-

-

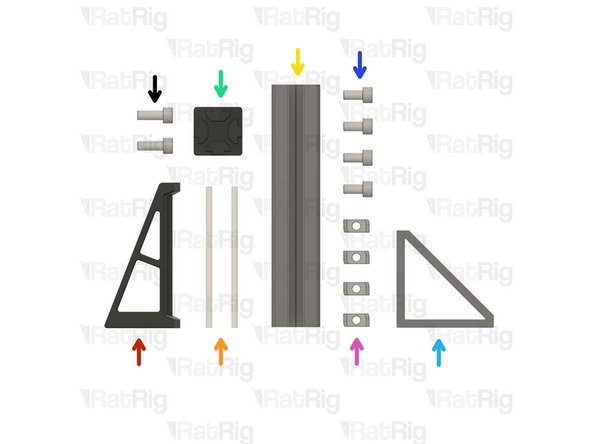

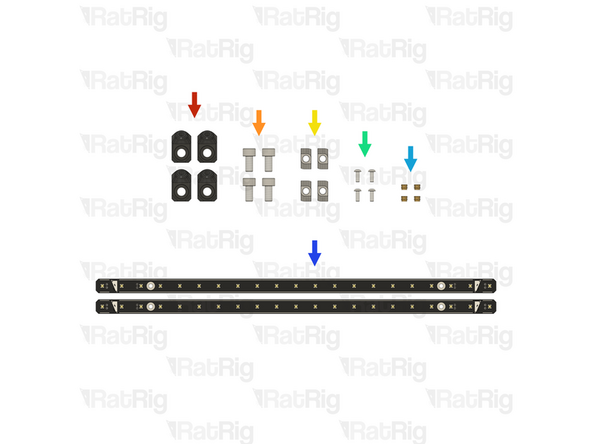

19x Heat Insert M3

-

4x vc4_trim_front

-

4x vc4_trim_rear

-

1x vc4_umbilical_frame

-

1x vc4_y_endstop_mount

-

-

-

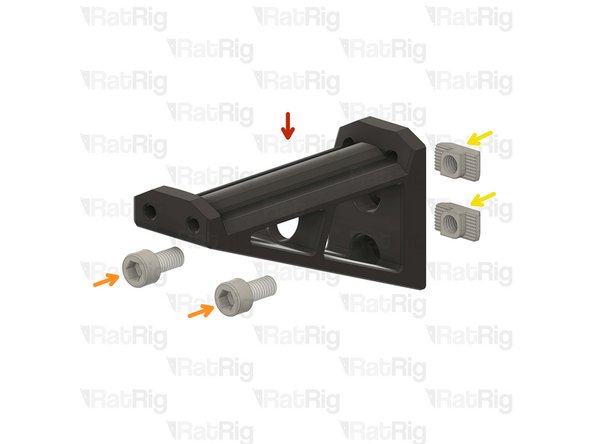

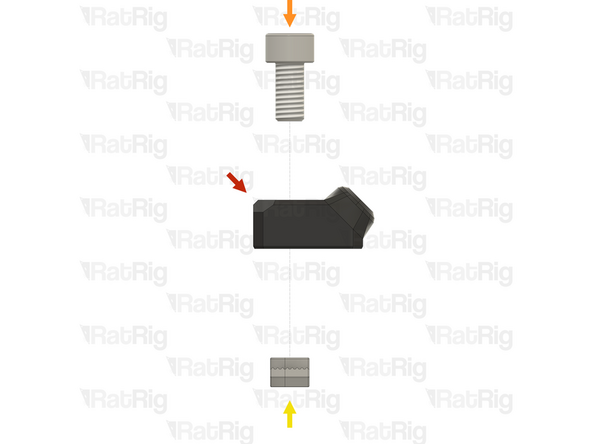

1x vc4_trim_front

-

2x Heat Insert M3

-

Repeat this step until all four parts have the heat inserts in place.

-

-

-

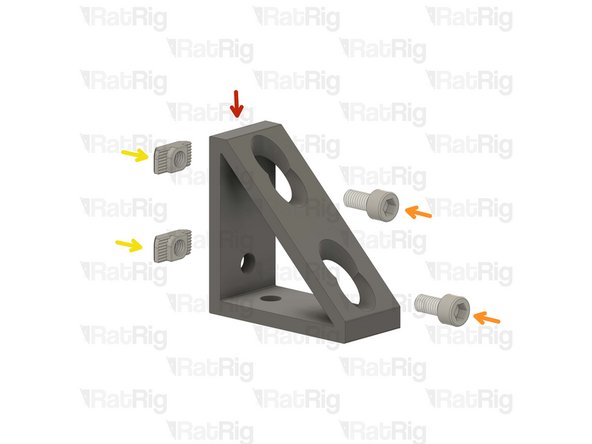

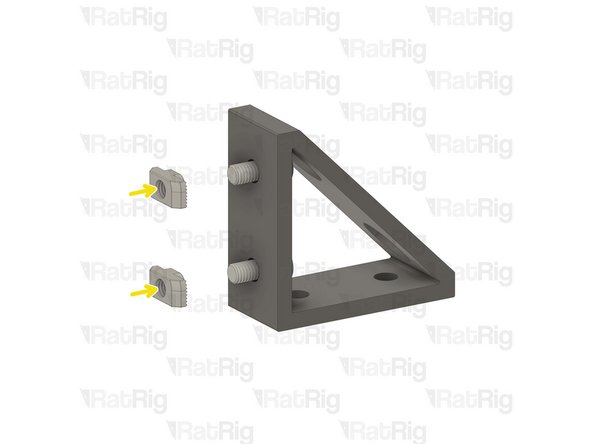

1x vc4_trim_rear

-

2x Heat Insert M3

-

Repeat this step until all four parts have the heat inserts in place.

-

-

-

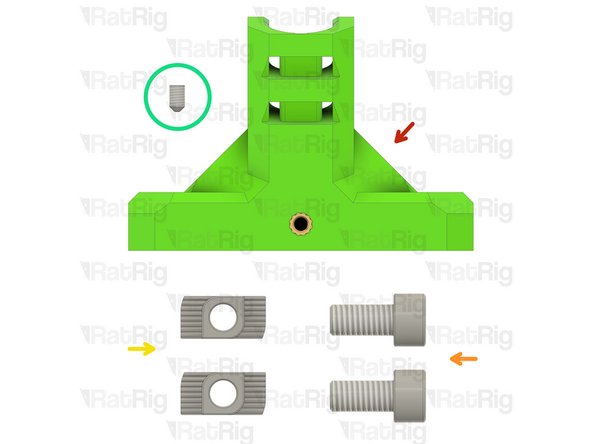

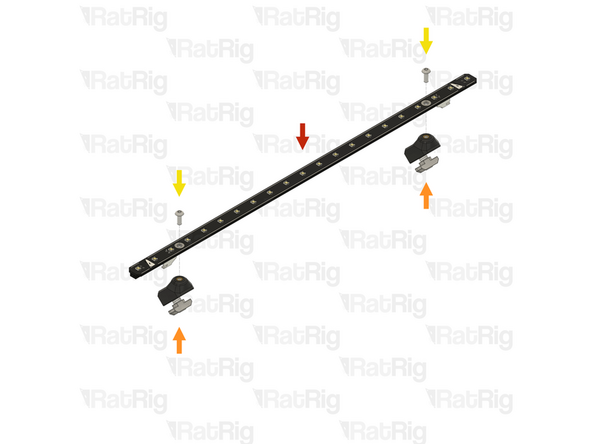

1x vc4_umbilical_frame

-

2x M6x12 Cap Head Screw

-

2x 3030 Drop-in T-Nut - M6

-

1x M3x5 Set Screw

-

-

-

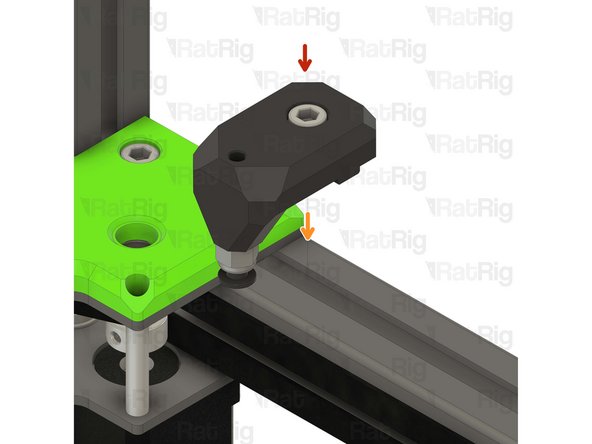

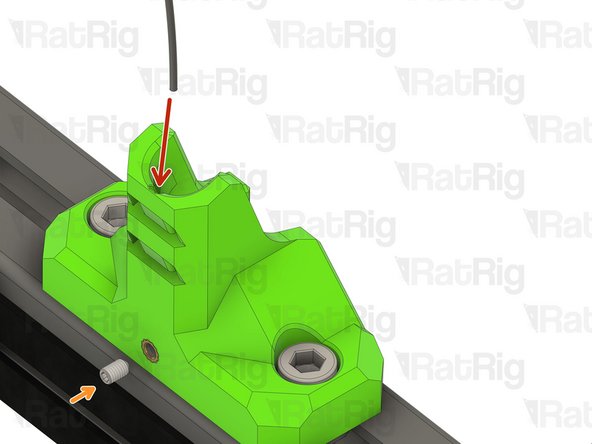

vc4_umbilical_frame

-

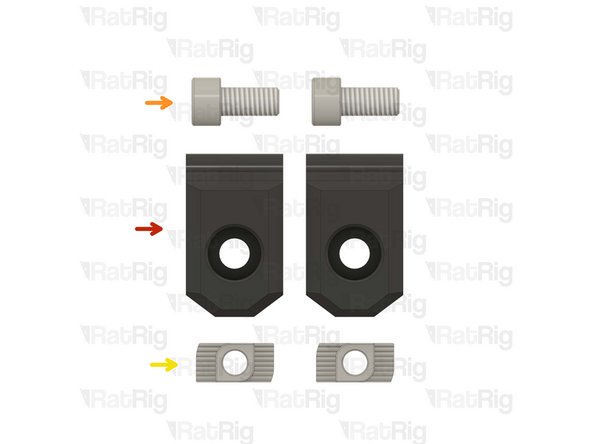

2x M6x12 Cap Head Screw

-

Install the M6 cap head screws into the umbilical frame as shown.

-

2x 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nuts onto the M6x12 screws. Do not tighten it at this point.

-

1x M3x5 Set Screw

-

-

-

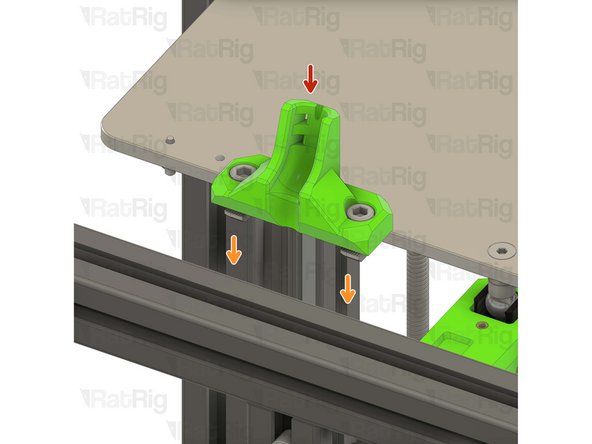

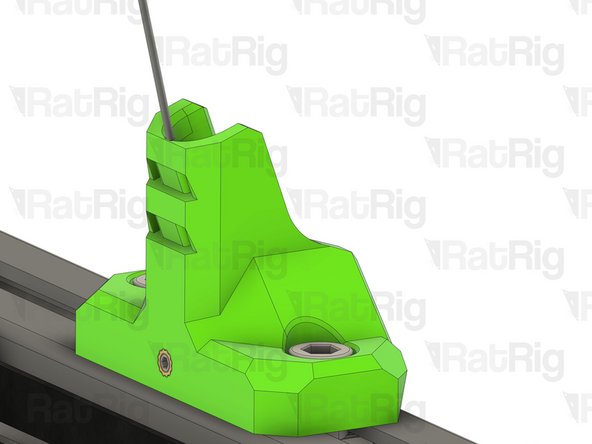

Umbilical frame assembly

-

Install the umbilical guide assembly to the V-Core 4 frame as shown.

-

Check that the printed part is seated in the middle of the frame.

-

Tighten the M6x12 screws to secure the umbilical frame.

-

Take care not to over-tighten the M6x12 screws as you can damage the printed parts

-

-

-

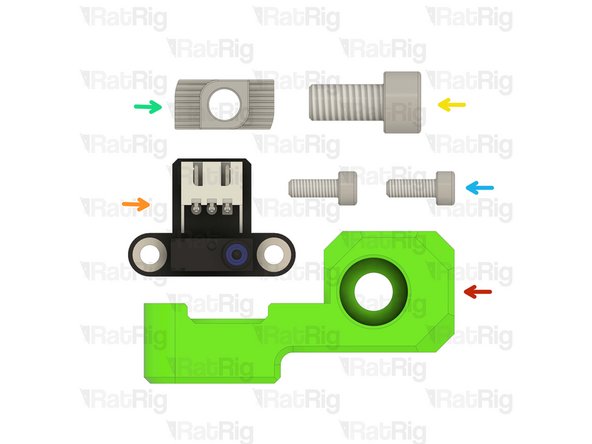

1x vc4_y_endstop_mount

-

1x Rat Rig Endstop

-

1x M6x12 Cap Head Screw

-

1x 3030 Drop-in T-Nut - M6

-

2x M3x8 Cap Head Screw

-

-

-

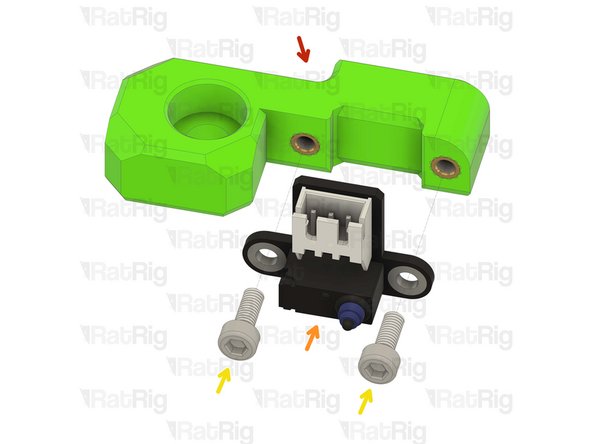

vc4_y_endstop_mount

-

Rat Rig Endstop

-

2x M3x8 Cap Head Screw

-

Tighten the M3x8 screws to secure the endstop to the printed part. Take care not to over tighten as you can damage the printed parts.

-

1x M6x12 Cap Head Screw

-

Install the M6 cap head screw into the Y endstop mount as shown.

-

1x 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto the M6x12 screw. Do not tighten it at this point.

-

-

-

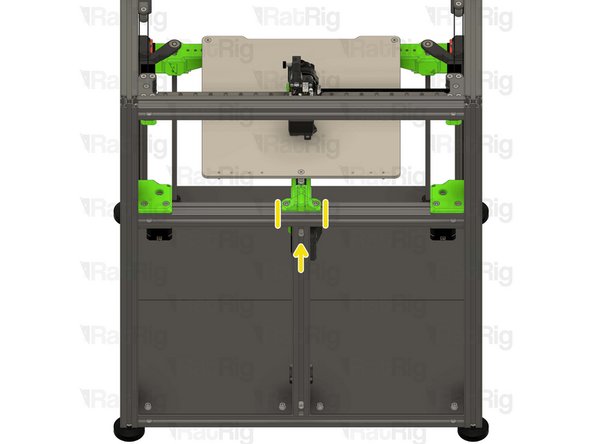

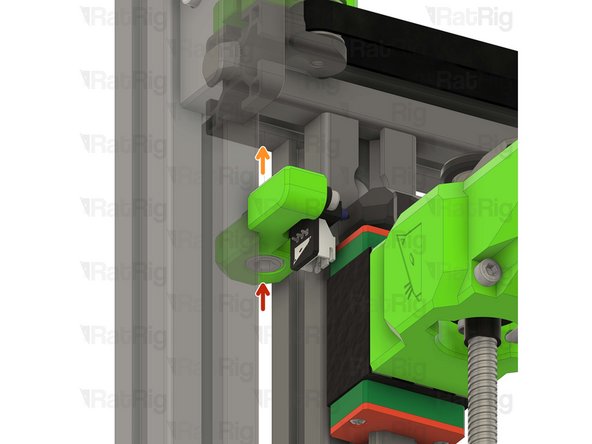

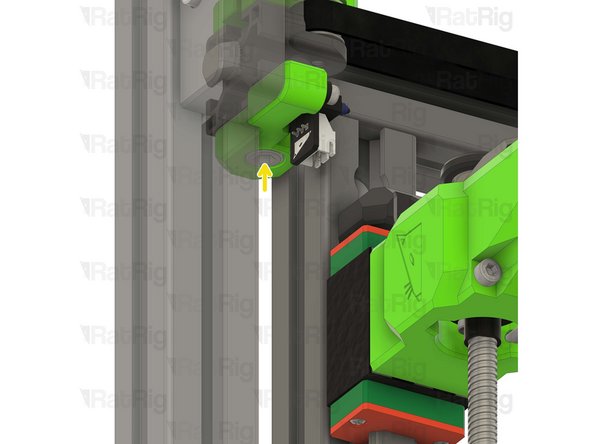

Y endstop mount assembly

-

Install the Y endstop mount assembly to the left side of the V-Core 4 frame as shown.

-

Tighten the M6x12 screw to secure the Y endstop mount.

-

Take care not to over-tighten the M6x12 screws as you can damage the printed parts

-

-

-

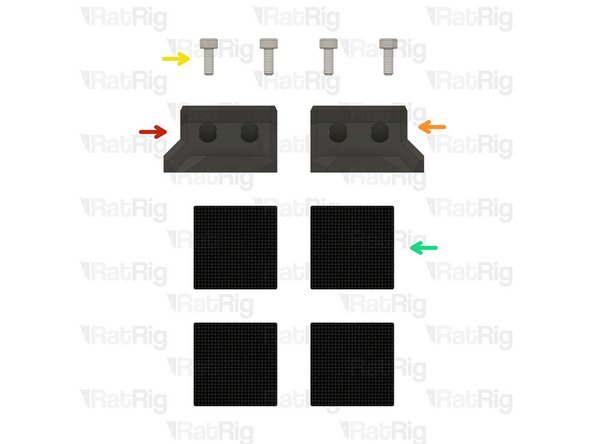

1x vc4_wiper_left

-

1x vc4_wiper_right

-

4x M3x8 Cap Head Screw

-

4x Felt Pad - 25x25x3mm

-

-

-

Felt Pad - 25x25x3mm

-

Peel the white paper on the back of the felt pads.

-

Bend all of the four felt pads as shown in order to insert them into the wiper housings.

-

Prepare four pads for the next step.

-

-

-

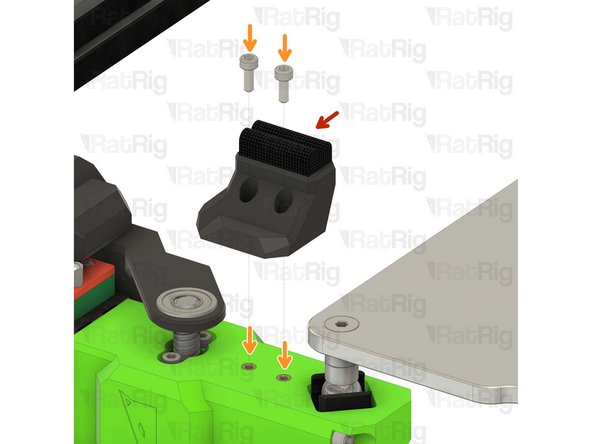

2x Felt Pad - 25x25x3mm

-

1x vc4_wiper_left

-

Squeeze two bent felt pads together while inserting them into the wiper body.

-

Repeat this step for the other wiper housing as well.

-

-

-

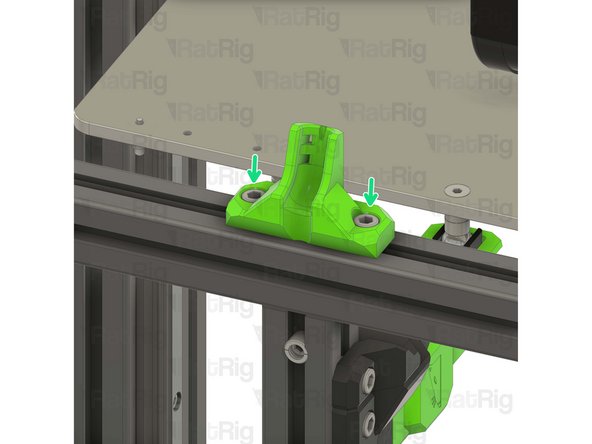

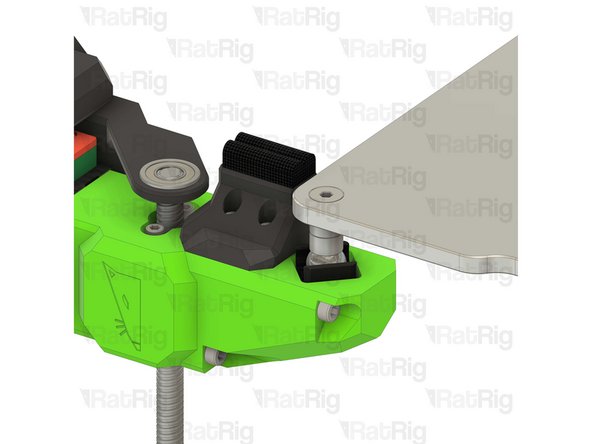

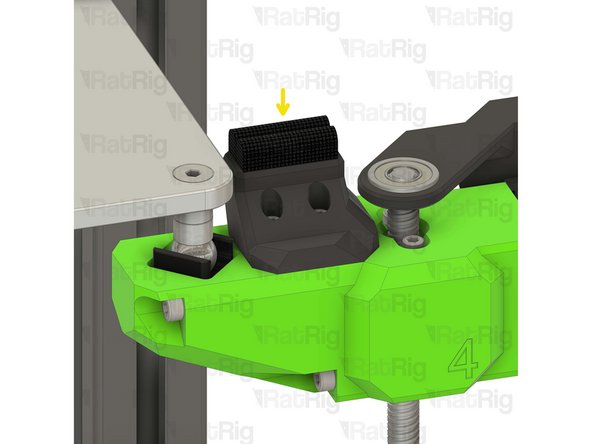

Left nozzle wiper

-

2x M3x8 Cap Head Screw

-

Secure the nozzle wiper to the bed arm as shown.

-

Take care not to over tighten the M3x8 screws as you can damage the printed parts.

-

Repeat this step to attach the opposite side nozzle wiper.

-

-

-

1x vc4_spoolholder_arm

-

2x 87mm PTFE Tube

-

1x T-Slot 3030 extrusion- 150mm

-

1x 3030_end_cap

-

1x Extruded 90° Corner- 6030 Tall

-

4x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

2x M6x16 Cap Head Screw

-

-

-

vc4_spoolholder_arm

-

2x M6x12 Cap Head Screw

-

2x 3030 Drop-in T-Nut - M6

-

Install the M6x12 Cap head screws into the spool holder as shown.

-

Loosely thread a 3030 T-Nuts onto the M6x12 screws. Do not tighten it at this point.

-

-

-

vc4_spoolholder_arm

-

87mm length of PTFE tubing

-

Using a sharp blade (such as a utility knife), cut two lengths of PTFE tubing measuring 87mm in length.

-

Insert a length of PTFE into each channel of the spool holder as shown.

-

-

-

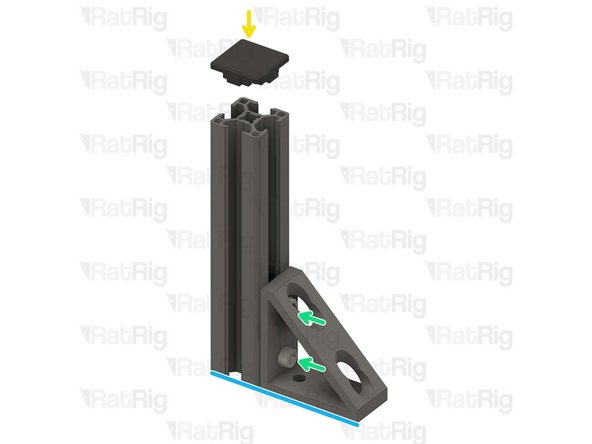

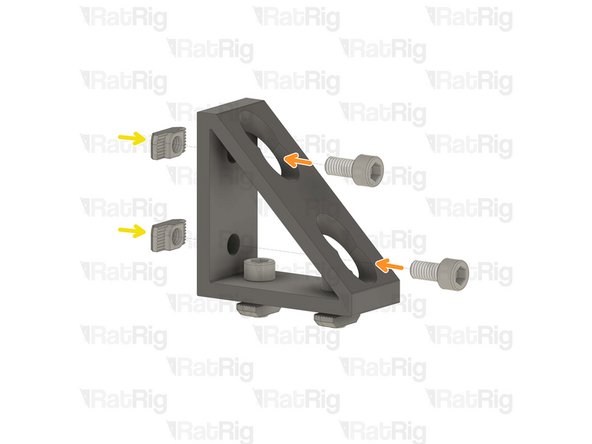

1x Extruded 90° Corner- 6030 Tall

-

2x M6x12 Cap Head Screw

-

2x 3030 Drop-in T-Nut - M6

-

Install the M6 cap head screws into the corner bracket as shown.

-

Loosely thread a 3030 T-Nuts onto the M6x12 screws. Do not tighten it at this point.

-

-

-

T-Slot 3030 extrusion- 150mm

-

Corner bracket assembly from the previous Step

-

Attach the corner bracket assembly to the aluminium extrusion, aligning the flat edges together.

-

3030_end_cap

-

Place the printed cap on the other end.

-

Tighten the M6x12 screws to secure the corner bracket to the extrusion.

-

Ensure the extrusion is flush with the corner bracket

-

-

-

Spool holder printed part

-

T-Slot 3030 extrusion- 150mm

-

Attach the spool holder printed part to the aluminium extrusion as shown, aligning the top edges.

-

Tighten the M6x12 screw to secure the spool holder to the extrusion.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

The spool holder can be mounted on either side of the machine, this guide will instruct you to install it on the left side of the machine for single-head configuration.

-

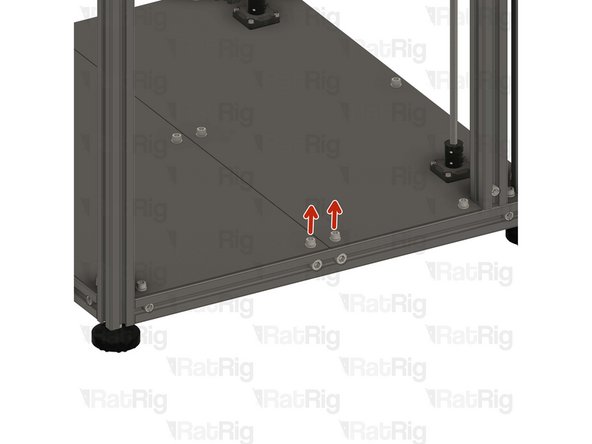

2x M6x12 Cap Head Screw

-

2x M6 Washer

-

Remove the shown M6x12 screws and their corresponding washers in order to allow for the spool holder arm to be installed.

-

Avoid moving the machine around or bumping into it, to prevent the t-nuts from moving.

-

-

-

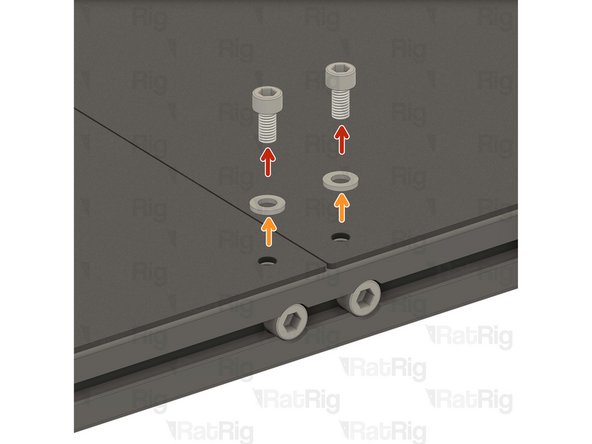

Spool holder arm assembly from the previous Step

-

2x M6x12 Cap Head Screws removed from step 22

-

Align the corner bracket of the spool holder with the holes in the base plates.

-

Carefully tighten the M6x12 screws to the T-Nuts inside the base aluminum extrusion, securing the spool holder in place.

-

-

-

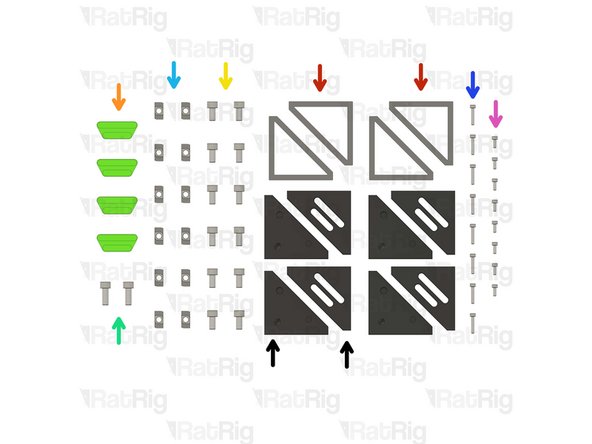

4x Extruded 90° Corner- 6030 Tall

-

4x vc4_trim_diffuser

-

12x M6x12 Cap Head Screw

-

2x M6x16 Cap Head Screw

-

12x 3030 Drop-in T-Nut - M6

-

8x M3x16 Cap Head Screw

-

8x M3x8 Cap Head Screw

-

4x vc4_trim_front + 4x vc4_trim_rear

-

-

-

vc4_trim_rear

-

2x M3x8 Cap Head Screw

-

These screws will be used to hold an Led PCB module, coming soon

-

Prepare the four assemblies.

-

-

-

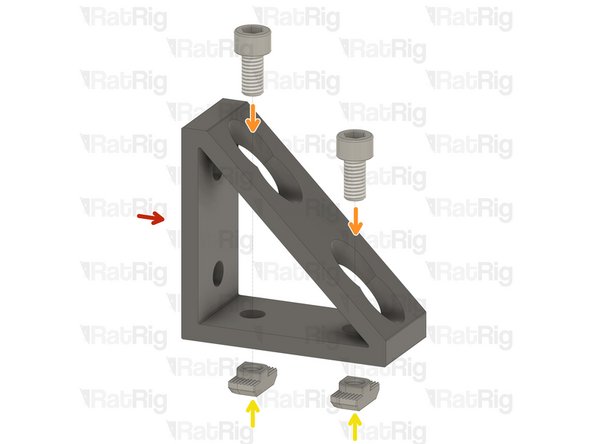

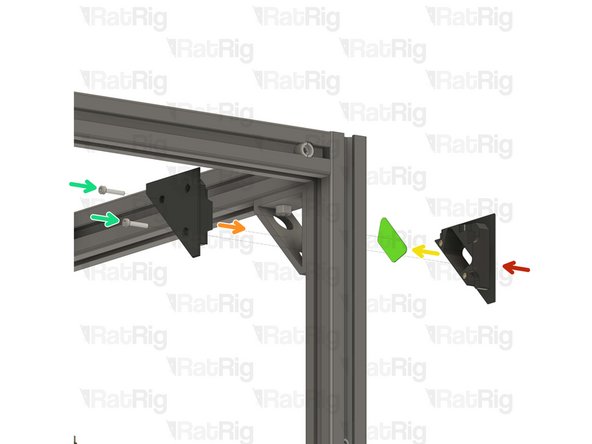

Extruded 90° Corner- 6030 Tall

-

4x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

Install the M6 cap head screws into the corner bracket as shown.

-

Loosely thread a 3030 T-Nuts onto the M6x12 screws. Do not tighten it at this point.

-

Repeat this step one more time, then go back and follow through Step 19 twice with the remaining corner brackets.

-

-

-

1x M6x12 Cap Head Screw

-

1x M6 Washer

-

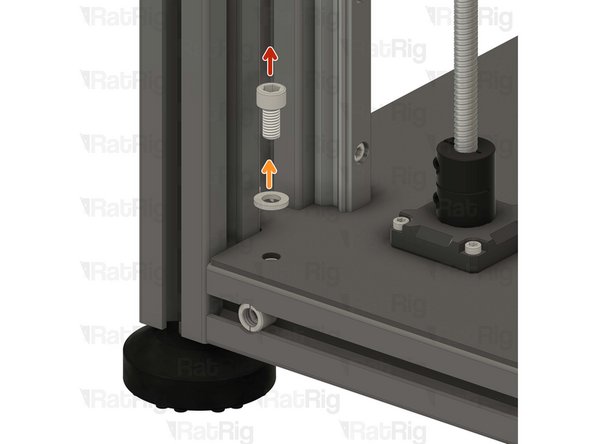

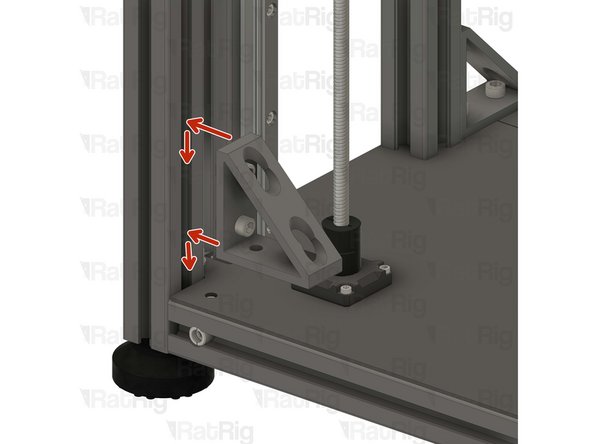

Remove the highlighted M6x12 screw and the corresponding washer in order to allow for the lower corner bracket assembly to be installed.

-

-

-

Lower corner bracket assembly

-

1x M6x16 Cap Head Screw

-

Install the lower corner bracket to the V-Core 4 frame as shown.

-

Tighten the M6x12 screws to attach the bracket.

-

Carefully tighten the M6x16 screw to the T-Nut inside the base aluminium extrusion, securing the bracket in place.

-

-

-

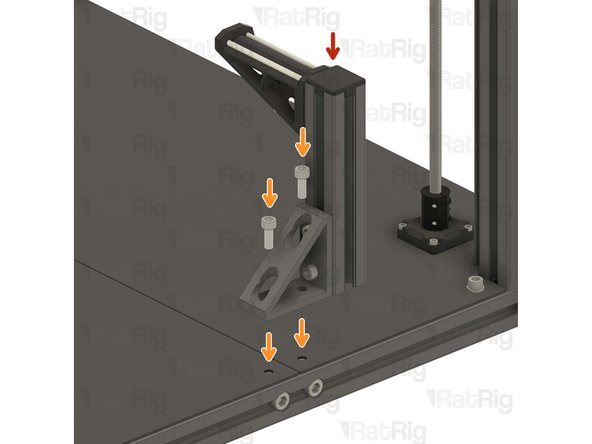

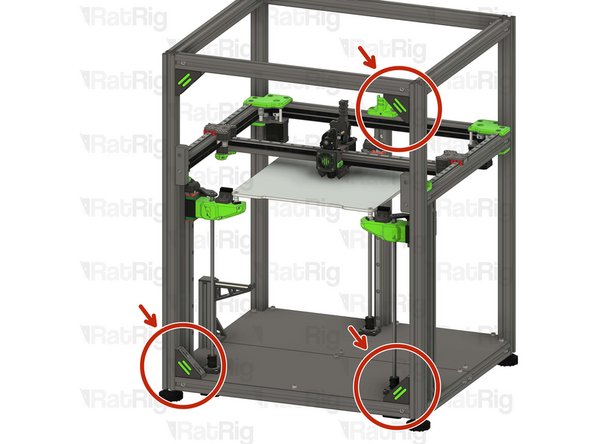

Upper corner bracket assembly

-

Install the upper corner bracket to the V-Core 4 frame as shown.

-

Tighten the M6x12 screws to secure the bracket to the frame.

-

Repeat Steps 27, 28 and 29 to attach the rest of the brackets to the other side.

-

-

-

1x vc4_trim_front

-

1x vc4_trim_rear

-

1x vc4_trim_diffuser

-

2x M3x16 Cap Head Screw

-

Tighten the M3x16 screws into the front trim printed part, inserting them through the rear trim printed part.

-

Sandwich the parts together enclosing the diffuser inside the corner bracket.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

1x vc4_ptfe_guide_upper

-

1x Bowden Pass-through Adaptor

-

1x M6x12 Cap Head Screw

-

1x 3030 Drop-in T-Nut - M6

-

-

-

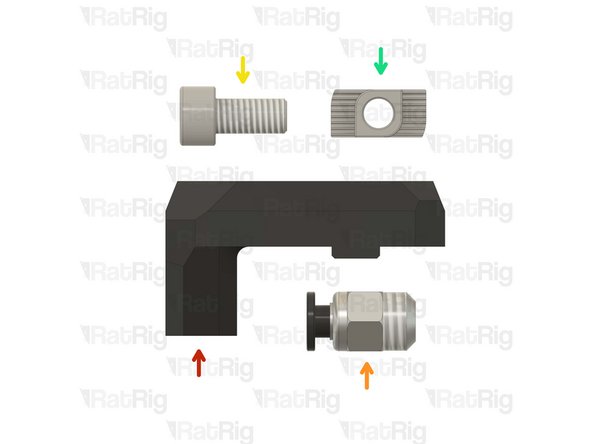

vc4_ptfe_guide_upper

-

1x M6x12 Cap Head Screw

-

Install the screw into the PTFE guide as shown.

-

1x 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto the M6x12 screw. Do not tighten it at this point.

-

Bowden Pass-through Adaptor

-

Thread the bowden adapter into the printed part and secure it in place.

-

Take care not to over tighten the bowden adapter as you can damage the printed parts.

-

-

-

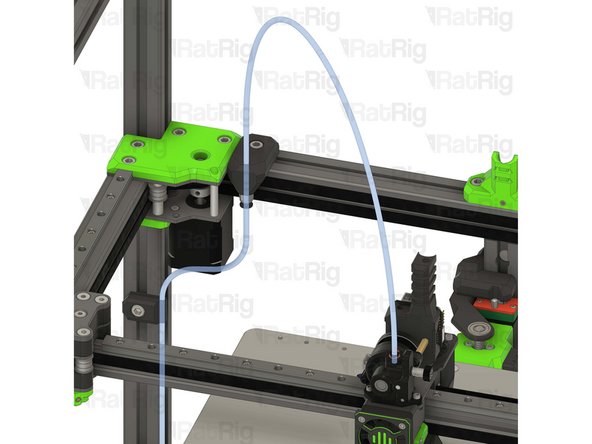

Upper PTFE guide assembly

-

Install the PTFE guide assembly to the left back side of the V-Core 4 frame as shown.

-

Tighten the M6x12 screw to secure the upper PTFE guide.

-

Insert the PTFE tubing through the bowden clamp, as shown. Then connect it to the orbiter extruder.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

2x vc4_ptfe_guide_lower

-

2x M6x12 Cap Head Screw

-

2x 3030 Drop-in T-Nut - M6

-

-

-

vc4_ptfe_guide_lower

-

1x M6x12 Cap Head Screw

-

Install the M6 cap head screw into the PTFE guide as shown.

-

1x 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto the M6x12 screws. Do not tighten it at this point

-

Repeat this step one more time to assemble the other PTFE guide.

-

-

-

2x Lower PTFE guide assembly from the previous Step

-

Position the PTFE guide assemblies on the left side of the V-Core 4 frame.

-

Insert the PTFE tubing into the guides, as shown.

-

Tighten the M6x12 screw to secure the guide assemblies and PTFE to the frame.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

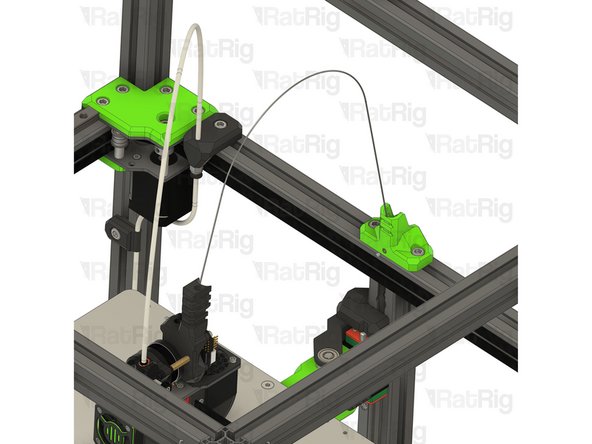

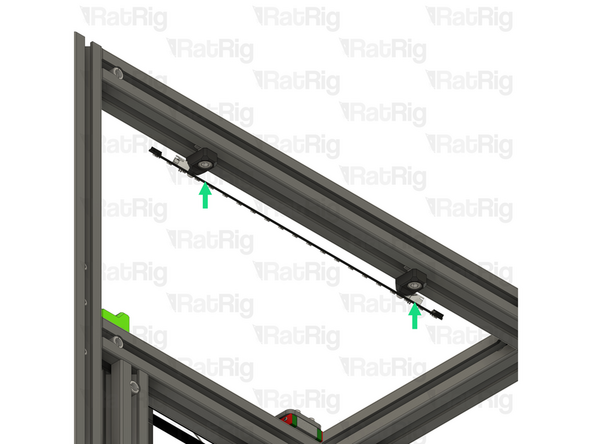

It is recommended to route the PTFE filament guide as shown.

-

If you are assembling the IDEX, go back to Step 32 and complete an additional filament path assembly, on the opposite side of the machine.

-

-

-

Piano Wire for Umbilical - 1000mm x 1.00mm

-

M3x5 Set Screw

-

The Piano wire need to be cut to length for you machine:

-

V-Core 4 300 - 650mm

-

V-Core 4 400 - 750mm

-

V-Core 4 500 - 850mm

-

Use a strong set of cutting pliers, as the piano wire is super stiff and can break small pliers.

-

-

-

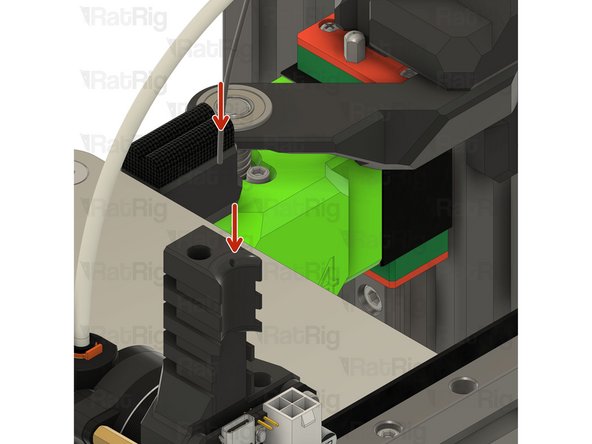

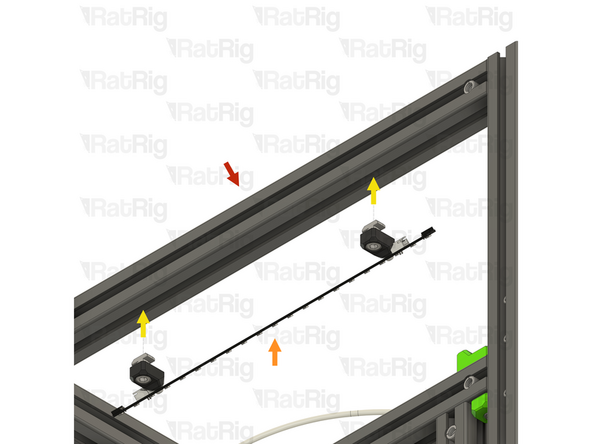

Insert the piano wire into the designated hole in the vc4_umbilical_frame printed part

-

thread the M3x5 set screw to secure the Piano wire in place

-

-

-

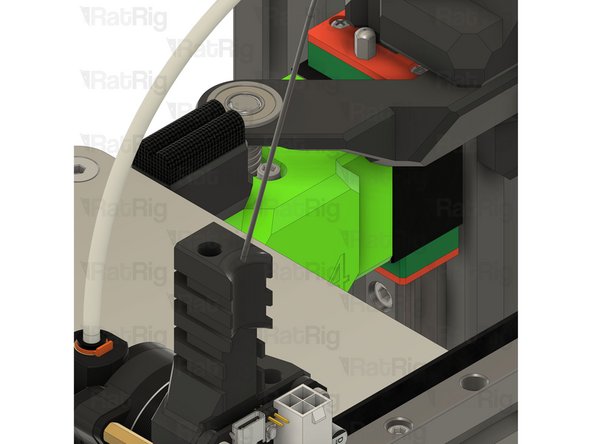

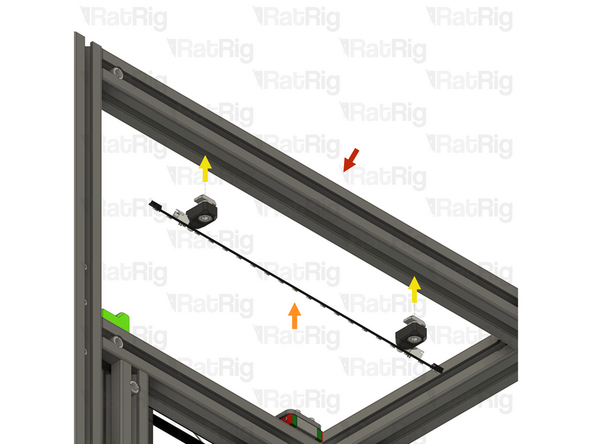

Insert the other end of the piano wire in the designated hole on the EBB toolboard mount

-

Be careful, the piano wire is super stiff, do not allow it to swing freely as it can hit you and create injury.

-

Once installed it should look like the picture, the piano wire will provide support to the USB and power cables, improving Input shaper results

-

-

-

4x vc4_led_holder_frame printed part

-

4x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

4x M3x8 Button Head Screw

-

4x M3 heat insert

-

2x Rat Rig Dayspring LED strip - 310mm

-

-

-

1x vc4_led_holder_frame

-

1x M3 heat insert

-

Install a heat insert into the printed part as shown

-

Prepare four of these parts

-

-

-

LED frame mount from the previous step

-

1x M6x12 Cap Head Screw

-

Insert an M6 cap head screw into the printed part as shown

-

1x 3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto the M6x12 screws. Do not tighten it at this point

-

Prepare four of these parts

-

-

-

1x Rat Rig Dayspring LED strip - 310mm

-

2x LED frame mount from the previous step

-

Align a frame mount assembly with mounting hole on the LED strip

-

2x M3x8 Button Head Screw

-

Insert an M3x8 button head screw through the mounting hole in the LED strip and screw it into the printed mount

-

Assemble two LED strips

-

-

-

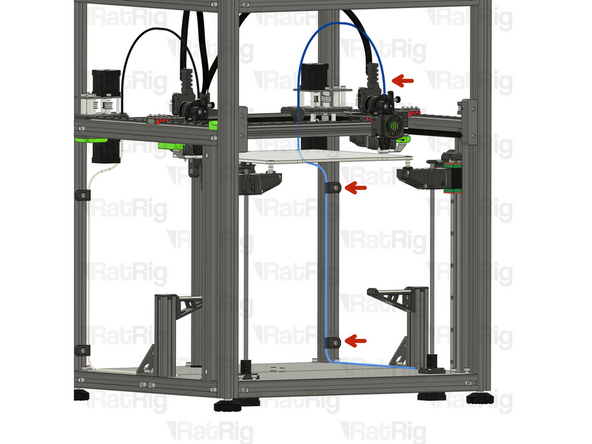

Rat Rig V-Core 4.0 assembly - Left side

-

1x LED strip assembly from the previous step

-

Align the LED strip mounts with the frame, making sure both T-nuts slot into the extrusion slots

-

Secure the LED strip to the frame by tightening both M6x12 screws

-

Take care not to overtighten the screws as you can damage the printed parts

-

-

-

Rat Rig V-Core 4.0 assembly - Right side

-

1x LED strip assembly from the step 45

-

Align the LED strip mounts with the frame, making sure both T-nuts slot into the extrusion slots

-

Secure the LED strip to the frame by tightening both M6x12 screws

-

Take care not to overtighten the screws as you can damage the printed parts

-

Cancel: I did not complete this guide.

34 other people completed this guide.

One Comment

Im IDEX mode due i Not need a second Piano wire for the other printhead? There is only one wire

ds3975@gmail.com - Open Reply