-

-

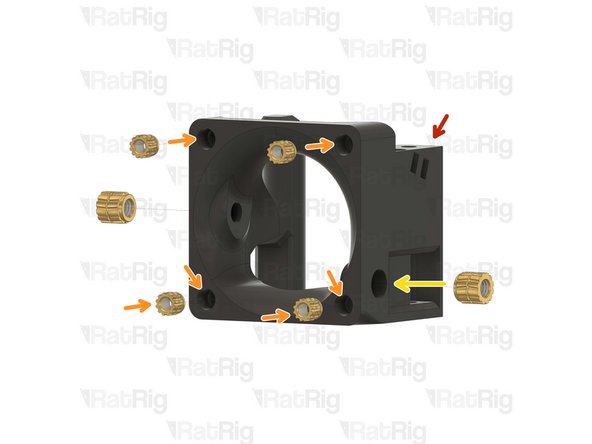

25x Heat Insert M3

-

2x Heat Insert M4

-

1x rr_vc4_toolhead_duct

-

2x rr_vc4_toolhead_back_clamp

-

1x rr_vc4_toolhead_front

-

1x rr_vc4_toolhead_toolboard_vertical

-

1x rr_vc4_toolhead_back

-

Clean the sacrificial layers on the rr_vc4_toolhead_back_clamp parts, obtaining a clean passthrough hole.

-

-

-

1x rr_vc4_toolhead_front

-

5x Heat Insert M3

-

2x Heat Insert M4

-

-

-

1x rr_vc4_toolhead_toolboard_vertical

-

4x Heat Insert M3

-

-

-

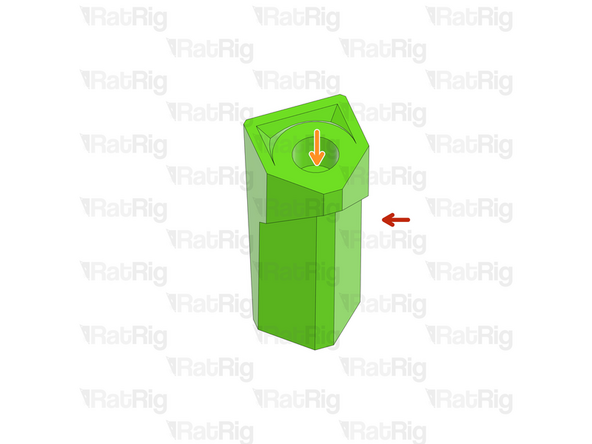

2x rr_vc4_toolhead_back_clamp

-

Remove the sacrificial layer

-

2x Heat Insert M3

-

-

-

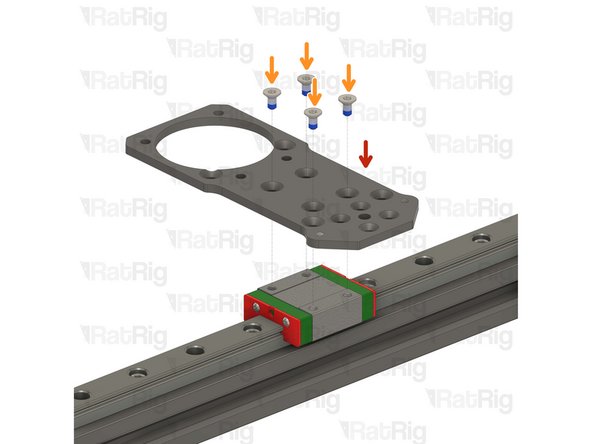

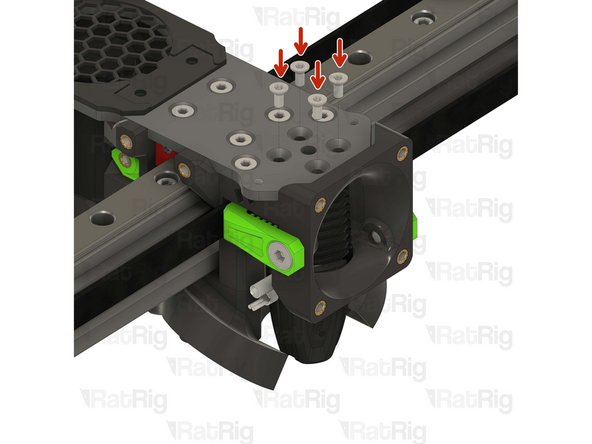

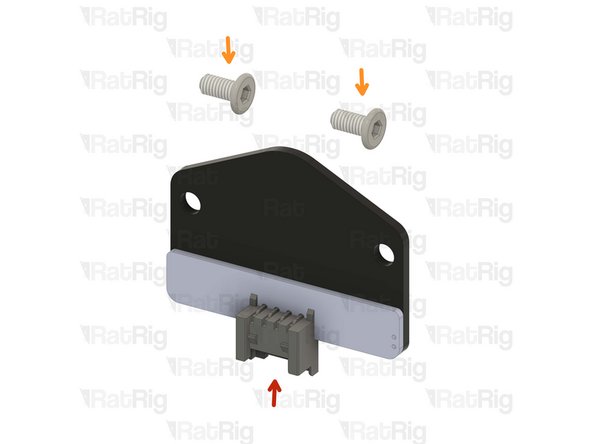

1x Rat Rig toolhead plate

-

4x M3x6 Countersink Screw with applied thread locker

-

-

-

Rat Rig toolhead plate

-

4x M3x6 Countersink Screw

-

Tighten the M3x6 Countersink Screws to secure the plate to the carriage.

-

Pay attention to the orientation of the metal plate, having the pointy side towards the front of the printer, chamfered holes up.

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

After tightening the screws, it is essential to verify that the X carriage retains its free movement. Excessive tightening of the screws may lead to the binding of the carriage.

-

-

-

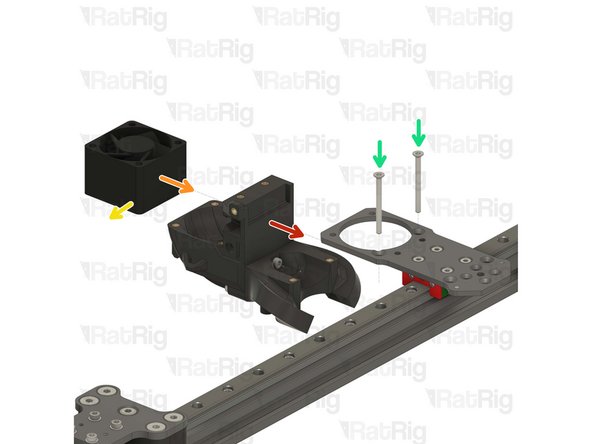

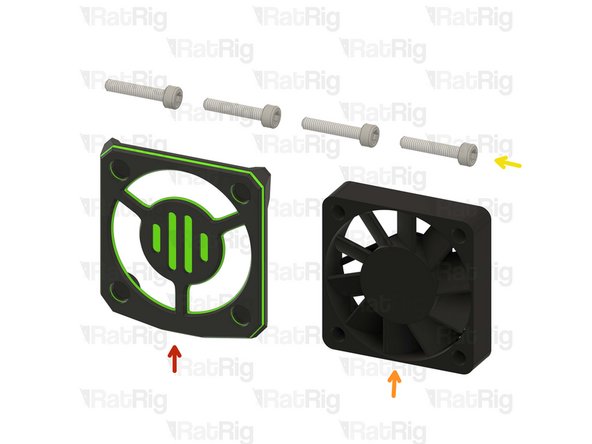

1x rr_vc4_toolhead_back

-

2x rr_vc4_toolhead_back_clamp

-

1x rr_vc4_toolhead_duct

-

1x 4028 Part Cooling Fan

-

2x M3x35 Countersink Screw

-

2x M3x35 Cap Head Screw

-

2x M3x16 Cap Head Screw

-

1x M3x8 Cap Head Screw

-

-

-

Remove the four rubber spacers on the 4028 Part Cooling Fan

-

-

-

Rat Rig toolhead back printed part

-

Rat Rig toolhead duct printed part

-

2x M3x16 Cap Head Screw

-

1x M3x8 Cap Head Screw

-

Insert the M3x16 screws through the back part and tighten them into the duct.

-

Feed the M3x8 screw from the opposite side and secure the parts together.

-

Take care not to over tighten the screws as you can damage the printed parts.

-

-

-

Back part & duct sub-assembly

-

4028 Part Cooling Fan

-

Pay special attention to the fan airflow, it should blow the air towards the cooling duct. Most fans have a small arrow indicating the airflow.

-

Point the fan wires to this side.

-

2x M3x35 Countersink Screw

-

Feed the M3x35 screws into the toolhead plate, through the 4028 part cooling fan and tighten them into the printed sub-assembly.

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

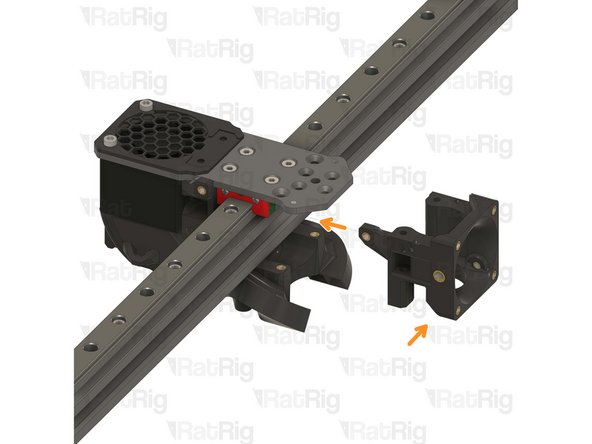

1x rr_vc4_toolhead_front

-

1x rr_vc4_toolhead_fan_grille

-

2x rr_vc4_toolhead_front_clamp

-

2x M4x10 Countersink Screw

-

2x M3x40 Countersink Screw

-

2x M3x35 Cap Head Screw

-

-

-

Rat Rig toolhead fan grille printed part

-

Rat Rig toolhead front printed part

-

2x M3x35 Cap Head Screw

-

Feed the M3x35 cap head screws through the grille (pay close attention to its orientation), the aluminium plate and the 4028 fan, tightening them into the back printed part.

-

2x M3x40 Countersink Screw

-

The M3x40 countersink screws must go through the holes on the front assembly and thread into the duct assembly.

-

Take care not to over tighten the screws as you can damage the printed parts

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M3 countersink screw head.

-

-

-

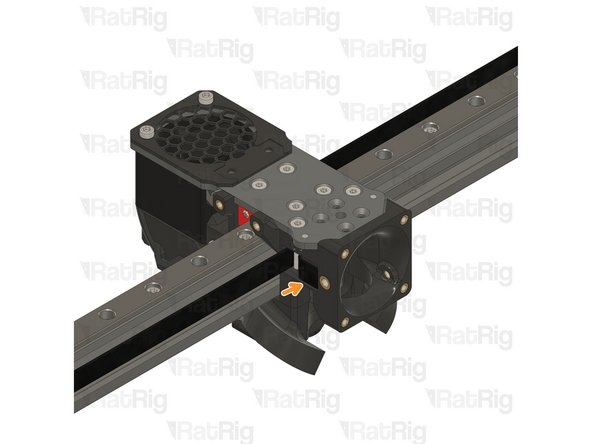

Insert the belt in the designated slot, and ensure the belt end is fed from behind the screw.

-

Pull the belt end and gently place it inside the groove.

-

The belt teeth must be facing the front of the machine.

-

-

-

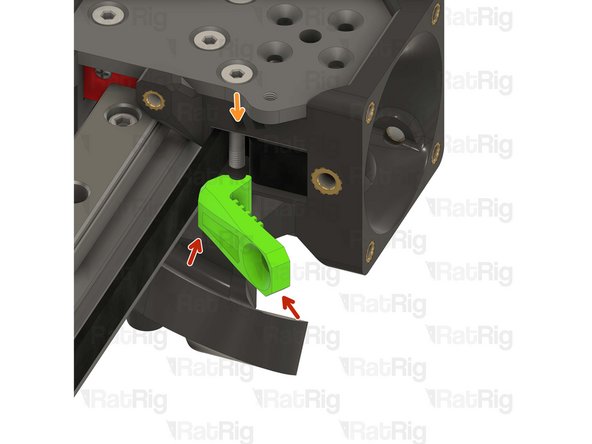

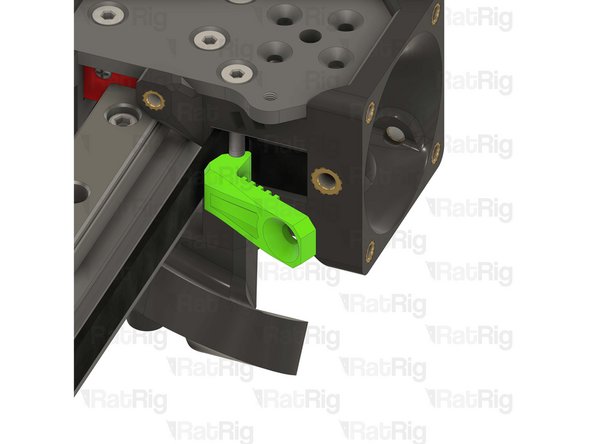

Rat Rig toolhead front belt clamp

-

Lever the belt clamp against the exposed screw section and place it inside the belt slot.

-

-

-

1x M4x10 Countersink Screw

-

Tighten the M4x10 screw making sure the teeth of the belt clamp mesh with the belt

-

Pay attention to seating the notch on the belt clamp on the exposed screw section. Pull on the belt to make sure it's secured properly.

-

Repeat Steps 15, 16 and 17 to attach the other belt

-

-

-

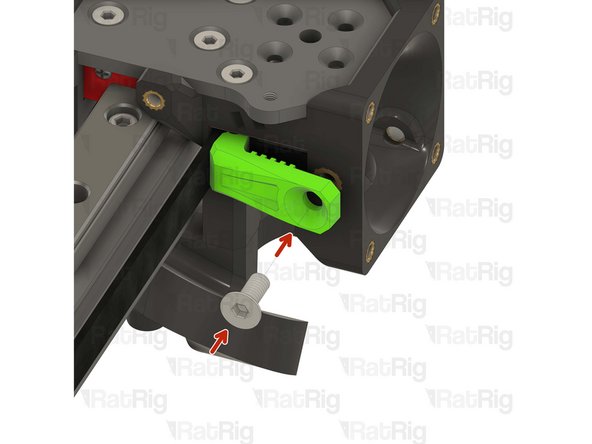

Feed the belt inside the slot on the back part of the toolhead.

-

Rat Rig toolhead back belt clamp

-

Insert the back belt clamp from the other side of the toolhead, while keeping some excess belt.

-

-

-

M3x35 Cap Head Screw

-

Tighten the M3x35 Cap Head screw while pulling on the belt from the other side.

-

-

-

Cut the excess belt.

-

Repeat Steps 18, 19 and 20 to attach the other belt.

-

The Hybrid belts will be installed later.

-

-

-

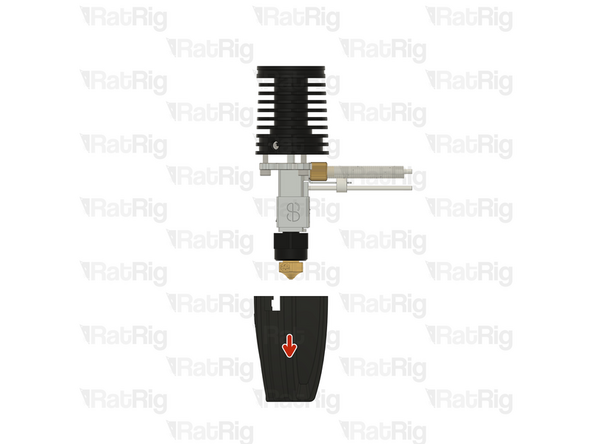

Phaetus Rapido V2 UHF Hotend

-

4x M2.5x6 Countersink Screw

-

PTFE tube - 24.5mm

-

Remove the two countersink screws on top of the rapido

-

Remove the V6-style adapter, it is not required for the RatRig toolhead

-

-

-

Phaetus Rapido V2 UHF

-

Place the Phaetus Rapido V2 UHF Hotend on the plate, making sure to route the cables through the designated slot

-

Look from above and see if all four holes line up correctly.

-

All the holes on the plate, hotend and printed part should line up:

-

If they align skip to Step 26

-

If they don't align follow the next steps

-

-

-

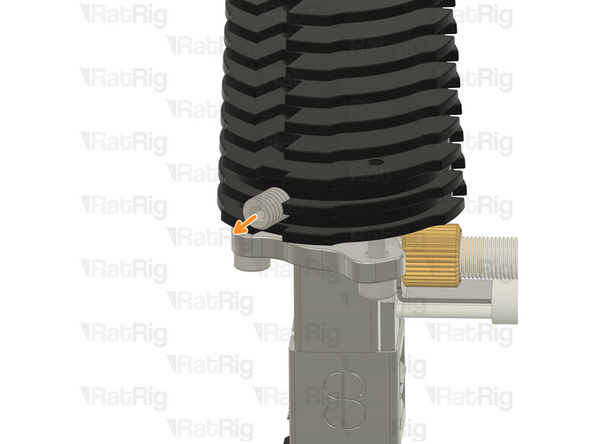

If the cables of your Rapido 2 hotend don't align perfectly with the toolhead slot, please follow the next steps:

-

Push down on the silicone sock to remove it

-

Loosen the set screw on the heatsink

-

Do not remove it completely to avoid losing it

-

-

-

Remove the 2.5mm Cap Head Screws from the hotend

-

Carefully rotate the heatsink until the three screw holes align again.

-

There isn't a way to tell how much you need to rotate you hotend, it might be just 120º or it might be 240º. It's a matter of trial and error.

-

-

-

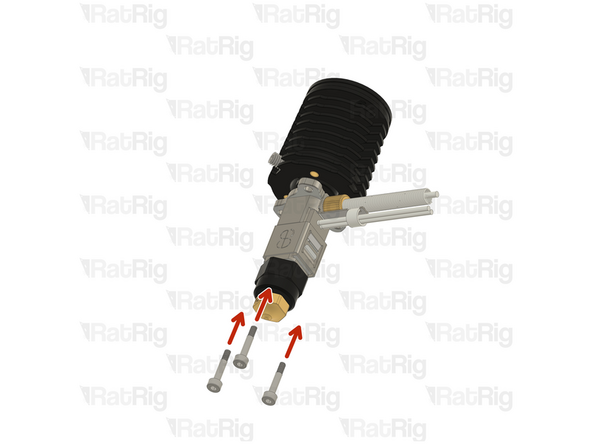

Insert the 2.5mm Cap Head Screws back in and tighten them.

-

DO NOT overtighten the screws, they are only 2.5mm and will break if excessive force is applied.

-

Tighten the set screw back in

-

DO NOT overtighten the screw, if excessive force is applied the heatbreak will be permanently damaged.

-

Put the socket back on

-

Try to insert the hotend on the toolhead and see if the cables align with the designated slot, if not, repeat Steps 23, 24 and 25 and try a different angle in Step 22

-

-

-

4x M2.5x6 Countersink Screw

-

Tighten the M2.5x6 Countersink Screws to secure the hotend to the plate.

-

Avoid using a ball end hex key, as they are more prone to damaging the sensitive M2.5 countersink screw head.

-

PTFE tube - 24.5mm

-

Insert the PTFE tube in to the marked hole and push it until it stops.

-

-

-

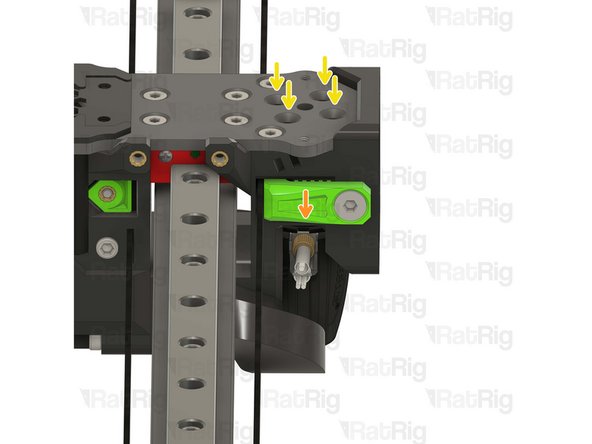

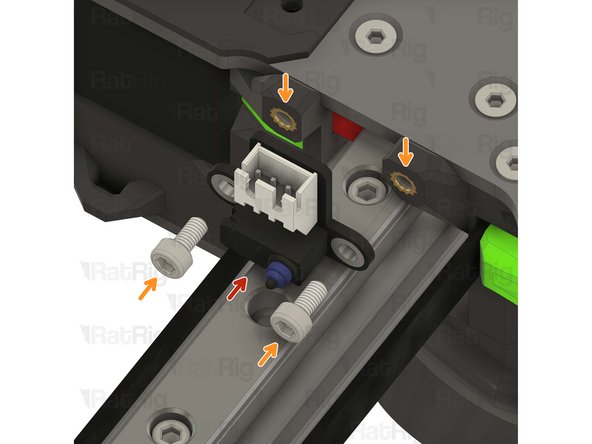

Rat Rig X Endstop

-

2x M3x6 Cap Head Screw

-

Tighten the M3x6 screws to secure the X endstop to the toolhead.

-

Take care not to over tighten the M3x6 screws as you can damage the printed parts.

-

-

-

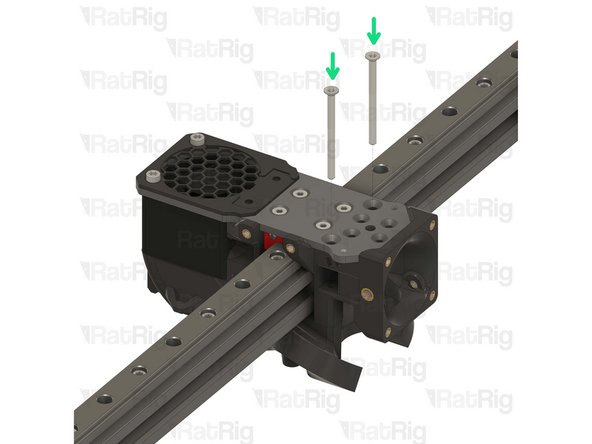

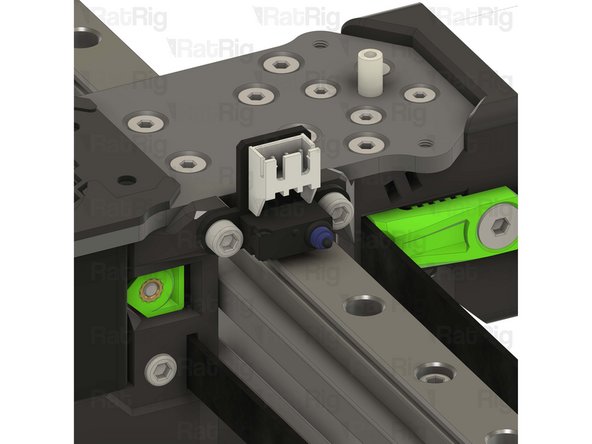

1x rr_vc4_toolhead_shroud

-

40x10mm 24V Axial Fan

-

4x M3x16 Cap Head Screw

-

Remove the sacrificial layers from the back of the rr_vc4_toolhead_shroud

-

-

-

Rat Rig toolhead fan shroud printed part

-

40x10mm 24V Axial Fan

-

The wires should be positioned where the arrow points.

-

4x M3x16 Cap Head Screw

-

Insert the M3x16 screws into the Rat Rig toolhead shroud printed part, through the 40mm fan, and fasten them into the Rat Rig toolhead front.

-

Take care not to over tighten the M3x16 screws as you can damage the printed parts.

-

Pay special attention to the fan airflow, it should blow the air towards the hot end heat sink. Most fans have a small arrow indicating the airflow. If not, the the fan label should be facing the hotend.

-

-

-

Remove the tensioning screw

-

Remove the two front screws

-

Carefully detach (or rotate) the stepper motor from the housing

-

-

-

Rotate the stepper motor 180º until the wires come out from the top.

-

Carefully reinstall the stepper on the housing.

-

Install the front screws

-

Install the tensioning screw

-

-

-

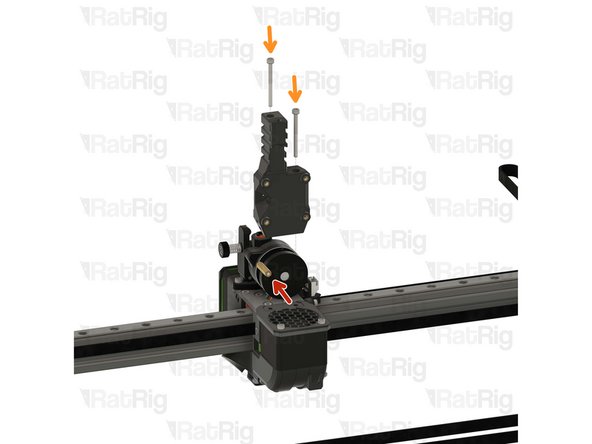

LDO Orbiter V2

-

2x M3x8 Cap Head Screw

-

Carefully align the extruder with the PTFE tube.

-

Insert the M3x8 screws into the LDO Orbiter V2 and fasten them to the Rat Rig toolhead plate.

-

Take care not to over tighten the M3x8 screws as you can strip the toolhead plate threads

-

-

-

Beacon Rev H Low Profile

-

Rat Rig recommends connecting the beacon's cable before mounting it to ensure the connector is fully and securely inserted.

-

2x M3x6 Wafer Head Screw

-

Tighten the M3x6 screws to secure the Beacon to the toolhead.

-

Take care not to over tighten the M3x6 screws as you can damage the PCB and the printed parts.

-

-

-

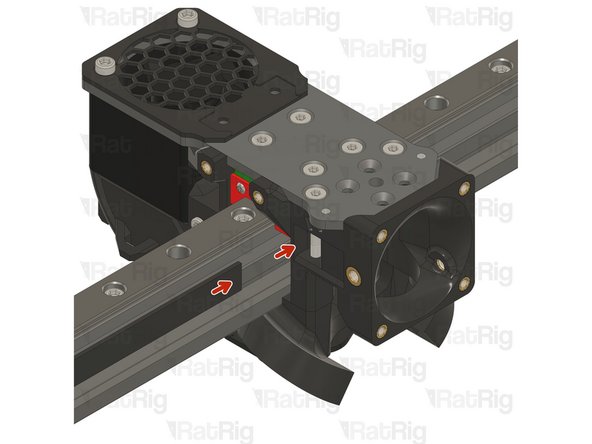

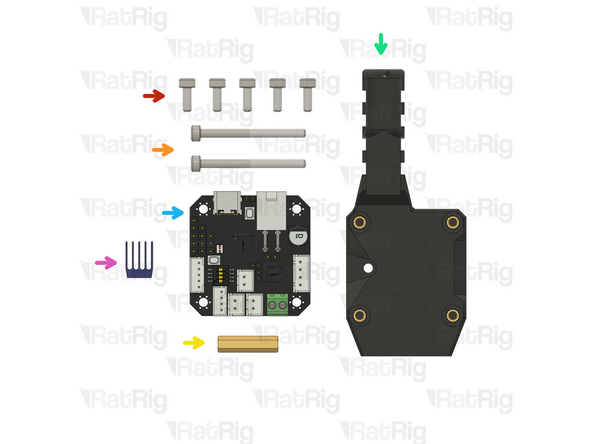

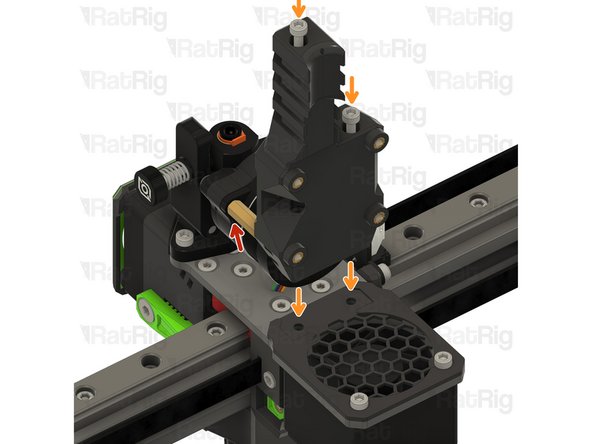

5x M3x8 Cap Head Screw

-

2x M3x35 Cap Head Screw

-

1x Hex standoff M3x20x4.5

-

rr_vc4_toolhead_toolboard_vertical

-

BIGTREETECH EBB42 USB/CAN TOOLBOARD V1.2

-

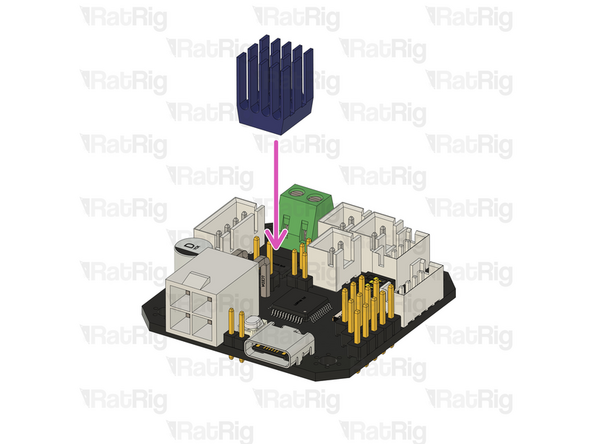

TMC2209 driver heatsink (included in the EBB42 box)

-

Remove the adhesive backing from the heatsink and gently press it onto the TMC2209 driver.

-

-

-

Thread the hex standoff on to the LDO Orbiter V2 screw.

-

Do not overtighten the hex standoffs. They are brass and it is possible to strip the threads.

-

Insert the M3x35 screws into the Rat Rig toolhead vertical toolboard mount printed part and secure it onto the toolhead.

-

Take care not to over tighten the M3x35 screws as you can damage the printed parts.

-

1x M3x8 Cap Head Screw

-

Insert the M3x8 screw through the printed part and into the thread to attach it to hex standoff.

-

-

-

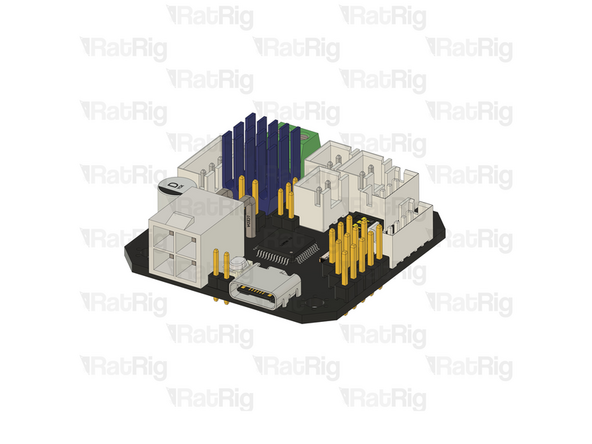

BIGTREETECH EBB42 USB/CAN TOOLBOARD V1.2

-

4x M3x8 Cap Head Screw

-

Insert the M3x8 screws into the toolboard and thread them into the Rat Rig toolhead vertical toolboard mount printed part

-

-

-

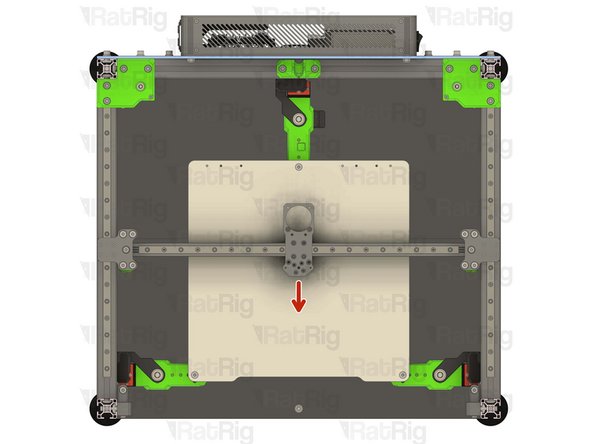

Your V-Core 4 now has the Rat Rig Toolhead installed and it's ready to melt some filament!

-

Cancel: I did not complete this guide.

21 other people completed this guide.

2 Comments

I would have prefered the change of connector being described here and not in chapter 12

JeanPhi 35 - Resolved on Release Reply