-

-

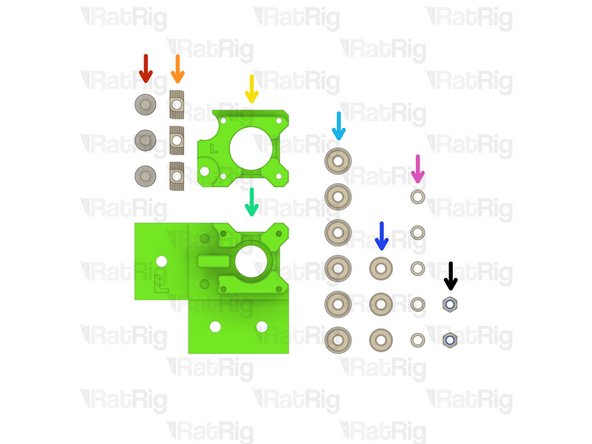

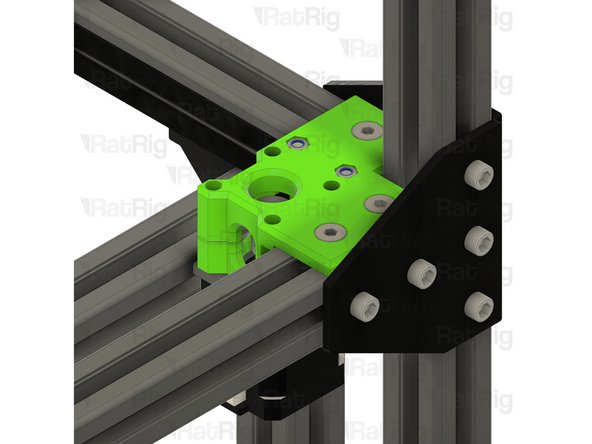

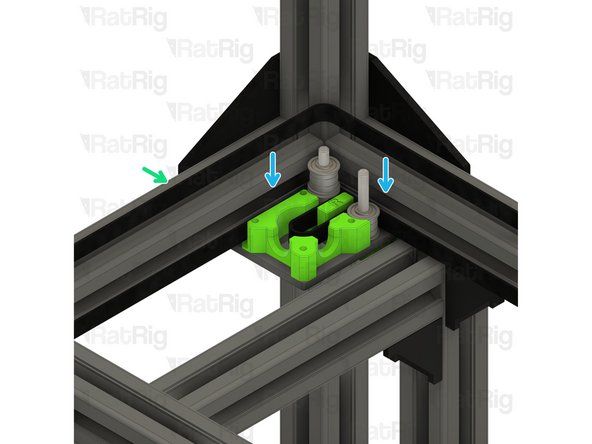

2x motor_plate

-

1x motor_support_left Printed Part

-

1x motor_support_right Printed Part

-

8x M6x12 Cap Head Screw

-

8x 3030 Drop-in T-Nut - M6

-

4x M5x40 Cap Head Screw

-

-

-

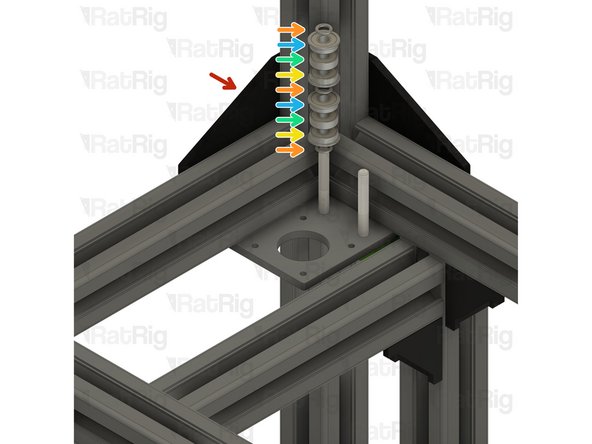

motor_plate

-

Make sure the motor plates are oriented as shown

-

motor_support_left Printed Part

-

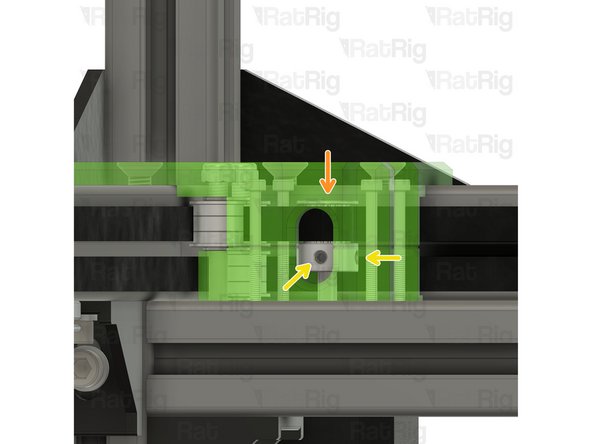

M6x12 Cap Head Screw

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x12 screws. Do not tighten them at this point.

-

motor_support_right Printed Part

-

Set the right motor plate assembly, and two M5x40 Cap Head Screws, aside until Step 12

-

-

-

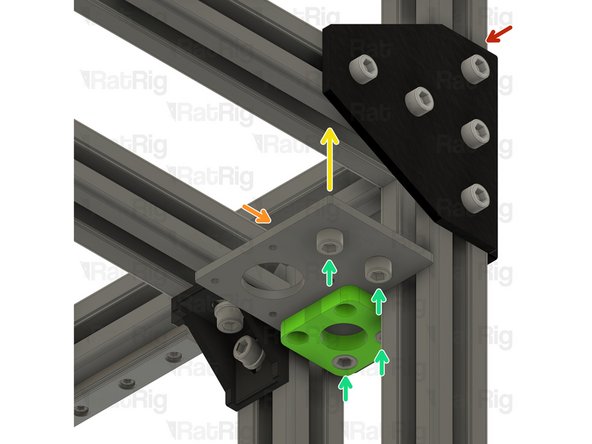

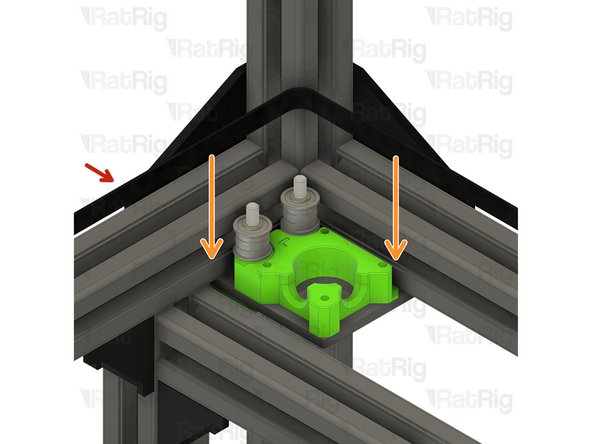

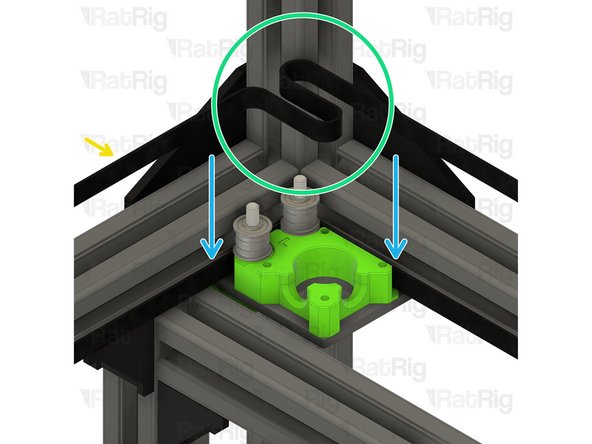

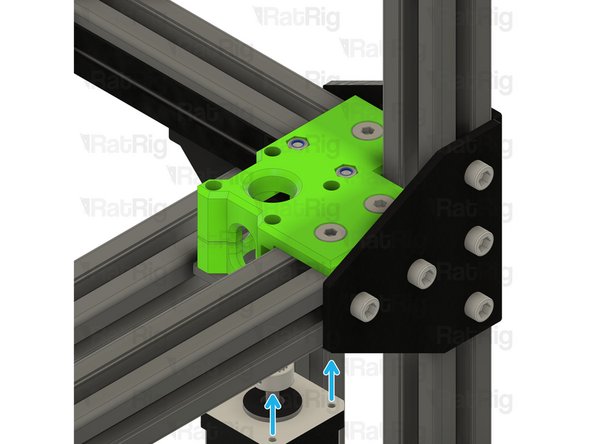

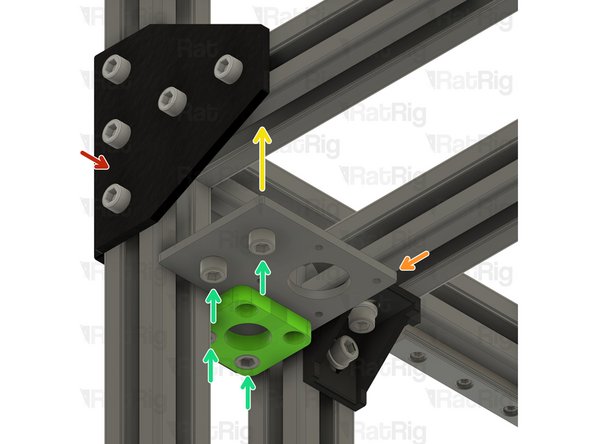

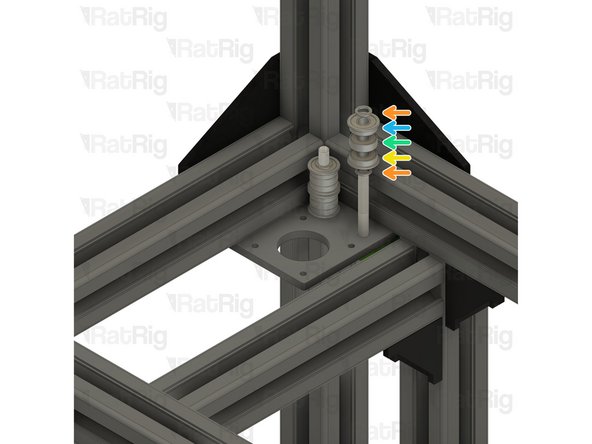

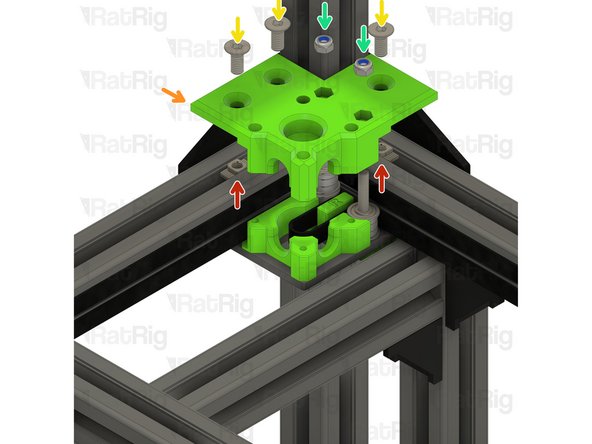

V-Core 3.1 Frame Assembly - Rear Left Corner

-

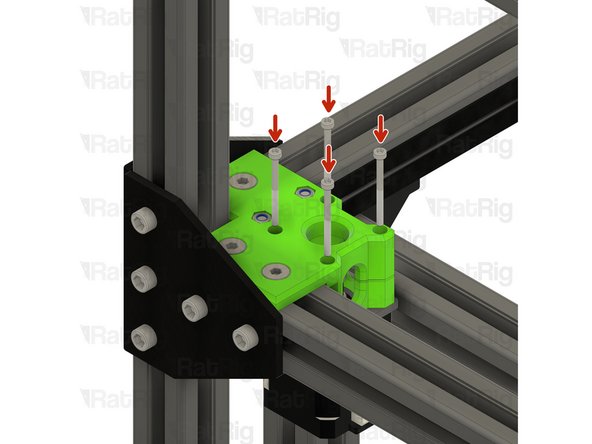

Left motor_plate assembly from Step 2

-

Install the left motor_plate assembly to the V-Core 3.1 frame as shown

-

Tighten the four M6x12 screws to secure the motor_plate assembly to the frame

-

Make sure the plate is fully seated against the 3030 extrusion before tightening the M6x12 screws

-

Insert two M5x40 screws into the motor_plate, as shown, in preparation for Step 5

-

-

-

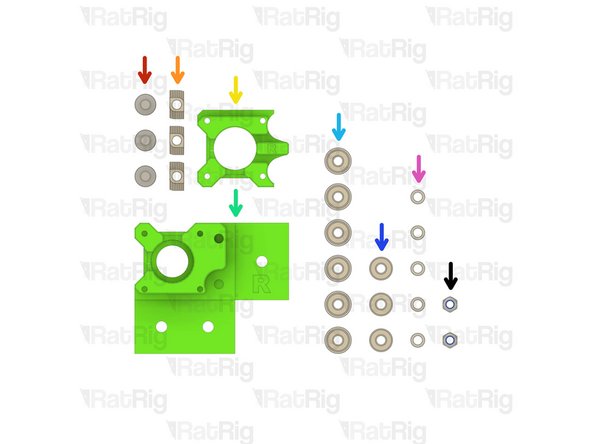

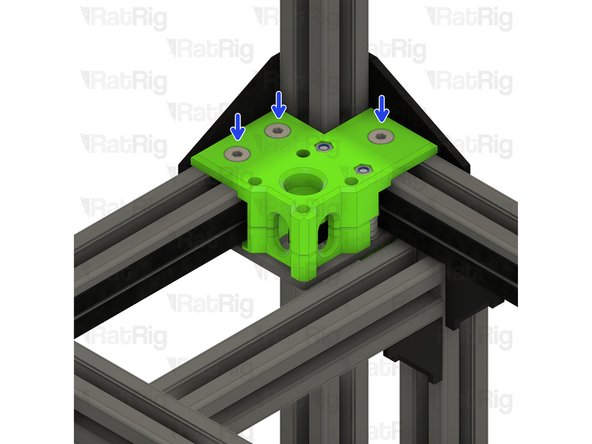

3x M6x14 Countersink Screw

-

3x 3030 Drop-in T-Nut - M6

-

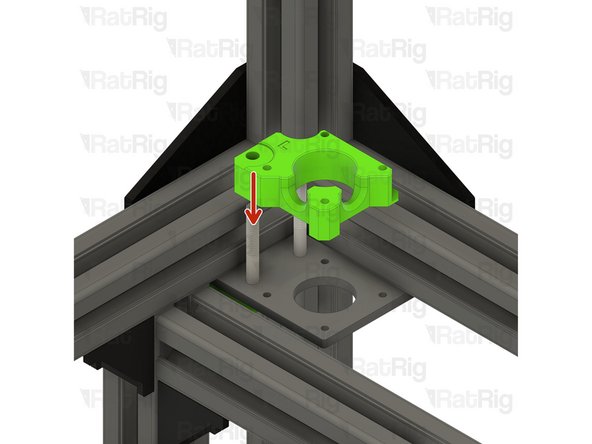

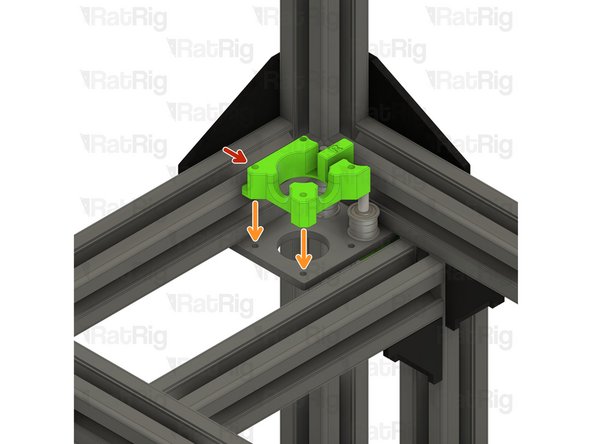

1x xy_motor_cage_bottom_left_3.1 Printed Part

-

1x xy_motor_cage_top_left_3.1_cutout Printed Part

-

6x F695ZZ Ball Bearing

-

3x 695ZZ Ball Bearing

-

5x Mini Precision Shim

-

2x M5 Nylon Locking Hex Nut

-

-

-

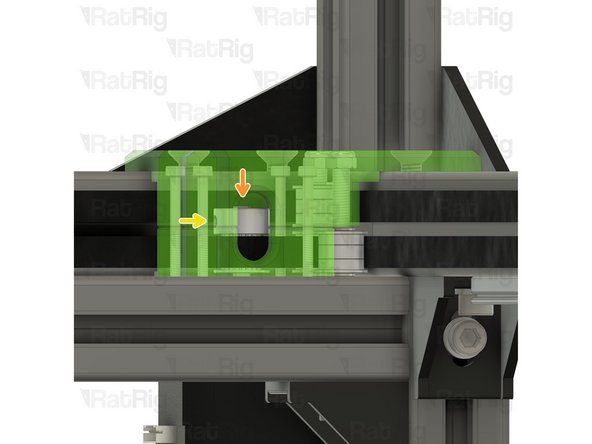

Install the xy_motor_cage_bottom_left printed part as shown

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

-

-

Proper installation of the belt is very important, failure to follow the instructions can lead to damage of the belt

-

The CoreXY belt is provided in one continuous length. Unroll the belt and cut it in half to give you two belts of the same length

-

Position one half of the belt so that the toothed side faces the frame, and the smooth side faces the bearing stacks

-

Slot this half to the bottom of the CoreXY motor assembly, it should align with the bottom bearing stack

-

Take the other half of the CoreXY belt. Again, position the belt so that the toothed side faces the frame and the smooth side faces the bearing stacks

-

Form a loop as shown, this will be used to engage with the NEMA17 motor pulley

-

Position the upper belt as shown

-

Make sure that both belts match the third image before proceeding

-

-

-

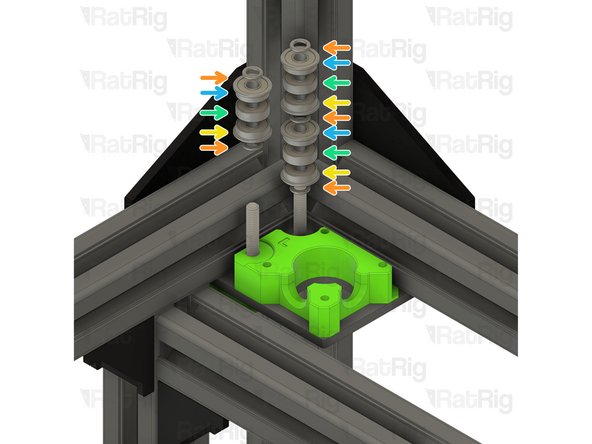

3030 Drop-in T-Nut - M6

-

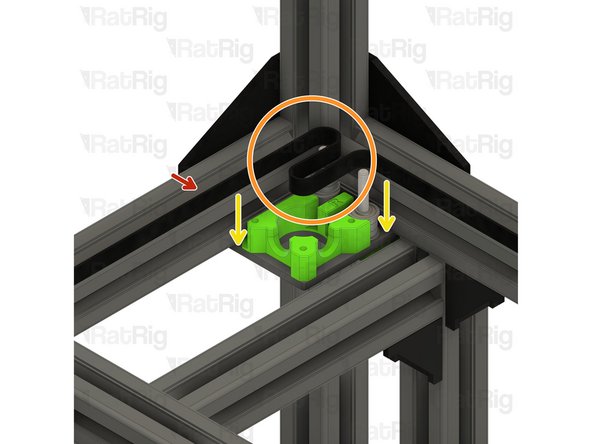

xy_motor_cage_top_left_3.1_cutout Printed Part

-

M6x14 Countersink Screw

-

Loosely thread a 3030 T-Nut onto each of the M6x14 screws. Do not tighten them at this point.

-

M5 Nylon Locking Hex Nut

-

-

-

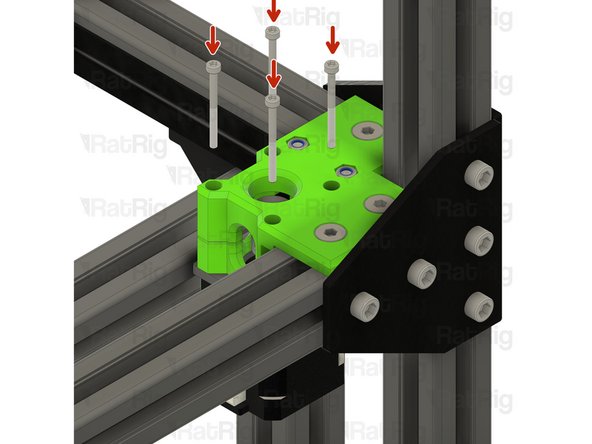

Install the xy_motor_cage_left_top assembly onto the frame as shown

-

Make sure the belt loop, created in Step 6, remains in the position shown

-

Tighten the three marked M6x14 screws to secure the CoreXY motor cage top to the frame

-

Take care not to over tighten the M6x14 screws as you can damage the printed part

-

Tighten the M5x40 screws to secure the bearing stacks into the CoreXY motor cage top

-

-

-

1x 20 Tooth 2GT Timing Pulley for 9mm Belt

-

1x 48mm NEMA17 Stepper Motor

-

4x M3x35 Cap Head Screw

-

-

-

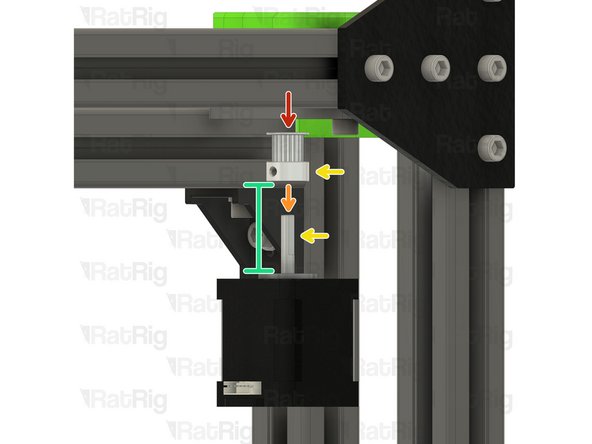

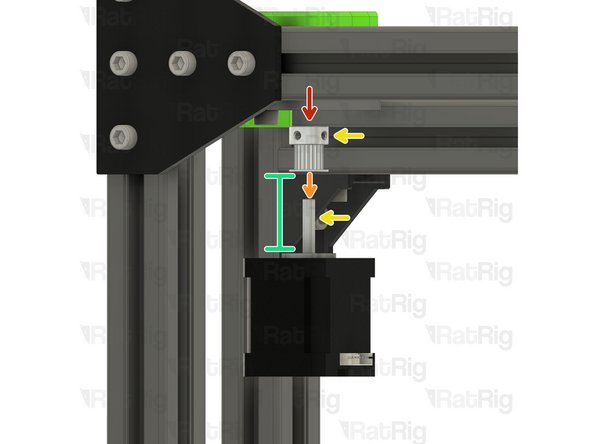

20 Tooth 2GT Timing Pulley for 9mm Belt

-

Install the timing pulley onto the NEMA17 shaft, oriented as shown

-

Align one of the M3 grub screws on the timing pulley so that it will tighten against the flat on the NEMA17 shaft

-

Position the timing pulley so the marked gap is 9.5mm

-

Slightly tighten one of the M3 grub screws to hold the timing pulley in position for now

-

The timing pulley will be aligned and fully secured in the next step

-

Position the NEMA17 motor up and into the motor cage from below, it will be secured in the next step

-

-

-

Insert the M3x35 screws into the xy_motor_cage_left_top as shown, and fasten them to secure the NEMA17 motor to the mount

-

Check the alignment of the timing pulley, the belt should be on the middle of the pulley as shown

-

Adjust the pulley up or down if required to make sure the belt is in the middle of the pulley

-

Fasten both M3 grub screws to securely mount the timing pulley to the NEMA17 motor shaft

-

-

-

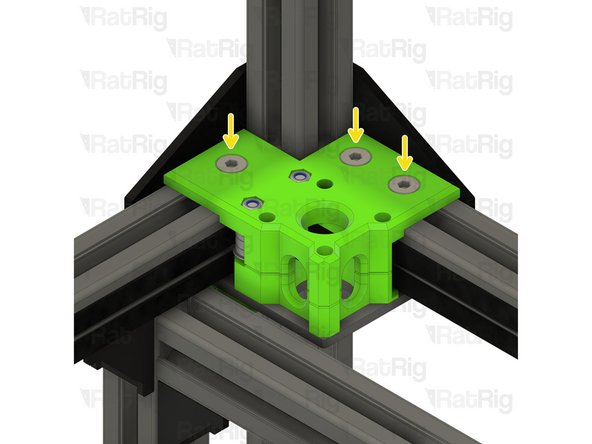

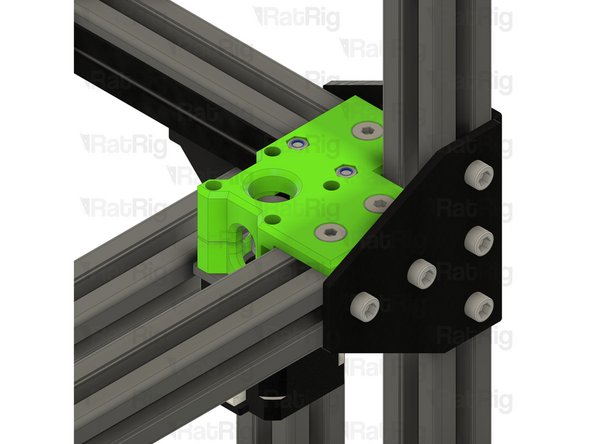

V-Core 3.1 Frame Assembly - Rear Right Corner

-

Right motor_plate assembly from Step 2

-

Install the right motor_plate assembly to the V-Core 3.1 frame as shown

-

Tighten the four M6x12 screws to secure the motor_plate assembly to the frame

-

Make sure the plate is fully seated against the 3030 extrusion before tightening the M6x12 screws

-

Insert two M5x40 Cap Head Screws into the motor_plate, as shown, in preparation for Step 14

-

-

-

3x M6x14 Countersink Screw

-

3x 3030 Drop-in T-Nut - M6

-

1x xy_motor_cage_bottom_right_3.1 Printed Part

-

1x xy_motor_cage_top_right_3.1_cutout Printed Part

-

6x F695ZZ Ball Bearing

-

3x 695ZZ Ball Bearing

-

5x Mini Precision Shim

-

2x M5 Nylon Locking Hex Nut

-

-

-

V-Core 3.1 Frame Assembly - Rear Right Corner

-

Install the following components in the order shown in the image:

-

Mini Precision Shim

-

F695ZZ Ball Bearing (Flange at the bottom)

-

695ZZ Ball Bearing

-

F695ZZ Ball Bearing (Flange at the top)

-

-

-

xy_motor_cage_bottom_right_3.1 Printed Part

-

Place the xy_motor_cage_bottom_right_3.1_cutout printed part as shown

-

The xy_motor_cage_bottom_right part will just sit on the plate for now, it will be secured in Step 20

-

-

-

Loose end of the bottom CoreXY belt

-

Form a loop as shown, this will be used to engage with the NEMA17 motor pulley

-

Position the bottom belt as shown

-

Loose end of the top CoreXY belt

-

Slot this end of the top CoreXY belt around the top bearing stack as shown

-

Make sure that both belts match the third image before proceeding

-

-

-

3030 Drop-in T-Nut - M6

-

xy_motor_cage_top_right_3.1_cutout Printed Part

-

M6x14 Countersink Screw

-

Loosely thread a 3030 T-Nut onto each of the M6x14 screws. Do not tighten them at this point.

-

M5 Nylon Locking Hex Nut

-

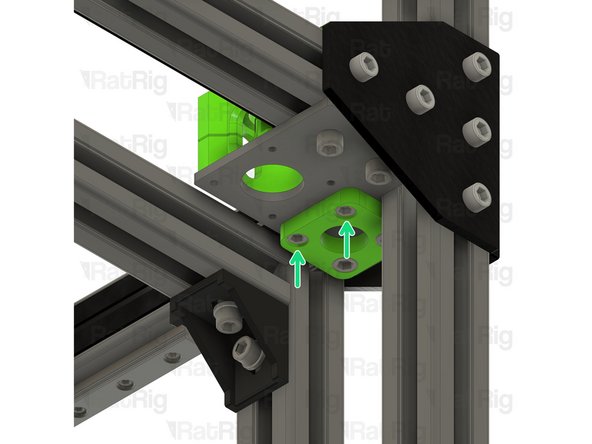

Install the xy_motor_cage_right_top assembly onto the frame as shown

-

Tighten the three marked M6x14 screws to secure the CoreXY motor cage top to the frame

-

Tighten the M5x40 screws, on the underside, to secure the bearing stacks into the CoreXY motor cage top

-

-

-

1x 20 Tooth 2GT Timing Pulley for 9mm Belt

-

1x 48mm NEMA17 Stepper Motor

-

4x M3x35 Cap Head Screw

-

-

-

20 Tooth 2GT Timing Pulley for 9mm Belt

-

Install the timing pulley onto the NEMA17 shaft, oriented as shown

-

Align one of the M3 grub screws on the timing pulley so that it will tighten against the flat on the NEMA17 shaft

-

Position the timing pulley so the marked gap is 3mm

-

Slightly tighten one of the M3 grub screws to hold the timing pulley in position for now

-

The timing pulley will be aligned and fully secured in the next step

-

Position the NEMA17 motor up and into the motor cage from below, it will be secured in the next step

-

-

-

Insert the M3x35 screws into the xy_motor_cage_right_top_3.1_cutout as shown, and fasten them to secure the NEMA17 motor to the mount

-

Check the alignment of the timing pulley, the belt should be on the middle of the pulley as shown

-

Adjust the pulley up or down if required to make sure the belt is in the middle of the pulley

-

Fasten both M3 grub screws to securely mount the timing pulley to the NEMA17 motor shaft

-

Cancel: I did not complete this guide.

18 other people completed this guide.