-

-

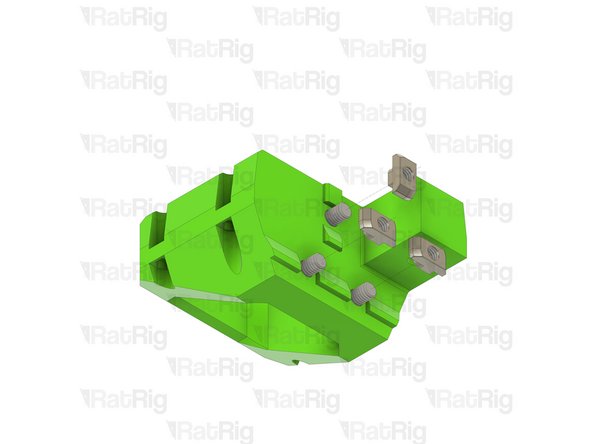

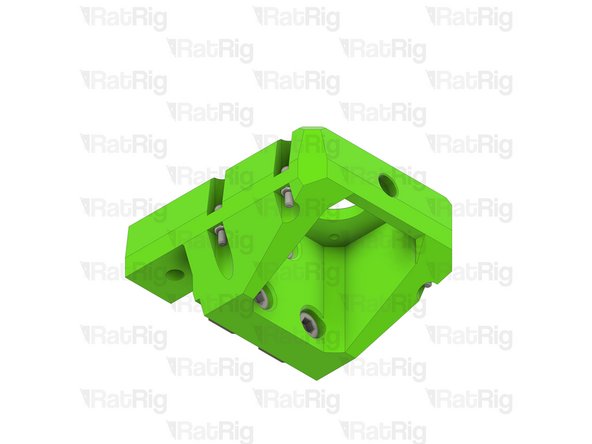

2x lead_screw_motor_cage_front_3.1 printed part

-

2x Axial Thrust Bearing

-

2x pillow_block printed part

-

2x Rigid Lead Screw Coupler

-

2x 48mm NEMA17 Stepper Motor

-

-

-

8x M3x18 Cap Head Screw

-

8x M6x20 Cap Head Screw

-

8x 3030 Drop-in T-Nut - M6

-

8x M3 Nylon Locking Hex Nut

-

8x M3x12 Cap Head Screw

I didn't get any M3x18 cap head screw with my order. Can I use m3x20 screw instead of m3x18?

Ugur Guver - Resolved on Release Reply

-

-

-

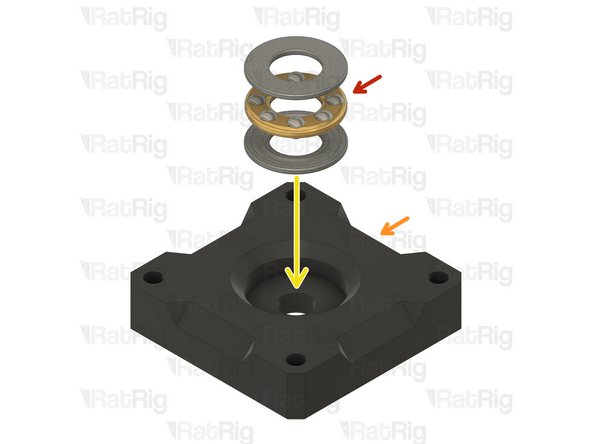

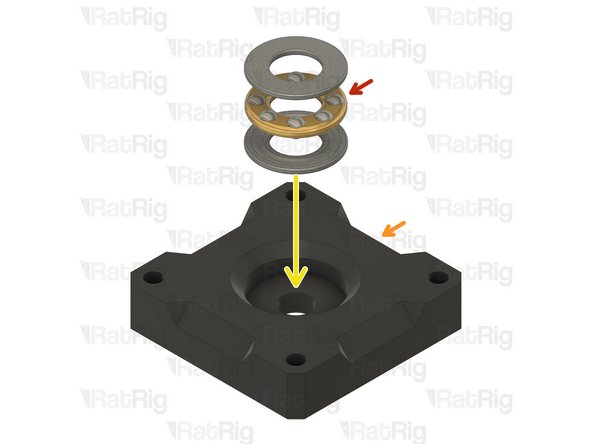

Axial Thrust Bearing

-

The axial thrust bearing has three components. Two end caps and an inner bearing assembly.

-

pillow_block printed part

-

Assemble the axial thrust bearing into the pillow_block as shown

-

Make sure that the thrust bearing is fully inserted into the printed part. The top ring of the thrust bearing should be flush with the top of the pillow_block.

-

If desired, you may add a drop of light oil to the inner bearing assembly of the thrust bearing

-

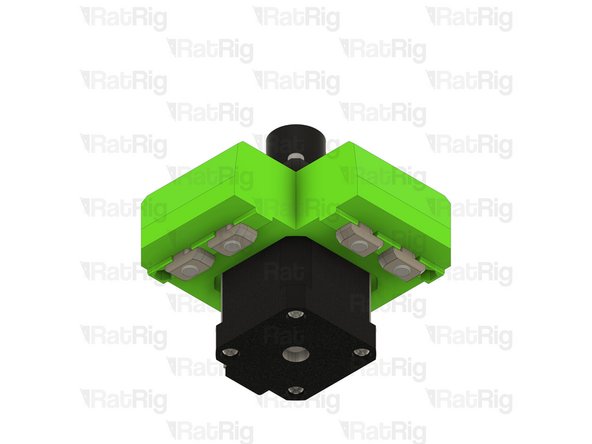

lead_screw_motor_cage_front_3.1 printed part

-

Place the pillow_block assembly atop the lead_screw_motor_cage_front_3.1 in preparation for the next step

-

-

-

pillow_block and axial thrust bearing assembly

-

lead_screw_motor_cage_front_3.1 printed part

-

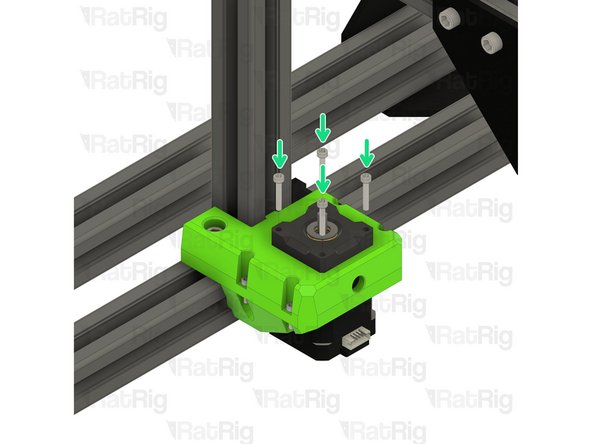

M3x18 Cap Head Screw

-

48mm NEMA17 Stepper Motor

-

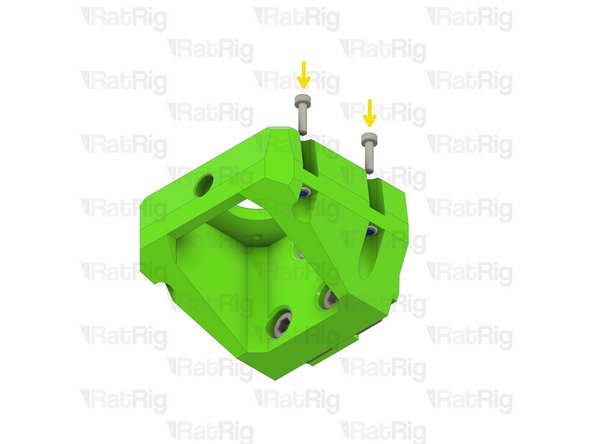

Insert the NEMA17 motor into the lead_screw_motor_cage printed part, as shown

-

Insert each M3x18 cap head screw through the pillow block, the lead screw motor cage, and fasten them into the NEMA17 motor

-

Take care not to over tighten the M3x18 screws as you can damage the printed parts

-

-

-

Assembly from the previous step

-

Rigid Lead Screw Coupler

-

Install the lead screw coupler on to the exposed shaft of the NEMA17 motor

-

Apply downward pressure to the top of the lead screw coupler whilst tightening the marked screw

-

Tighten the marked M3 screw to secure the lead screw coupler to the motor shaft

-

-

-

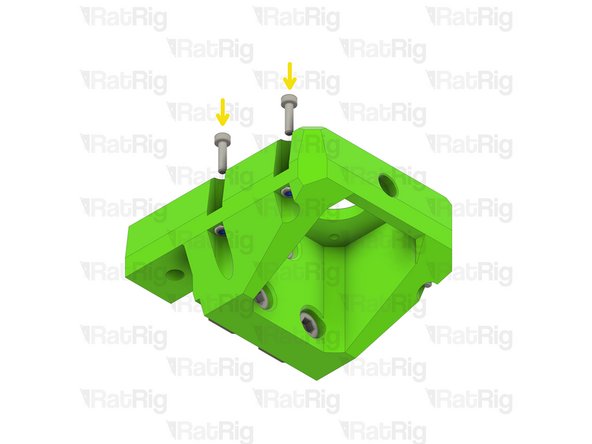

M6x20 Cap Head Screw

-

Insert each M6x20 cap head screw into the lead screw motor mount as shown

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x20 screws. Do not tighten them at this point.

-

-

-

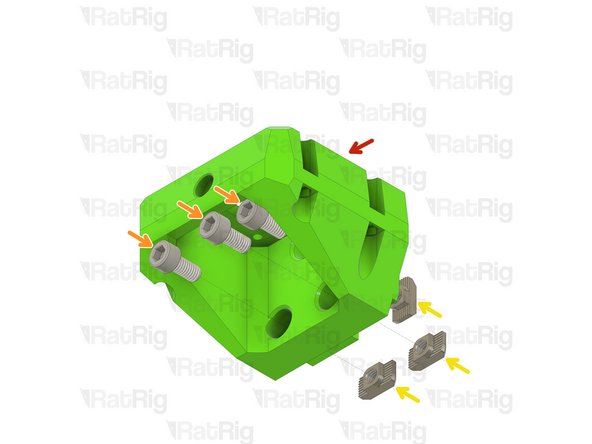

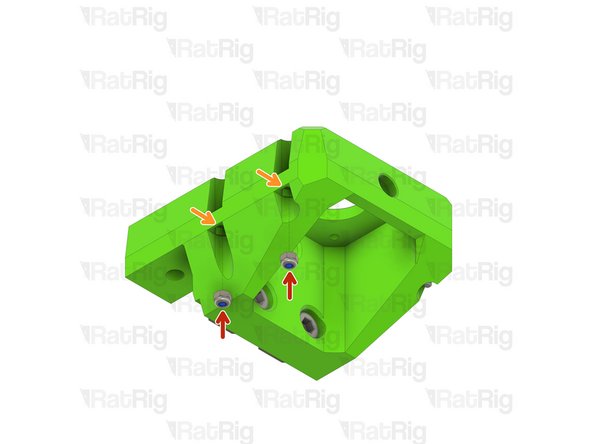

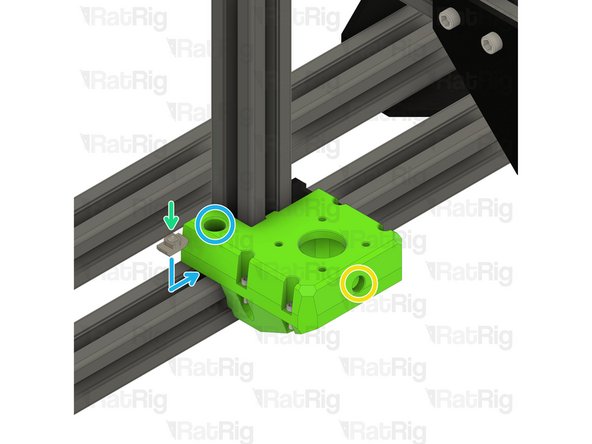

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

Do not worry about fully seating the M3 nuts into the mount, this will be done in the next step

-

-

-

M3x12 Cap Head Screw

-

Insert each M3x12 cap head screw into the lead screw motor mount as shown

-

Slowly tighten the each screw to seat the M3 nut below

-

Take care not to over tighten the M3x12 screws as you can damage the printed part

-

These screws are used to mount the optional printed trim part when using a base panel

-

-

-

Repeat Steps 3 to 8 to assemble the right Z-axis motor mount

-

Once you have both front Z-axis motor mounts assembled as shown, proceed to the next step

-

-

-

lead_screw_motor_cage_rear_3.1 printed part

-

pillow_block printed part

-

Axial Thrust Bearing

-

48mm NEMA17 Stepper Motor

-

Rigid Lead Screw Coupler

-

-

-

4x M3x18 Cap Head Screw

-

1x M6x20 Cap Head Screw

-

3x M6x12 Cap Head Screw

-

4x 3030 Drop-in T-Nut - M6

-

4x M3x12 Cap Head Screw

-

4x M3 Nylon Locking Hex Nut

-

-

-

Axial Thrust Bearing

-

The axial thrust bearing has three components. Two end caps and an inner bearing assembly.

-

pillow_block printed part

-

Assemble the axial thrust bearing into the pillow_block as shown

-

Make sure that the thrust bearing is fully inserted into the printed part. The top ring of the thrust bearing should be flush with the top of the pillow_block.

-

If desired, you may add a drop of light oil to the inner bearing assembly of the thrust bearing

-

Set the pillow block assembly aside until Step 17

-

-

-

lead_screw_motor_cage_rear_3.1 printed part

-

M6x12 Cap Head Screw

-

Insert each M6x12 cap head screw into the lead screw motor cage as shown

-

3030 Drop-in T-Nut - M6

-

Loosely thread a 3030 T-Nut onto each of the M6x20 screws. Do not tighten them at this point.

This should read loosely thread 3030 T-nut onto m6x12 screws. Do not tighten them at this point

Todd schisler - Resolved on Release Reply

-

-

-

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

M3x12 Cap Head Screw

-

Insert each M3x12 cap head screw into the lead screw motor cage as shown

-

Slowly tighten the each screw to seat the M3 nut below

-

Take care not to over tighten the M3x12 screws as you can damage the printed part

-

These screws are used to mount the optional printed trim part when using a base panel

Don’t worry about deciding which 2 you are doing. You are doing all 4 - see next step.

Donald Fast - Resolved on Release Reply

-

-

-

M3 Nylon Locking Hex Nut

-

Insert an M3 nut into each marked position

-

M3x12 Cap Head Screw

-

Insert each M3x12 cap head screw into the lead screw motor cage as shown

-

Slowly tighten the each screw to seat the M3 nut below

-

Take care not to over tighten the M3x12 screws as you can damage the printed part

-

These screws are used to mount the optional printed trim part when using a base panel

-

-

-

V-Core 3.1 Frame Assembly

-

Install the rear lead screw motor cage onto the frame as shown

-

The rear lead screw motor cage is designed so that it can only be installed in the correct position. If the part doesn't fit correctly, check the position of the 3030 T-nuts and make sure it is positioned as shown

-

Tighten the three M6x12 screws inside the rear lead screw motor cage to secure it to the frame. The top M6x12 screw can be accessed through the marked hole

-

3030 Drop-in T-Nut - M6

-

Place the 3030 T-nut into the extrusion channel and slide it under the lead screw motor cage as shown. Position the T-nut so that you are able to see it through the marked hole

-

M6x20 Cap Head Screw

-

Insert the M6x20 screw as shown and secure it into the previously positioned 3030 T-nut

-

-

-

pillow_block and axial thrust bearing assembly

-

M3x18 Cap Head Screw

-

48mm NEMA17 Stepper Motor

-

Insert the NEMA17 motor into the rear lead screw motor cage printed part, as shown

-

Insert each M3x18 cap head screw through the pillow block, the lead screw motor cage, and fasten them into the NEMA17 motor

-

Take care not to over tighten the M3x18 screws as you can damage the printed parts

-

-

-

Rigid Lead Screw Coupler

-

Install the lead screw coupler on to the exposed shaft of the NEMA17 motor

-

Apply downward pressure to the top of the lead screw coupler whilst tightening the marked screw

-

Tighten the marked M3 screw to secure the lead screw coupler to the motor shaft

If you purchased a set of Mandala Rose Works Z motor mounts you must install the bottom plate after step 17 and before step 18.

Michael Discala - Resolved on Release Reply

-

-

-

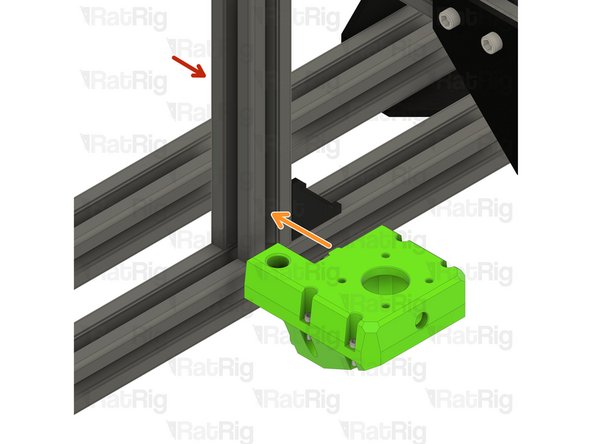

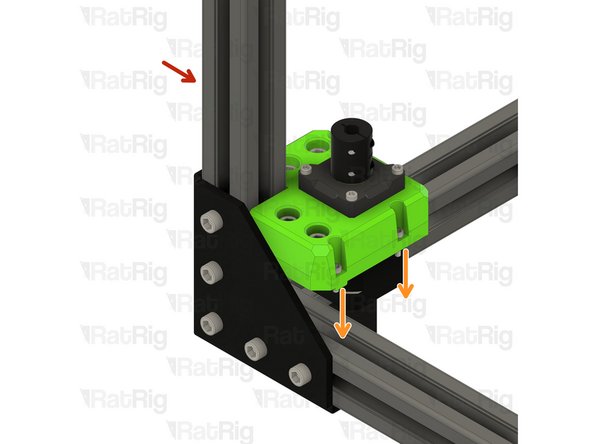

V-Core 3.1 Frame Assembly - Front Left Corner

-

Install the front left lead screw motor cage onto the frame as shown

-

The front lead screw motor cages are designed so that they can only be installed in the correct position. If the part doesn't fit correctly, check the position of the 3030 T-nuts and make sure the assembly is positioned as shown

-

Tighten the four marked M6x12 screws to secure the front lead screw motor cage to the frame

-

-

-

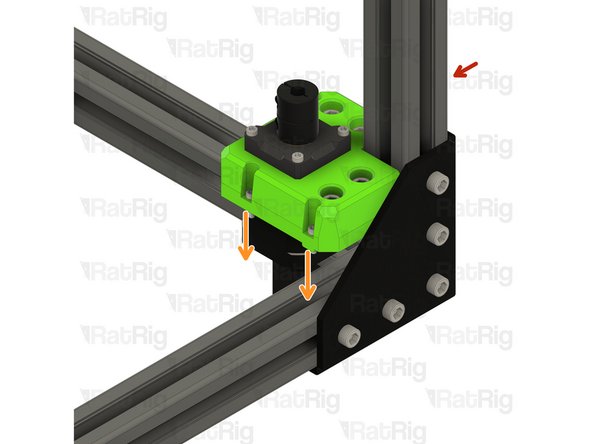

V-Core 3.1 Frame Assembly - Front Right Corner

-

Install the front right lead screw motor cage onto the frame as shown

-

The front lead screw motor cages are designed so that they can only be installed in the correct position. If the part doesn't fit correctly, check the position of the 3030 T-nuts and make sure the assembly is positioned as shown

-

Tighten the four marked M6x20 screws to secure the front lead screw motor cage to the frame

-

-

-

Continue with the next guide: 03. Linear Rails

This is a good moment to install a base panel. I wired the Z-stepper motors (wire in the extrusion) after that I installed the base panel and the trims. I routed the stepper wires to the backside and tie ripped them temporarily to the electronic panel. This way I don't have to flip over the frame to install the wires to the Z-steppers later ion.

Flip Breukers - Resolved on Release Reply

-

Cancel: I did not complete this guide.

17 other people completed this guide.

3 Comments

It would have been helpful if you had named and colored the parts as they are provided:

- 8x M3x18 Cap Head Screw

8x M6x20 Cap Head Screw

8x M3x12 Cap Head Screw

should have been black

- "Axial Thrust Bearing" is labeled as "Thrust bearing F8-16m" in the plastic bag

and in the step 1 image you don't show all the three parts

- "Rigid Lead Screw Coupler" is labeled as "Coupler Rigid Type BLK" in the plastic bag

- The orientation of the step motor is not shown until step 6, someone could not notice that and orient it the wrong way

Francesco Brasina - Resolved on Release Reply

Had to go looking ahead for the motor position as well as it clearly shows the motor but not the connector...

Chris -

The trim part for the rear motor is upside down, or mirrored. Until it is fixed, you will need to mirror the part in order to use it.

William Bosacker - Resolved on Release Reply