Introduction

NOTE: all measurements in this guide assume you’re assembling the 300x300x300mm machine!

As a general rule, add 100mm to the measurements if you’re assembling a 400 machine, or 200mm if you’re assembling a 500 machine (this may not be valid for some of the measurements provided).

Video Overview

-

-

Repeat this step for 4 Joining plates (2 are mirrored)

-

Cap Head Screw M6x12

-

Cap Head Screw M5x18

-

Rubber foot

-

Joining plate

-

3030 Drop-in T-Nut M6

-

3030 Drop-in T-Nut M5

-

Set the T-Nuts in position, but do not tighten them just yet.

-

-

-

Set up all remaining Joining Plates in the kit

-

Cap Head Screw M6x12mm

-

3030 Drop-in T-Nut M6

-

Set T-Nuts into position, but do not tighten them just yet.

-

-

-

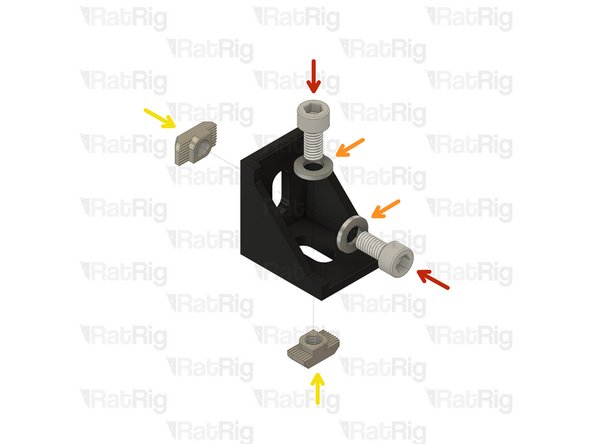

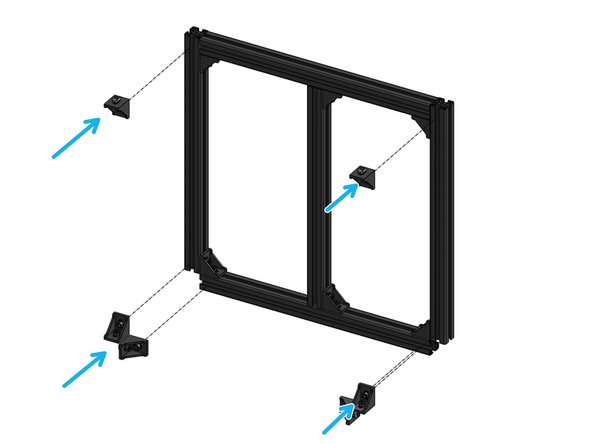

Set up all Corner Brackets (x12) in your kit.

-

Cap Head Screw M6x12

-

M6 Washer

-

3030 Drop-in T-Nut M6

-

Set T-Nuts into position, but do not tighten them just yet.

-

-

-

For the next step you will need:

-

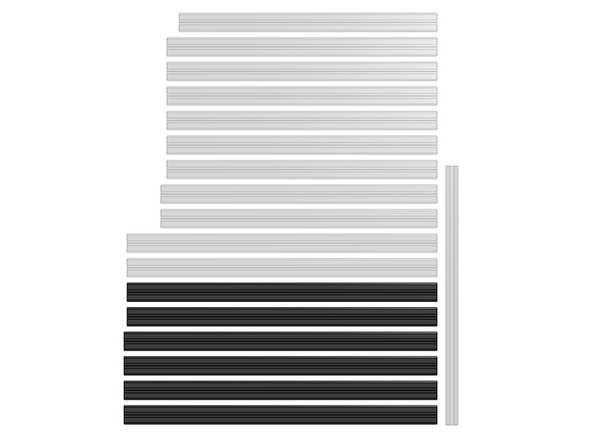

1 X 420mm 3030 extrusion

-

2 X 440mm 3030 extrusion

-

2 X 450mm 3030 extrusion

-

-

-

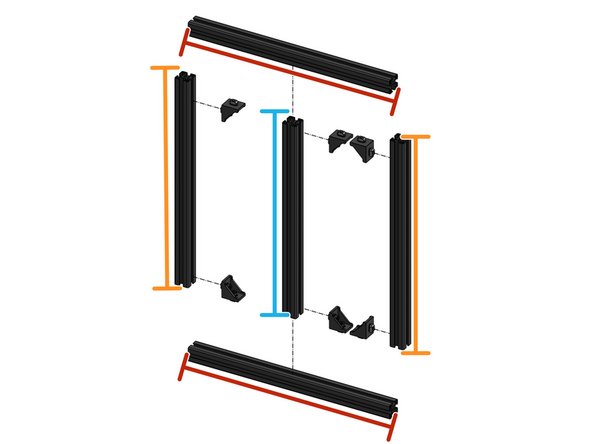

Prepare the 3030 extrusions:

-

440mm (540mm, 640mm)

-

450mm (550mm, 650mm)

-

420mm (520mm, 620mm)

-

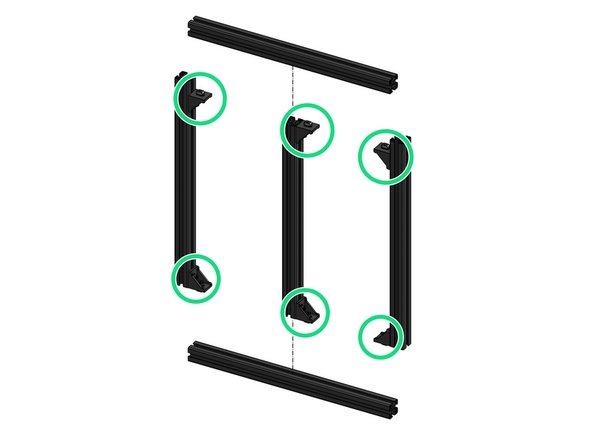

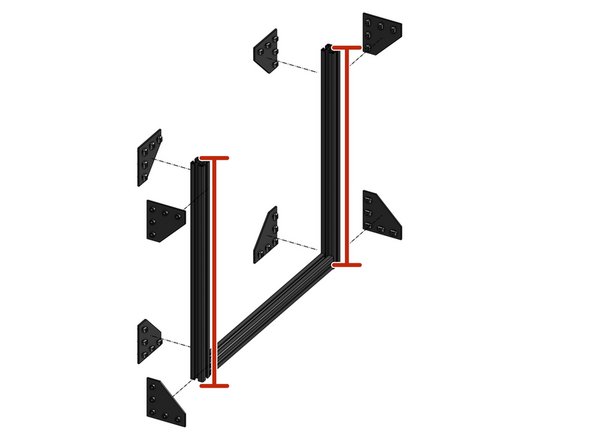

Attach 6 Corner Brackets to the ends of the vertical extrusions

-

205mm (255mm, 305mm)

-

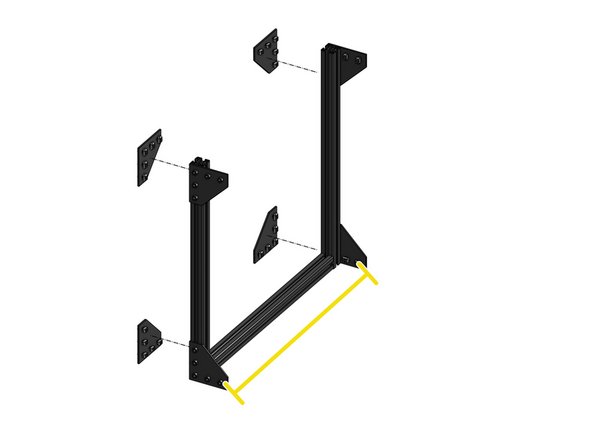

Carefully attach the extrusions by tightening all screws on the Corner Brackets. Make sure the frame is perfectly square. A flat surface may help.

-

-

-

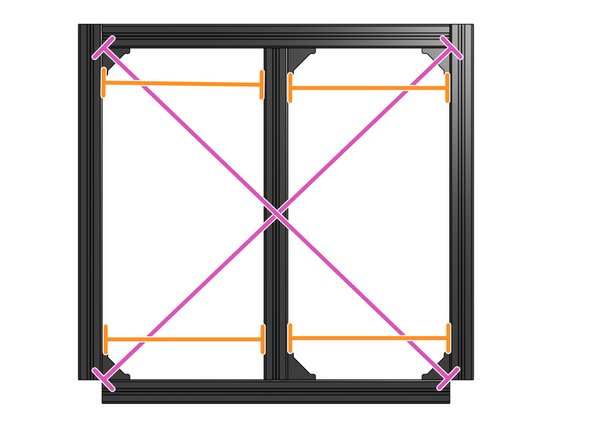

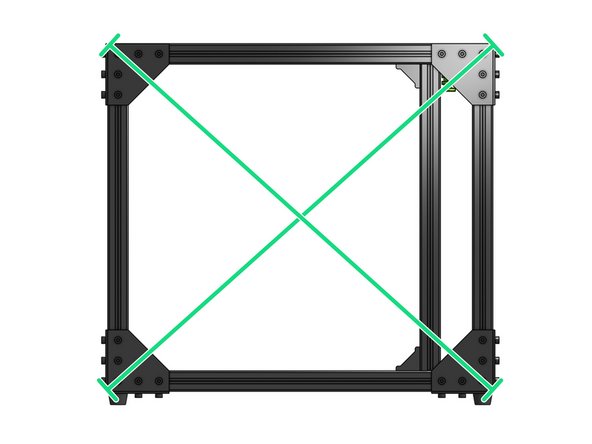

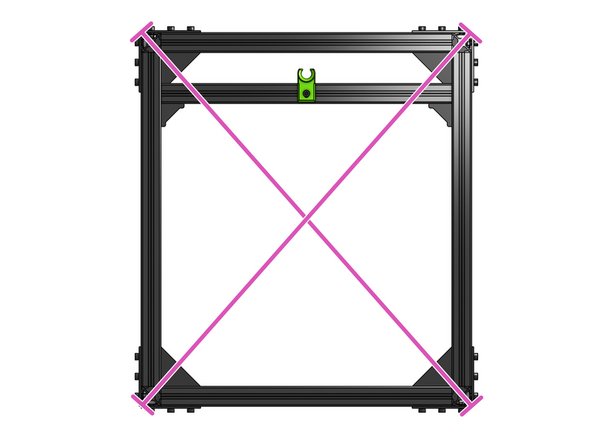

Make sure the frame is square. The diagonal lengths should be equal

-

The middle extrusion should be in the exact middle of the inner frame - 205mm (or 255mm or 305mm) from the side extrusions

-

-

-

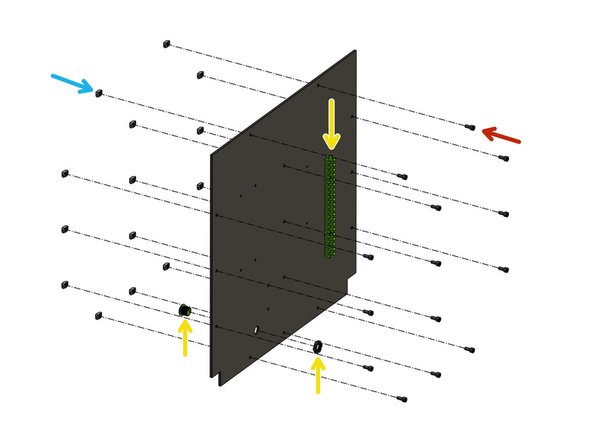

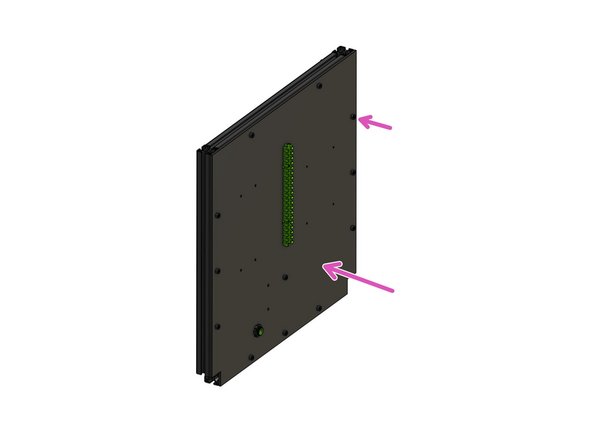

If you are opting for a back panel this is a good time to attach it. It's going to be difficult later.

-

Panels are not supplied by Rat Rig, they are meant to be sourced locally. DXF files are provided for each panel and machine size.

-

CAUTION: Panel should not be thicker than 4mm, or it will not fit.

-

If needed, drill the M6 holes and fasten the Cap Head Screw M6x12 through them

-

Attach the 3030 Drop-in T-Nut M6 to the screws

-

Some kits may use M5x12 screws with M5 T-Nuts for this step. If this is the case for your kit, it will include 18 M5x12 Cap head screws. If not, it will include only 4 of those screws.

-

Cable Management Printed Parts (Optional and not included in the kit shipped by Rat Rig)

-

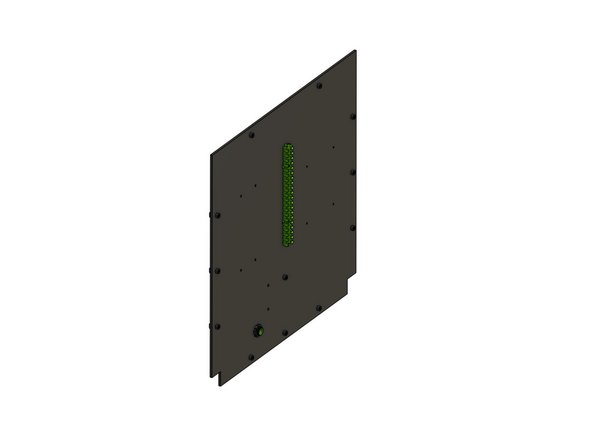

Fit the panel on the inner frame and fasten all of the screws

-

-

-

CAUTION: These lengths are very similar, do not mix them up!

-

Prepare 3030 extrusions:

-

2x 505mm

-

4x 510mm

-

-

-

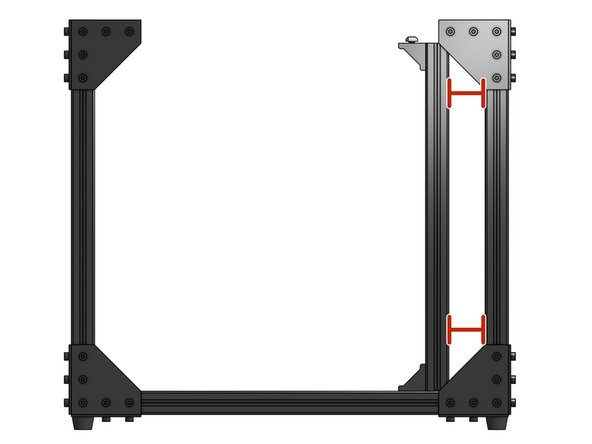

Attach the corner plate assemblies to the Z extrusions (510mm)

-

Add the Y extrusion (505mm)

-

Repeat for the other side of the frame

-

Don't worry about the top Y extrusions - those will be added later

-

-

-

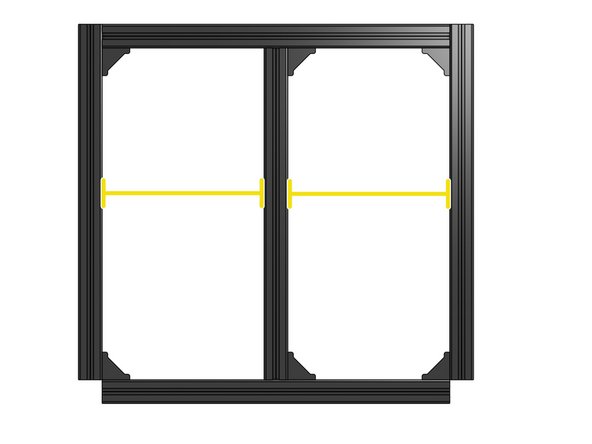

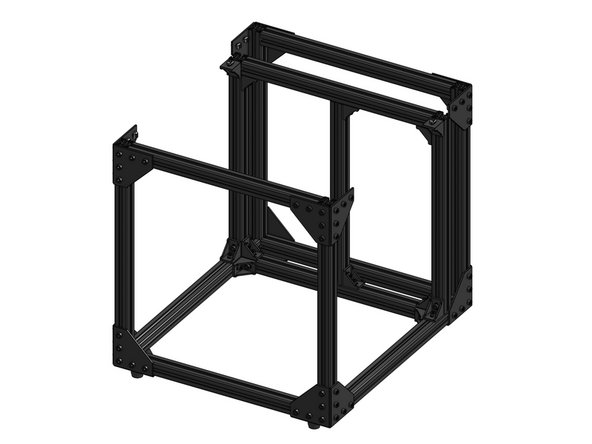

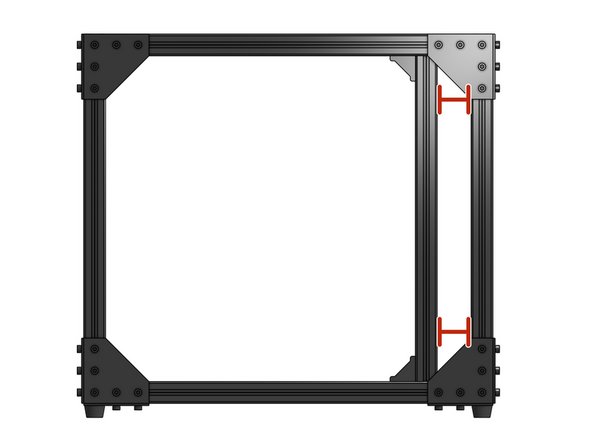

Join the two frame sides with 440mm X extrusions

-

Attach the bottom corner assemblies

-

Add the top 440mm X extrusions

-

-

-

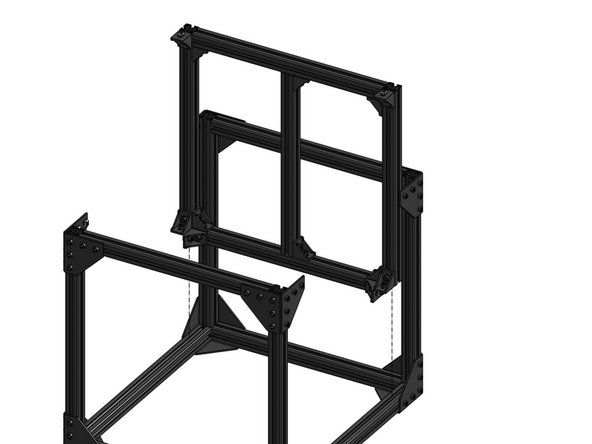

Insert the inner frame into the main frame.

-

You will need to loosen the bottom corner assemblies a little

-

The distance between the inner frame and the main Z extrusions should be 47mm

-

Use the motor_plates (from Part 0.2 XY Drive Assembly) to align the inner frame bottom position in the correct place.

-

-

-

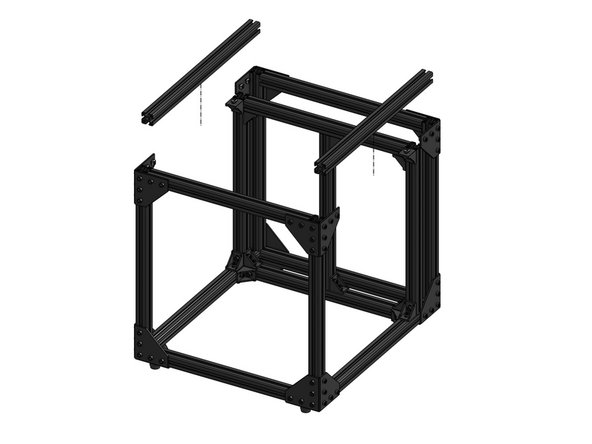

Attach the top Y extrusions

-

You will need to loosen the corner brackets in the top of the inner frame

-

Again, ensure the inner frame is parallel to the main frame - the distance between those should be 47mm

-

Use the motor_plates (from Part 0.2 XY Drive Assembly) to align the inner frame top position in the correct place.

-

-

-

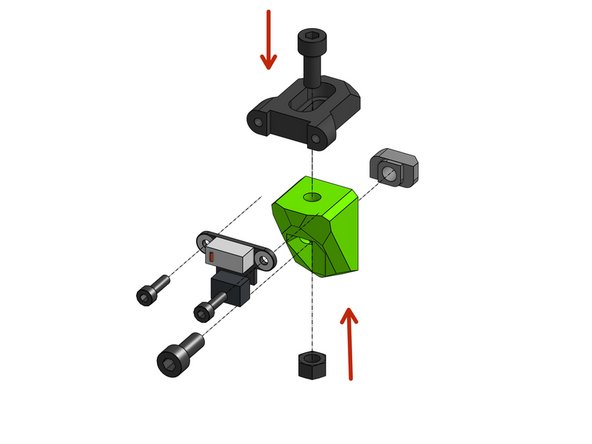

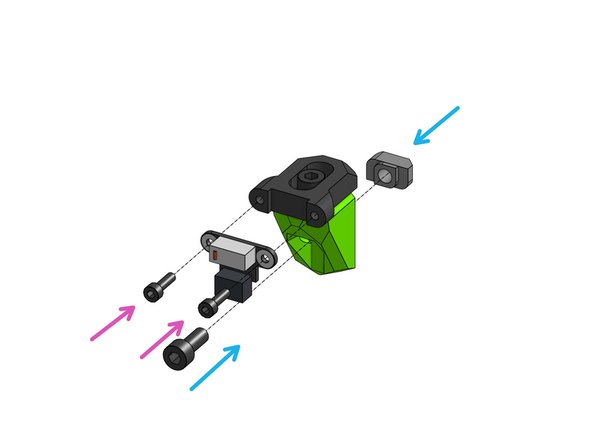

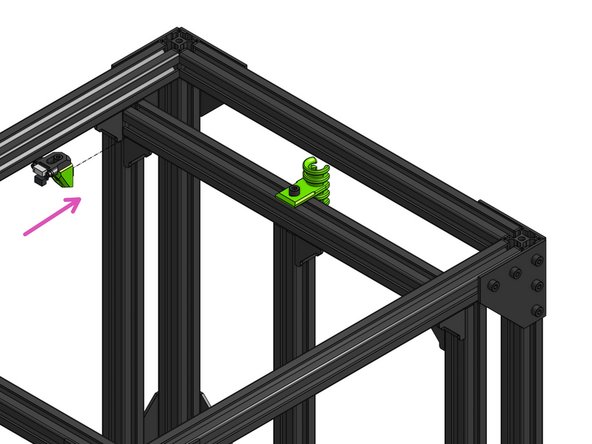

Backpull the M5 hex locking nut and fasten the two printed parts together with a Cap Head Screw M5x12

-

Attach the 3030 M5 T-nut to a Cap Head Screw M5x12 through the bottom part

-

Fasten the endstop to the top printed part with 2x Cap Head Screws M3x10

-

-

-

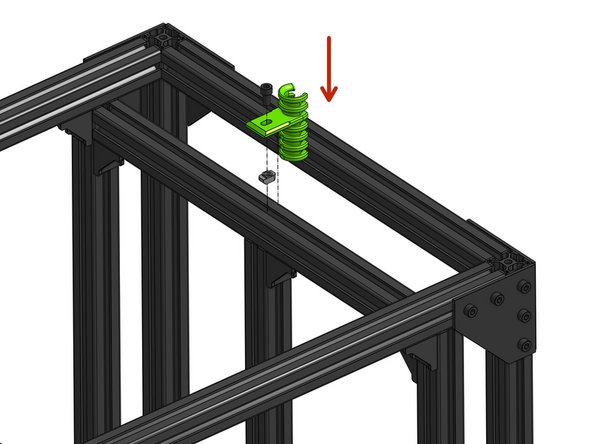

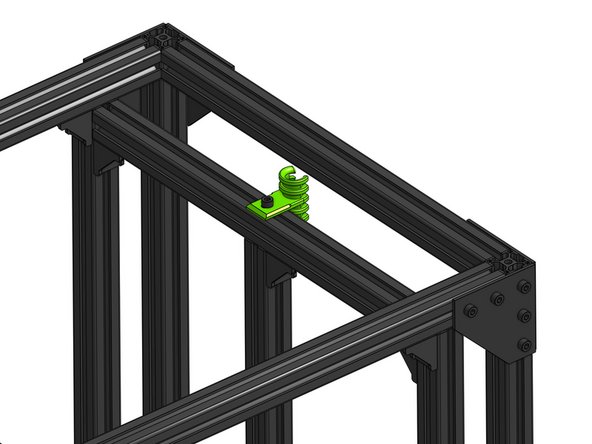

Thread the M6x12mm screw through the back cable guide and attach the 3030 M6 T-nut

-

Screw the part the the center of the inner frame's top extrusion

-

Don’t tighten too hard

-

Attach the Y endstop to the frame

-

-

-

VERY IMPORTANT: a frame that is not square will produce noise and will wear out parts like bearings and belts

-

Go around your frame and check the diagonal lengths - those need to be as equal as possible (a difference of less than 1mm is acceptable)

-

Front and back

-

Right and left

-

Top and bottom

-

Cancel: I did not complete this guide.

57 other people completed this guide.