-

-

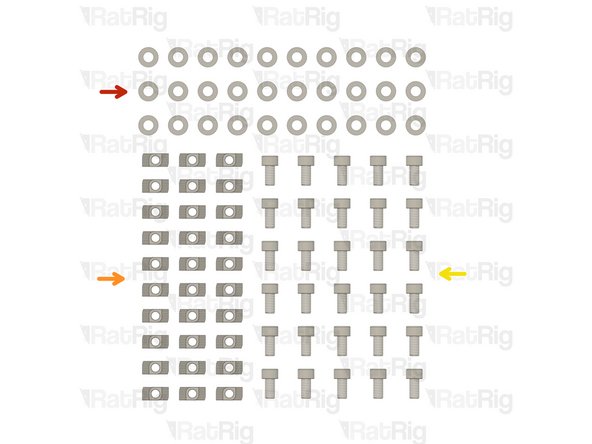

24x M6 Nylon Locking Hex Nut

-

16x M6 Washer

-

16x M6x12 Cap Head Screw

-

2x vc4_magnet_handle

-

8x M6x16 Cap Head Screw

-

8x vc4_magnet_panel

-

4x vc4_printed_handle

-

20x Magnet - Neodymium disc 10x4mm

-

-

-

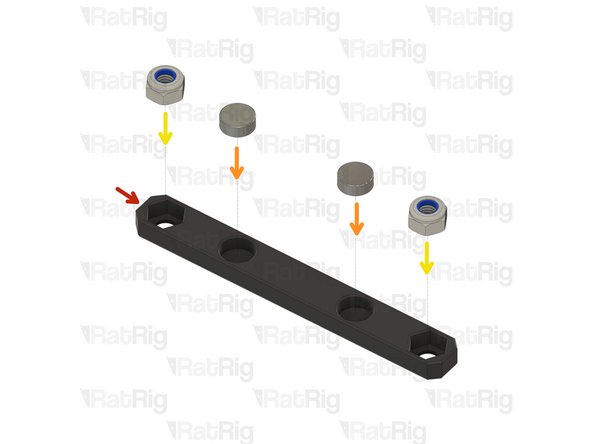

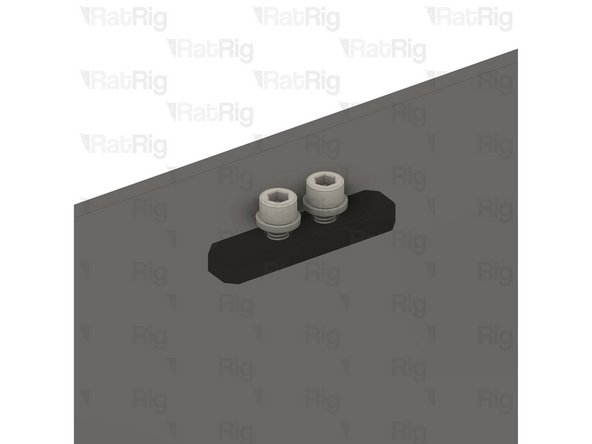

vc4_magnet_handle

-

Magnet - Neodymium disc 10x4mm

-

M6 Nylon Locking Hex Nut

-

Prepare two assemblies

-

Tip: Use a drop of super glue to prevent the magnets from coming off over time.

-

-

-

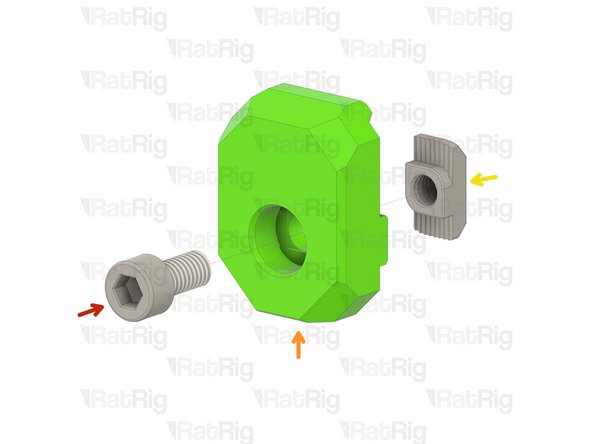

vc4_magnet_panel

-

Magnet - Neodymium disc 10x4mm

-

M6 Nylon Locking Hex Nut

-

Prepare eight assemblies

-

Tip: Use a drop of super glue to prevent the magnets from coming off over time.

-

-

-

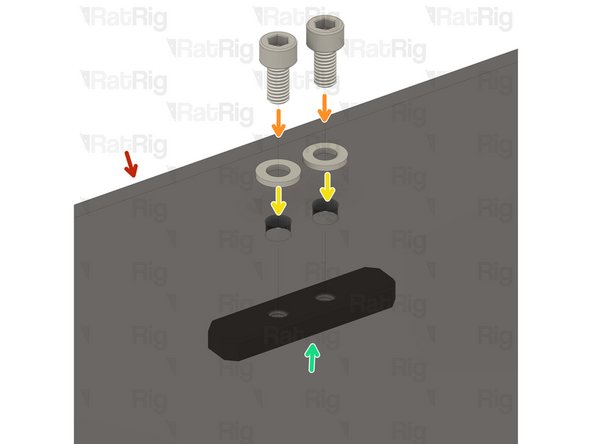

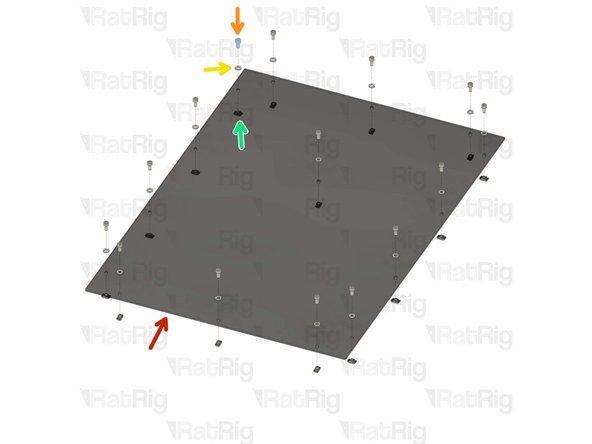

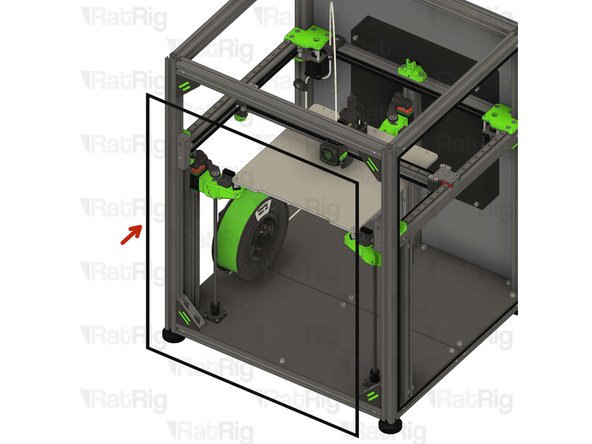

vc4_panel_door

-

M6x12 Cap Head Screw

-

M6 Washer

-

Door magnet panel assembly from Step 4

-

Repeat this step all around the panel

-

Take care not to over tighten the M6x12 screw as you can damage the printed parts

-

-

-

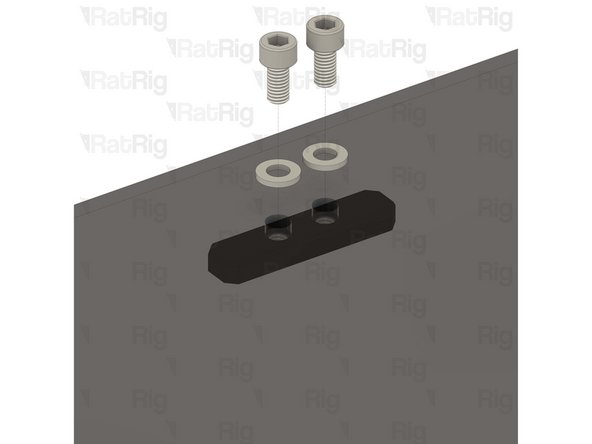

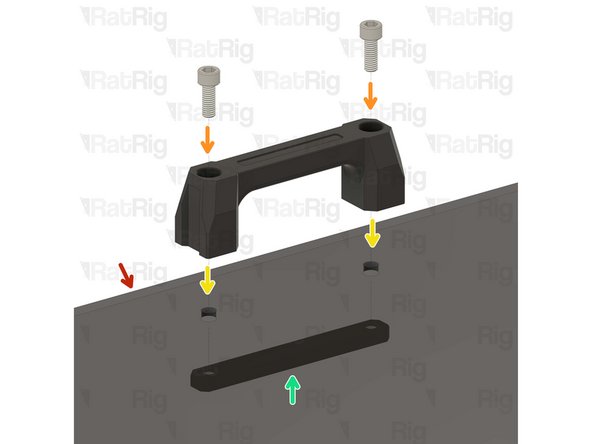

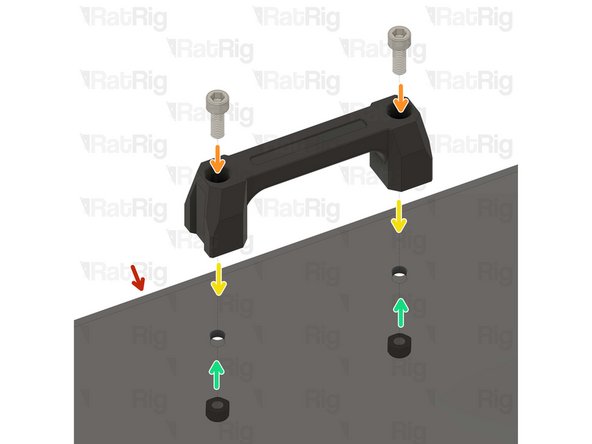

vc4_panel_door assembly

-

M6x16 Cap Head Screw

-

vc4_printed_handle

-

door magnet handle assembly from Step 3

-

Do not overly tighten the M6 nylon locking hex nuts when securing the handles, as this can cause the panel to warp which will prevent a good seal to the printer

-

-

-

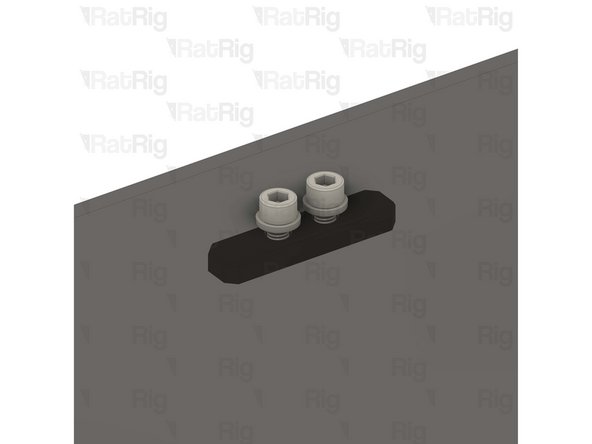

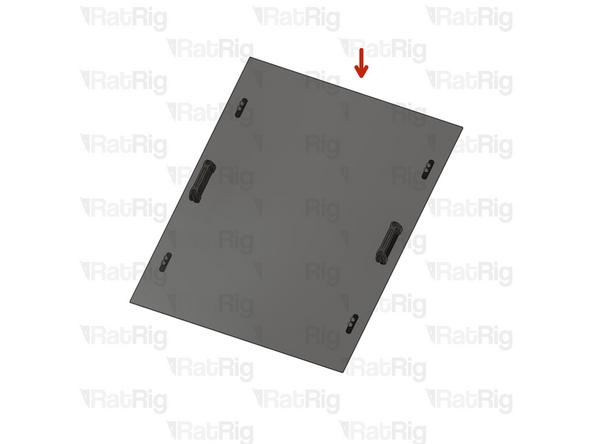

Completed door panel assembly

-

Set the completed door assembly aside until Step 23

-

-

-

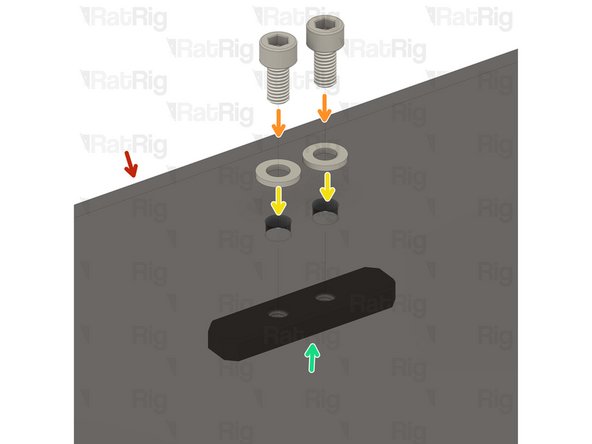

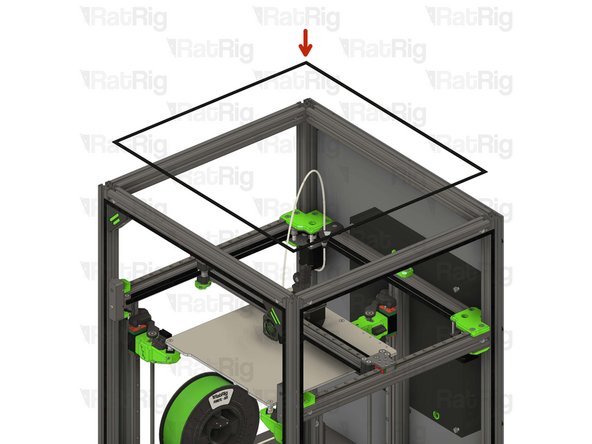

vc4_panel_top

-

M6x12 Cap Head Screw

-

M6 Washer

-

Door magnet panel assembly from Step 4

-

Repeat this step all around the panel

-

Take care not to over tighten the M6x12 screw as you can damage the printed parts

-

-

-

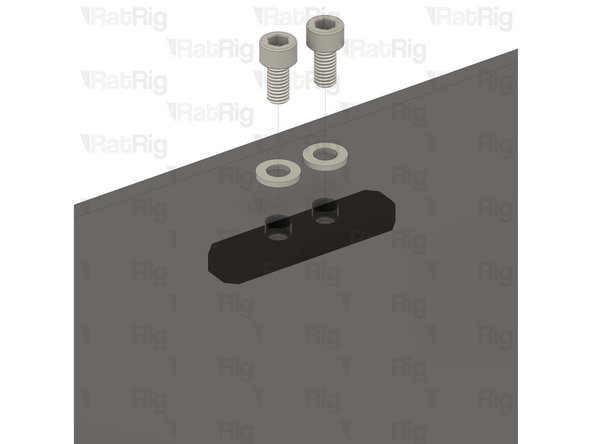

vc4_panel_top

-

M6x16 Cap Head Screw

-

vc4_printed_handle

-

M6 Nylon Locking Hex Nut

-

Do not overly tighten the M6 nylon locking hex nuts when securing the handles, as this can cause the panel to warp which will prevent a good seal to the printer

-

-

-

Completed top panel assembly

-

Set the completed top assembly aside until Step 21

-

-

-

30x M6 Washer

-

30x 3030 Drop-in T-Nut - M6

-

30x M6x12 Cap Head Screw

-

-

-

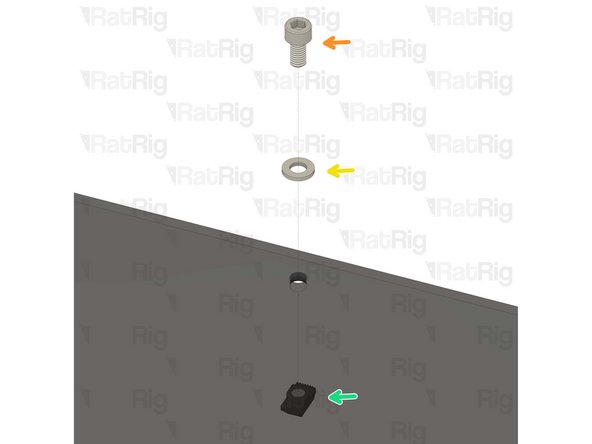

vc4_panel_side

-

M6x12 Cap Head Screw

-

M6 Washer

-

3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

-

-

1x Adhesive backed foam sealing tape

-

10x vc4_magnet_frame

-

2x vc4_door_support

-

12x M6x12 Cap Head Screw

-

12x 3030 Drop-in T-Nut - M6

-

20x Magnet - Neodymium disc 10x4mm

-

-

-

M6x12 Cap Head Screw

-

vc4_door_support

-

3030 Drop-in T-Nut - M6

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Prepare two assemblies

-

-

-

vc4_magnet_frame

-

Magnet - Neodymium disc 10x4mm

-

3030 Drop-in T-Nut - M6

-

M6x12 Cap Head Screw

-

Loosely thread the 3030 T-Nuts onto the M6x12 screws. Do not tighten them at this point.

-

Please verify the magnet polarity in relation to the magnets on the door panel. If the polarity is inverted, the magnets will repel each other instead of attracting.

-

Prepare ten assemblies

-

-

-

Adhesive foam tape

-

Cut sections of foam tape to fit in the sections shown

-

The foam seal tape is provided with an adhesive backing, peel the backing off and apply it to the frame as shown

-

-

-

Adhesive foam tape

-

Cut sections of foam tape to fit in the sections shown

-

The foam seal tape is provided with an adhesive backing, peel the backing off and apply it to the frame as shown

-

-

-

Adhesive foam tape

-

Cut sections of foam tape to fit in the sections shown

-

The foam seal tape is provided with an adhesive backing, peel the backing off and apply it to the frame as shown

-

-

-

Adhesive foam tape

-

Cut sections of foam tape to fit in the sections shown

-

The foam seal tape is provided with an adhesive backing, peel the backing off and apply it to the frame as shown

-

-

-

Horizontal 3030 panel holder assembly from Step 14

-

Tighten the M6x12 screws to secure the assemblies to the frame

-

Take care not to over tighten the M6x12 screws as you can damage the printed parts

-

-

-

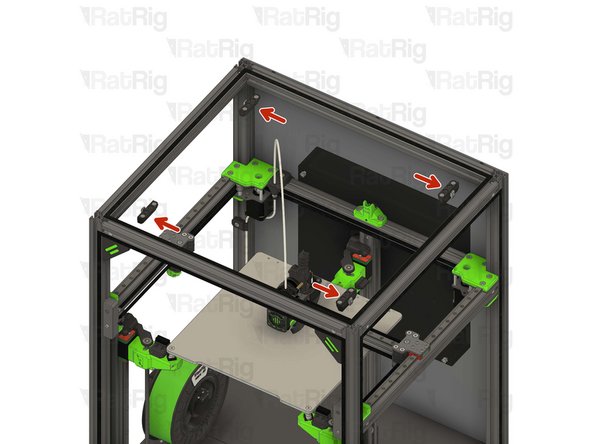

Frame magnet mount assemblies from Step 15

-

Position each magnet mount assembly as shown

-

The marked gap should measure 31.50mm

-

Tighten the M6x12 screw to secure each assembly to the frame

-

Take care not to over tighten the M6x12 screws as you can damage the printed parts

-

The exact position of the magnet mounts can be adjusted once the top panel in in place

-

-

-

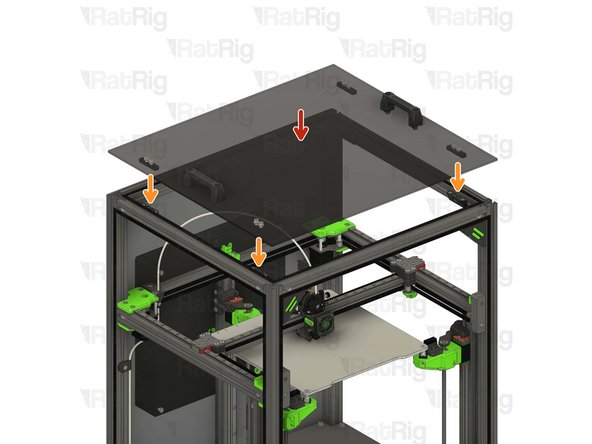

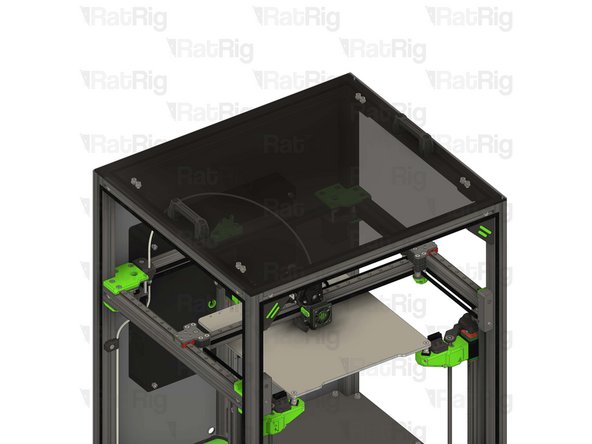

Top panel assembly from Step 10

-

Place the top panel onto the top of the printer

-

The magnets should align the panel automatically. If the alignment needs to be adjusted, alter the position of the magnet holders installed in Step 21

-

-

-

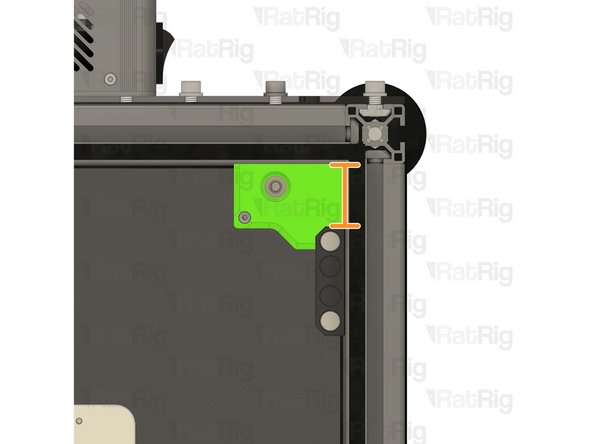

Frame magnet mount assemblies from Step 15

-

Position each magnet mount assembly as shown

-

The marked gap should measure 19.50mm

-

Tighten the M6x12 screw to secure each assembly to the frame

-

Take care not to over tighten the M6x12 screws as you can damage the printed parts

-

The exact position of the magnet mounts can be adjusted once the front panel in in place

-

-

-

Door panel assembly from Step 7

-

Rest the door panel on the horizontal 3030 panel mounts

-

Rotate towards the printer to secure it

-

The magnets should align the panel automatically. If the alignment needs to be adjusted, alter the position of the magnet holders installed in Step 23

-

-

-

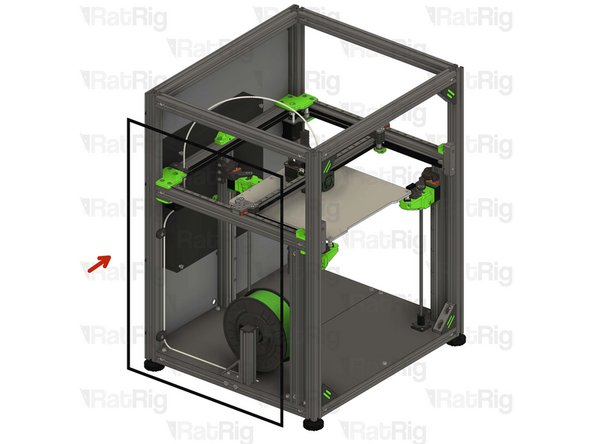

Right enclosure panel from Step 12

-

Align the panel to the frame as shown

-

Secure the panel in place by fastening the nineteen M6x12 screws

-

-

-

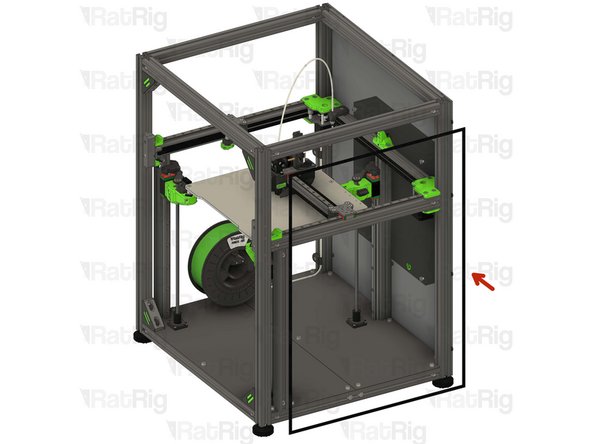

Right enclosure panel from Step 12

-

Align the panel to the frame as shown

-

Secure the panel in place by fastening the nineteen M6x12 screws

-

Cancel: I did not complete this guide.

10 other people completed this guide.