-

-

2x vc4_xy_joiner_upper plate

-

2x vc4_x_endstop printed part

-

2x vc4_xy_joiner_middle plate

-

8x M5x60 Countersink Screw

-

2x Low Profile Screw 30mm

-

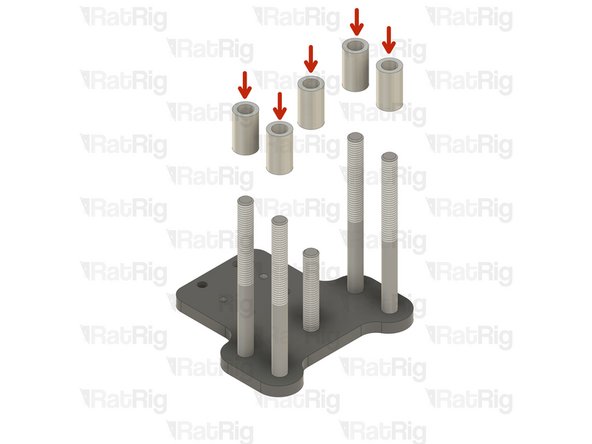

14x Aluminium Spacer 5x8x14mm

-

-

-

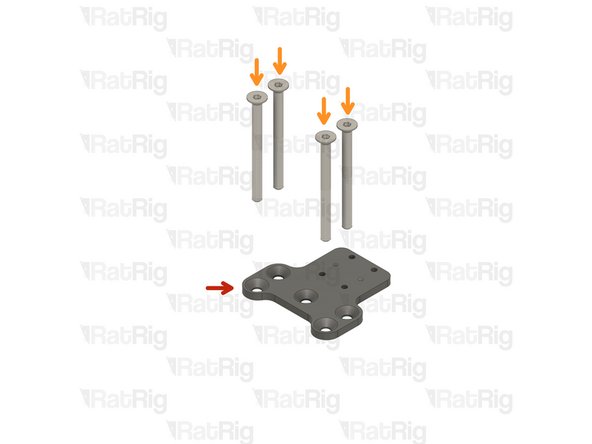

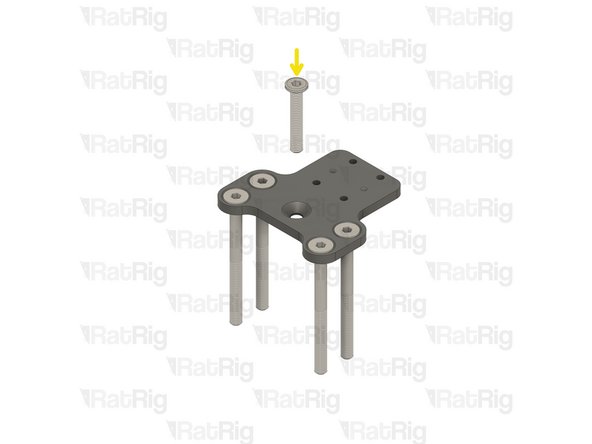

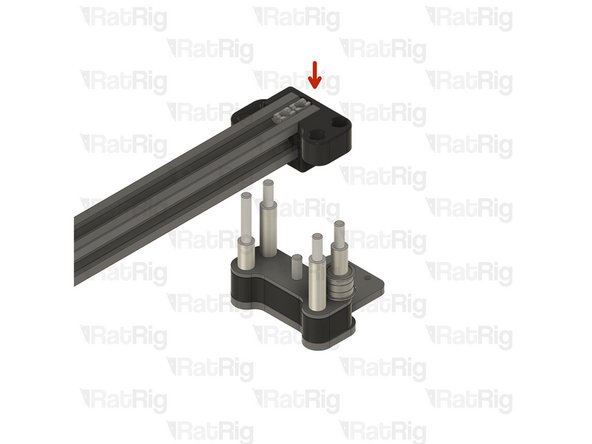

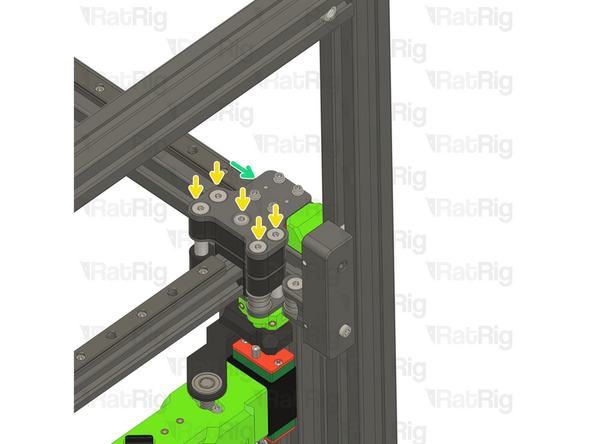

vc4_xy_joiner_upper plate

-

M5x60 Countersink Screw

-

M5x30 Low Profile Screw

-

Insert the screws on the plate and flip the assembly upside down as shown.

-

-

-

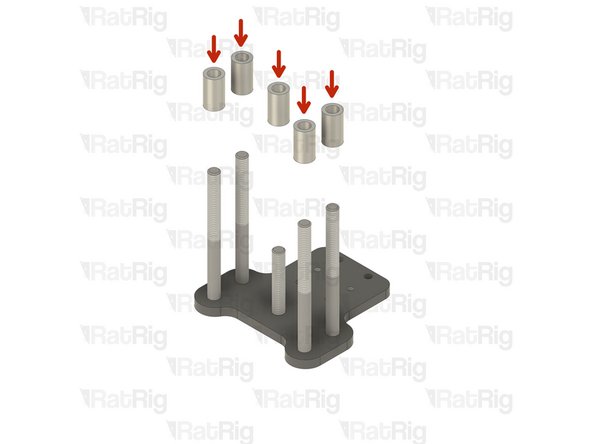

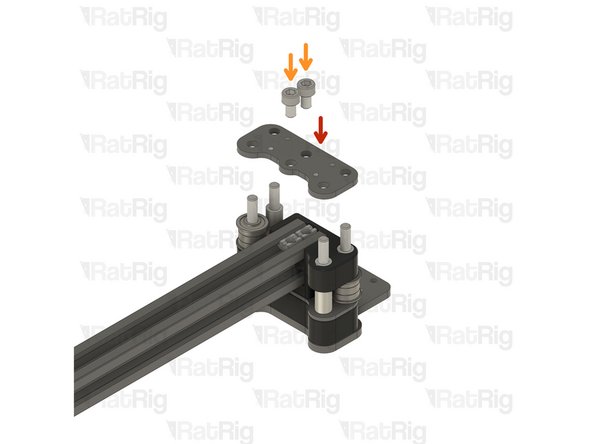

Aluminium Spacer 5x8x14mm

-

Insert one Aluminium spacer on each screw

-

vc4_x_endstop printed part

-

Align the printed part and insert it through the aluminium spacers.

-

vc4_xy_joiner_middle plate

-

Align the plate and insert it through the screws.

-

-

-

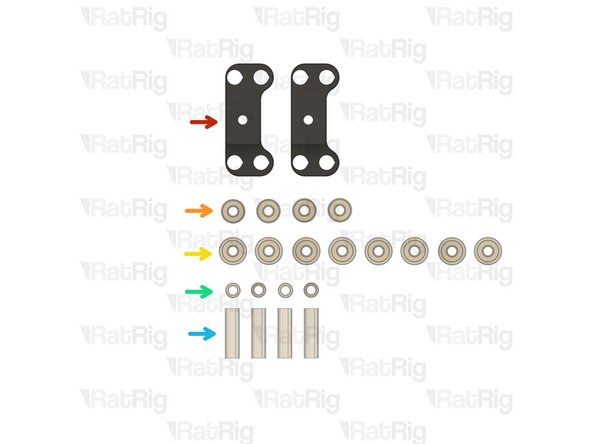

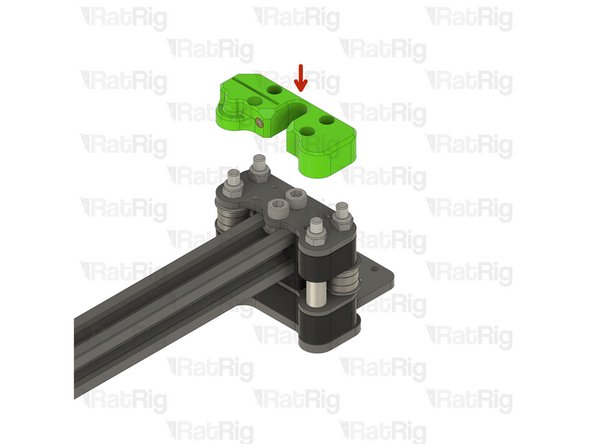

2x vc4_xy_spacer

-

4x Ball Bearing 695ZZ

-

8x Ball Bearing F695ZZ

-

4x Mini Precision Shim 8x5x1mm

-

4x Aluminium Spacer 5x8x27mm

-

4x Heavy-Duty Idler – The latest V-Core 4 kits now feature these heavy-duty idlers as a replacement for the previously used bearing stack assemblies.

-

-

-

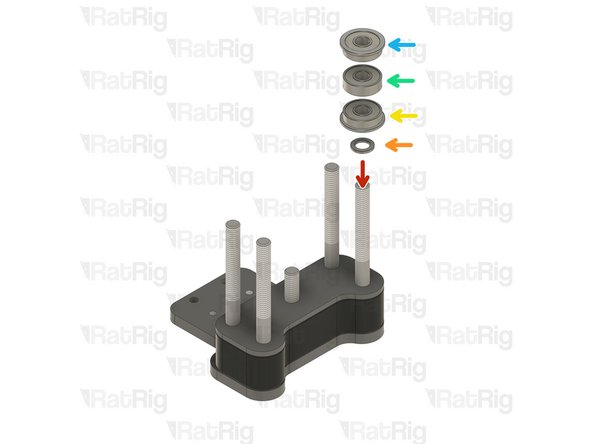

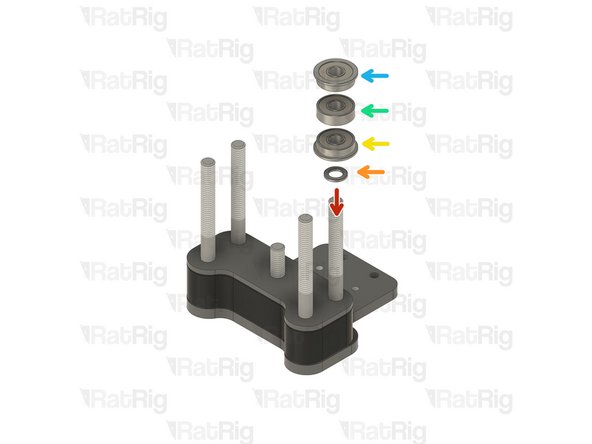

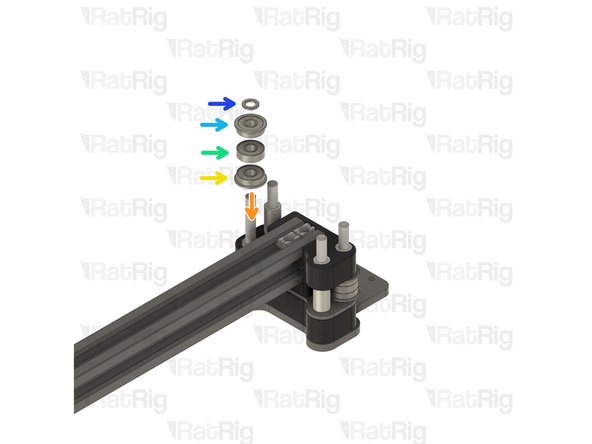

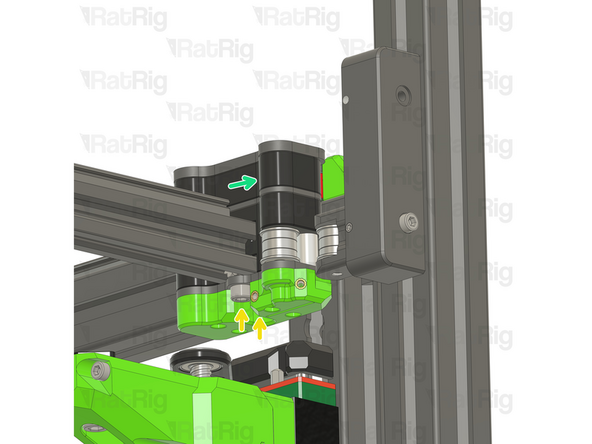

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Aluminium Spacer 5x8x27mm

-

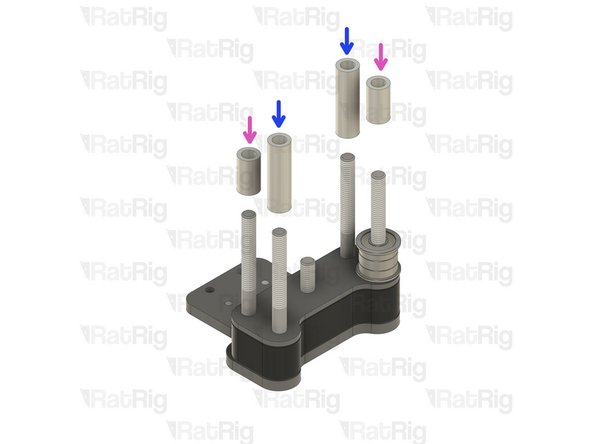

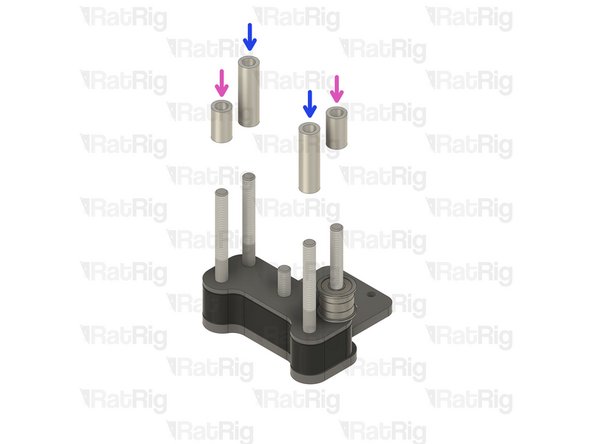

Aluminium Spacer 5x8x14mm

-

Insert the aluminium spacers on the designated screws.

-

-

-

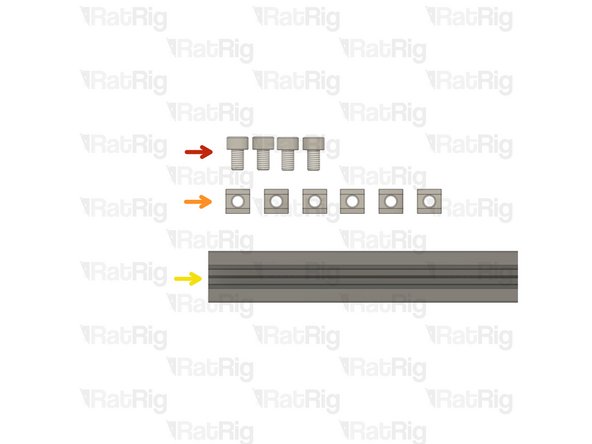

4x M5x8 Cap Head Screw

-

6x T-Nut M5 Square type for 2020

-

V-Slot 2020 - 525mm

-

-

-

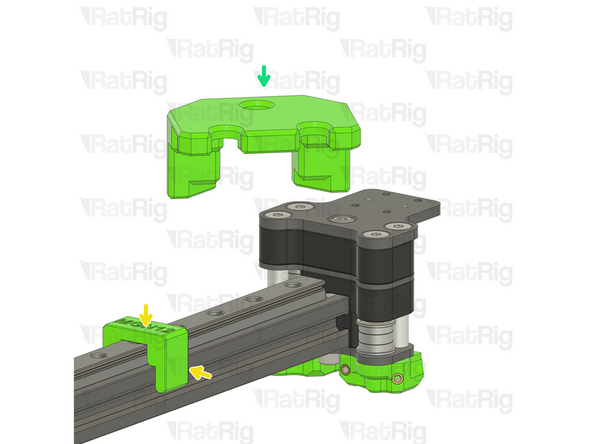

Insert two T-Nut Square type for 2020 on the top slot.

-

Insert one T-Nut Square type for 2020 on the lower slot.

-

Gently insert the V-Slot 2020 extrusion inside the vc4_xy_spacer. The two square T-nuts must be facing the opening on the printed part, as shown.

-

Ensure the extrusion and the printed part are flush.

-

-

-

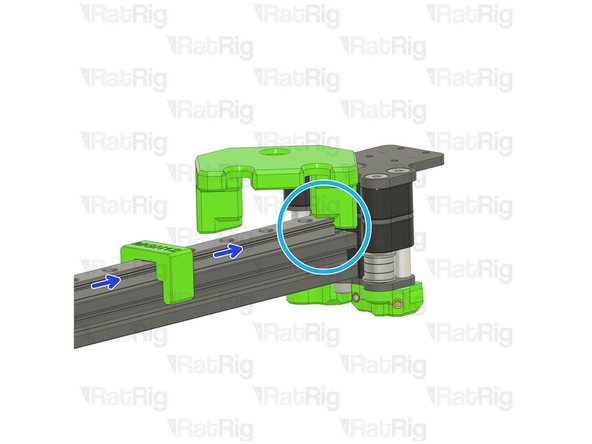

Push the two T-Nut Square type to the end of the assembly

-

Flip the gantry upside down and push the single T-Nut Square type underneath the printed part, ensuring it is aligned with the hole on the printed part.

-

Repeat Steps 7 and 8 and prepare the other end of the assembly.

-

-

-

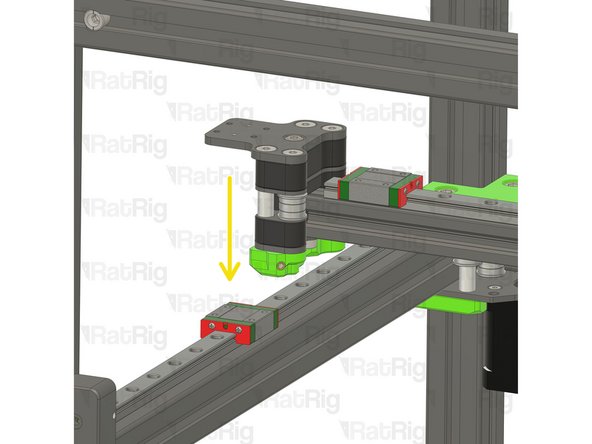

Take the assembly from the previous Step and insert the printed part holes in the aluminium spaces of the left joiner from Step 5

-

Install the following components in the order shown in the image:

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Mini Precision Shim

-

-

-

2x vc4_xy_joiner_lower plate

-

vc4_xy_trim_left printed part

-

vc4_xy_trim_right printed part

-

8x M5 Hex Locking nut

-

8x M3x8 Cap Head Screw

-

-

-

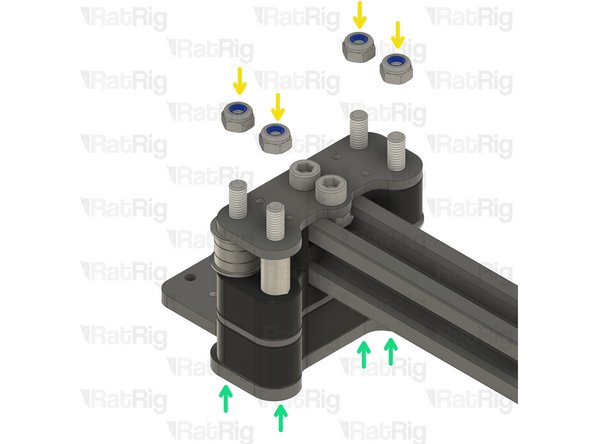

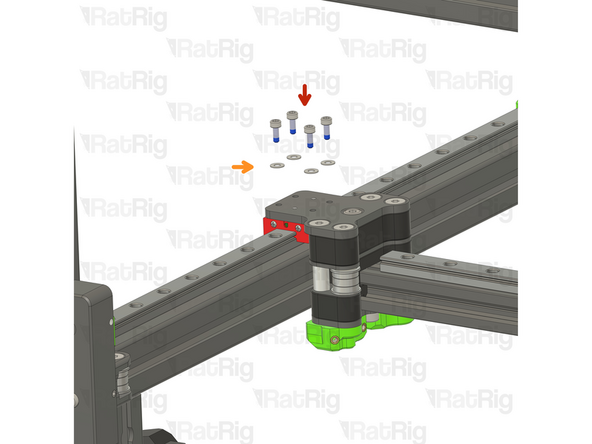

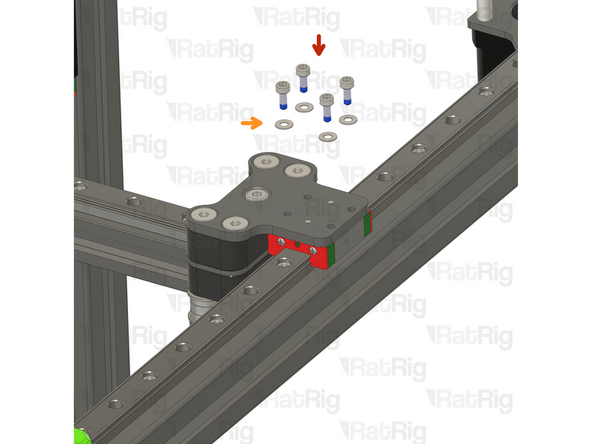

vc4_xy_joiner_lower plate

-

2x M5x8 Cap Head Screw

-

Insert the screws through the plate, and tighten them to the t-nuts on the 2020 extrusion.

-

M5 Hex Locking nut

-

Thread a M5 hex locking nut in each screw

-

Tighten the screws in each of M5 hex locking nuts were inserted

-

Do not overtighten the screws as too much force can cause the gantry to bind when installed on the V-Core 4.

-

-

-

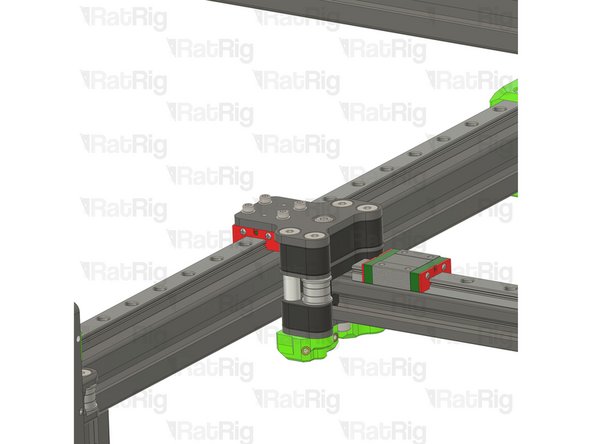

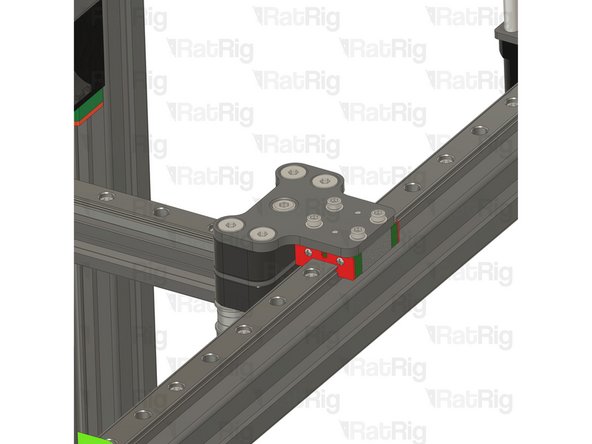

vc4_xy_trim_left printed part

-

4x M3x8 Cap Head Screw

-

Insert the screws through the printed part and tighten them to the plate

-

-

-

Tighten the marked screw to better secure the gantry to the joiner.

-

This is how the left joiner should look like, carefully inspect your assembly before proceeding.

-

-

-

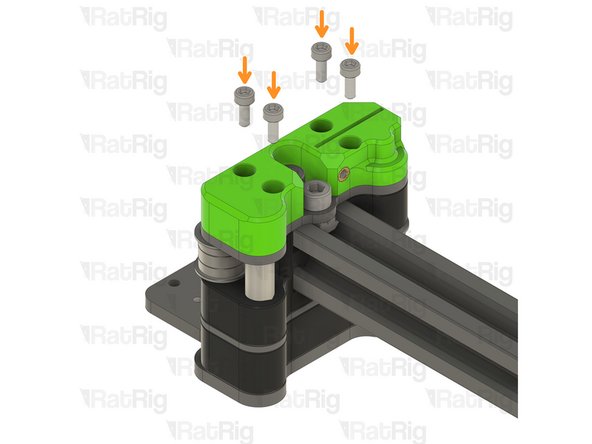

vc4_xy_joiner_upper plate

-

M5x60 Countersink Screw

-

M5x30 Low Profile Screw

-

Insert the screws on the plate and flip the assembly upside down as shown.

-

-

-

Aluminium Spacer 5x8x14mm

-

Insert one Aluminium spacer on each screw

-

vc4_x_endstop printed part

-

Align the printed part and insert it though the aluminium spacers.

-

vc4_xy_joiner_middle plate

-

Align the plate and insert it though the screws.

-

-

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Aluminium Spacer 5x8x27mm

-

Aluminium Spacer 5x8x14mm

-

Insert the aluminium spacers on the designated screws.

-

-

-

Take the assembly from Step 16 and insert the printed part holes in the aluminium spaces of the right joiner from the previous Step.

-

Install the following components in the order shown in the image:

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

Mini Precision Shim

-

-

-

vc4_xy_joiner_lower plate

-

2x M5x8 Cap Head Screw

-

Insert the screws through the plate, and tighten them to the t-nuts on the 2020 extrusion.

-

M5 Hex Locking nut

-

Thread a M5 hex locking nut in each screw

-

Tighten the screws in each of M5 hex locking nuts were inserted

-

Do not overtighten the screws as too much force can cause the gantry to bind when installed on the V-Core 4.

-

-

-

vc4_xy_trim_left printed part

-

4x M3x8 Cap Head Screw

-

Insert the screws through the printed part and tighten them to the plate

-

Tighten the marked screw to better secure the gantry to the joiner.

-

Set the assembly aside, it will be used further in the Guide

-

-

-

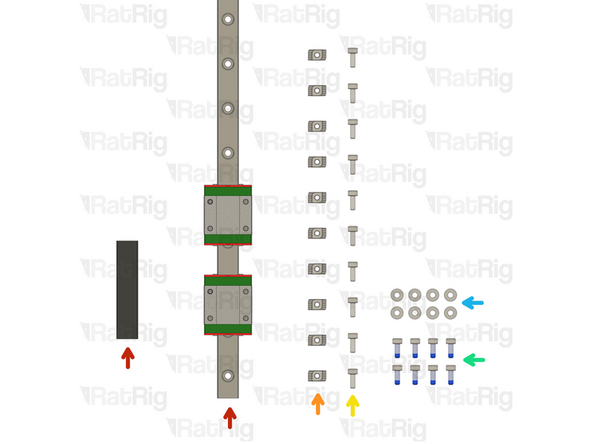

475mm MGN12C Linear Rail & MGN12C carriage holder

-

10x 2020 Drop-in T-Nut - M3

-

10x M3x8 Cap Head Screw

-

V-Core 4 400 - 12 Screws + T-nuts

-

V-Core 4 500 - 14 Screws + T-nuts

-

8x M3x8 Cap Head Screw with blue thread lock

-

The plastic bag has a BT label

-

8x M3 Washer

-

-

-

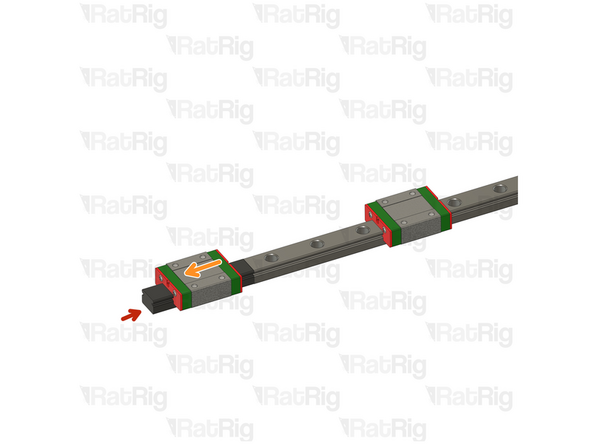

ONLY remove the second carriage if you are not assembling the IDEX variant.

-

Keeping the second carriage in the X rail will result in poor belt tunning and input shaper results.

-

Align the mgn12c carriage mount with the linear rail

-

Slowly slide one carriage to the mount

-

Carefully store the carriage, this will be essential for the IDEX upgrade.

-

Ensure the carriage never leaves the mount, to avoid loosing any of the ball bearings inside.

-

-

-

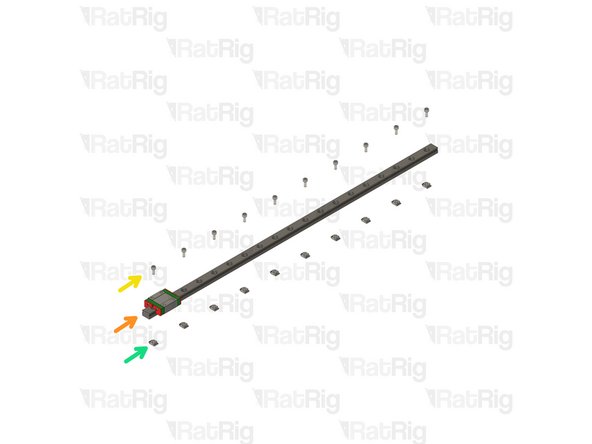

Remove the plastic stops installed in the ends of the linear rail

-

475mm MGN12 Linear Rail

-

10x M3x8 Cap Head Screw

-

10x 2020 Drop-in T-Nut - M3

-

-

-

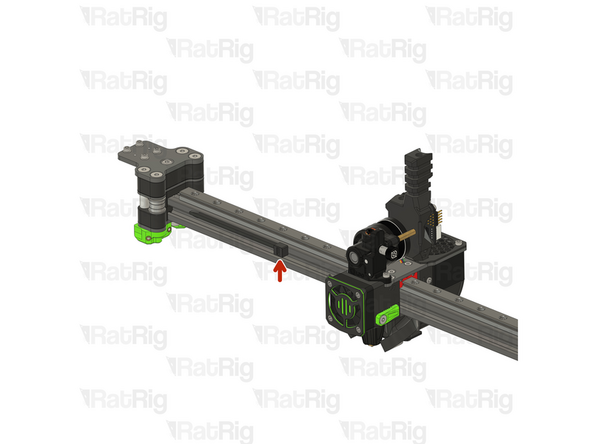

X-Axis Gantry Assembly from Step19

-

Linear rail assembly from the previous Step

-

2x align_2020_mgn12

-

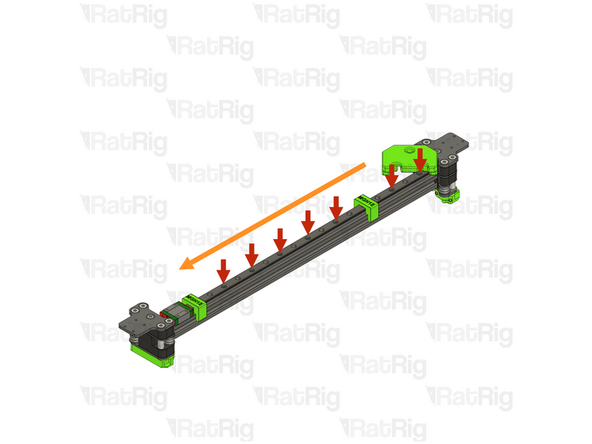

Use the jigs to align the mng12 linear rail on the 2020 extrusion

-

Frame jig from Chapter One

-

Insert the small tab between the gantry joiner and the linear rail as shown

-

Push the linear rail against the frame jig to ensure they sit flush.

-

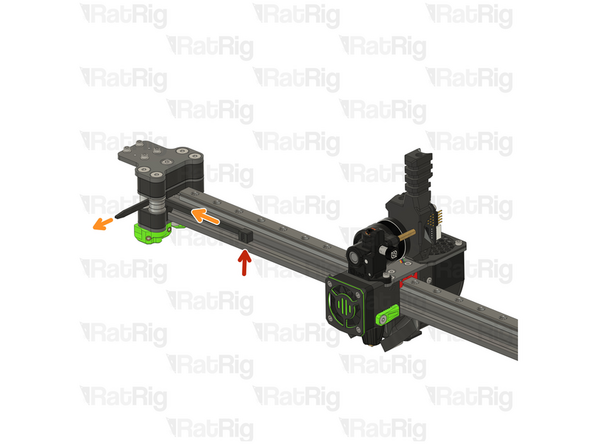

-

-

Fasten all M3x8 screws, starting from the jig side. The orange arrow indicates the direction to follow.

-

Do not overtighten the screws as it can cause the linear rail to bind.

-

-

-

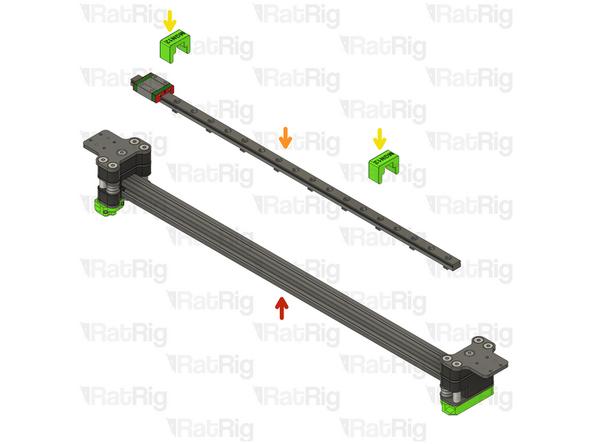

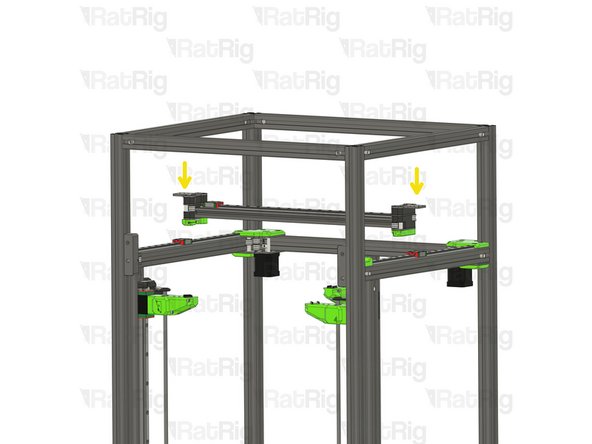

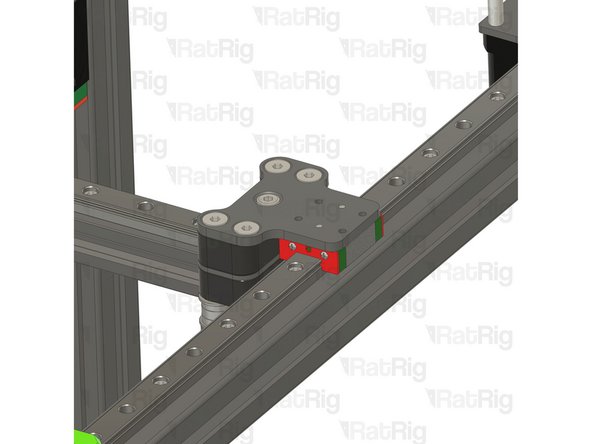

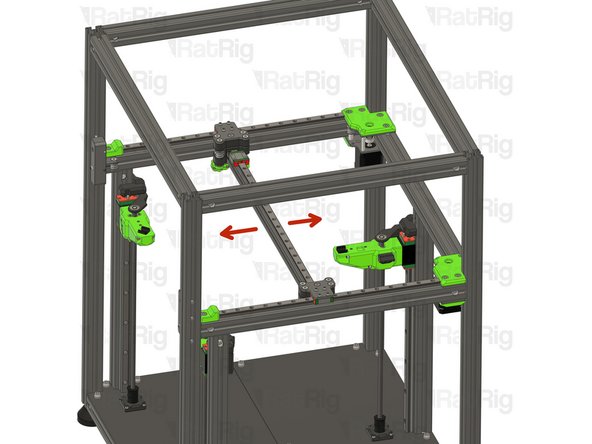

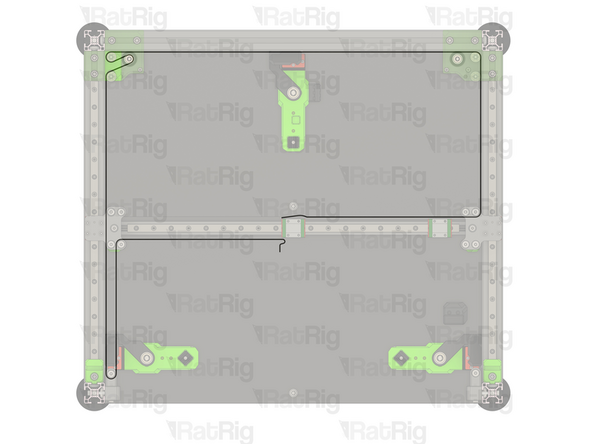

V-Core 4 Frame Assembly

-

X-Axis gantry Assembly

-

Carefully insert the gantry assembly into the V-Core 4 frame from the side, as shown.

-

Place the Joiners on top of the linear rail carriages.

-

When installing, keep the gantry's left and right orientation in mind. Installing it in reverse will prevent the belt routing from working.

-

-

-

4x M3x8 Cap Head Screw with threadlock (blue on ends of screw threads)

-

4x M3 washer

-

Insert an M3x8 Cap Head screw with an M3 washer through the joiner plate and tighten it to the linear rail carriage

-

Don't overtighten the screws as it can cause the gantry to bind in the Y direction

-

-

-

4x M3x8 Cap Head Screw

-

4x M3 washer

-

Insert an M3x8 Cap Head screw with an M3 washer through the joiner plate and tighten it to the linear rail carriage

-

Don't overtighten the screws as it can cause the gantry to bind in the Y direction

-

-

-

Test the movement of the y-axis over the full travel distance

-

Small changes in resistance are normal, but becoming much harder to push, or binding completely are not

-

If the Gantry feels hard to push, you can undo the M3x8 Cap Head screws installed on the previous Steps a quarter of a turn, ensuring there is no play between the joiner plates and the linear rail carriages

-

-

-

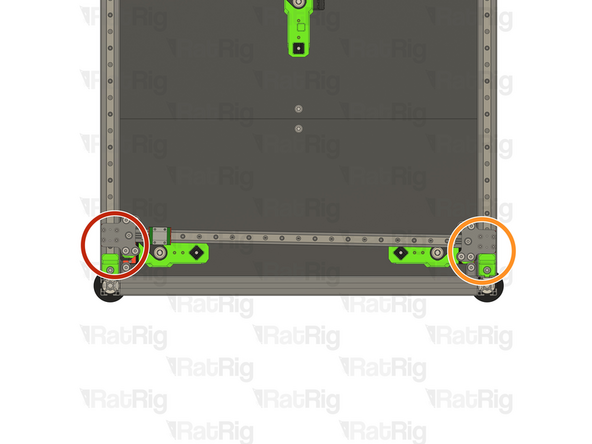

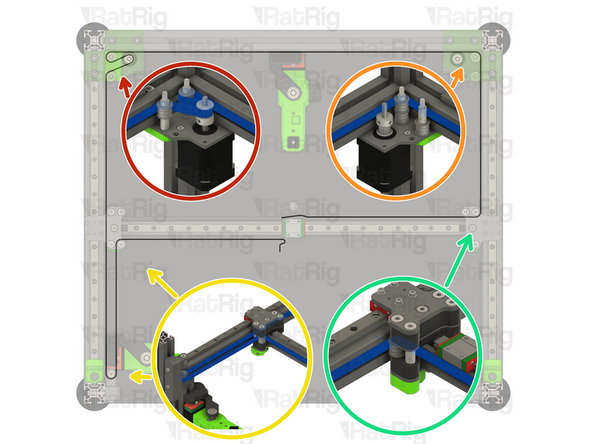

Move the gantry to the front.

-

Both Joiners must hit the Y bumper printed parts at the same time.

-

An exaggerated example of a misaligned gantry, there is a gap on one side, but not the other.

-

The right side sits flush with the Y bumper, or vice versa.

-

If your gantry isn't bumping into both printed parts at the same time, follow the next steps:

-

Gently loosen all screws in both joiners.

-

Push the joiners against the Y bumper printed parts by hand.

-

Firmly Retighten all screws on both Joiners and go back to Step 27

-

-

-

Take the belt package inside the HW3693MK - Rat Rig V-Core 4.0 - Base Hardware Pack - All Versions and cut it in half, one half will be used for the top belt path and the other for the lower belt path.

-

If you are building the hybrid machine you have 2 belt packages, you should use the longest one at this stage.

-

-

-

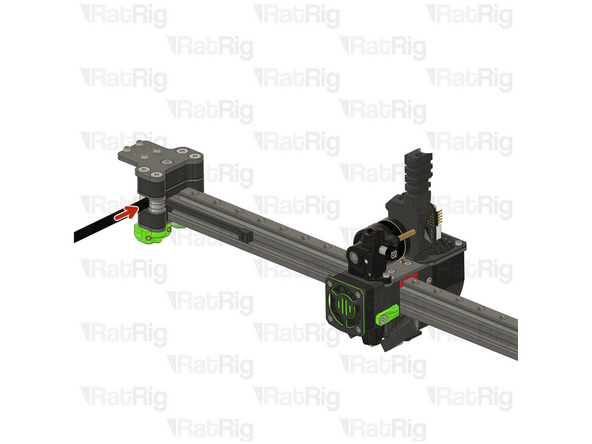

This step is not mandatory, it's just a Rat Rig tip on how to feed the belts on the idlers.

-

Zip Tie

-

The wider the zip tie is, the easier the process will be

-

Bend the tip of the zip tie a little bit and feed it between the joiner assembly and the idler, as shown

-

-

-

Insert the belt between the zip tie and the idler

-

Slowly feed the belt and pull the zip tie at the same time

-

-

-

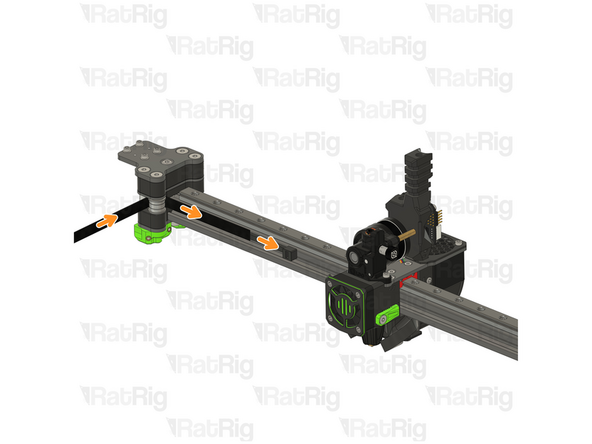

Ensure the belt teeth are facing the stepper motor pulleys.

-

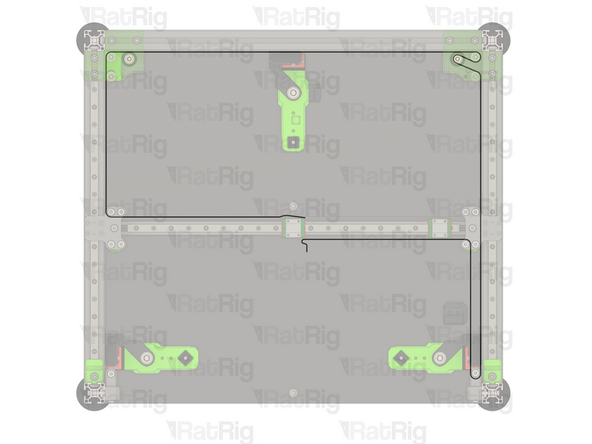

Take one end of the top CoreXY belt, and feed it as shown:

-

Feed the belt through the left stepper motor bearing stacks.

-

Feed the belt behind the left xy_joiner, through the front tensioner and finally the front bearing stack on the xy_joiner.

-

Take the other end of the top CoreXY belt, and feed it as shown:

-

Feed the belt through the right stepper motor bearing stacks.

-

Feed the belt around the rear bearing stack on the xy_joiner.

-

Do not cut the excess belt at this stage.

-

-

-

Ensure the belt teeth are facing the stepper motor pulleys.

-

Ensure the belt teeth are facing the stepper motor pulleysTake one end of the lower CoreXY belt, and feed it as shown:

-

Feed the belt through the left stepper motor bearing stacks.

-

Feed the belt around the rear bearing stack on the xy_joiner.

-

Take the other end of the top CoreXY belt, and feed it as shown:

-

Feed the belt through the right stepper motor bearing stacks.

-

Feed the belt behind the left xy_joiner, through the front tensioner and finally the front bearing stack on the xy_joiner.

-

Do not cut the excess belt at this stage.

-

Cancel: I did not complete this guide.

46 other people completed this guide.