Introduction

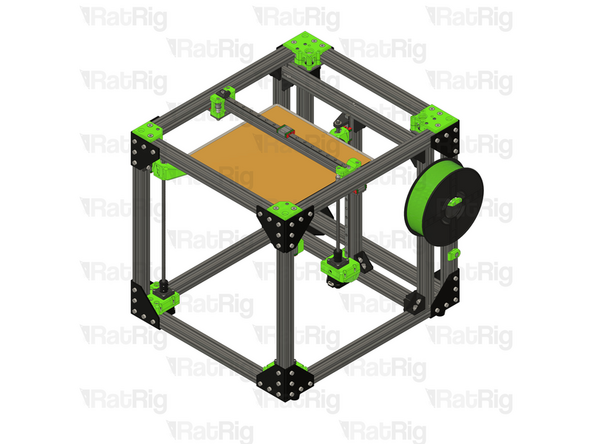

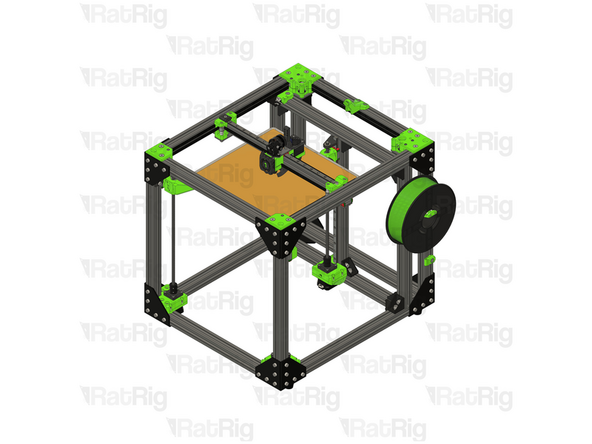

This guide provides a thorough overview of the disassembly of the EVA3, the preparation of the V-Core 3.1 frame, and the installation procedure for the Rat Rig toolhead V1.0 Upgrade Kit.

The Rat Rig Toolheads are streamlined to be used specifically with our favourite combination:

Orbiter V2

Phaetus Rapido UHF hot end

4028 part cooling fan

Rat Rig “SuperPinda” Probe by P&F

-

-

This guide is divided into 3 parts, to help you quickly find the instructions you need:

-

-

-

-

-

-

Remove the M3x25 Cap Head Screw

-

Remove the Hex Nut - M3

-

Remove the M3 Nylon Locking Hex Nut

-

Remove the M3x35 Cap Head Screw

-

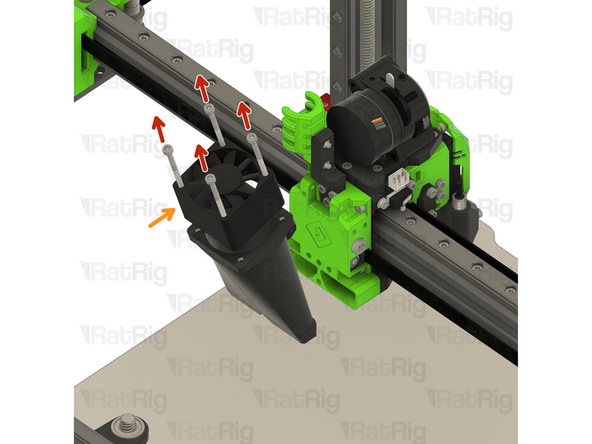

Remove the 40mm_fan_duct assembly as shown

-

-

-

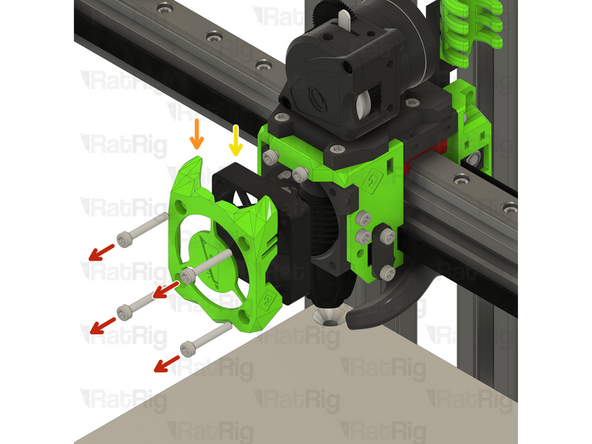

Remove the four M3x35 Cap Head Screws

-

Remove the 4028 Part Cooling Fan from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

Remove the four Hex Nuts - M3

-

-

-

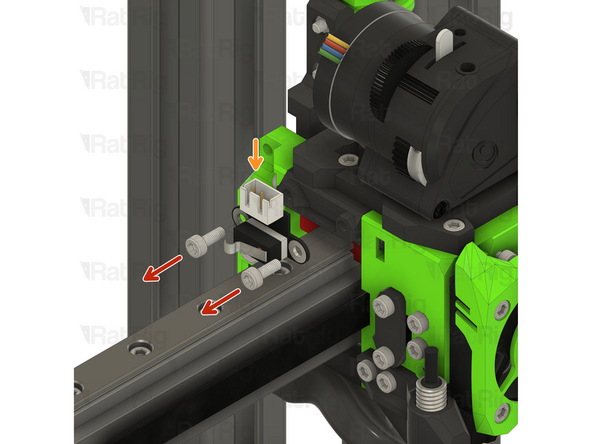

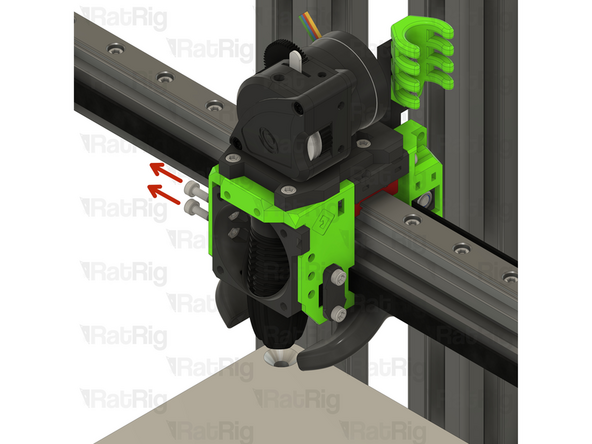

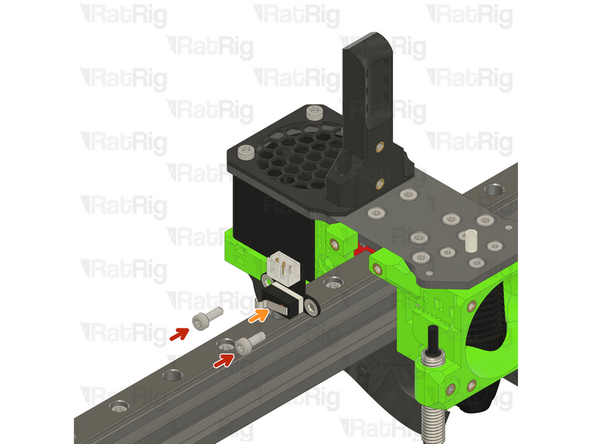

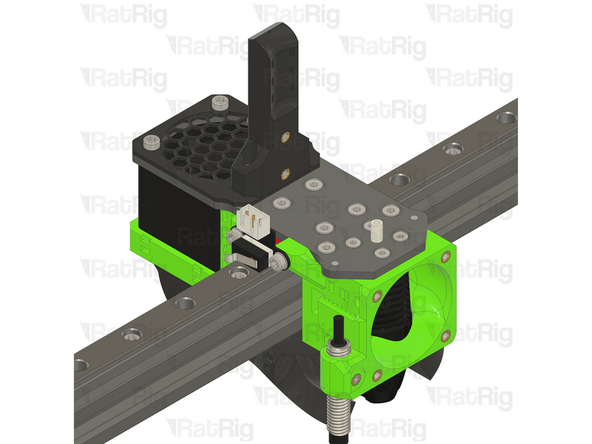

Remove the two M3x8 Cap Head Screws

-

Disconnect the Endstop Module and set it aside, it will be re-used on the Rat Rig Toolhead V1.0

-

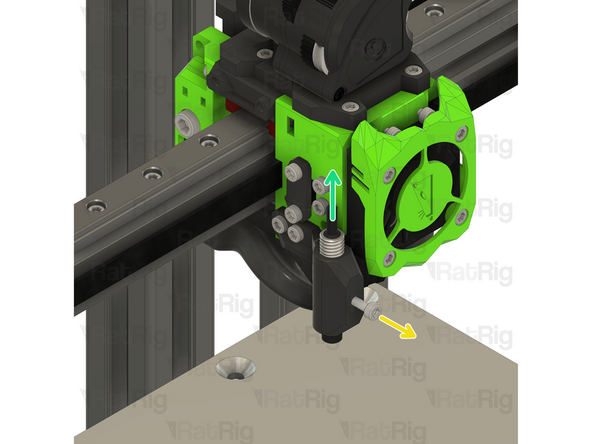

Loosen the M3x8 Cap Head Screw

-

Remove the Z-probe from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

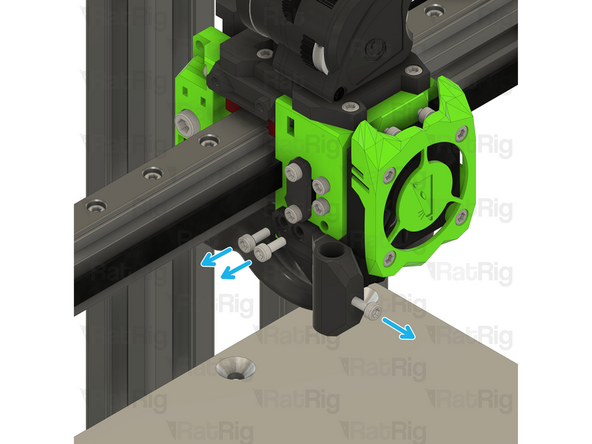

Remove the three M3x8 Cap Head Screws

-

-

-

Remove the four M3x20 Cap Head Screws

-

Remove the ratrig_eva3_shroud Printed Part

-

Remove the 4010 Axial Fan from the assembly, it will be re-used on the Rat Rig Toolhead V1.0

-

Remove the four M3x8 Cap Head Screws

-

-

-

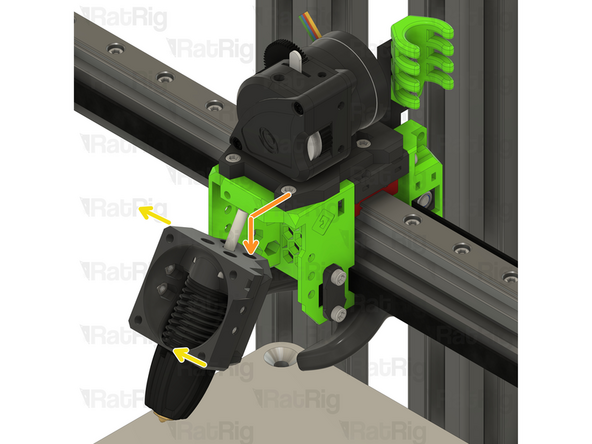

Remove the four M3x8 Cap Head Screws

-

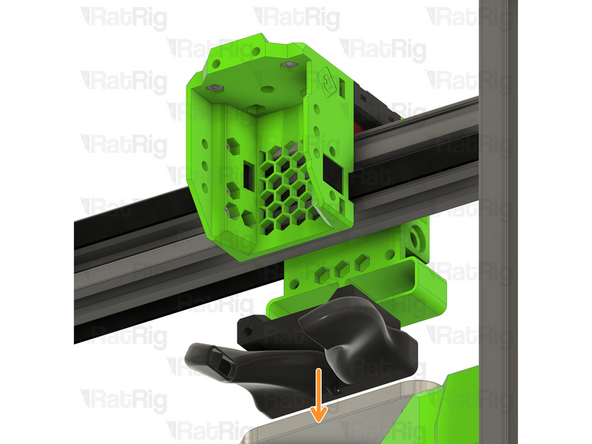

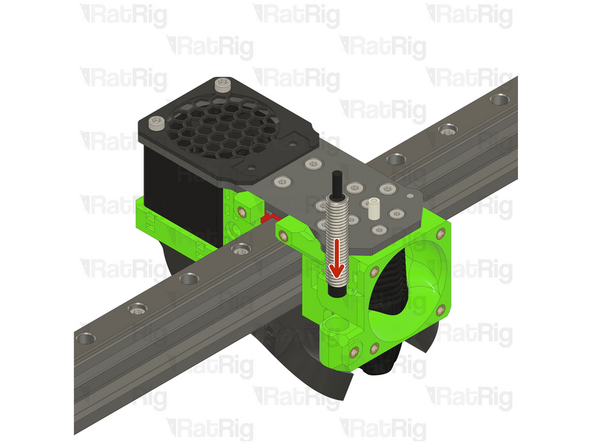

Gently push the hotend assembly down and away from the toolhead-

-

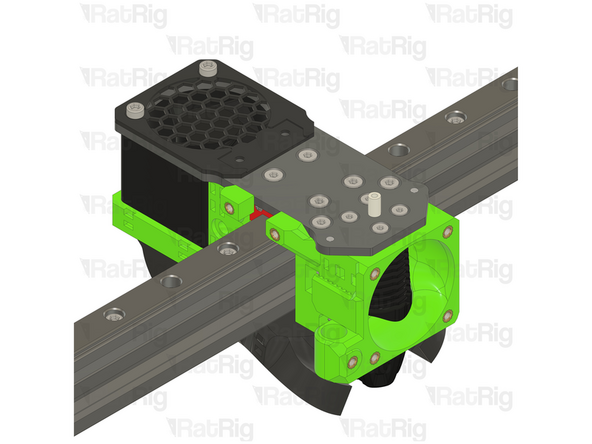

Rotate the hot end assembly into position as shown

-

-

-

Remove the PTFE line

-

Remove the four M2.5x8 Cap Head Screws

-

Remove the Rapido hotend from the printed part, it will be re-used on the Rat Rig Toolhead V1.0

-

Tip: Insert the four M2.5x8 Cap Head Screws back in the Rapido hotend mounting points to avoid losing them.

-

-

-

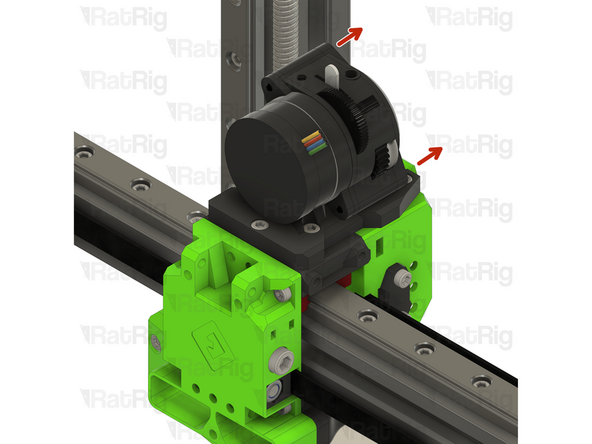

Remove the two M3x25 screws on the face of the LGX Lite which secure the motor in place

-

Remove the Bondtech LGX Lite motor from the back of the LGX Lite extruder

-

Remove the three M3x12 Cap Head Screws

-

-

-

Remove the two M3x8 Cap Head Screws

-

Remove the extruder assembly

-

The new Rat Rig toolhead uses the Orbiter V2,

-

Remove the M3x8 Cap Head Screws holding the LGX Lite to the EVA3 drive_lgx_lite Printed Part

-

Reassemble the LGX Lite so you can safely store it.

-

-

-

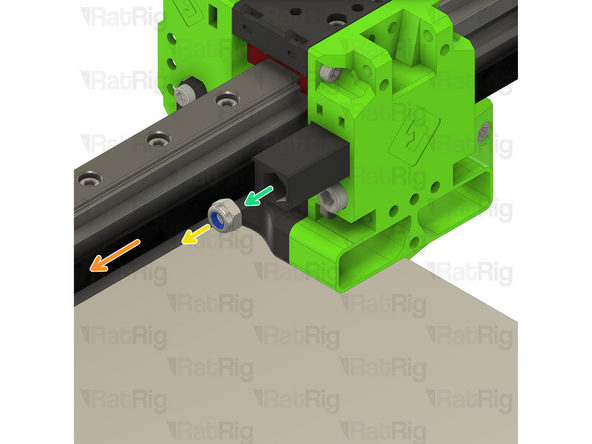

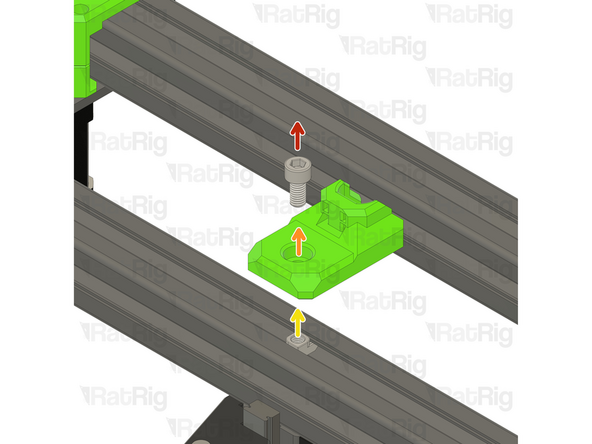

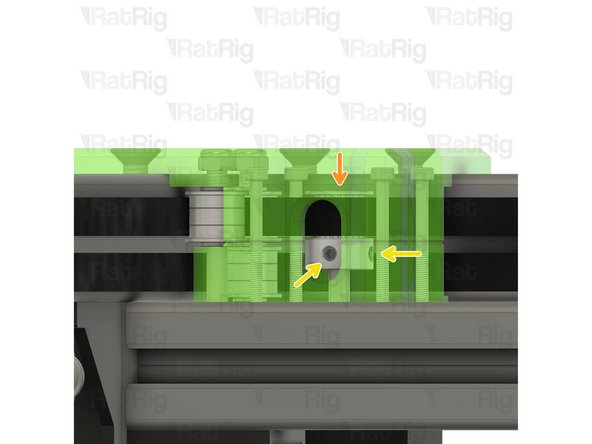

Loosen the M5x40 Cap Head Screw

-

Pull the belt to help remove the CoreXY belt grabber

-

Remove the M5 nylon locking nut

-

Remove the belt grabber from the toolhead

-

Repeat the previous steps and remove the other CoreXY belt grabber

-

-

-

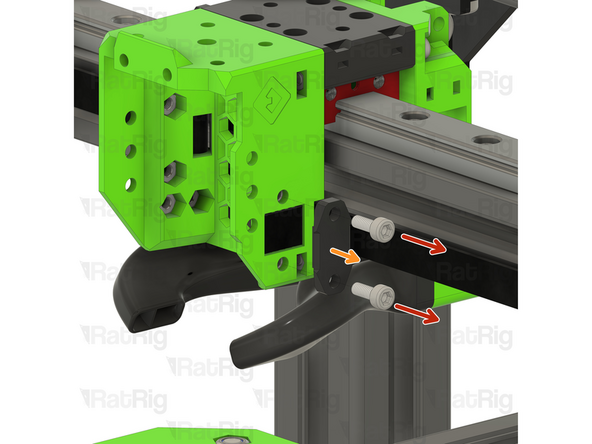

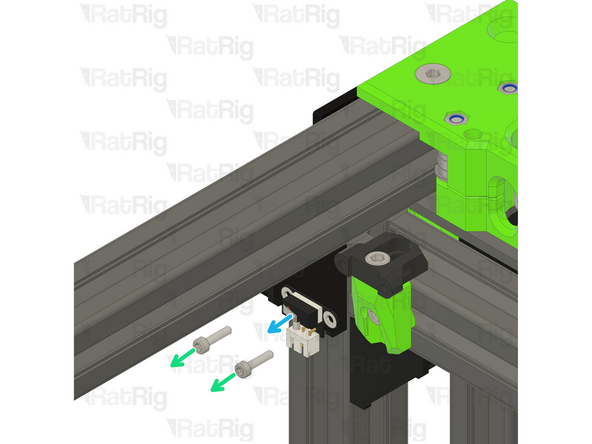

Remove the two M3x8 Cap Head Screws

-

Remove the belt front belt holder

-

Repeat the previous steps for the other front belt holder

-

-

-

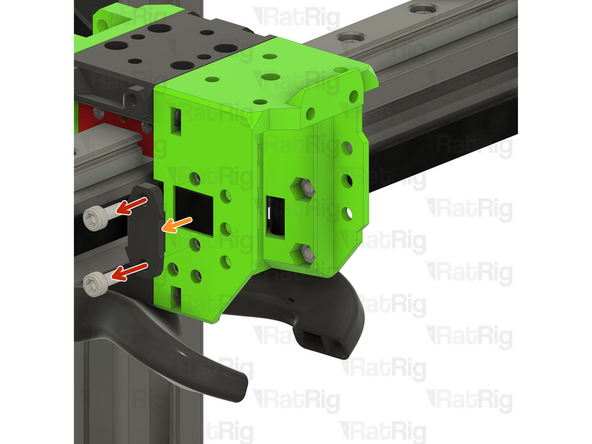

Remove the two M3x35 Cap Head Screws

-

Pull down on the EVA horn ducts

-

-

-

Remove the two M3x35 Cap Head Screws

-

Pull on the EVA3 front assembly to remove it

-

Pull on the EVA3 back assembly to remove it

-

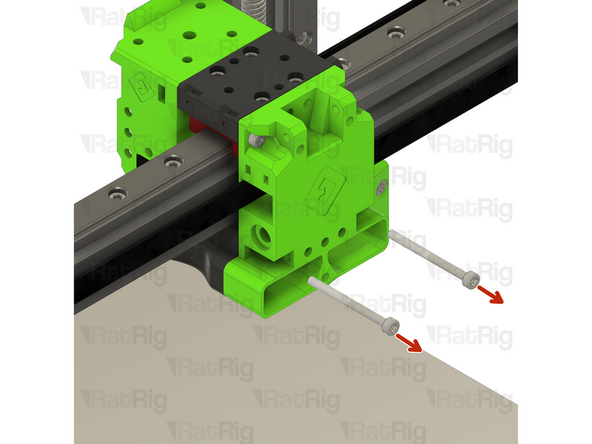

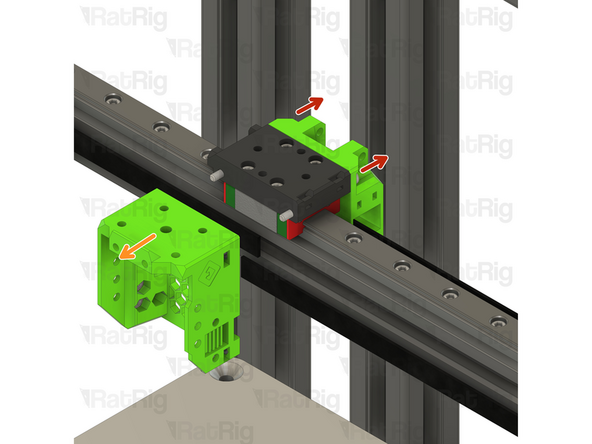

Remove the four M3x8 Cap Head Screws

-

Remove the EVA3 mgn12 mount

-

-

-

Some components of the V-Core 3.1 need to be upgraded to support the new Rat Rig Toolhead. The following steps will show you how.

-

-

-

Locate the rear cable holder

-

Remove the M6x12 Cap Head Screw

-

Remove the electronics_wire_guide_rear printed part from the frame

-

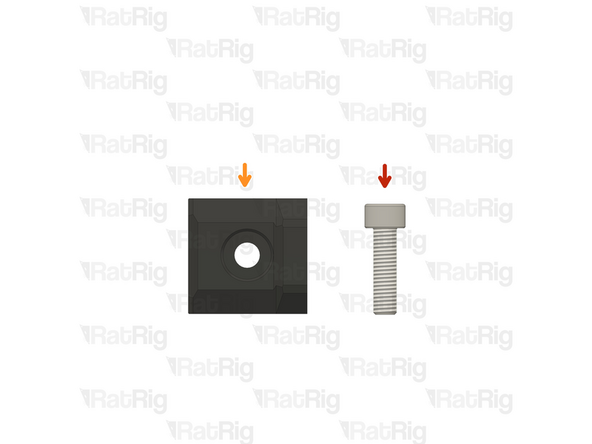

Remove the M6 3030 Drop in T-nut

-

Locate the Y endstop mount

-

Remove the two M3x12 Cap Head Screws

-

Disconnect the Enstop Module and set it aside, it will be re-used on the Rat Rig Toolhead V1.0

-

-

-

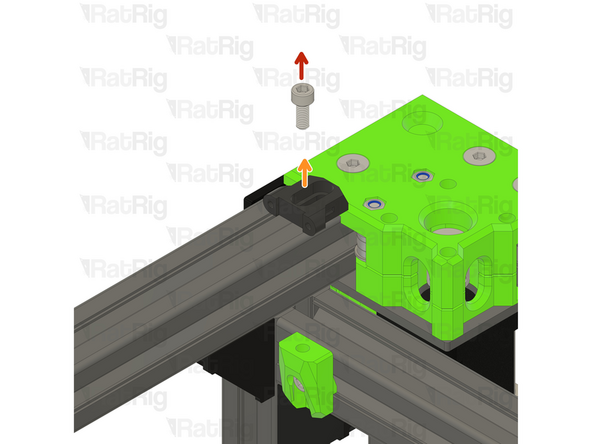

Remove the M5x12 Cap Head Screw

-

Remove the Y_max_endstop_slider printed part

-

Remove the M5x10 Cap Head Screw

-

Remove the Y endstop_max_block printed part

-

Remove the M5 3030 Drop in T-nut

-

-

-

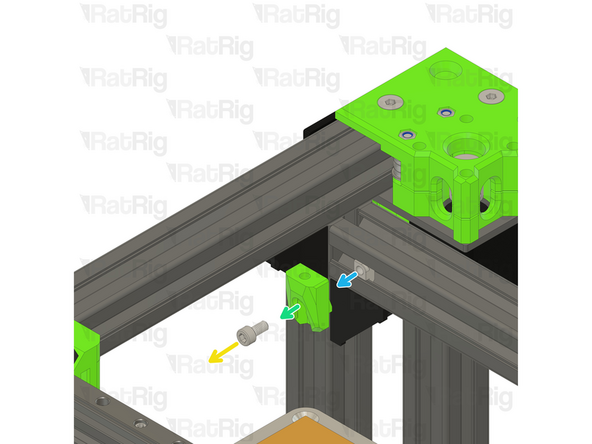

Remove the M5x18 Cap Head Screw

-

Remove the EVA3 endstop block

-

Avoid moving the machine around at this point, os the M5 Drop in T-nut doesn't slide around on the gantry extrusion.

-

-

-

The V-Core 3.1 is now ready to receive the Rat Rig Toolhead V1.0 Upgrade kit

-

-

-

The next steps will cover the assembly of the Rat Rig toolhead V1.0 upgrade kit

-

-

-

M5x18 Cap Head Screw

-

x_endstop printed part

-

Carefully insert the M5x18 Cap Head Screw into the already existing M5 Drop in T-nut

-

-

-

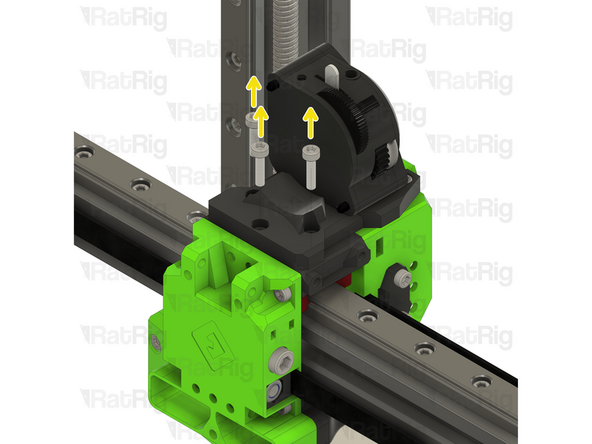

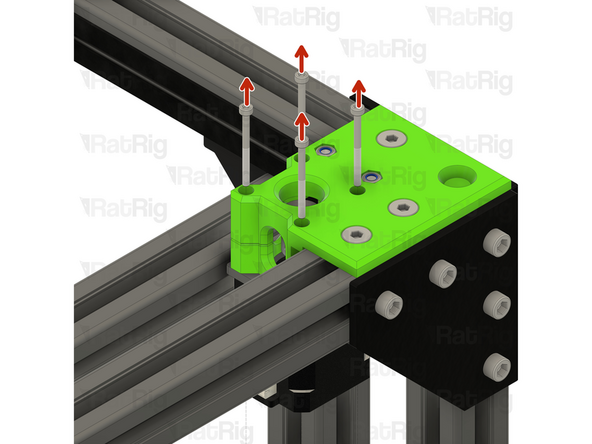

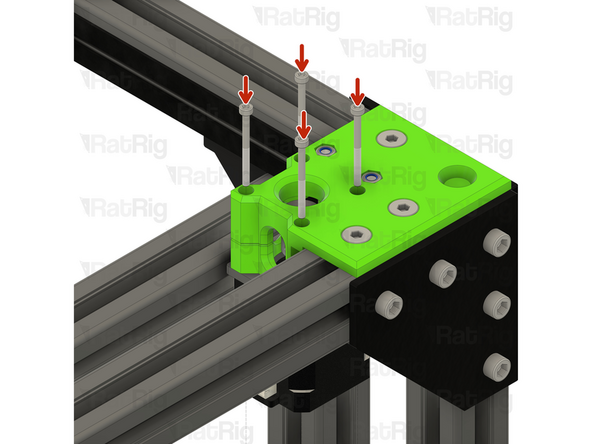

Remove the M3x45 Cap Head Screws

-

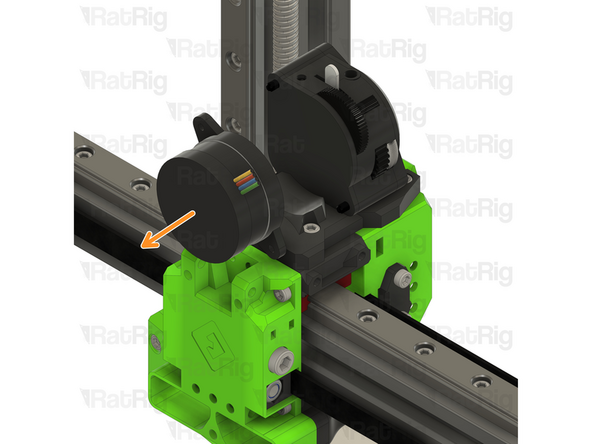

Remove the Stepper motor

-

Remove the M5x40 Cap Head Screws

-

-

-

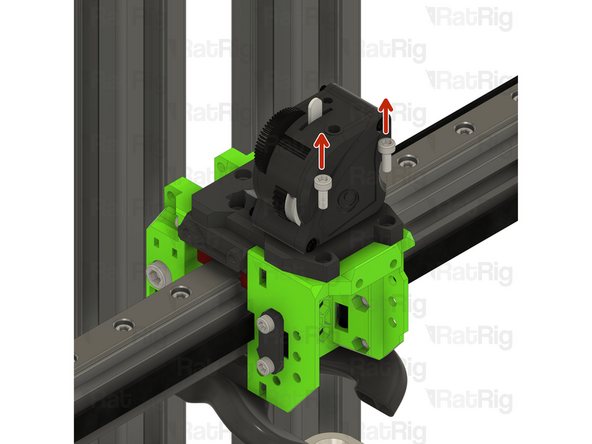

Remove the three M6x14 Screws

-

If the M6 Drop in T-nuts fall off, loosely thread them in the screws so you can easly reinstall the CoreXY motor cage top easily.

-

Remove the CoreXY motor cage top

-

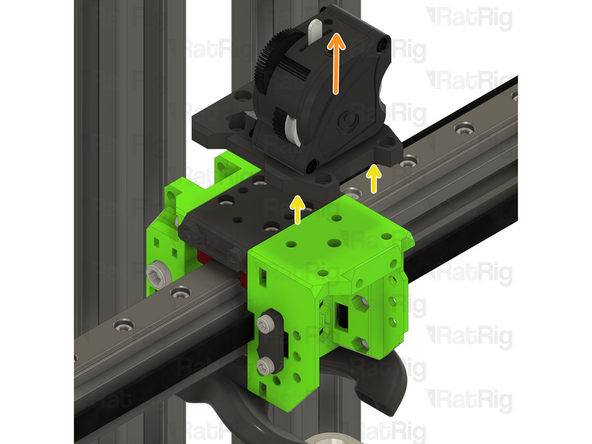

Remove both of the old belts, then insert the two new ones following the same paths

-

Reinstall the CoreXY motor cage top

-

-

-

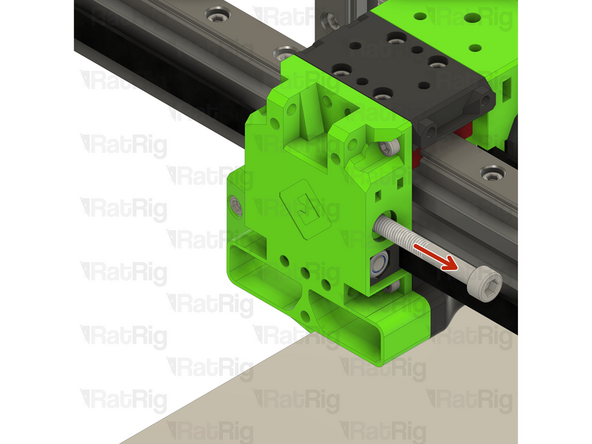

Tighten the three marked M6x14 screws to secure the CoreXY motor cage top to the frame

-

Tighten the M5x40 screws to secure the bearing stacks into the CoreXY motor cage top

-

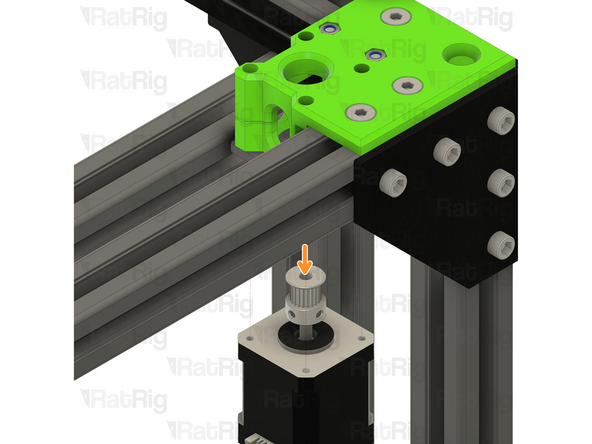

Position the NEMA17 motor up and into the motor cage from below, it will be secured in the next step

-

-

-

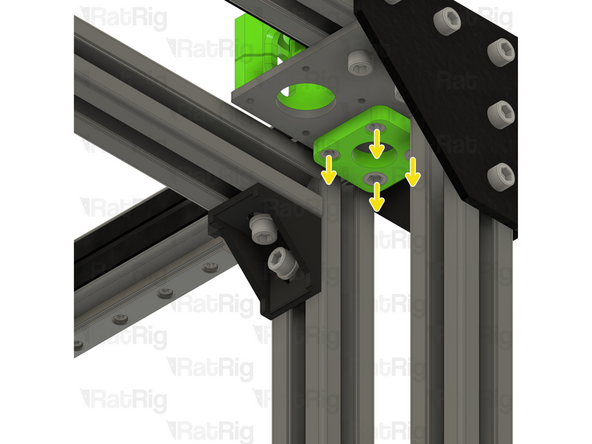

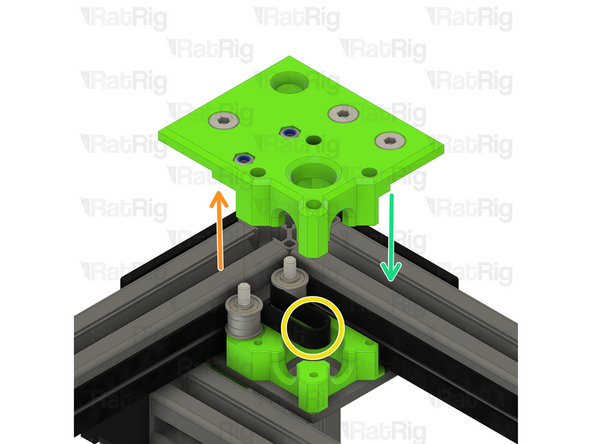

Insert the M3x35 screws into the xy_motor_cage_left_top as shown, and fasten them to secure the NEMA17 motor to the mount

-

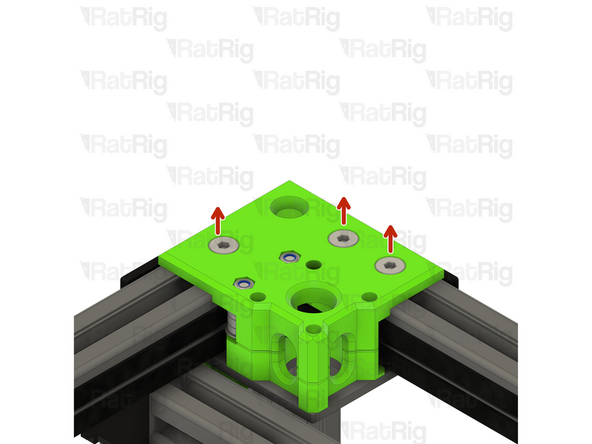

Check the alignment of the timing pulley, the belt should be on the middle of the pulley as shown

-

Adjust the pulley up or down if required to make sure the belt is in the middle of the pulley

-

Fasten both M3 grub screws to securely mount the timing pulley to the NEMA17 motor shaft

-

Repeat Steps 21 - 24 for the other CoreXY motor mount cage.

-

-

-

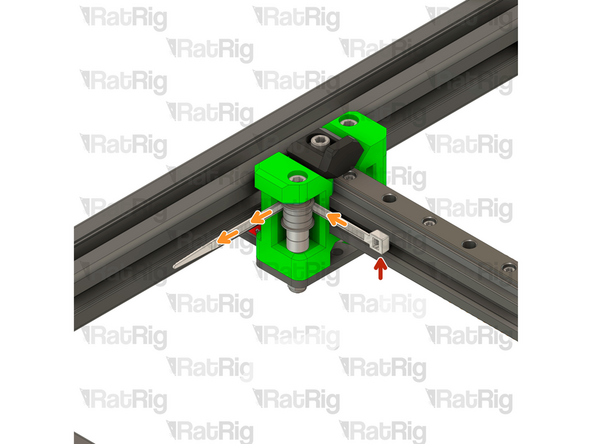

This step is not mandatory, it's just a Rat Rig tip on how to feed the belts on the idlers.

-

Zip Tie

-

The wider the zip tie is, the easier the process will be

-

Bend the tip of the zip tie a little bit and feed it between the printed part and the idler, as shown

-

Insert the belt between the zip tie and the idler

-

Slowly feed the belt and pull the zip tie at the same time

-

-

-

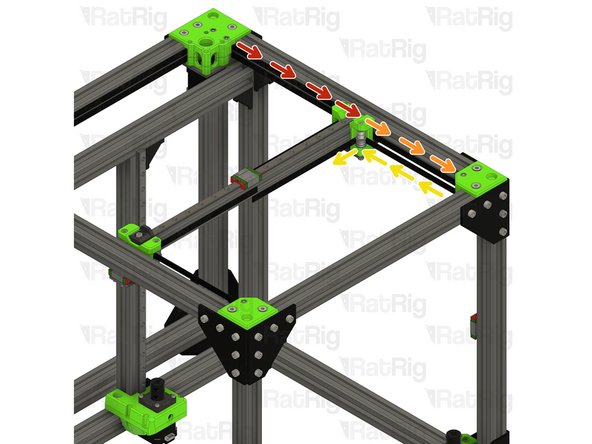

Take the loose end of the top CoreXY belt on the left hand side:

-

Feed the belt behind the left xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the left xy_joiner

-

Take the loose end of the bottom CoreXY belt on the left hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-

-

-

Take the loose end of the bottom CoreXY belt on the right hand side:

-

Feed the belt behind the right xy_joiner

-

Down and around the front xy_idler

-

Around the front bearing stack on the right xy_joiner

-

Take the loose end of the top CoreXY belt on the right hand side:

-

Feed the belt around the rear bearing stack on the xy_joiner

-

-

-

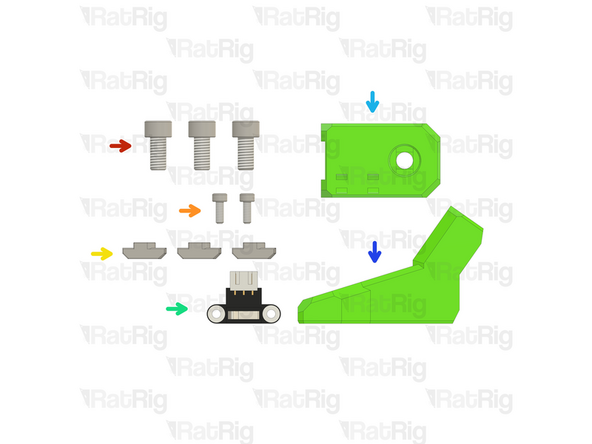

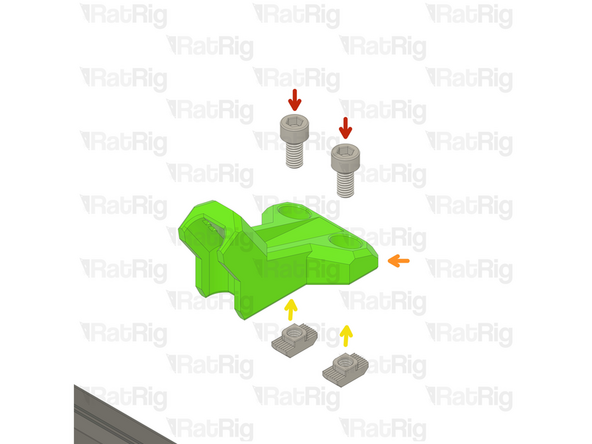

3x M6x12 Cap Head Screw

-

2x M3x8 Cap Head screw

-

3x 3030 M6 Drop In T-nut

-

Y endstop

-

Y_endstop printed part

-

Umbilical_frame printed part

-

-

-

2x M6x12 Cap Head Screw

-

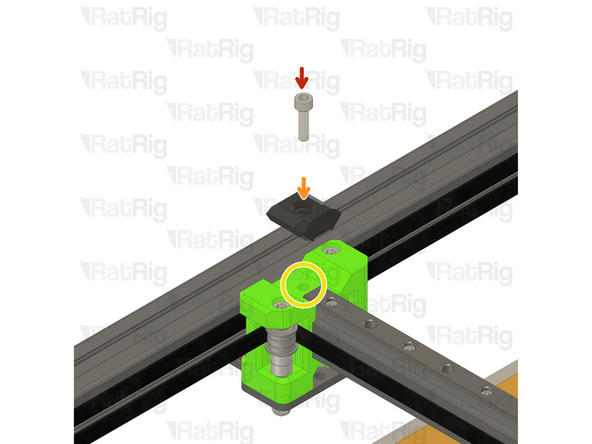

Install the M6 cap head screws into the printed part as shown.

-

Umbilical_frame printed part

-

3030 M6 Drop In T-nut

-

Loosely thread a 3030 M6 T-Nut onto the M6x12 screws. Do not tighten it at this point

-

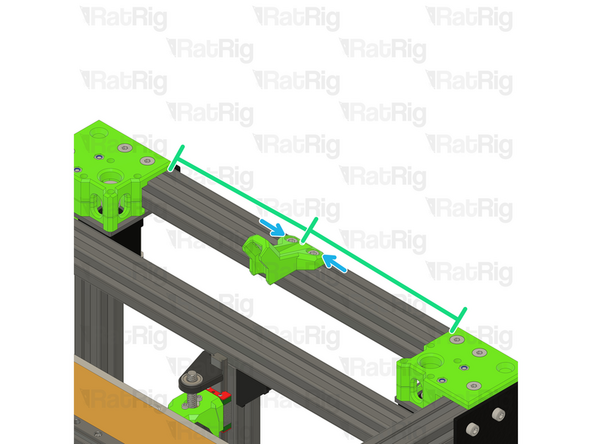

Make sure the printed part is on the middle of the rear extrusion.

-

Tighten the M6x12 screw to secure the umbilical mount to the frame.

-

-

-

M6x12 Cap Head Screw

-

Y_endstop printed part

-

3030 M6 Drop In T-nut

-

Loosely thread a 3030 M6 T-Nut onto the M6x12 screw. Do not tighten it at this point

-

2x M3x8 Cap Head Screw

-

Y Endstop

-

Tighten the M6x12 screws to secure the endstop mount.

-

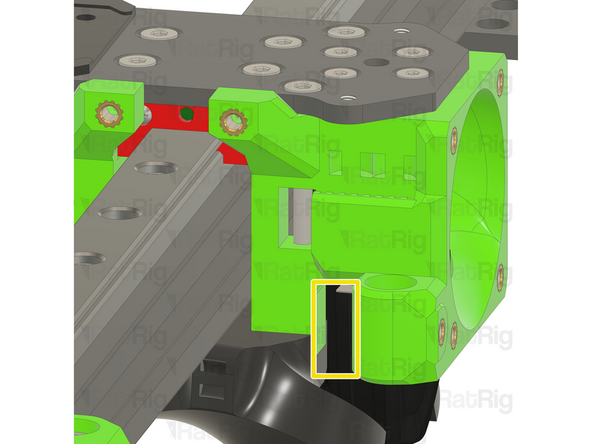

Ensure a 5mm gap between the 3030 extrusion and the Y_endstop printed part, this distance is required for the belts to operate smoothly.

-

-

-

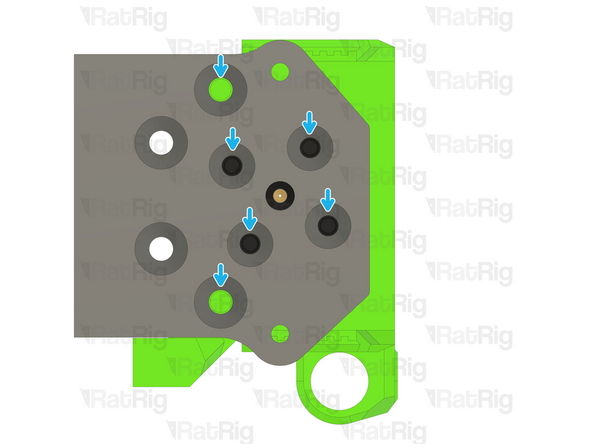

Rat Rig toolhead plate

-

Rat Rig toolhead front printed part

-

Insert the rapido on the printed part as shown, and make sure the cables are positioned in the designated slot.

-

Look from above and see if all the holes line up correctly.

-

All the holes on the plate, hotend and printed part should line up:

-

If they align skip to step 35

-

If they don't align follow the next steps

-

-

-

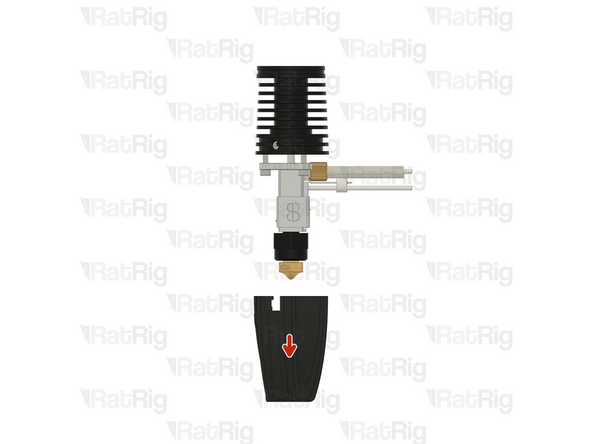

If the cables of your Rapido 2 hotend don't align perfectly with the toolhead slot, please follow the next steps:

-

Push down on the silicone sock to remove it

-

Loosen the set screw on the heatsink

-

Do not remove it completely to avoid losing it

-

-

-

Remove the 2.5 Cap Head Screws from the hotend

-

Carefully rotate the heatsink until the three screw holes align again.

-

There isn't a way to teel how much you need to rotate you hotend, it might be just 120º or it might be 240º. It's a matter of trial and error.

-

-

-

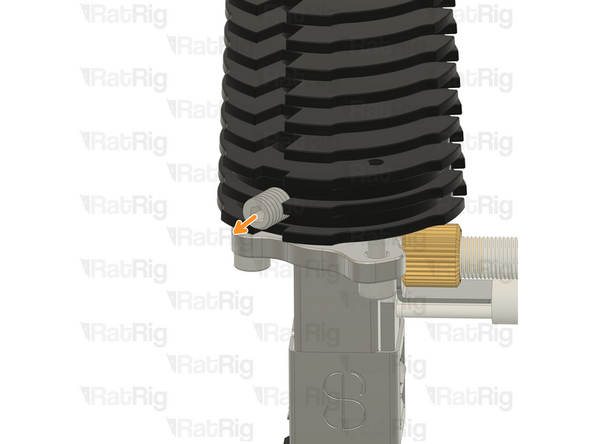

Insert the 2.5mm Cap Head Screws back in and tighten them.

-

DO NOT overtighten the screws, they are only 2.5mm and will break if excessive force is applied.

-

Tighten the set screw back in

-

DO NOT overtighten the screw, if excessive force is applied the heatbreak will be permanently damaged.

-

Put the socket back on

-

Try to insert the hotend on the toolhead and see if the cables align with the designated slot, if not, repeat steps 32-34 and try a different angle in step 34

-

-

-

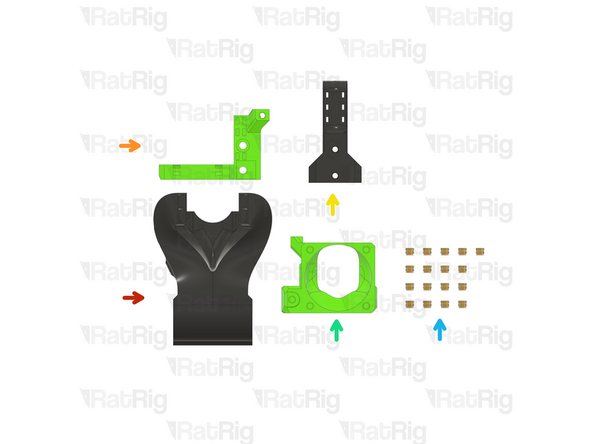

1x Rat Rig toolhead duct printed part

-

1x Rat Rig toolhead back printed part

-

1x Rat Rig toolhead umbilical printed part

-

1x Rat Rig toolhead front printed part

-

17x Heat insert M3

-

If you bought the printed parts from Rat Rig, the heat inserts are already in place. Skip to Step 40.

-

-

-

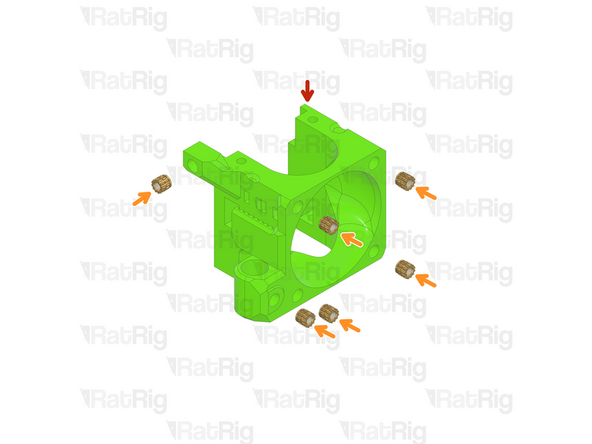

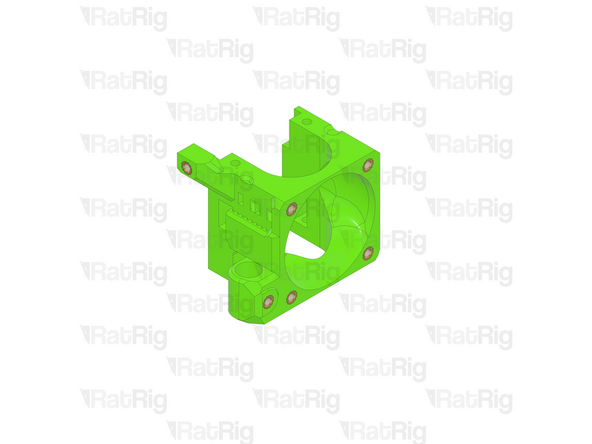

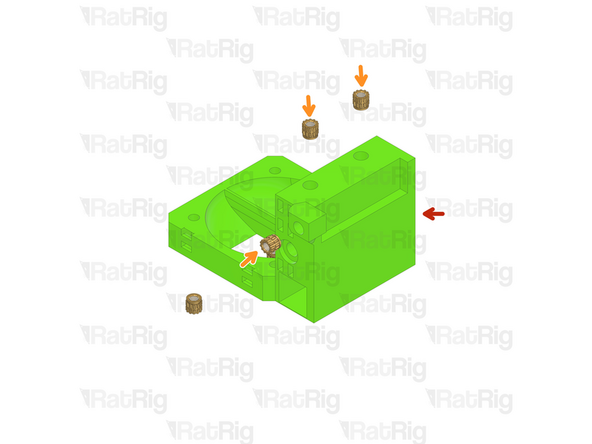

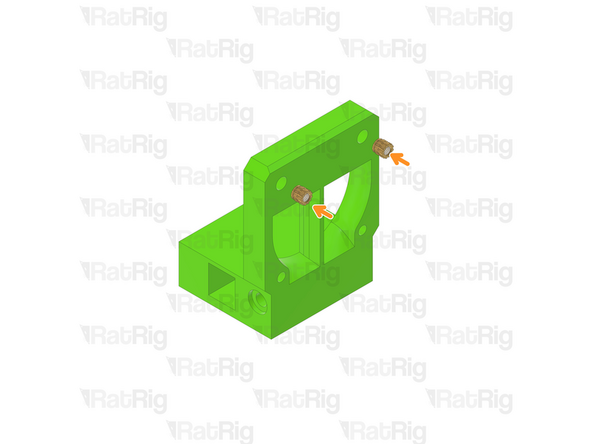

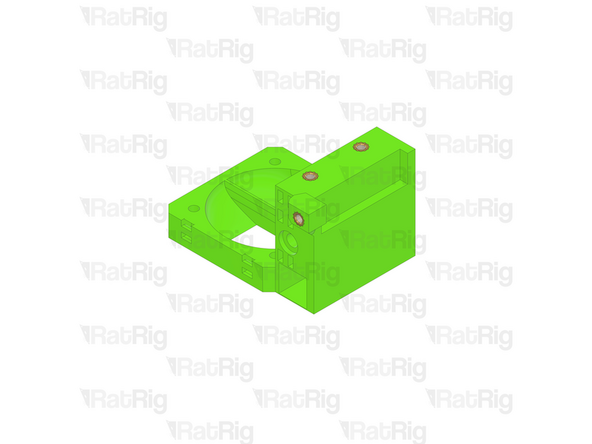

Rat Rig toolhead front printed part

-

6x Heat insert M3

-

-

-

Rat Rig toolhead back printed part

-

5x Heat insert M3

-

-

-

Rat Rig toolhead duct printed part

-

This printed part has sacrificial layers. It is recommended to remove them by using a screwdriver, a hex key, or a drill, to push through the layers. This clears the holes for the screws.

-

4x Heat insert M3

-

-

-

Rat Rig toolhead umbilical printed part

-

2x Heat insert M3

-

-

-

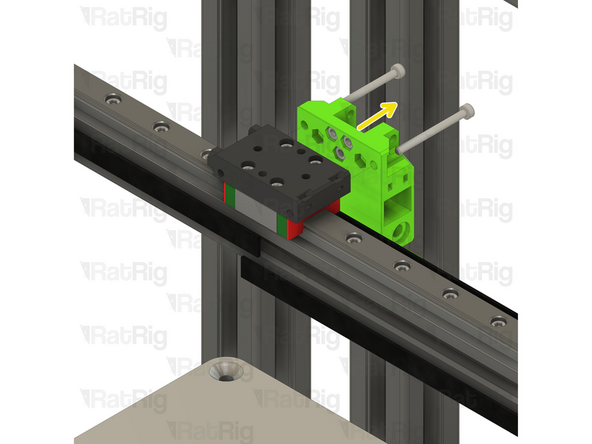

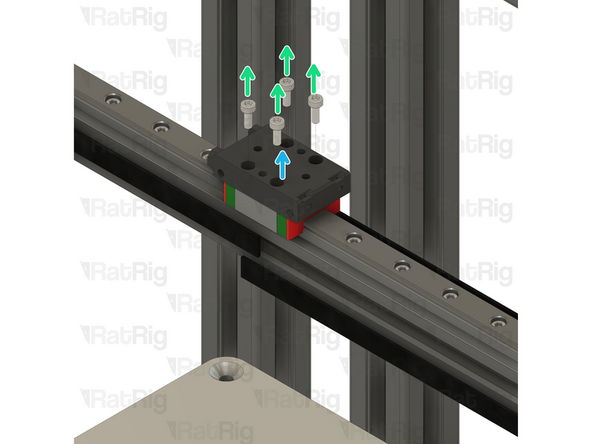

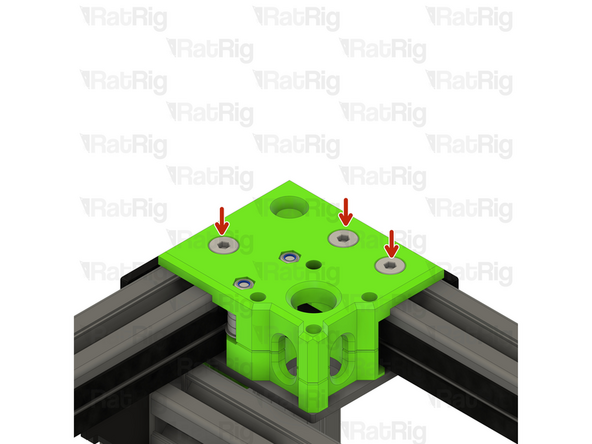

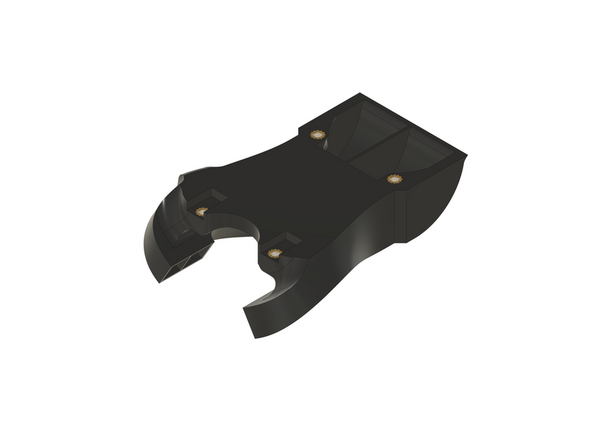

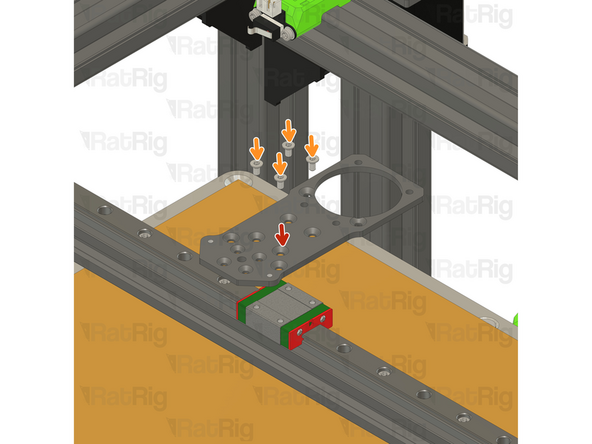

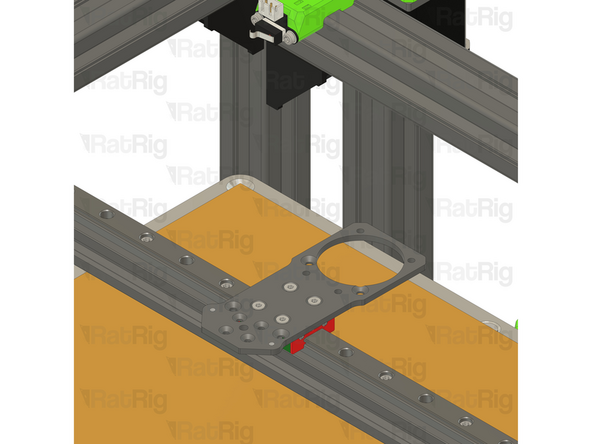

Rat Rig toolhead plate

-

4x M3x6 Countersink Screw

-

Tighten the M3x6 Countersink Screws to secure the plate to the carriage.

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

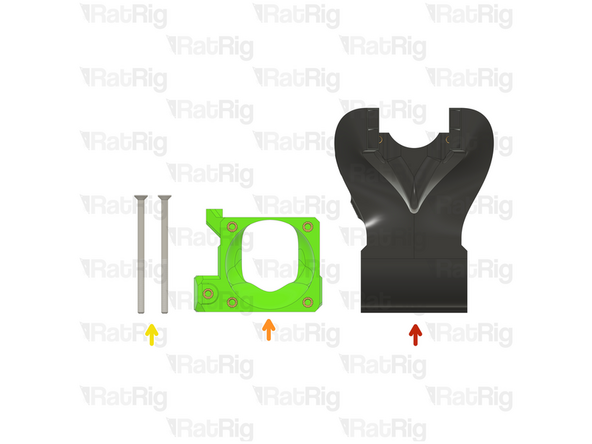

1x Rat Rig toolhead duct assembly

-

1x Rat Rig toolhead front assembly

-

2x M3x50 Countersink Screw

-

-

-

2x M3x50 Countersink Screw

-

Rat Rig toolhead front assembly

-

Rat Rig toolhead duct assembly

-

The M3x50 countersink screws must go through the holes on the front assembly

-

Take care not to over tighten the M3x50 screw as you can damage the printed parts

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

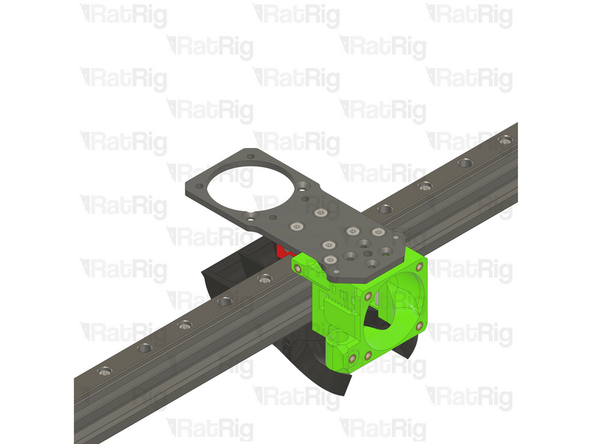

1x Rat Rig toolhead back assembly

-

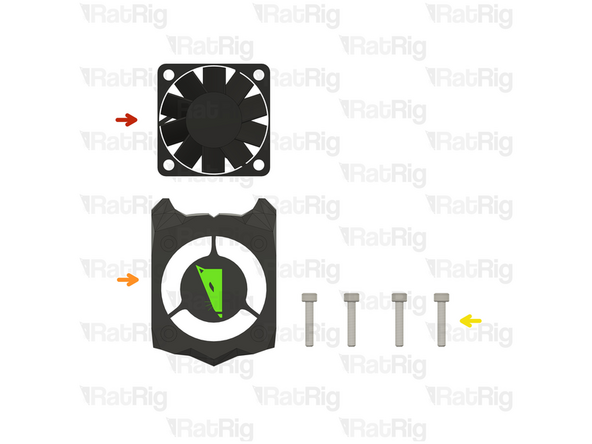

1x 4028 Part Cooling Fan

-

1x Rat Rig toolhead fan grille printed part

-

2x M3x40 Cap Head Screw

-

2x M3x45 Countersink Screw

-

-

-

Remove the four rubber washers on the 4028 Part Cooling Fan

-

-

-

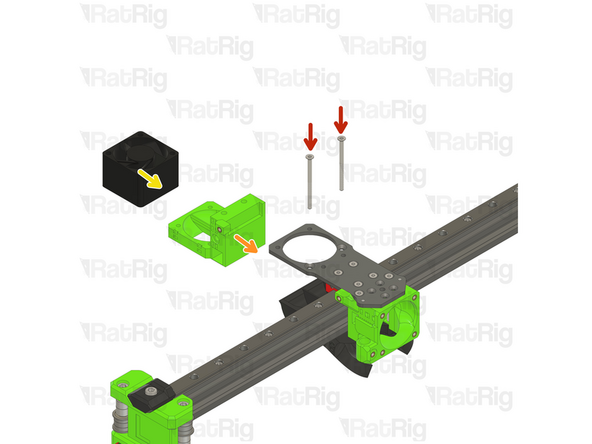

2x M3x45 Countersink Screw

-

Rat Rig toolhead back assembly

-

4028 Part Cooling Fan

-

Tighten the M3x45 screws.

-

Take care not to over tighten the M3x45 screws as you can damage the printed parts

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

2x M3x40 Cap Head Screw

-

Rat Rig toolhead fan grille printed part

-

Take care not to over tighten the M3x45 screws as you can damage the printed parts

-

-

-

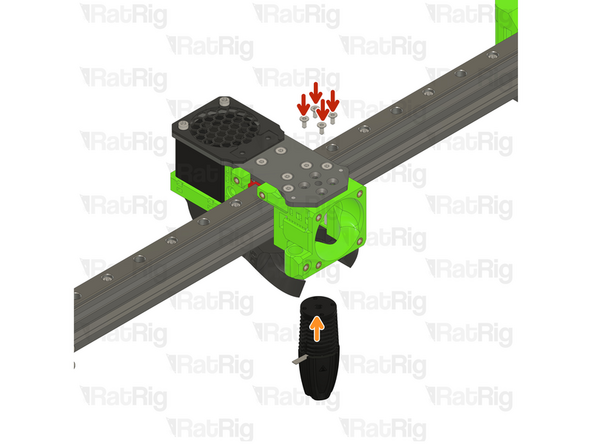

Insert the belt on the toolhead slot, behind the screw.

-

Reverse the belt around the screw and then reinsert it into the slot.

-

Insert the belt on the toolhead grabber.

-

Repeat for the other front belt end.

-

-

-

1x Phaetus Rapido UHF Hotend

-

1x Rat Rig SuperPinda Probe by P&F

-

1x M3x5 Set Screw

-

1x PTFE tube - 24.5mm

-

4x M2.5x6 Countersink Screw

-

-

-

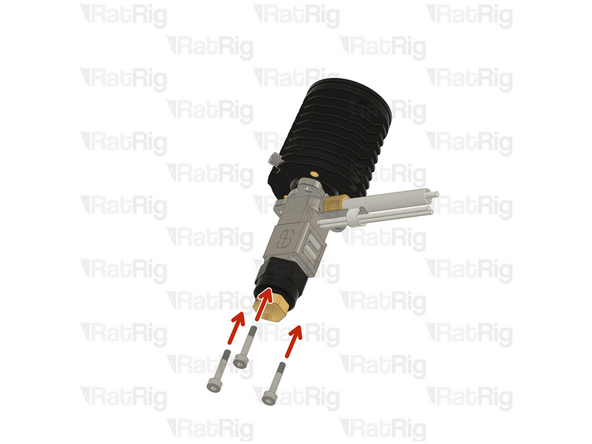

4x M2.5x6 Countersink Screw

-

Phaetus Rapido UHF Hotend

-

Place the Phaetus Rapido UHF Hotend on the plate, making sure to route the cables through the designated slot

-

Tighten the M2.5x6 Countersink Screws to secure the hotend to the plate

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M2.5 countersink screw head.

-

-

-

PTFE tube - 24.5mm

-

Insert the PTFE tube in to the marked hole and push it until it stops

-

-

-

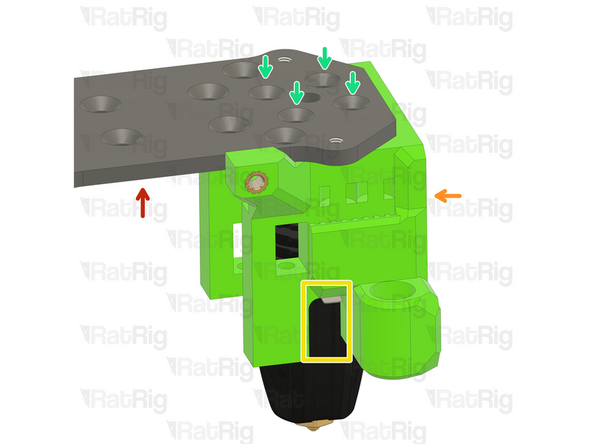

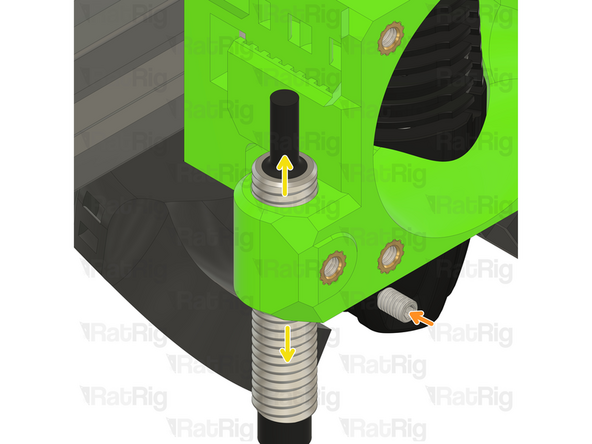

Rat Rig SuperPinda Probe by P&F

-

The Rat Rig SuperPinda Probe needs to be at the correct height to trigger properly

-

A recommended method to set the correct height is to rest the hot end nozzle on the bed, and then place a cable tie between the bed and the tip of the probe

-

Adjust the probe up to down as necessary to position the tip 1mm higher than the hot end nozzle

-

M3x5 Set Screw

-

Tighten the M3x5 to secure the probe in place

-

Do not over-tighten the M3x5 screw, doing so can damage the probe or printed probe mount

-

-

-

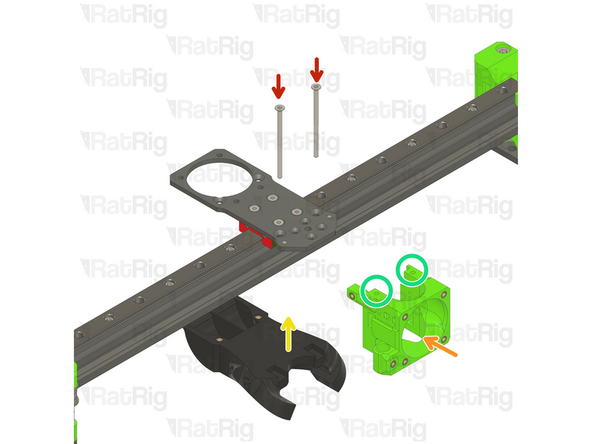

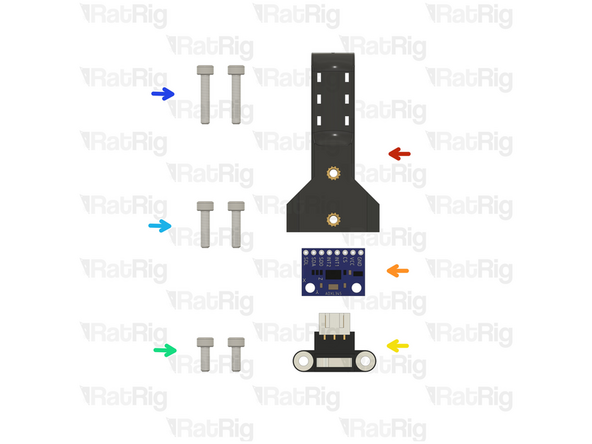

1x Rat Rig toolhead umbilical assembly

-

1x ADXL 345 Accelerometer

-

1x X Endstop

-

2x M3x8 Cap Head Screw

-

2x M3x12 Cap Head Screw

-

2x M3x16 Cap Head Screw

-

If your configuration uses a toolboard, you can skip to Step 56. The toolboard mount will be installed later.

-

-

-

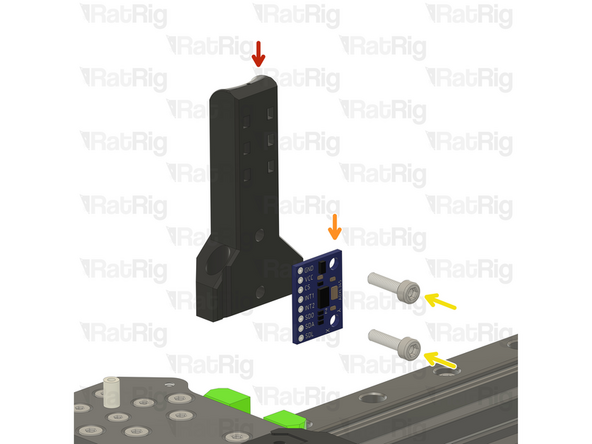

Rat Rig toolhead umbilical assembly

-

ADXL 345 Accelerometer

-

2x M3x12 Cap Head Screw

-

Mount the ADX 345 to the umbilical assembly

-

Take care not to over tighten the M3x12 screws as you can damage the printed parts

-

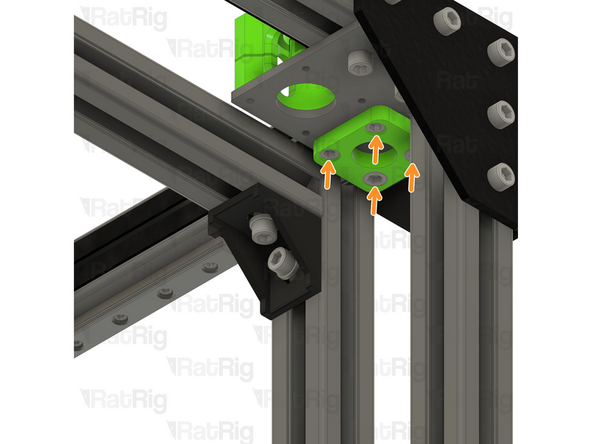

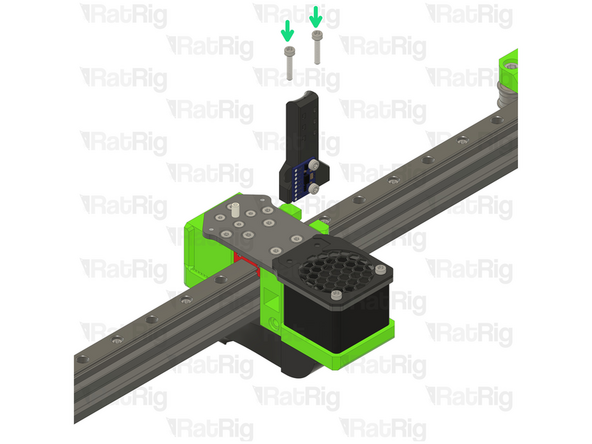

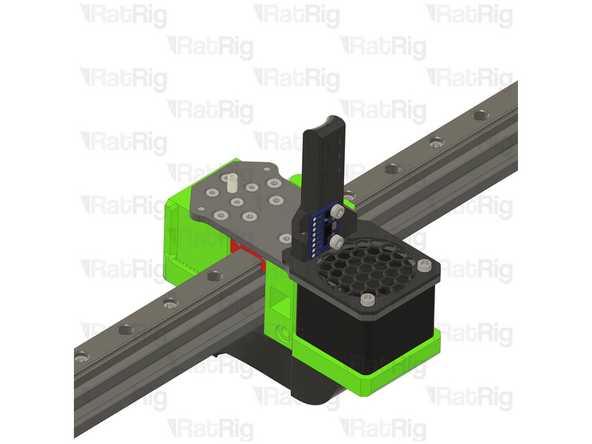

2x M3x16 Cap Head Screw

-

Tighten the M3x16 screws to secure the umbilical assembly to the plate.

-

Take care not to over tighten the M3x16 screws as you can damage the printed parts

-

-

-

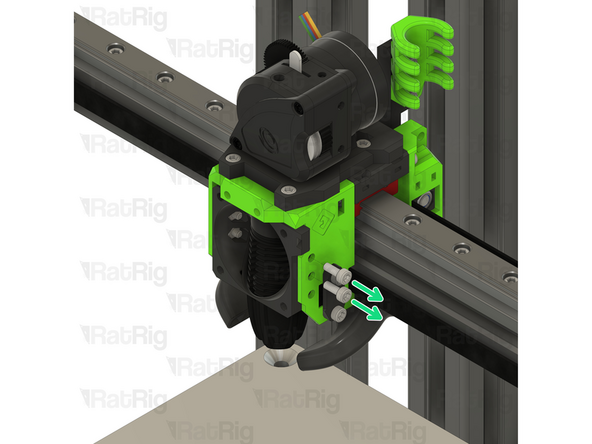

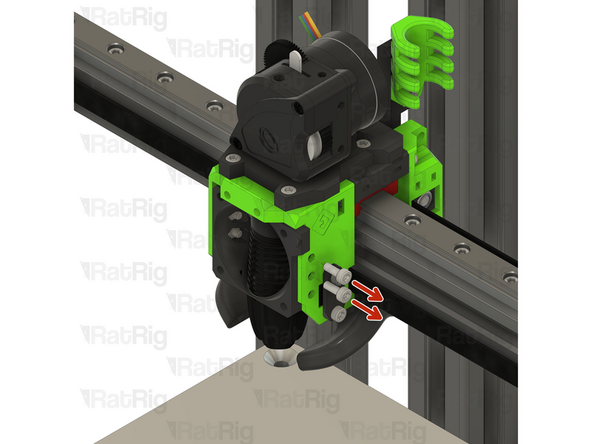

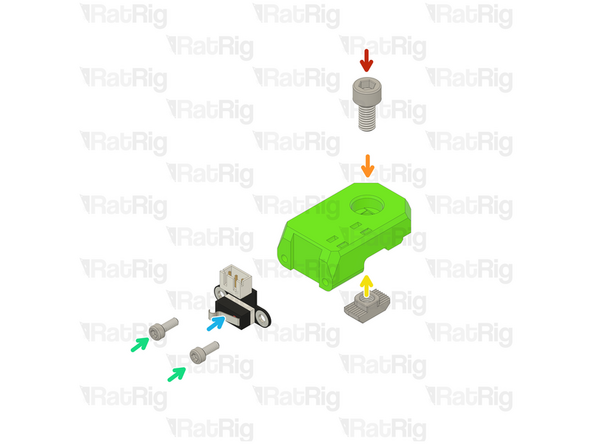

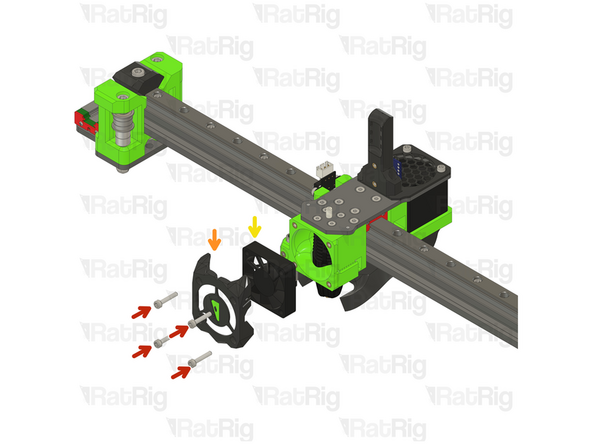

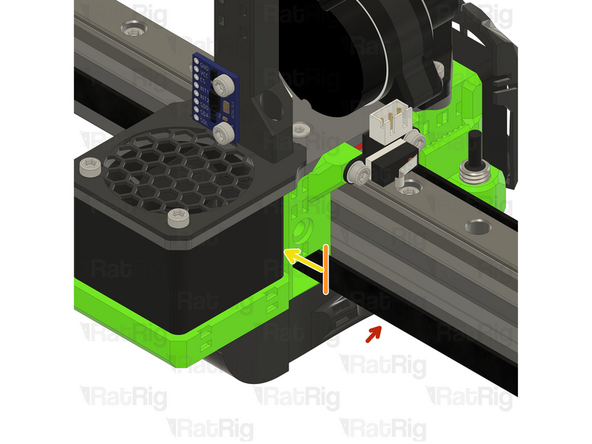

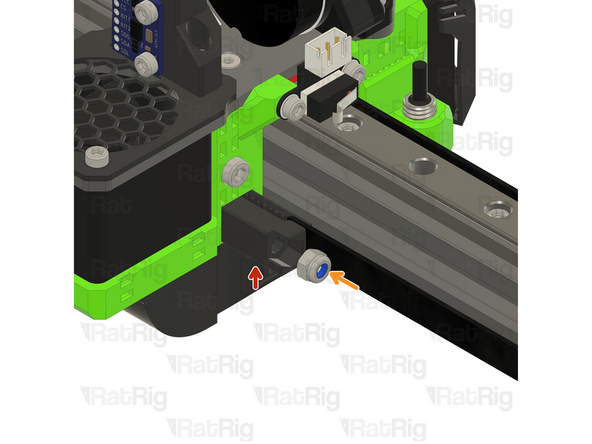

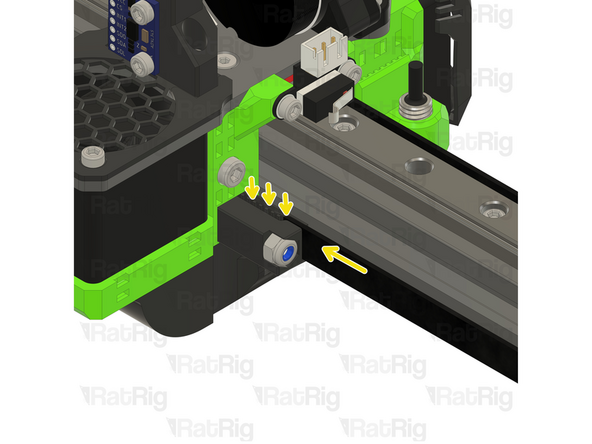

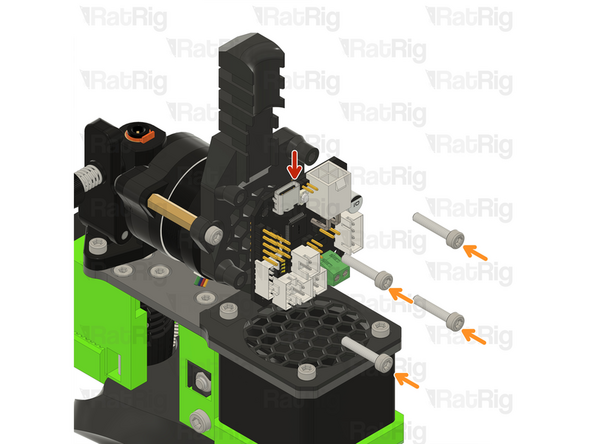

2x M3x8 Cap Head Screw

-

X Endstop

-

Tighten the M3x8 screws to secure the X endstop to the toolhead.

-

Take care not to over tighten the M3x8 screws as you can damage the printed parts

-

-

-

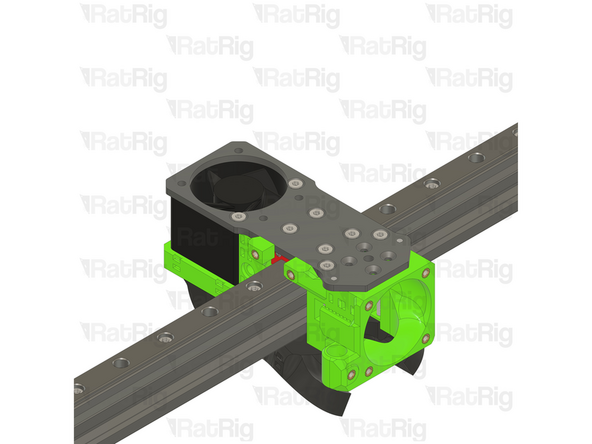

1x 40x10mm 24V Axial Fan

-

1x Rat Rig toolhead shroud printed part

-

4x M3x16 Cap Head Screw

-

-

-

4x M3x16 Cap Head Screw

-

Rat Rig toolhead shroud printed part

-

40x10mm 24V Axial Fan

-

Insert the M3x16 screws into the Rat Rig toolhead shroud printed part, through the 40mm fan, and fasten them into the Rat Rig toolhead front

-

-

-

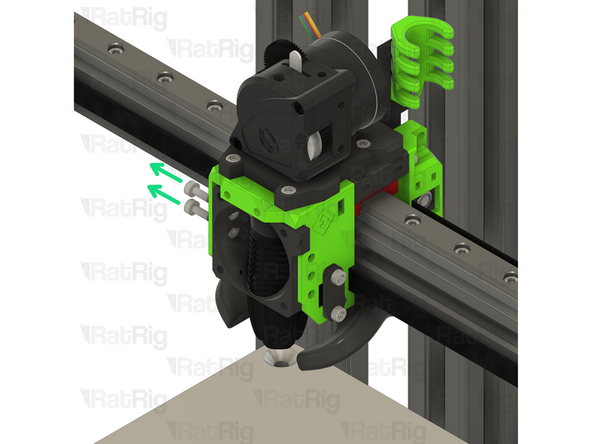

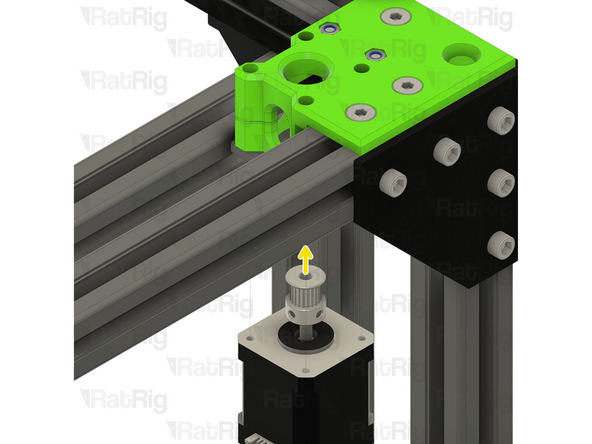

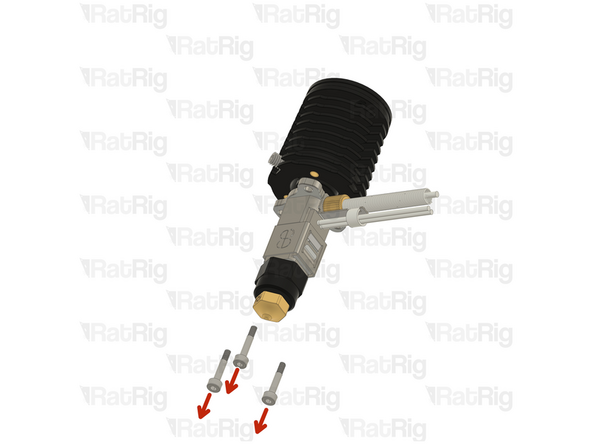

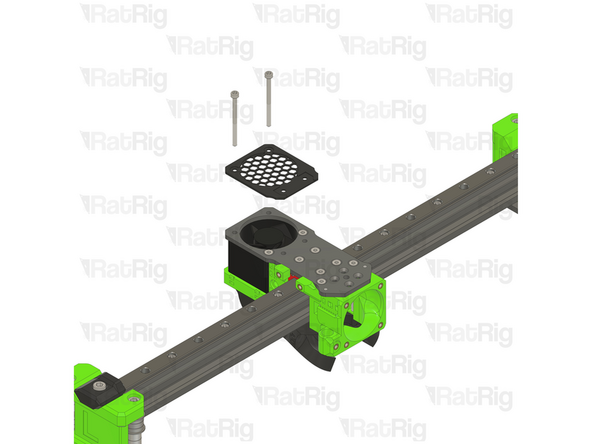

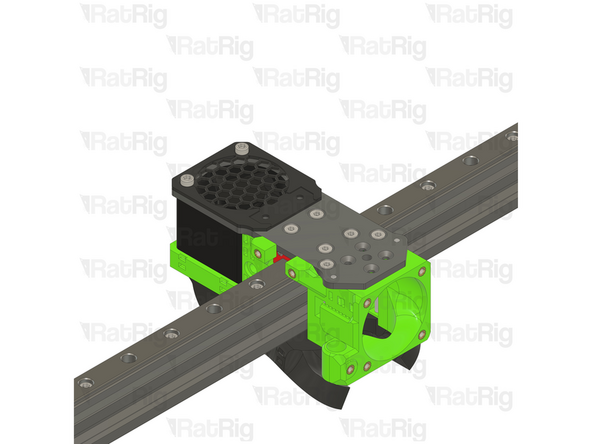

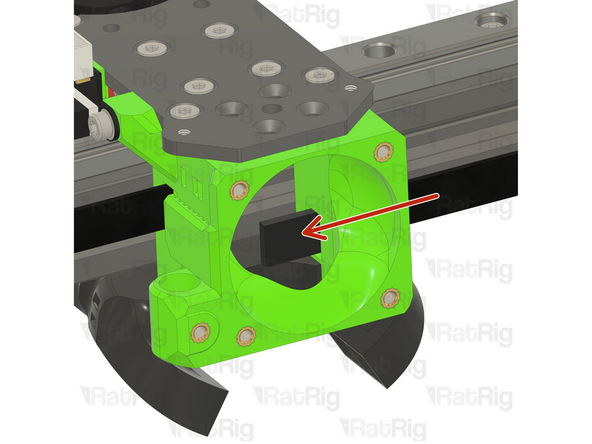

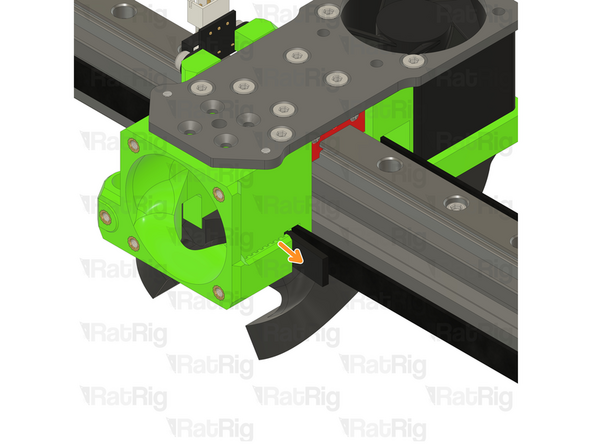

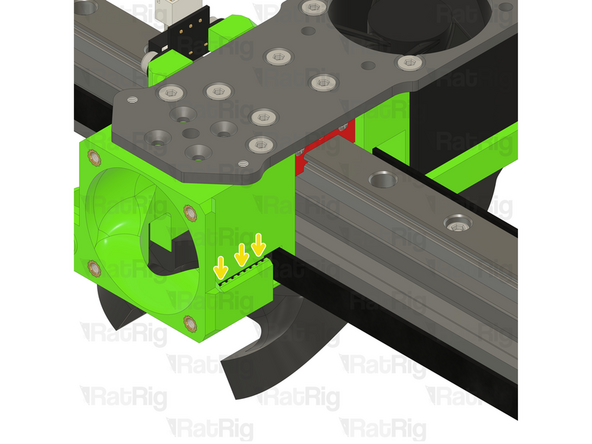

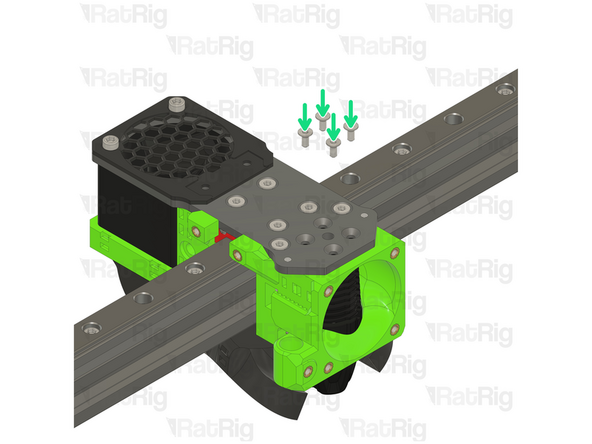

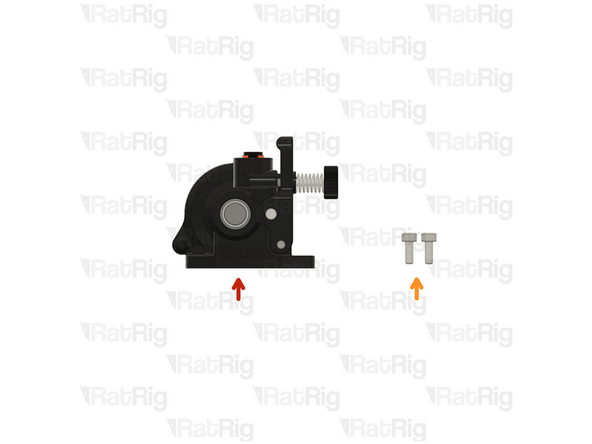

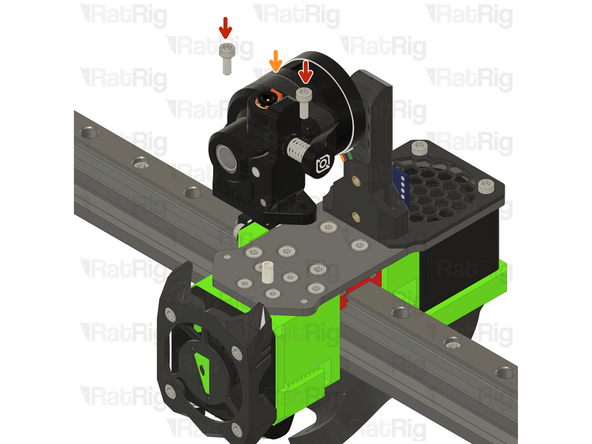

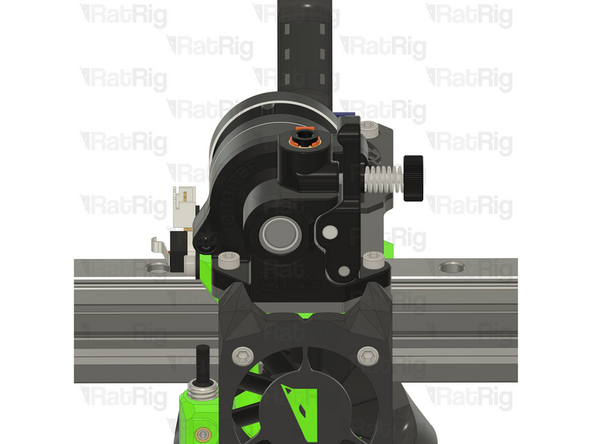

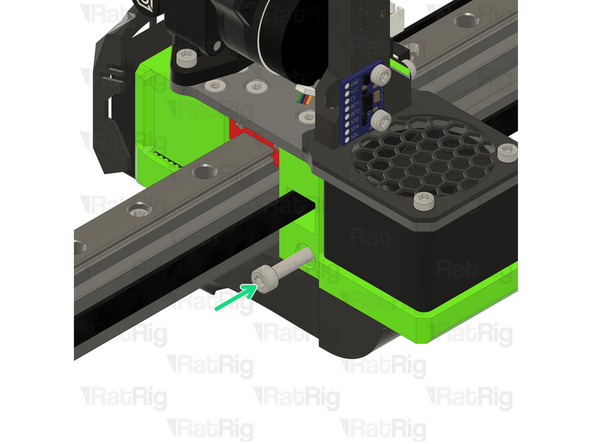

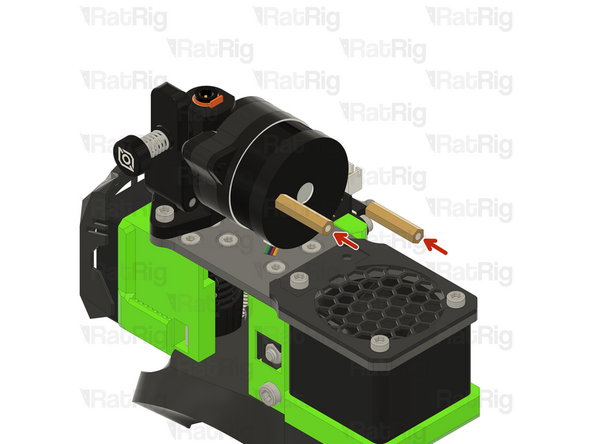

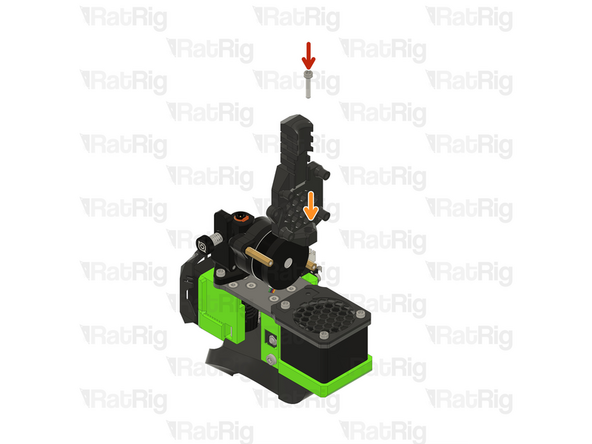

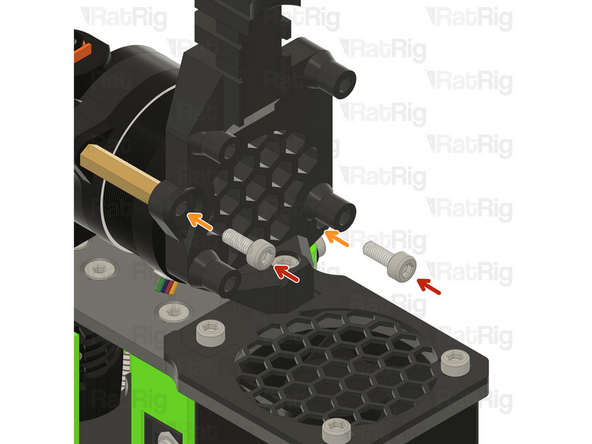

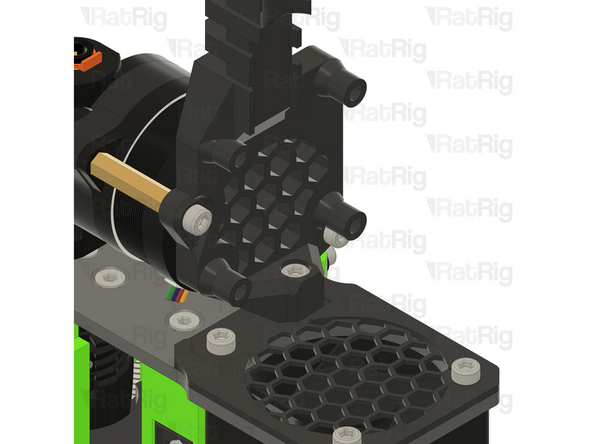

2x M3x8 Cap Head Screw

-

LDO Orbiter V2

-

Insert the M3x8 screws into the LDO Orbiter V2 and fasten them to the Rat Rig toolhead plate.

-

-

-

Make sure the belt is properly seated on all idlers and pulleys.

-

Mark the belt where it meets the Rat Rig toolhead assembly. This can be done with a marker, or simply by holding it.

-

From the mark, towards the loose end of the belt, measure 23mm (or count 12 teeth)

-

It is better to cut the belt too long than too short! If you are unsure, cut it longer than expected, you can always remove more if needed

-

Double check your measurements and then cut the belt at this point

-

-

-

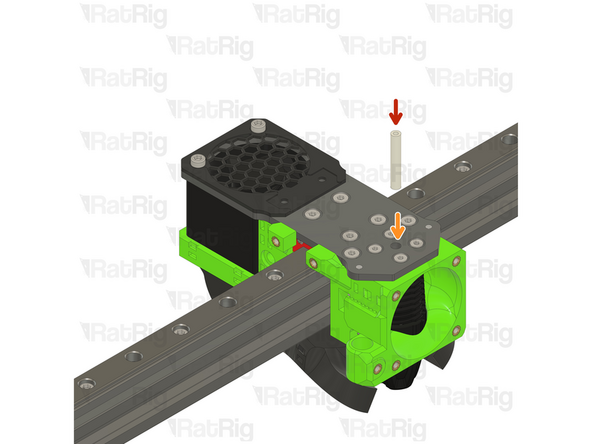

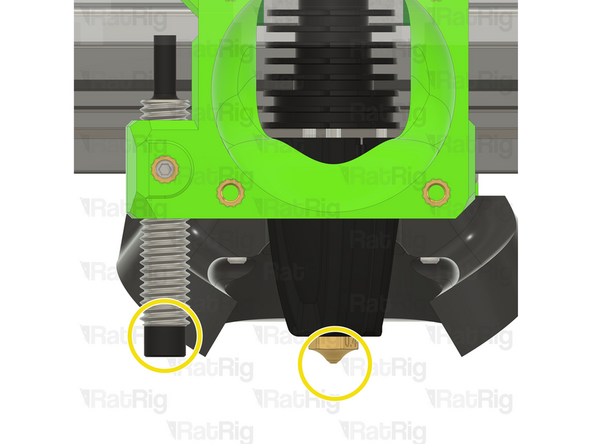

Rat Rig toolhead belt tensioner

-

M4 Nylon Locking Hex Nut

-

Insert an M4 nylon locking nut into the Rat Rig toolhead belt tensioner as shown

-

Insert the end of the belt inside the belt tensioner, and make sure the teeth are secured.

-

M4x40 Cap Head Screw

-

Tighten the M4x40 Cap Head just enough to hold the M4 Nylon Locking Hex Nut

-

The belts should not be tighten at this point.

-

Repeat Steps 60 and 61 to cut and insert the other belt.

-

-

-

The toolboard configuration is optional, please skip to Step 68 if you are not using it.

-

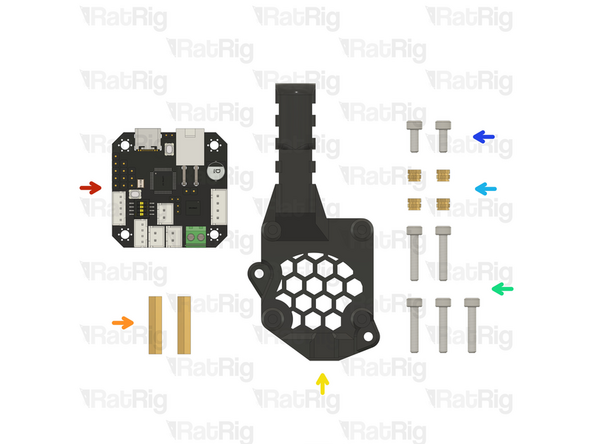

BIGTREETECH EBB42 USB/CAN TOOLBOARD V1.2

-

2x Hex standoff brass M3x20x4.5

-

Rat Rig toolhead_vc3_ebb42_vertical

-

5x M3x16 Cap Head Screw

-

4x Heat insert M3

-

2x M3x8 Cap Head Screw

-

-

-

Rat Rig toolhead_vc3_ebb42_vertical

-

4x Heat insert M3

-

This printed part has sacrificial layers which need to be removed prior to assembly.It is recommended to remove them by using a screwdriver, a hex key, or a drill, to push through the layers. This clears the holes for the screws to thread in to the head inserts

-

-

-

Thread the hex standoffs on to the LDO Orbiter V2 screws.

-

Do not overtighten the hex standoffs as they are brass and it is possible to strip the threads.

-

-

-

Insert the M3x16 Cap Head Screw in to the Rat Rig toolhead_vc3_ebb42_vertical printed part and thread it on the toolhead.

-

Assembly from Step 63

-

Take care not to over tighten the M3x16 screws as you can damage the printed parts

-

-

-

2x M3x8 Cap Head Screw

-

Insert the M3x8 Cap Head Screws in to the printed part and thread them to the hex standoffs

-

Take care not to over tighten the M3x8 screws as you can damage the printed parts

-

-

-

BIGTREETECH EBB42 USB/CAN TOOLBOARD V1.2

-

Insert the M3x16 Cap Head Screws into the toolboard and thread them into the vertical toolboard mount

-

Take care not to over tighten the M3x16 screws as you can damage the printed parts and the toolboard

-

-

-

Follow this guide to correctly align the X-Axis Gantry: 11. X-Axis Gantry Alignment

-

-

-

Your V-Core 3.1 is now upgraded with the Rat Rig Toolhead V1.0 and it's ready to melt some filament!

-

A new toolhead is a big change for any 3D printer, make sure to follow the commissioning guide to properly tune it.

-

Cancel: I did not complete this guide.

One other person completed this guide.

One Comment

Come on RatRig you can do better than this. At least give us a hint to where the wires are routed because it isn't obvious from your instructions. The toolhead has been designed without a thought of wire routing. I have tried everything with this over several nights and I am very disappointed.