the screws as you can damage the panel

-

-

-

4x M6x12 Cap Head Screw (SKU: HW1836SC)

-

4x M6 Locking Hex Nut (SKU: HW1311NC)

-

-

-

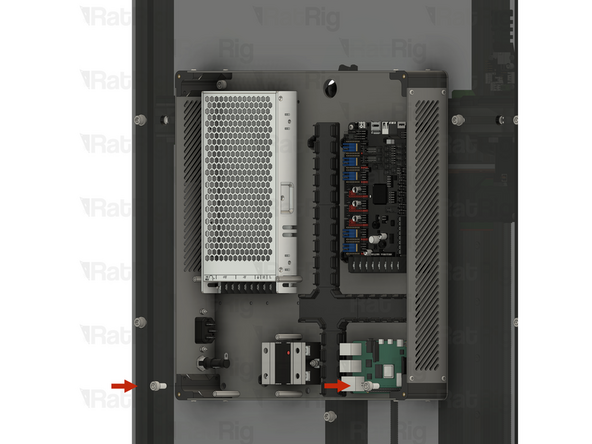

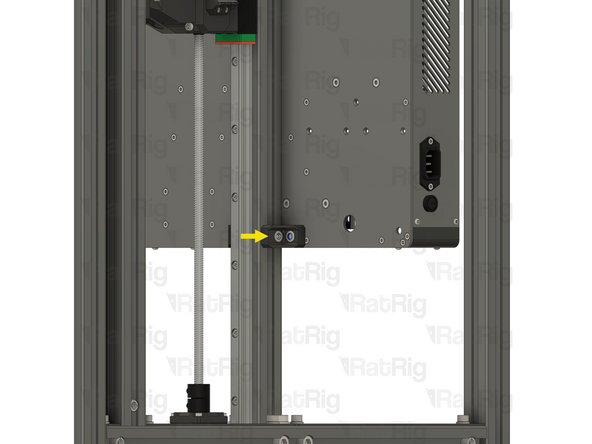

Electronics enclosure assembly from step 50 (or step 56 for IDEX)

-

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the marked holes within the electronics enclosure

-

Align the M6x12 screws with the holes in the rear panel and push them through

-

Continue to support the electronics enclosure until the locking hex nuts are installed in the next step

-

-

-

2x M6 Locking Hex Nut

-

Install an M6 Locking Hex Nut onto each of the M6x12 screws and tighten them to secure the electronics enclosure to the panel

-

The M6 Locking Hex Nuts can be held with a 10mm spanner, wrench or socket

-

Do not overtighten the screws as you can damage the panel

-

-

-

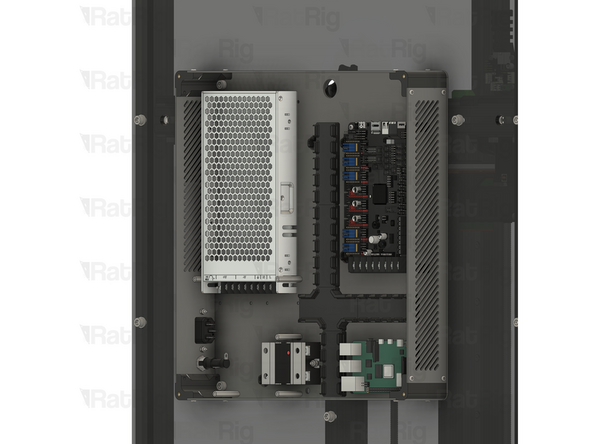

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the marked holes within the electronics enclosure, and through the panel

-

-

-

2x M6 Locking Hex Nut

-

Install an M6 Locking Hex Nut onto each of the M6x12 screws and tighten them to secure the electronics enclosure to the panel

-

The M6 Locking Hex Nuts can be held with a 10mm spanner, wrench or socket

-

Do not overtighten the screws as you can damage the panel

-

-

-

2x vc4_electronics_mount_upper (SKU: PP000320)

-

2x vc4_electronics_mount_lower (SKU: PP000319)

-

8x M6x12 Cap Head Screw (SKU: HW1836SC)

-

4x T-Nut Drop-in for 30 series - M6 (SKU: HW1361NC)

-

4x M6 Locking Hex Nut (SKU: HW1311NC)

-

-

-

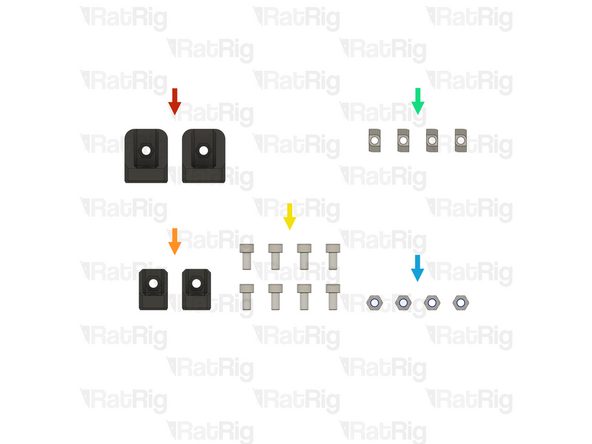

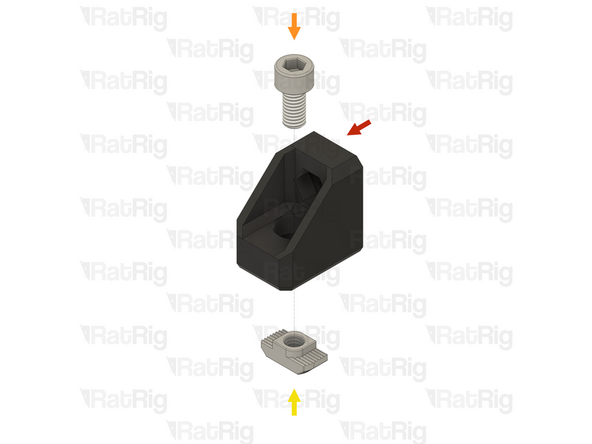

1x vc4_electronics_mount_upper

-

1x M6x12 Cap Head Screw

-

1x T-Nut Drop-in for 30 series - M6

-

Loosely thread a 3030 T-nut onto the M6x12 screw. Do not tighten it at this point

-

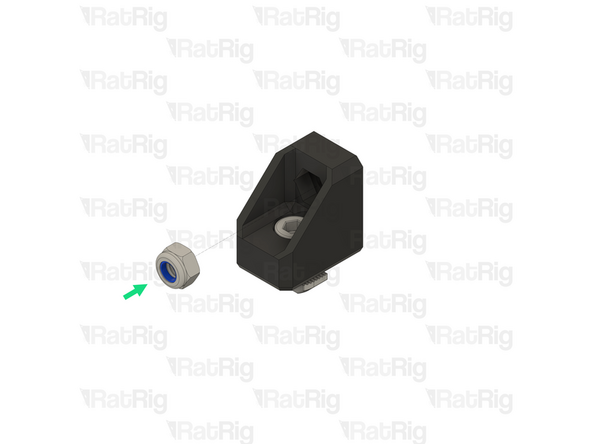

1x M6 Locking Hex Nut

-

Insert the M6 Locking Hex Nut into the printed part as shown

-

Prepare two of these assemblies and set them aside until step 76

-

-

-

1x vc4_electronics_mount_lower

-

1x M6x12 Cap Head Screw

-

1x T-Nut Drop-in for 30 series - M6

-

Loosely thread a 3030 T-nut onto the M6x12 screw. Do not tighten it at this point

-

1x M6 Locking Hex Nut

-

Insert the M6 Locking Hex Nut into the printed part as shown

-

Prepare two of these assemblies and set them aside until step 78

-

-

-

Electronics enclosure assembly from step 50 (or step 56 for IDEX)

-

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the marked holes within the electronics enclosure

-

2x Upper electronics enclosure mount assemblies from step 74

-

Fasten an upper mount assembly on to each M6x12 cap head screw. Do not fully tighten the screws yet, they will be tightened in an upcoming step

-

-

-

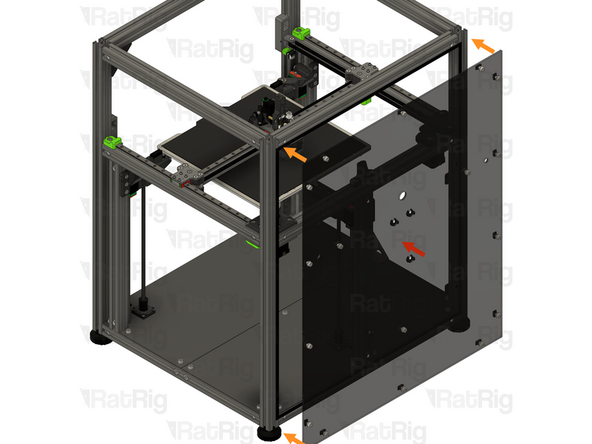

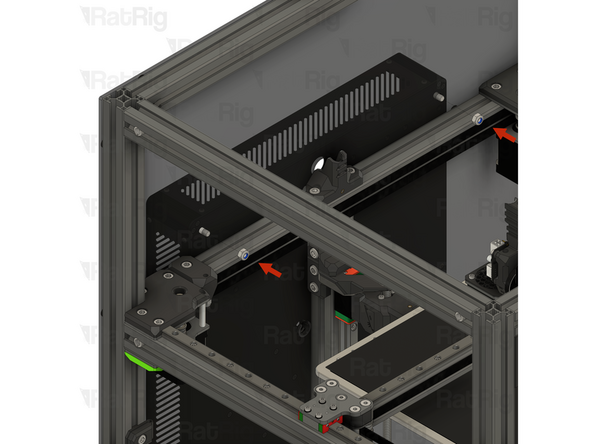

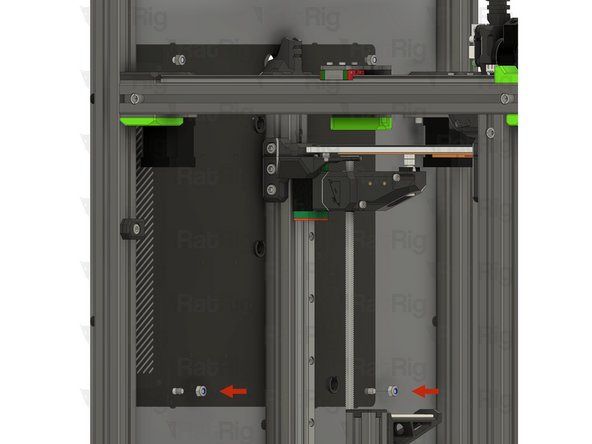

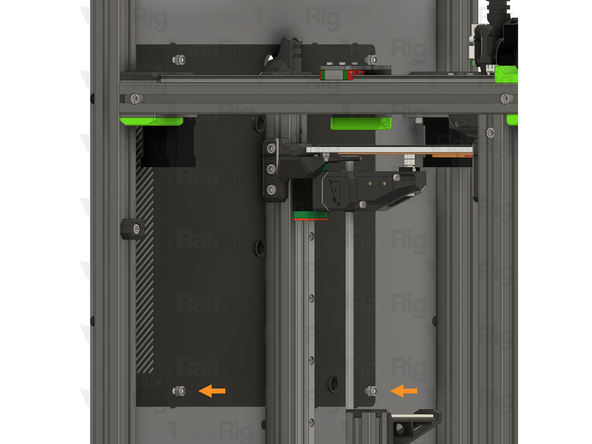

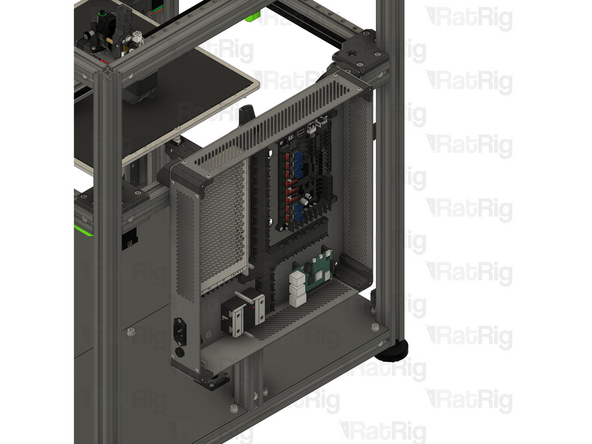

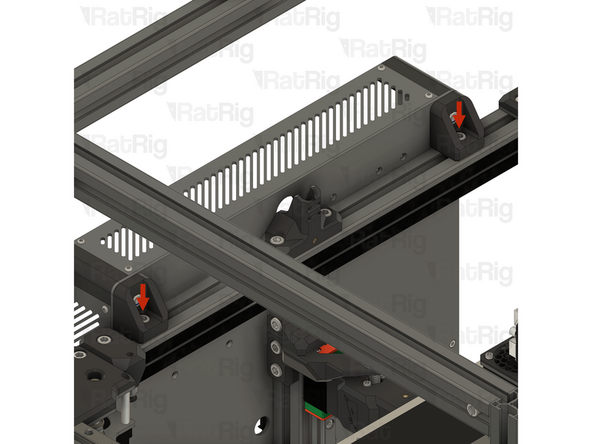

V-Core 4.0 Assembly - Rear side

-

Electronics enclosure assembly

-

Install the electronics enclosure by positioning the upper mounts onto the 3030 extrusion as shown

-

Make sure the T-nuts on the upper mounts fit inside the extrusion slot

-

The electronics enclosure should now support itself, even though the screws have not yet been tightened

-

Position the electronics enclosure so it is roughly centered with the marked 3030 extrusion. The exact position will be set in the next step

-

-

-

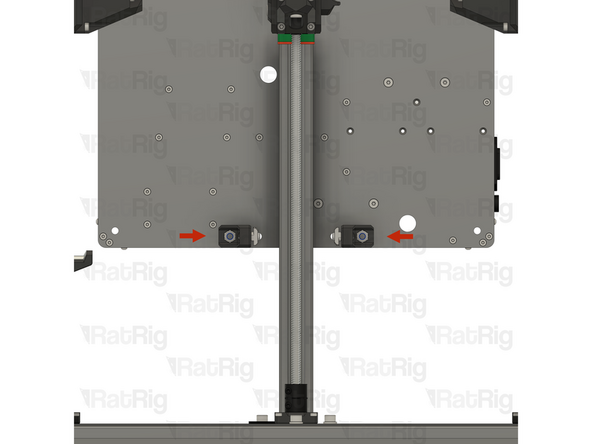

2x Lower electronics enclosure mount assemblies from step 75

-

Align each lower mount assembly so that the T-nut fits into the extrusion slot and the locking hex nut aligns with the hole in the electronics enclosure

-

Tighten the M6x12 Cap Head Screw to secure the mount to the extrusion

-

Be careful not to overtighten the screws as you can damage the printed parts

-

-

-

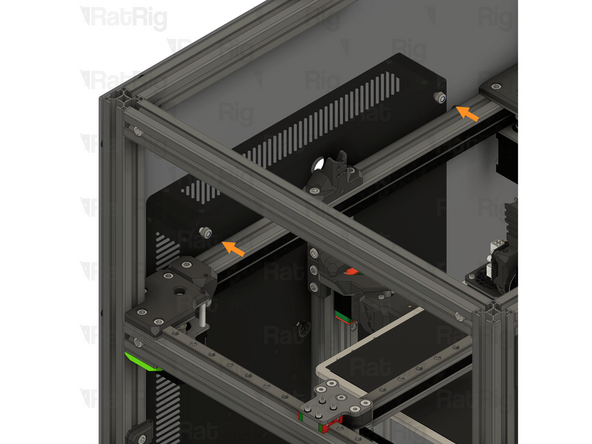

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the marked holes within the electronics enclosure

-

Thread the M6x12 Cap Head Screws into the locking nuts in the lower electronics enclosure mounts

-

Fully tighten both M6x12 Cap Head Screws to secure the electronics enclosure to the frame

-

-

-

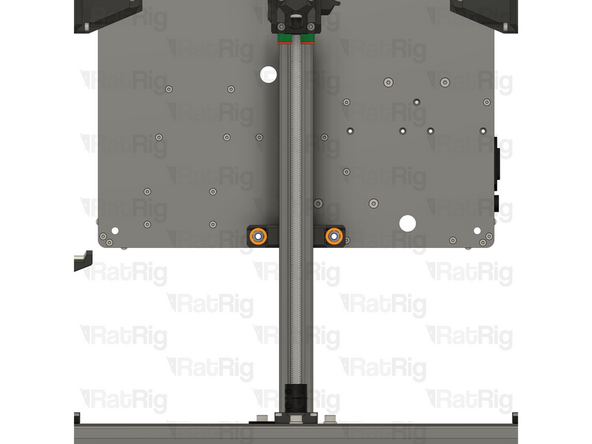

Fully tighten both marked M6x12 Cap Head Screws to secure the upper mounts to the frame

-

Fully tighten both marked M6x12 Cap Head Screws to secure the lower mounts to the frame

-

Fully tighten all four marked M6x12 Cap Head Screws to secure the electronics enclosure to the upper and lower mounts

-

Be careful not to overtighten the screws as you can damage the printed parts

-

Cancel: I did not complete this guide.

4 other people completed this guide.

One Comment

I Like to use an Alu Bond Plate as Backplate instaed of PTEG any thoughts on this one? IS that possible ?

ds3975@gmail.com - Open Reply