-

-

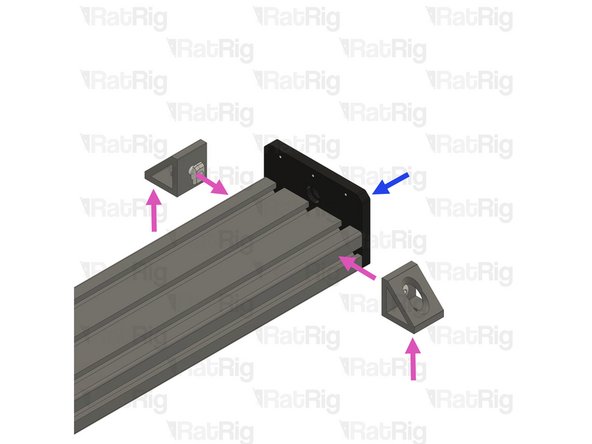

1x T-Slot extrusion 40120 - 502mm

-

1x Rat Rig StrongHold ONE CNC TopPlate

-

3x M12x25 Cap Head Screw

-

3x M12 Washer

-

1x Mill front Y plate

-

3x M12x25 Countersink screws

-

40-series brackets

-

2x M8x16 Button head screw + 2x M8 4040 Drop in T-nuts

-

-

-

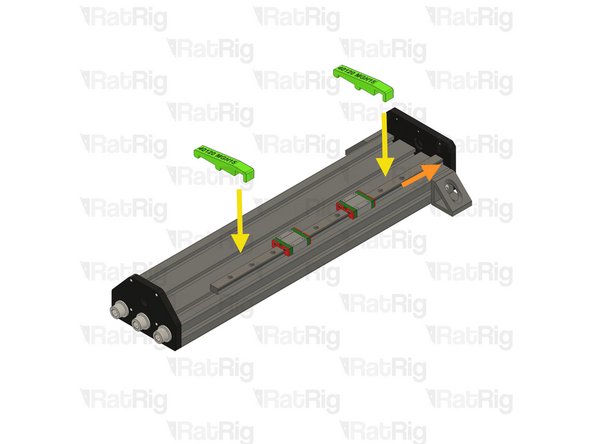

T-Slot extrusion 40120 - 502mm

-

Rat Rig StrongHold ONE CNC TopPlate

-

3x M12 Washer

-

3x M12x25 Cap Head Screw

-

Ensure the bearing groove is facing towards the T-Slot extrusion.

-

Secure the plate to one end of the extrusion as shown.

-

-

-

Mill front Y plate

-

3x M12x25 Countersink screws

-

Both plates must be facing upwards.

-

Ensure the bearing groove is facing towards the T-Slot extrusion.

-

On the Mill front Y plate side:

-

Install the two 40-series brackets.

-

-

-

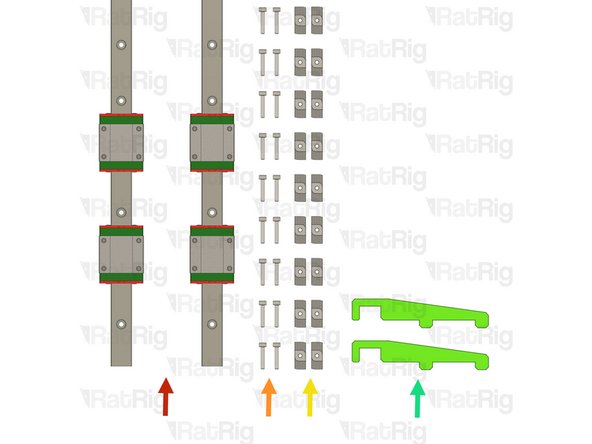

2x Linear Rail - MGN15 420mm + 2 x MGN15C carriage

-

20x M3x16 Cap Head screws

-

20x 4040 Drop-in T-Nut - M3

-

2x align_40120_mgn15 printed part

-

-

-

The linear rails are supplied with a protective oil coating on them. It is strongly recommended to prepare your work surface with paper towels and to wear disposable gloves.

-

Paper Towels

-

Linear Rail

-

With the rail still on the absorbent paper towels, carefully and slowly move the carriage from one end of the rail to the other

-

Small changes in resistance are normal, but the carriage becoming very hard to push, or binding completely are not

-

If the carriage does not move smoothly, or binds completely, refer to the Linear Rail Troubleshooting Guide

-

The linear rail carriages are not interchangeable. Do not try to use a carriage on a different linear rail than the one it was supplied with.

-

Check this guide if one or more carriages don't move smoothly.

-

-

-

Do not allow the linear rail carriages to leave the end of the rail at any point

-

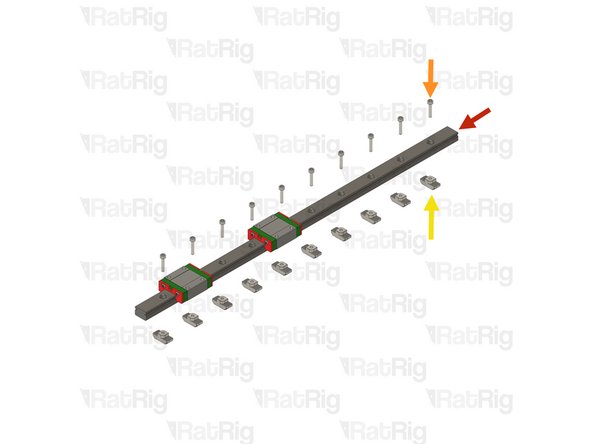

MGN15 Linear Rail

-

Insert an M3x16 cap head screw in each of the holes on the linear rail

-

Loosely thread a 4040 T-Nut on to each of the M3x16 screws

-

Repeat these instructions for the second linear rail

-

-

-

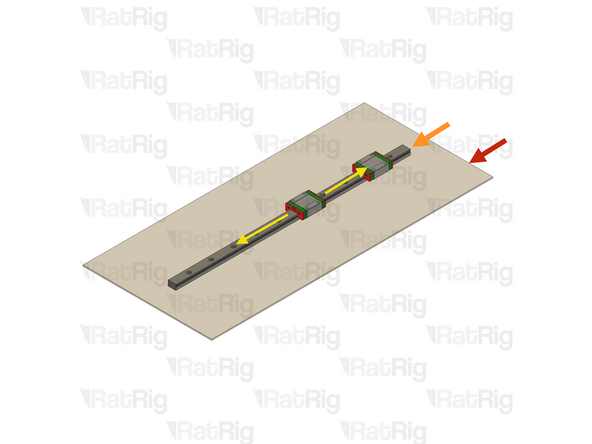

Place one Y linear rail assembly on the designated T-slot.

-

Ensure the Y rail is sitting flush against the Mill front Y plate.

-

Insert the two align_40120_mgn15 printed jigs in the T-Slot and rail.

-

Make sure the align_40120_mgn15 printed jigs are correctly placed and centering the rail on the T-slot

-

Tighten the linear rails screws one at a time starting from the front and making your way towards the back, one by one.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

-

-

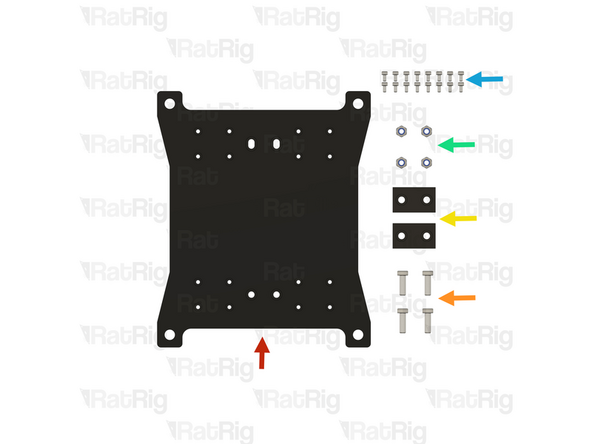

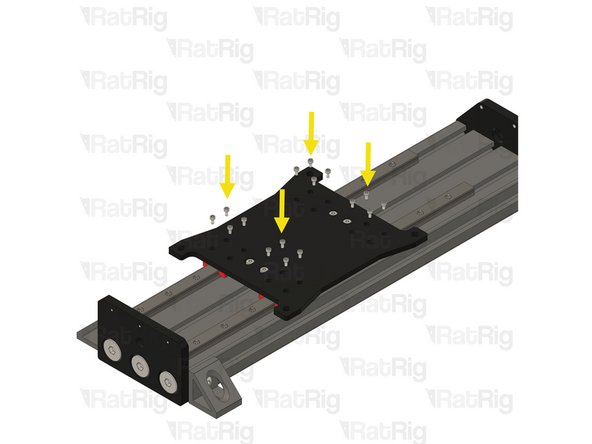

Rat Rig Mill - Y Gantry Plate

-

4x M5x16 Low Head Screw

-

2x Nut Block for TR8x8

-

Do not misplace the TR8x8 blocks with the TR8x4 blocks. If uncertain, test by threading them onto the TR8x8 lead screw.

-

4x M5 Nylon Locking Hex Nuts

-

16x M3x6 Cap Head Screws

-

-

-

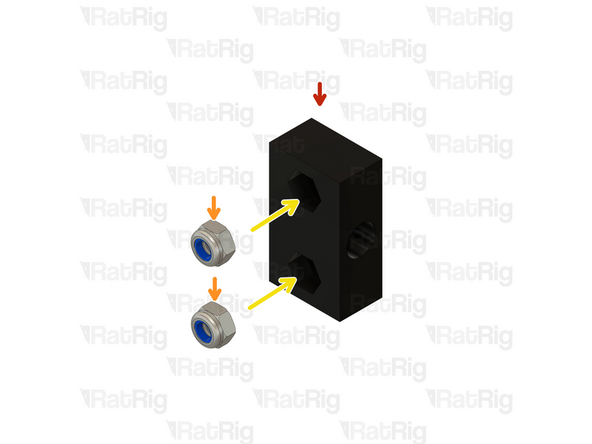

Nut Block for TR8x8

-

M5 Nylon Locking Hex Nut

-

Insert the M5 Locking Hex Nuts in to the Nut Block

-

Prepare two assemblies.

-

-

-

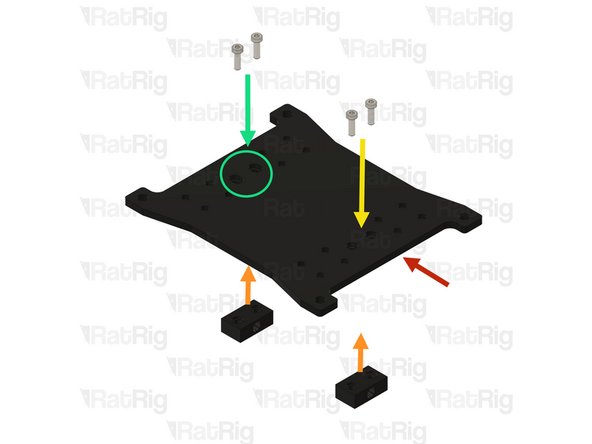

Rat Rig Mill - Y Gantry Plate

-

Ensure that the Y gantry plate is not mistaken for the X gantry plate. The X gantry plate features M3 threaded holes along its edges, whereas the Y gantry plate does not.

-

Nut Block for TR8x8 assembly from the last step.

-

The M5 Nylon Locking Hex Nuts, must be facing away from the Y gantry plate.

-

Gently tighten the M5x16 Low Head Screws on the designated holes.

-

Do not overtighten the screws as it will cause binding in the lead screw. Tighten until the nut block is flush with the plate and add half a turn on the screws.

-

Thread the M5x16 Low Head Screws on the designated slot, Do not tighten this Nut Block, it will be adjusted later.

-

These Screws must be installed on the M5 slot in the Y gantry plate.

-

-

-

Place the second Y linear rail assembly on the T-slot but DO NOT tighten the screws.

-

Install the Y Joiner assembly on the linear rails.

-

Using the 16x M3x6 Cap Head screws, fasten the XY joiner plate assembly to the mgn15 carriages.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

Tip: Blue thread lock can be added to the thread of the M3x6 Cap Head screws.

-

-

-

While the second linear rail remains loose, the Y plate should move smoothly without resistance. If you experience any binding or drag, slightly loosen the carriage screws, as they may be overtightened.

-

Be careful to ensure that the Y joiner plate carriages do not detach from the linear rail during the process.

-

Move the Y joiner fully to the front as demonstrated. Then, gradually move it toward the back, exposing one linear rail screw at a time, and tighten each screw as you progress.

-

Ensure that all linear rail screws are tightened from front to back. Avoid overtightening, as this may cause binding and restrict movement.

-

MGN15 Rails should be tightened to 98 N-cm of torque, overtightening the screws will result in rail binding.

-

Move the Y plate assembly slightly back to gain access to the last screws on the linear rail.

-

At this stage, the joiner plate should move back and forth smoothly. Test its movement to ensure it operates freely. If you encounter any resistance, adjust the screw tension as needed until the assembly moves without friction.

-

-

-

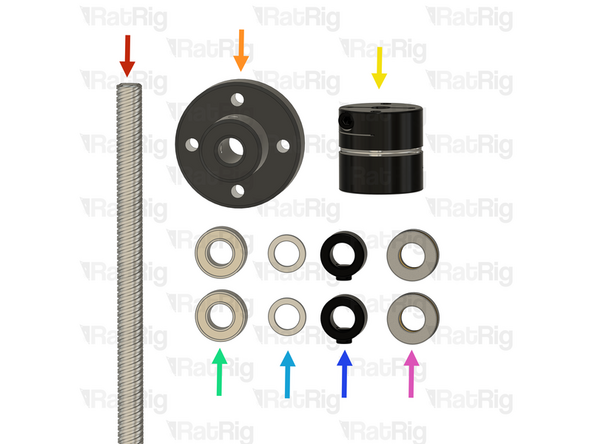

Leadscrew - TR8x8 Metric - 565mm

-

Jog Knob

-

Coupler - Disc Type

-

2x Ball Bearing 688ZZ

-

2x Shim - 12 x 8 x 1mm

-

2x Lock Collar

-

2x Thrust Bearing F8-16M

-

-

-

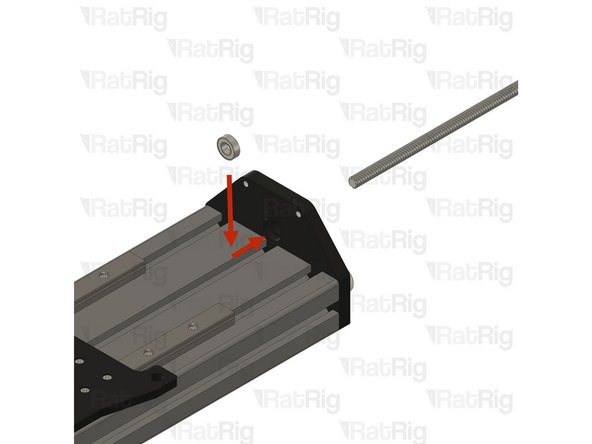

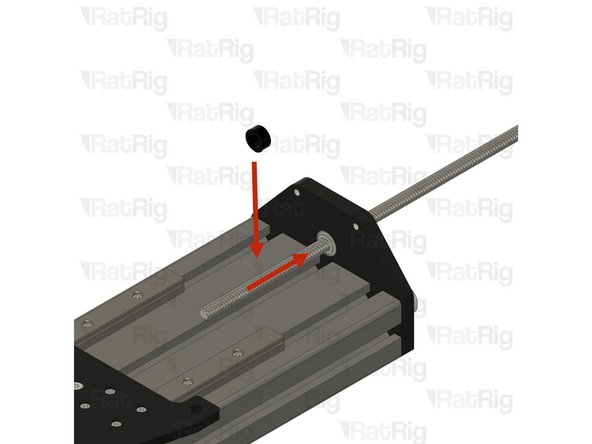

688ZZ Ball bearing

-

Push the ball bearing against the inner side of the plate, ensuring it stays inside the designated groove.

-

Push the Lead Screw through the hole in the ball bearing

-

Precision Shim 12x8x1mm

-

Slide the Precision Shim on to the Lead Screw

-

-

-

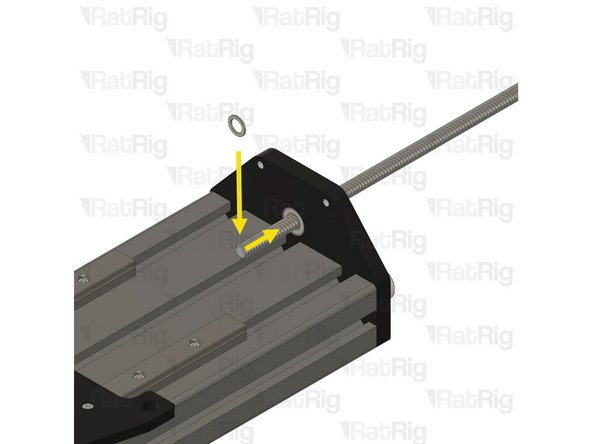

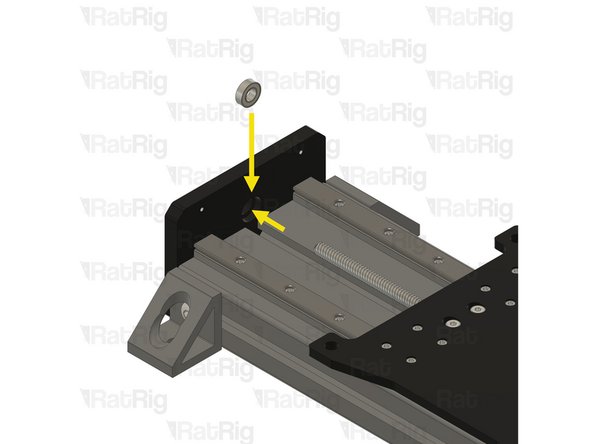

Lock Collar

-

Slide the Lock Collar on to the Lead Screw

-

Insert the lead screw until it reaches the Y joiner plate.

-

Screw the Lead Screw through both Nut Blocks under the Y joiner plate.

-

-

-

While threading the lead screw, ensure that it moves smoothly. It should thread effortlessly while the second POM block remains loose.

-

Gently tighten the screws on the second POM block while rotating the lead screw by hand. Monitor the resistance carefully—as soon as you feel any increase in resistance, stop tightening. Avoid over-tightening, as this could introduce unnecessary drag to the system.

-

Gently pull and push the lead screw along its axis to check for backlash. There should be no play when performing this movement. If you detect any play, tighten the screws slightly and test again. Repeat this process until the play is fully eliminated, ensuring a secure fit without introducing excessive resistance.

-

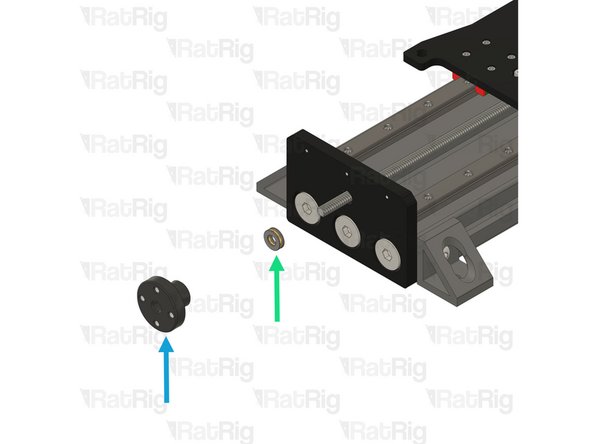

688ZZ Ball bearing - Push the ball bearing against the inner side of the plate, ensuring it stays inside the designated groove.

-

Precision Shim 12x8x1mm - Prepare the Shim to be inserted in the lead screw.

-

-

-

Lock Collar

-

The Precision Shim 12x8x1mm should be in between the 688ZZ Ball bearing and the Lock Collar

-

Insert the lead screw in the following order: lock collar, precision shim, and ball bearing.

-

Thrust Bearing F8-16M

-

Install the Thrust Bearing on to the exposed end of the Lead Screw as shown

-

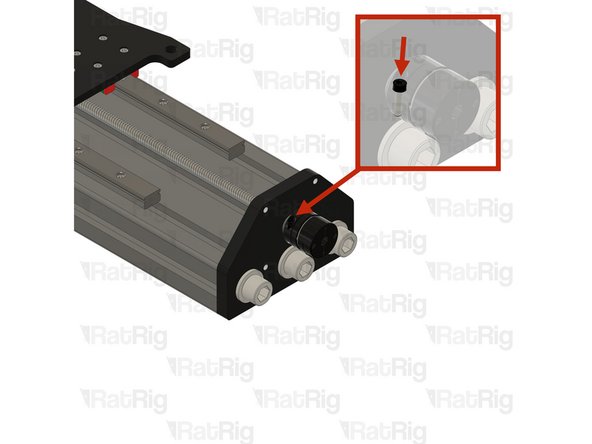

Jog wheel

-

Install the Jog wheel on to the exposed end of the Lead Screw as shown

-

-

-

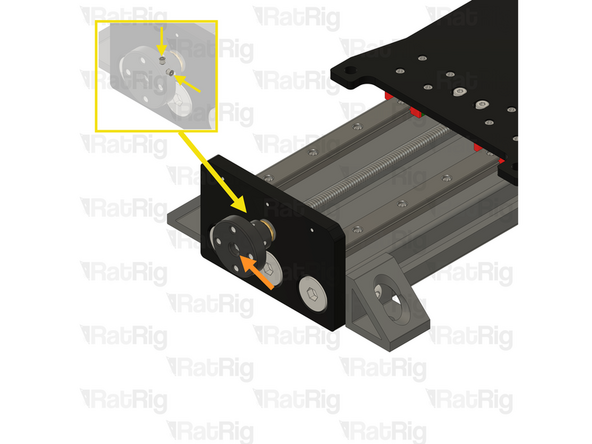

Install the Jog wheel on to the exposed end of the Lead Screw as shown

-

Ensure the lead screw surface is roughly1-2mm inside the jog wheel

-

After positioning the jog wheel, tighten the two set screws to secure it in place.

-

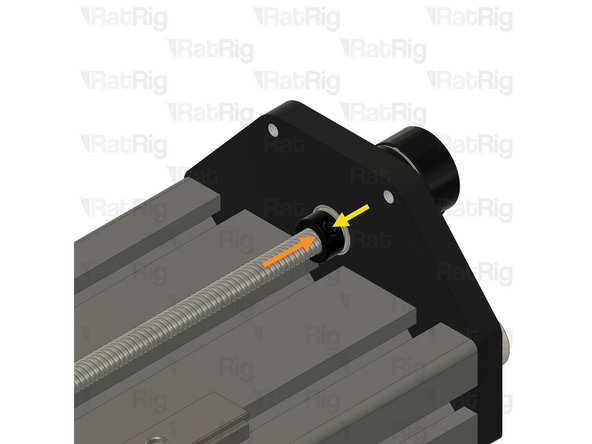

Pull the Y joiner plate away from the jog wheel, as to ensure the jog wheel and thrust bearing sit tight against the front Y plate.

-

Excessive force is unnecessary, as it may cause the lead screw to bind.

-

Push the lock collar against the Y front plate.

-

Tighten the set screw on the lock collar to secure it in place.

-

-

-

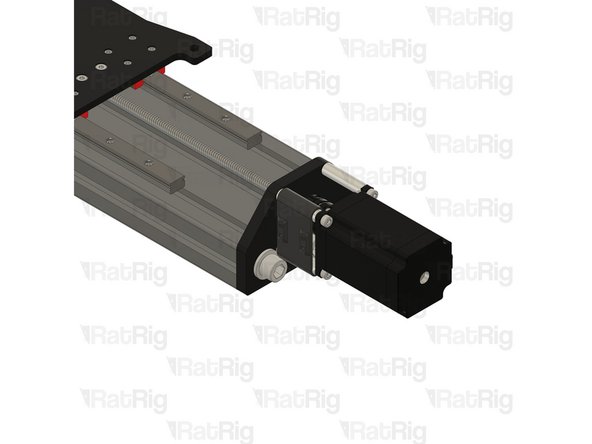

Thrust Bearing F8-16M

-

Install the Thrust Bearing on to the exposed end of the Lead Screw as shown

-

Coupler - Disk Type

-

Install the Coupler on to the exposed end of the Lead Screw.

-

-

-

Gently push the coupler against the Thrust Bearing and tighten the set screw.

-

Push the lock collar against the Y rear plate.

-

Tighten the set screw on the lock collar to secure it in place.

-

Rotate the coupler to verify that the lead screw moves smoothly and the Y joiner plate operates as expected.

-

-

-

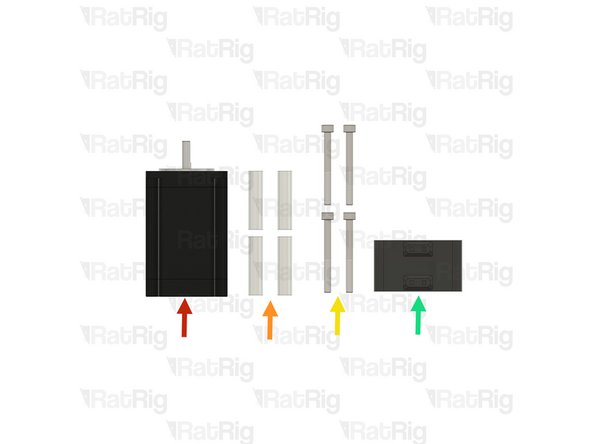

Nema 23 Stepper Motor High Torque

-

4x 40mm Aluminium Spacer

-

4x M5x50 Cap Head Screw

-

mill_stepper_cable_management printed part

-

-

-

4x 40mm Aluminium Spacer

-

Nema 23 Stepper Motor High Torque

-

4x M5x50 Cap Head Screw

-

Assemble the components above as shown.

-

Tighten the set screw on the coupler, to secure the stepper motor shaft to it.

-

-

-

Insert the mill_stepper_cable_management printed part as shown.

-

Almost done!

Finish Line