Introduction

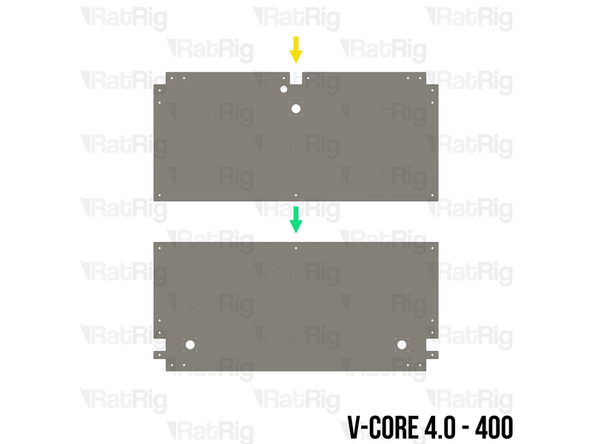

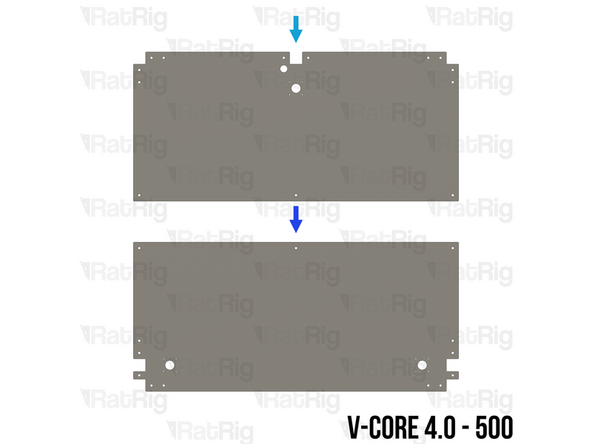

Please note: All measurements provided in this guide are based on building a 300x300 V-Core 4.0.

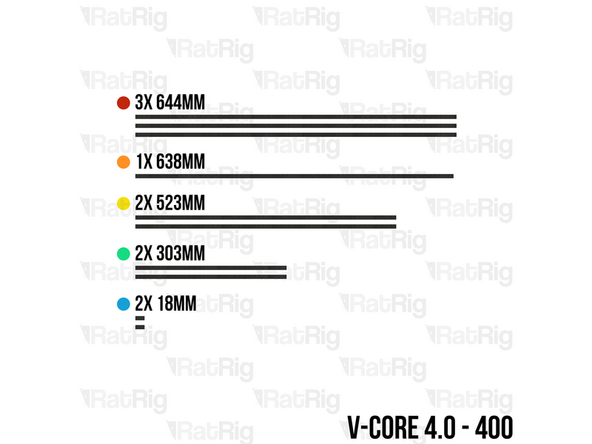

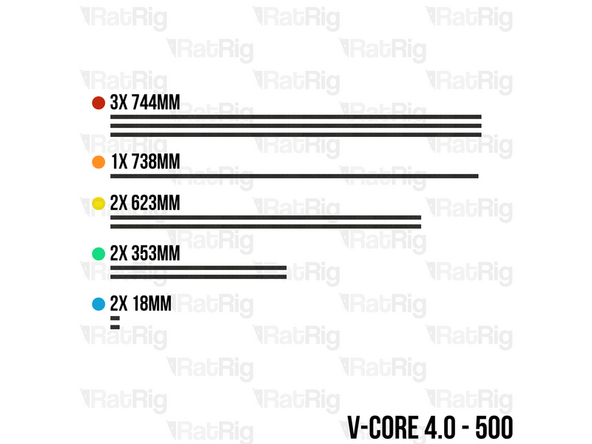

If you are building a machine of a different size, the following adjustments can be made to the stated extrusion and linear rail lengths:

- 400x400: Add 100mm

- 500x500: Add 200mm

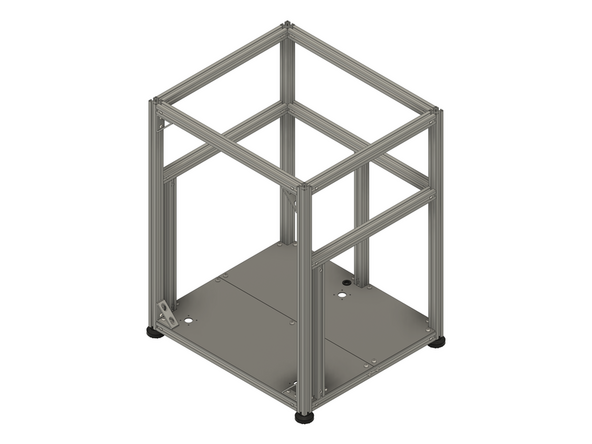

It is strongly recommended to assemble the frame on a known flat surface (such as a solid table, work surface or similar). Assembling the frame on a carpeted floor, tile floor or other non-flat surface can cause the finished frame to not be square. This can cause issues with print quality and performance.

-

-

The following tools are required for this section of the guide:

-

Allen key / hex wrenches in the following sizes: 4mm & 5mm

-

Avoid using ball end hex wrenches on the Quick Connectors as they are more prone to damaging the heads of the Set Screws

-

Spanners / wrenches in the following size: 13mm

-

A pair of scissors

-

The following tools are recommended for this guide:

-

A tape measure

-

An Engineer Square

-

-

-

The following steps show how the aluminium extrusion Quick Connectors are prepared and installed. The V-Core 4.0 frame assembly begins on step 7

-

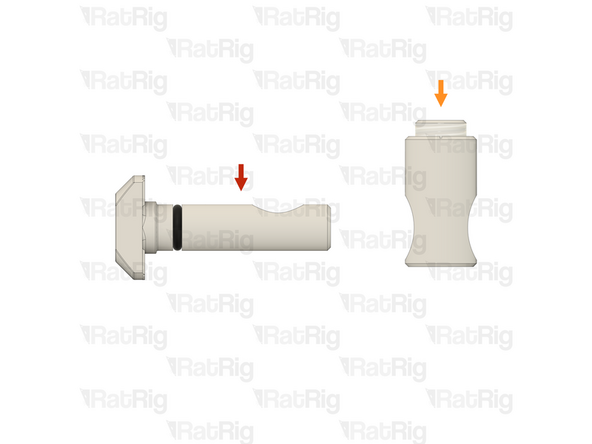

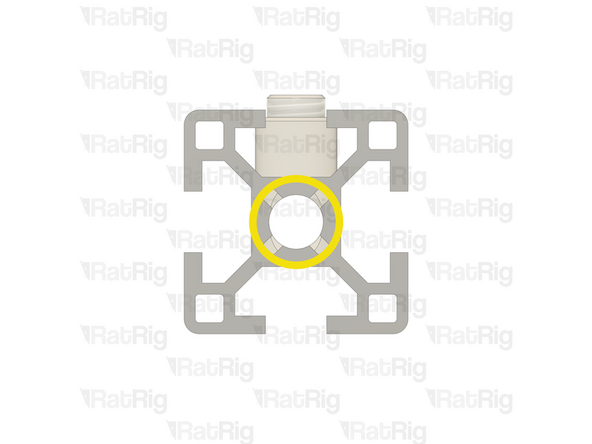

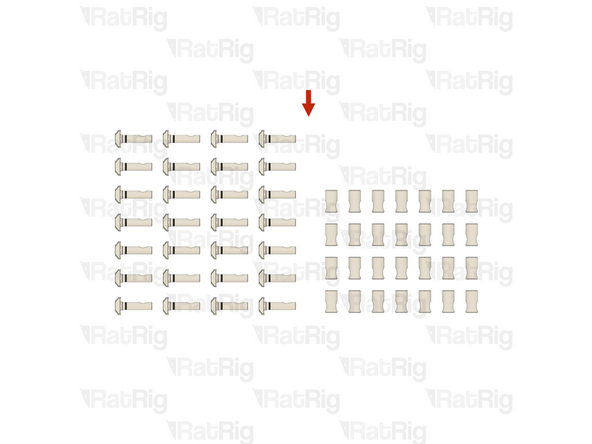

The Quick Connectors are supplied in two parts:

-

Quick Connector T-Nut Pin with the O-Ring pre-installed

-

Quick Connector Housing with the Set Screw pre-installed

-

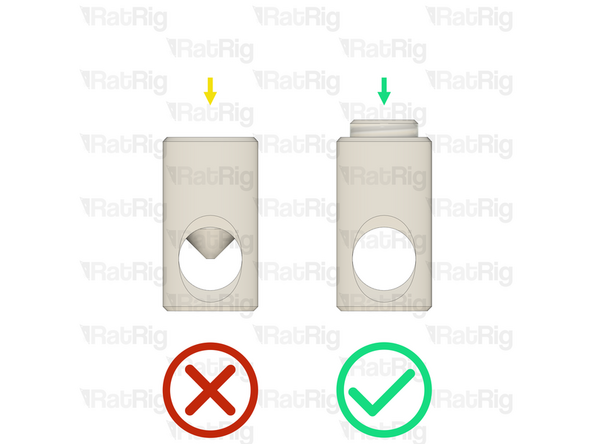

Before trying to install a Quick Connector Housing into an extrusion, check that the Set Screw is not blocking the hole in the Quick Connector Housing

-

If the Set Screw is blocking the hole in the Quick Connector Housing, slightly unscrew it to achieve the necessary clearance

-

-

-

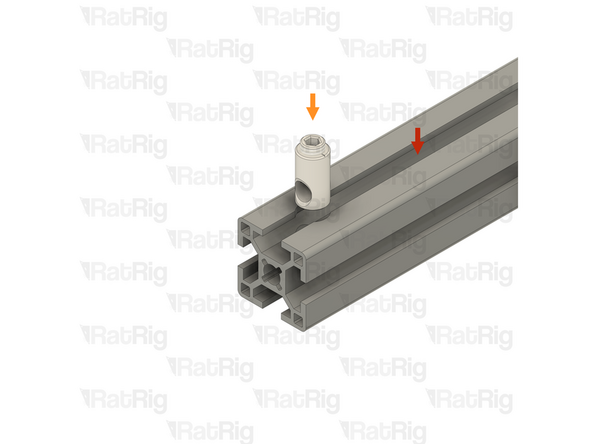

Example extrusion

-

Quick Connector Housing

-

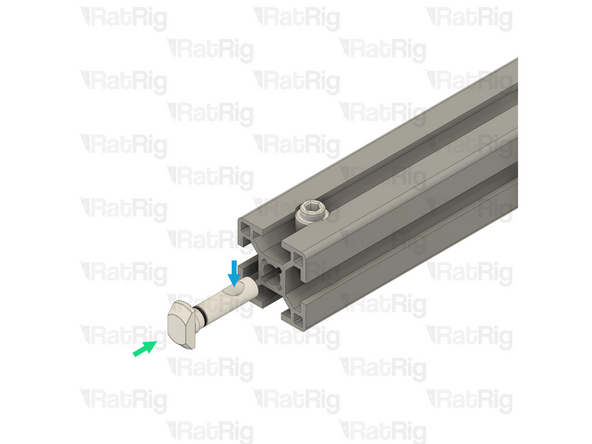

Insert the Quick Connector Housing into the hole in the aluminium extrusion

-

Please note: If the Quick Connector Housing is difficult to insert into the aluminium extrusion, try inserting it from the opposite side

-

Make sure that the Quick Connector Housings all face the same direction

-

Make sure that the hole in the Quick Connector Housing is aligned with the central hole on the aluminium extrusion as shown

-

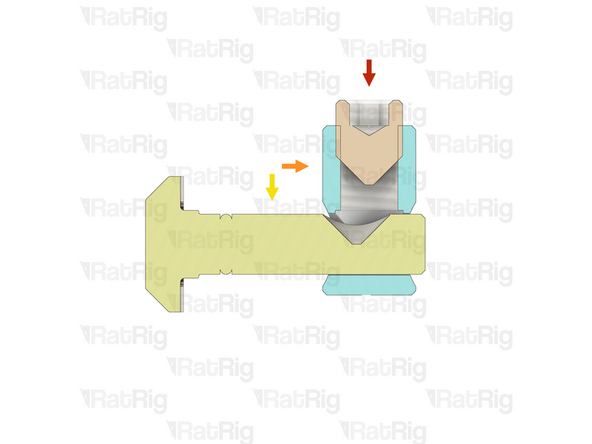

Insert the Quick Connector T-Nut Pin into the central hole on the extrusion slot

-

Make sure the "notch" in the pin is facing towards the Set Screw

-

-

-

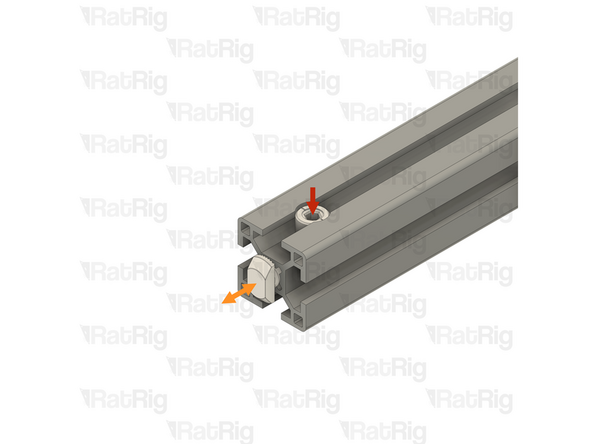

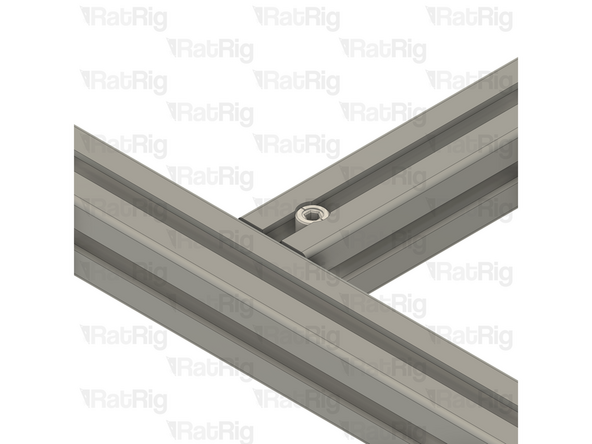

Quick Connector Set Screw

-

Using a 4mm hex key, tighten the Set Screw just enough to hold the Quick Connector T-Nut Pin inside the extrusion

-

If correctly tightened, the Quick Connector T-Nut Pin should still move slightly backwards and forwards, but should not come loose

-

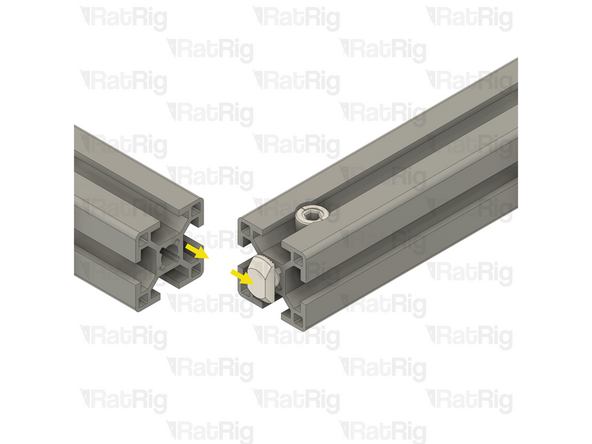

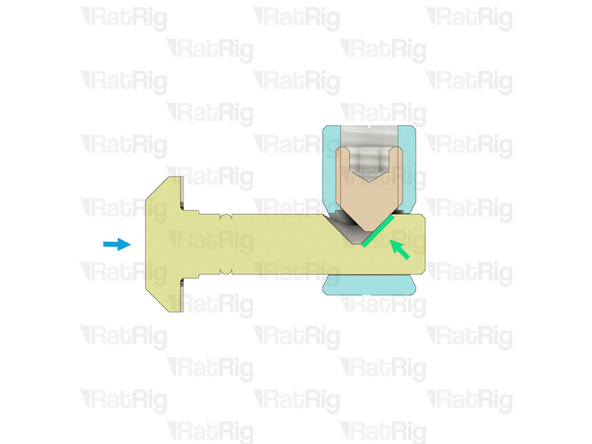

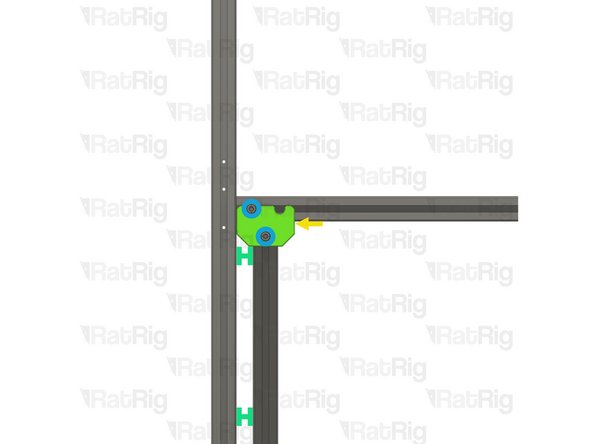

Slide the second aluminium extrusion into position, aligning the Quick Connector T-Nut Pin into the slot of the second aluminium extrusion

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

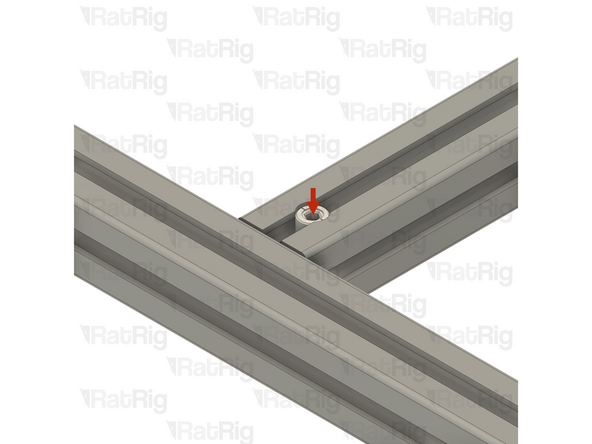

Quick Connector Housing Set Screw

-

Fully tighten the Set Screw to secure the extrusions together

-

The Set Screw will cause the Quick Connector T-Nut Pin to pull tight against the second extrusion, securing them together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

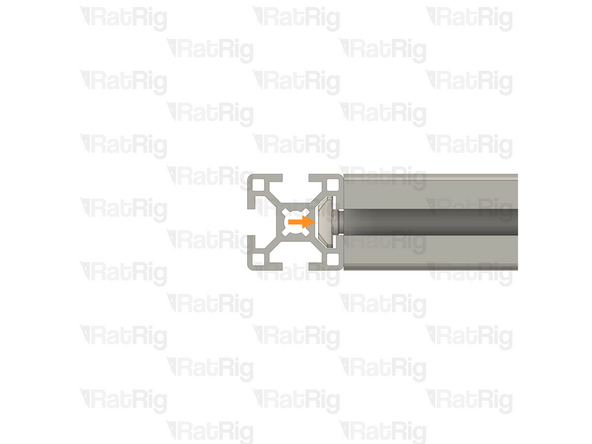

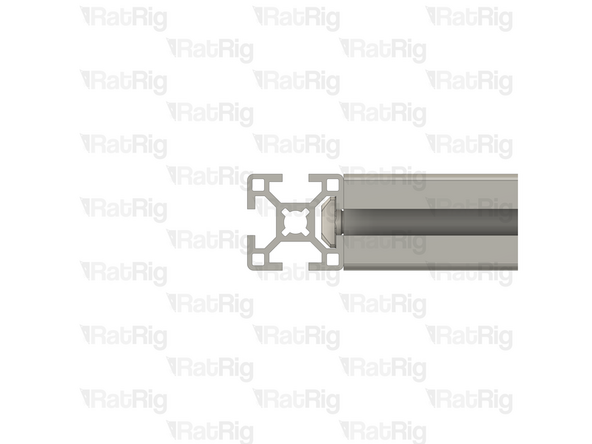

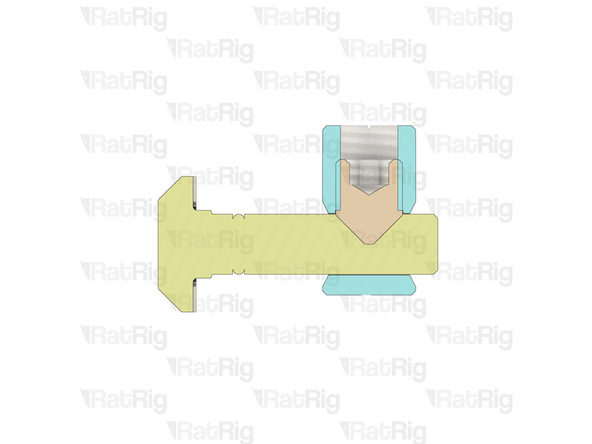

Set Screw

-

Quick Connector Housing

-

Quick Connector T-Nut Pin

-

The Set Screw within the Quick Connector Housing engages with the "notch" in the Quick Connector T-Nut Pin

-

As the Set Screw is fastened, the T-Nut Pin is pulled inwards, causing the extrusions to lock together

-

-

-

As mentioned in the introduction, all extrusion measurements in this guide are based on a V-Core 4.0 in the 300 size

-

If you are building a machine of a different size, the stated extrusion lengths can be adjusted as follows:

-

V-Core 4.0 - 400: Add 100mm to all measurements

-

V-Core 4.0 - 500: Add 200mm to all measurements

-

If a measurement requires a different adjustment—or none at all—it will be noted when relevant

-

-

-

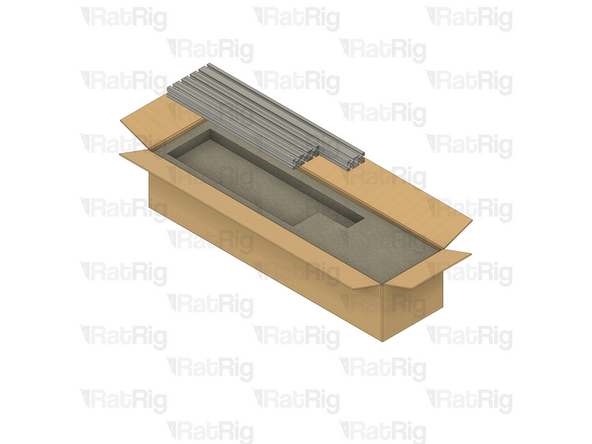

All of the extrusions for the V-Core 4.0 are provided packed in the same box. The SKU varies depending on the size being assembled:

-

V-Core 4.0 - 300: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 300 (SKU: HW3984MK)

-

V-Core 4.0 - 400: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 400 (SKU: HW3985MK)

-

V-Core 4.0 - 500: Rat Rig V-Core 4.0 - CNC Milled Profile Pack v1.0 - 500 (SKU: HW3986MK)

-

Be careful when opening the package. Do not use a long blade to cut the box open as you can damage the extrusions

-

Unpack each layer carefully, placing the extrusions to the side for now

-

There are four layers of extrusions to unpack

-

The 2020 V-Slot extrusion will be used in a later guide. All others are used in the construction of the frame

-

-

-

If you are building a machine of a different size, add 100mm to all listed extrusion lengths for the V-Core 4.0 400 or 200mm for the V-Core 4.0 500

-

28x Quick Connector for 30 series B-Type - 0º (SKU: HW3347GC)

-

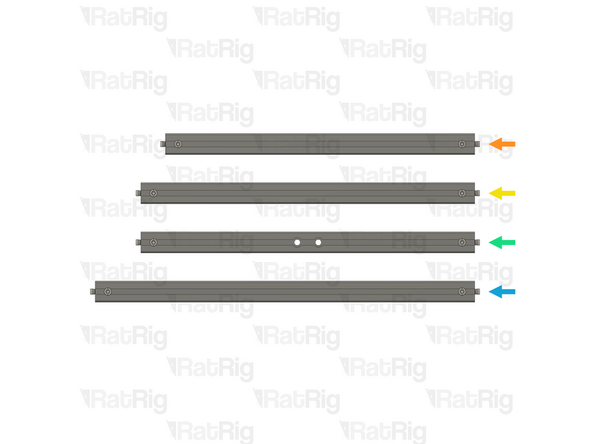

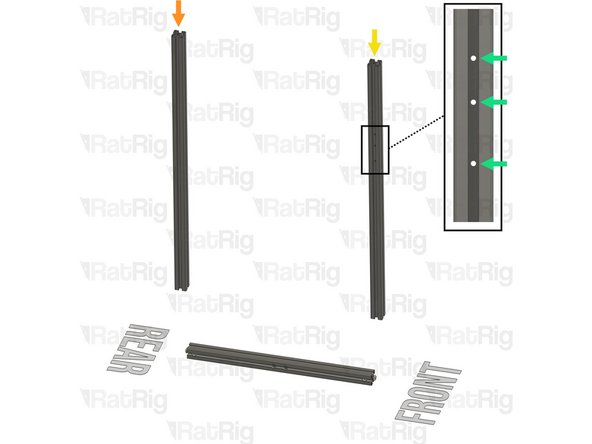

Install Quick Connectors into both ends of the following extrusions:

-

3x T-Slot 3030 Milled Extrusion - 440mm

-

4x T-Slot 3030 Milled Extrusion - 475mm

-

2x T-Slot 3030 Milled Extrusion - 475mm with two M8 holes

-

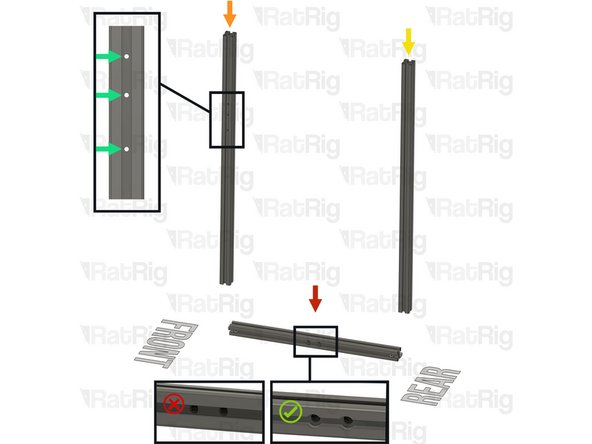

Make sure the Quick Connector Set Screws are facing the same side as the counterbores for the M8 screw holes

-

5x T-Slot 3030 Milled Extrusion - 540mm

-

-

-

If you are building a machine of a different size, add 100mm to all listed extrusion lengths for the V-Core 4.0 400 or 200mm for the V-Core 4.0 500

-

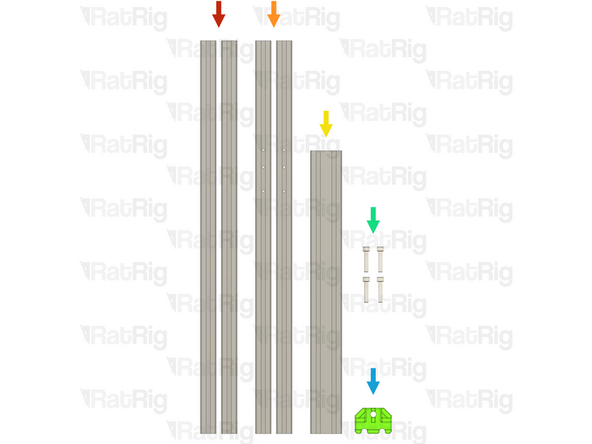

In addition to the extrusions prepared in the previous step, the following extrusions are needed to assemble the frame:

-

2x T-Slot 3030 Milled Extrusion - 750mm

-

2x T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

1x T-Slot 3060 Milled Extrusion - 540mm

-

4x M8x40 Cap Head Screw (SKU: HW1871SC)

-

1x vc4_frame_jig Printed Part (SKU: PP000279)

-

Please note: The Frame Jig may have been printed in green or black. The design is the same regardless of colour

-

-

-

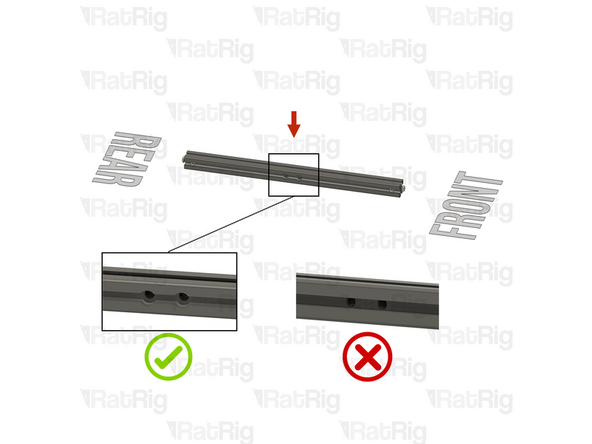

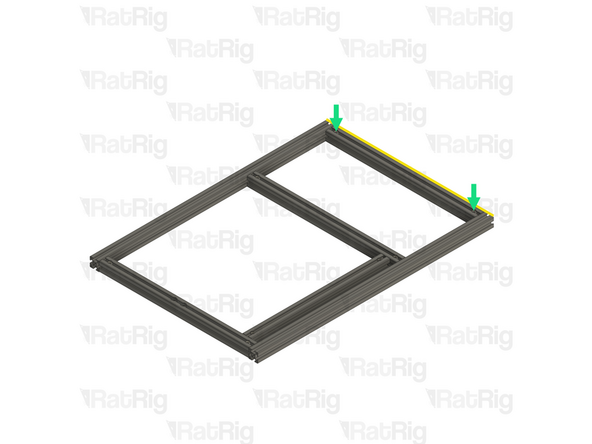

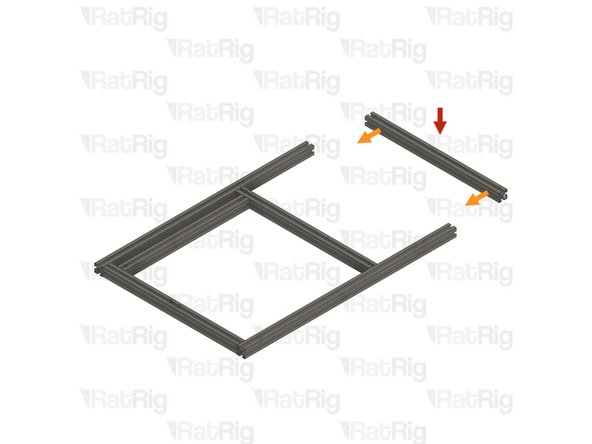

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors and two M8 holes from step 9

-

Make sure that the counterbores for the M8 holes are oriented as shown

-

T-Slot 3030 Milled Extrusion - 750mm

-

T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

Make sure this extrusion is installed as shown. It should be at the front, with the three M4 holes at the top and facing to the side

-

Assemble the extrusions as shown but do not fasten them together yet

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

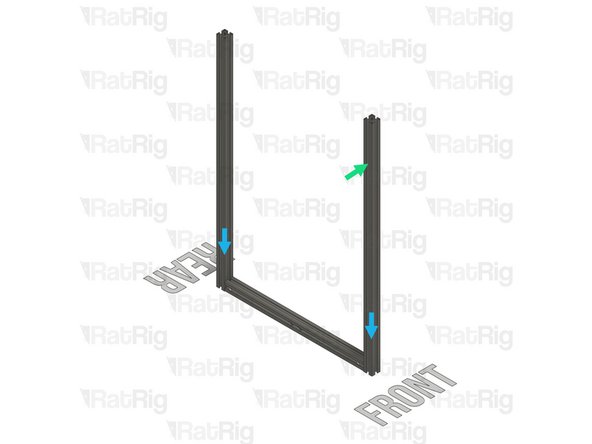

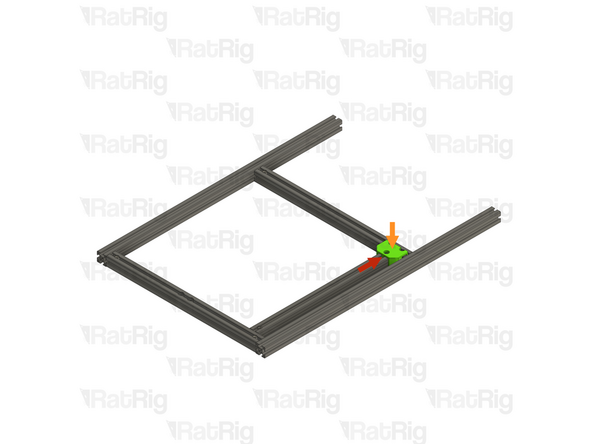

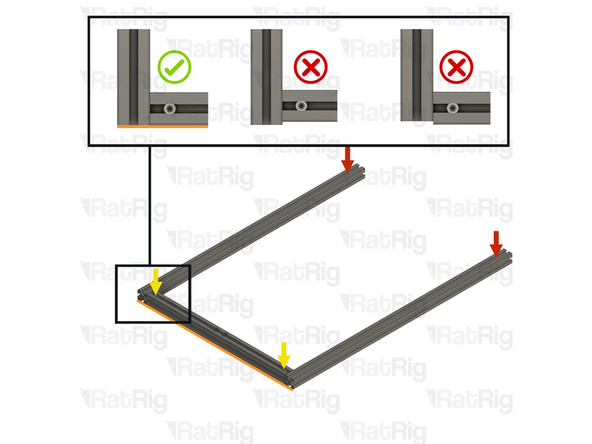

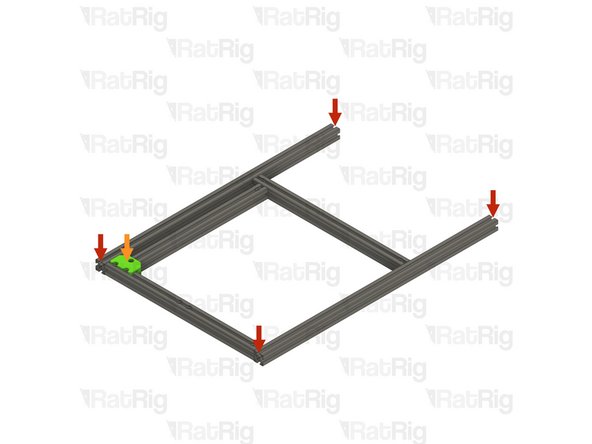

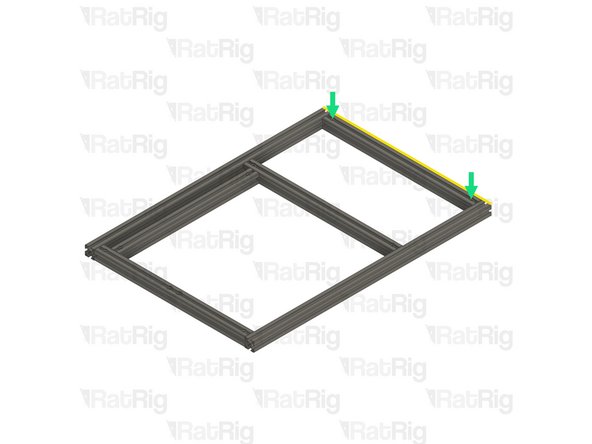

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Good surfaces: Poured self-levelled concrete, glass, or a stone countertop

-

Bad surfaces: Carpeted floor, a tile floor, or rough concrete

-

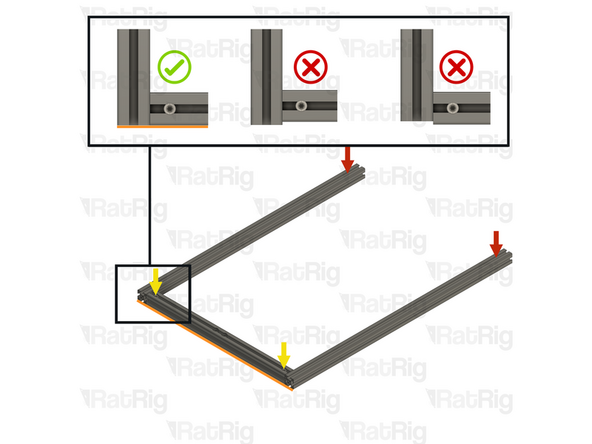

Align the extrusions as shown - making sure the ends are flush

-

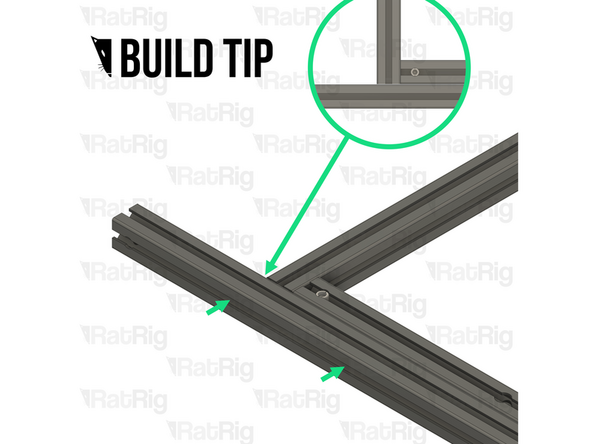

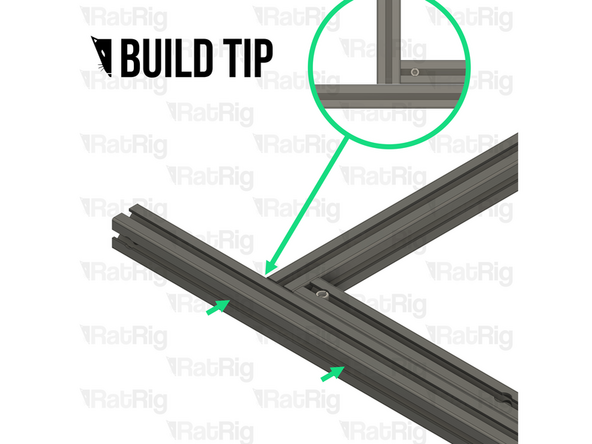

Build Tip: You can use a spare 3030 extrusion or an Engineer Square to help align the assembly

-

Fasten the Set Screws in both of the Quick Connectors to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

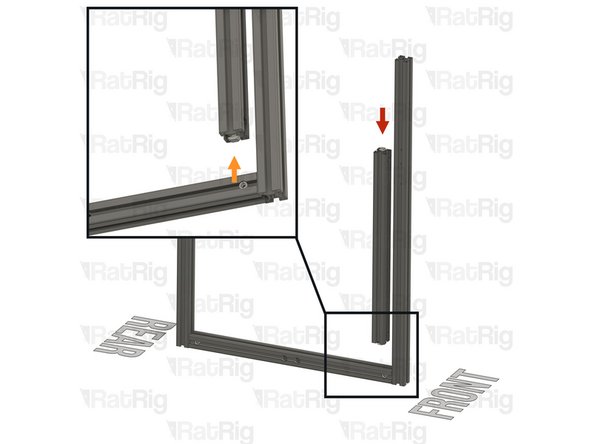

T-Slot 3030 Milled Extrusion - 440mm with Quick Connectors from step 9

-

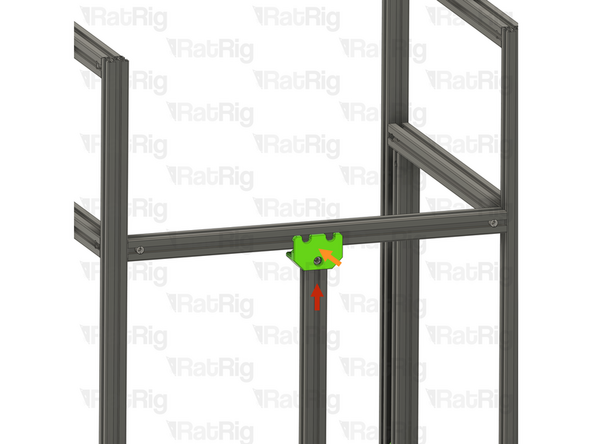

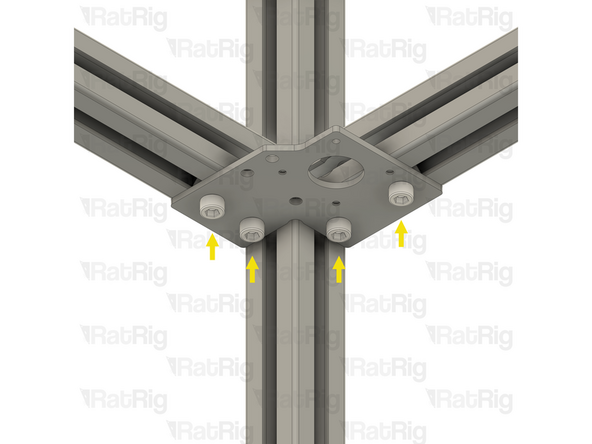

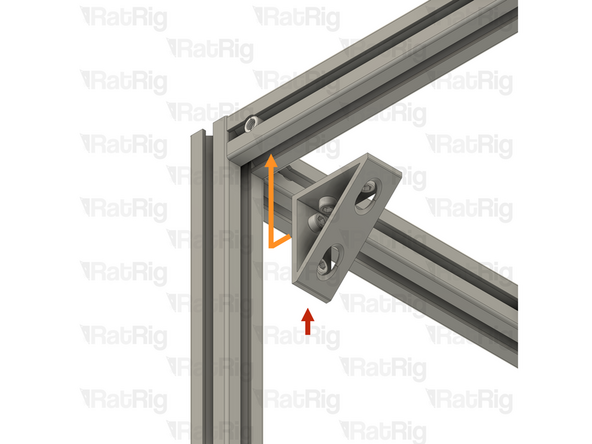

Align the Quick Connector T-Nut Pin with the bottom extrusion slot

-

Insert the Quick Connector T-Nut Pin into the bottom extrusion slot

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

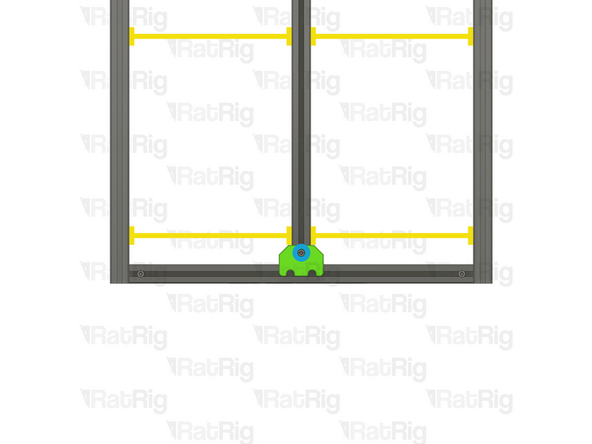

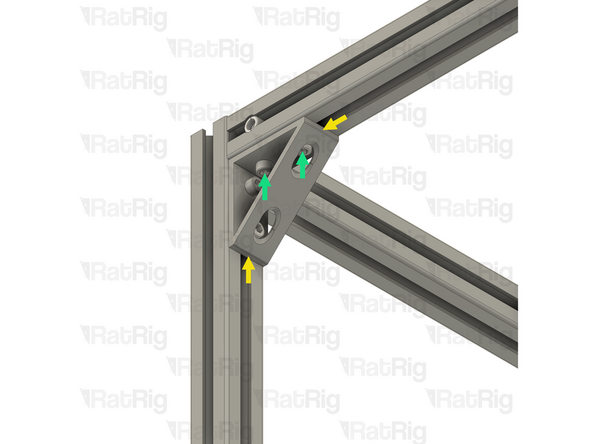

Slide the marked extrusion downwards, making sure the Quick Connector T-Nut Pin on the 440mm extrusion fits inside the extrusion slot

-

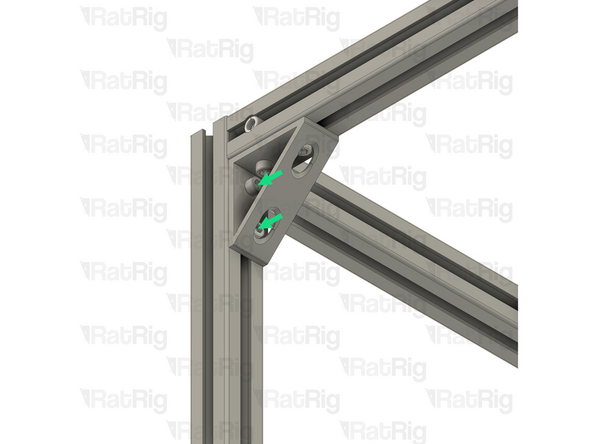

Carefully rotate the marked extrusion 90 degrees so that the Quick Connector Set Screws face outwards as shown

-

Look into the extrusion slots and make sure that both the upper and lower Quick Connector T-Nut Pins have rotated correctly

-

Be careful not to scratch the aluminium extrusions when assembling them

-

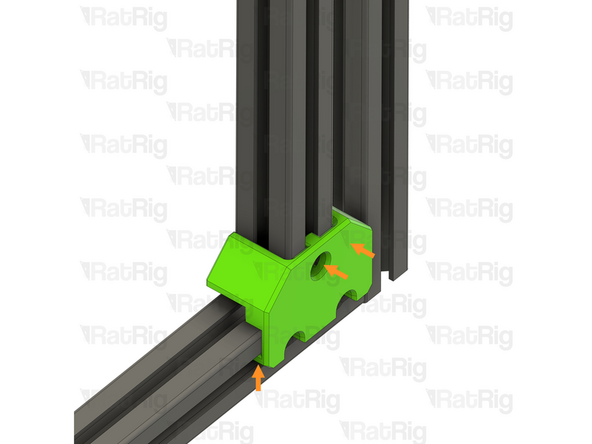

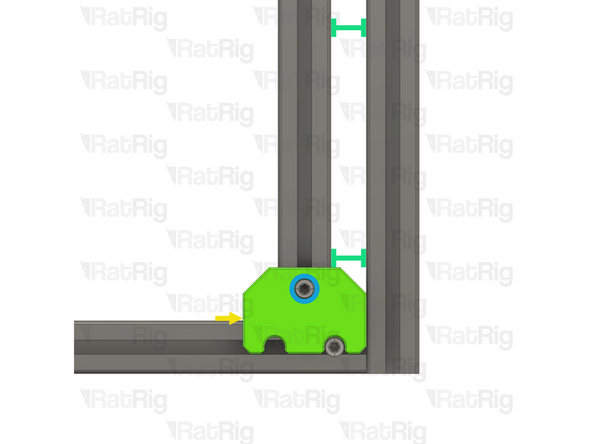

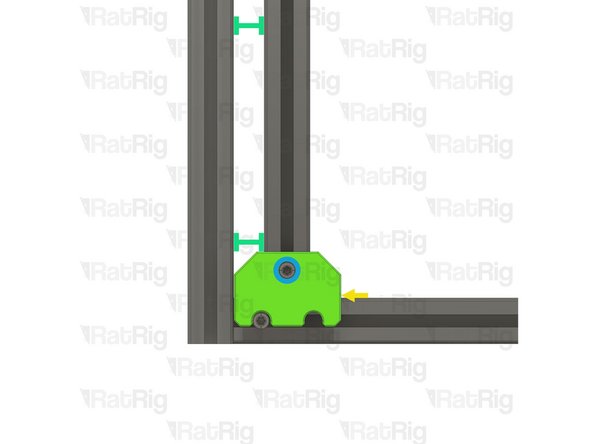

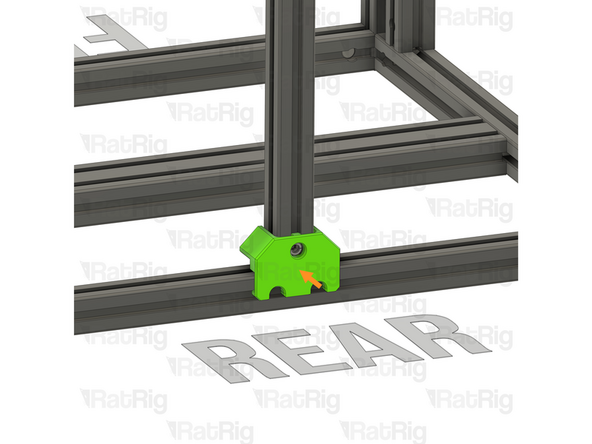

V-Core 4.0 Frame Jig

-

Install the Frame Jig onto the assembly as shown

-

-

-

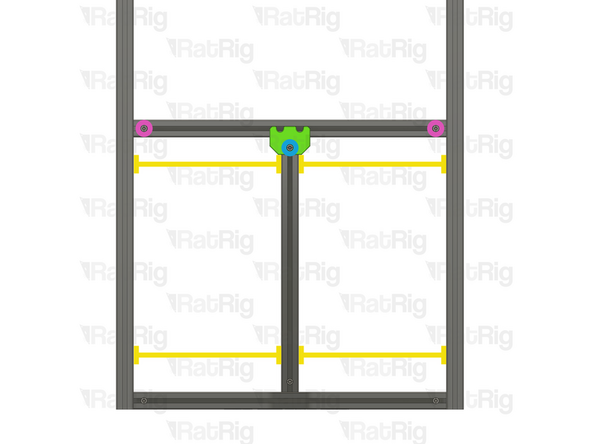

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the right to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm. This measurement is the same for all V-Core 4.0 sizes

-

Build Tip: You can use the 2020 V-Slot extrusion to verify the gap but be careful not to scratch the aluminium extrusions

-

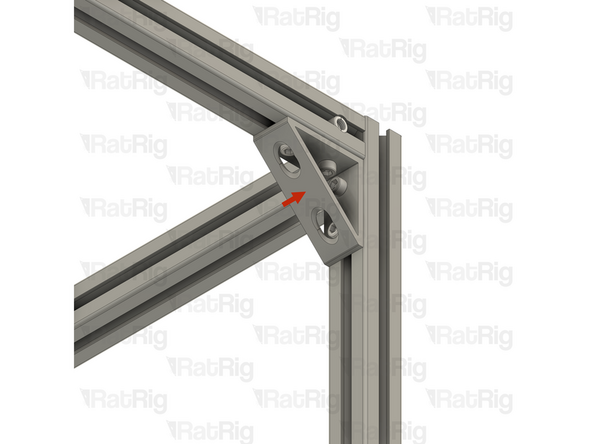

Fully tighten the marked Set Screw to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

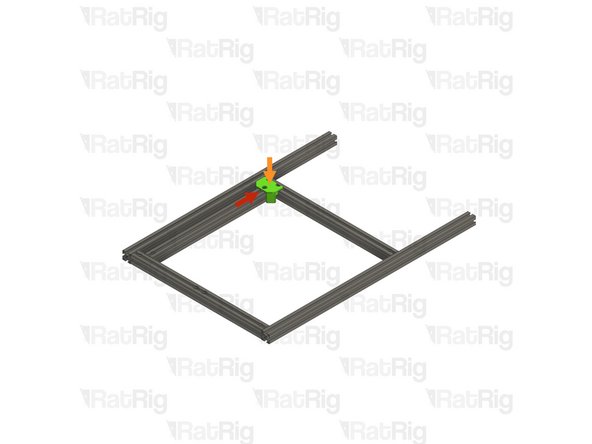

Move the Frame Jig to the marked position

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the right to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

Double check that the marked distance is 250mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

Set this assembly aside until step 24

-

-

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors and two M8 holes from step 9

-

Make sure that the counterbores for the M8 holes are oriented as shown

-

T-Slot 3030 Milled Extrusion - 750mm with three M4 holes

-

T-Slot 3030 Milled Extrusion - 750mm

-

Make sure this extrusion is installed as shown. It should be at the front, with the three M4 holes at the top and facing to the side

-

Assemble the extrusions as shown but do not fasten them together yet

-

-

-

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Good surfaces: Poured self-levelled concrete, glass, or a stone countertop

-

Bad surfaces: Carpeted floor, a tile floor, or rough concrete

-

Align the extrusions as shown - making sure the ends are flush

-

Build Tip: You can use a spare 3030 extrusion or an Engineer Square to help align the assembly

-

Fasten the Set Screws in both of the Quick Connectors to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

T-Slot 3030 Milled Extrusion - 440mm with Quick Connectors from step 9

-

Align the Quick Connector T-Nut Pin with the bottom extrusion slot and insert it

-

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots

-

Slide the extrusion downwards, making sure the Quick Connector T-Nut Pin on the 440mm extrusion fits inside the extrusion slot

-

Carefully rotate the marked extrusion 90 degrees so that the Quick Connector Set Screws face outwards as shown

-

Look into the extrusion slots and make sure that both the upper and lower Quick Connector T-Nut Pins have rotated correctly

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

Lay the assembly on a flat surface, this is crucial to ensure a square frame

-

Install the Frame Jig onto the assembly as shown

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the left to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm. This measurement is the same for all V-Core 4.0 sizes

-

Build Tip: You can use the 2020 V-Slot extrusion to verify the gap but be careful not to scratch the aluminium extrusions

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

Move the Frame Jig to the marked position

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Push the Frame Jig to the left to eliminate any space between the Frame Jig and the front extrusion

-

The marked gap should measure 20mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

Double check that the marked distance is 250mm. This measurement is the same for all V-Core 4.0 sizes

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

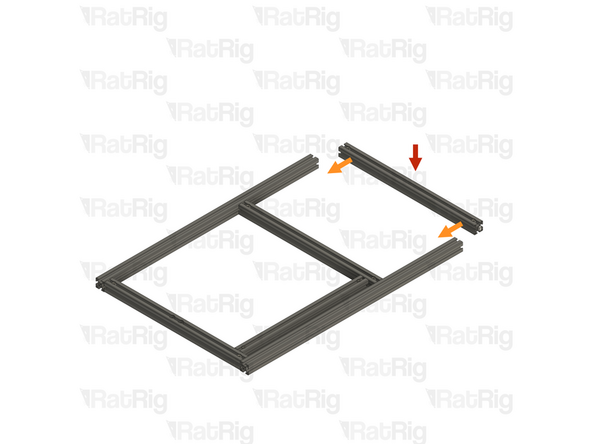

T-Slot 3030 Milled Extrusion - 475mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

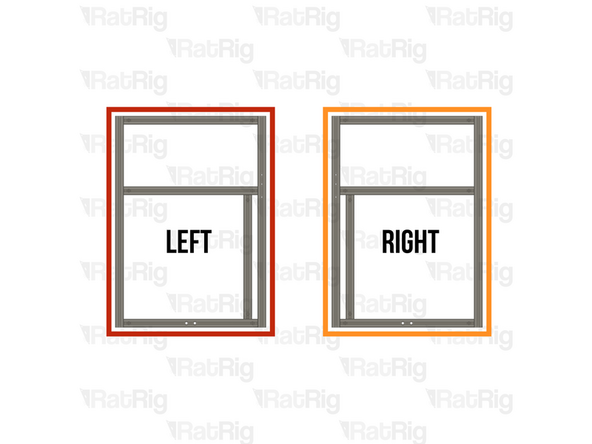

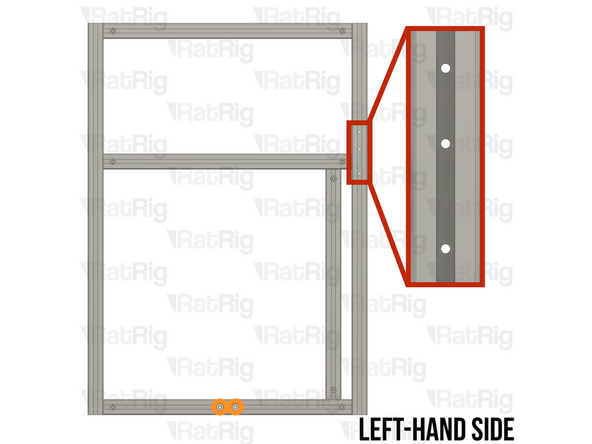

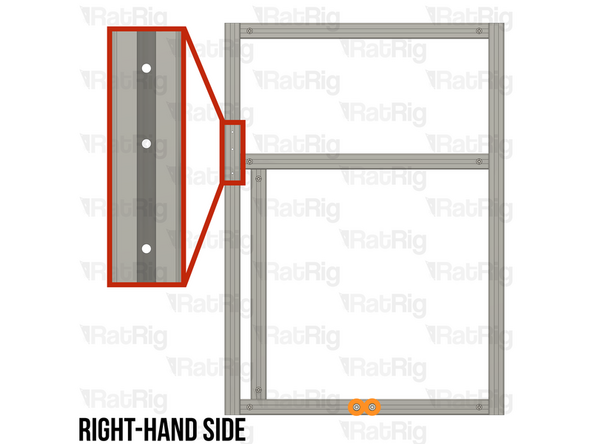

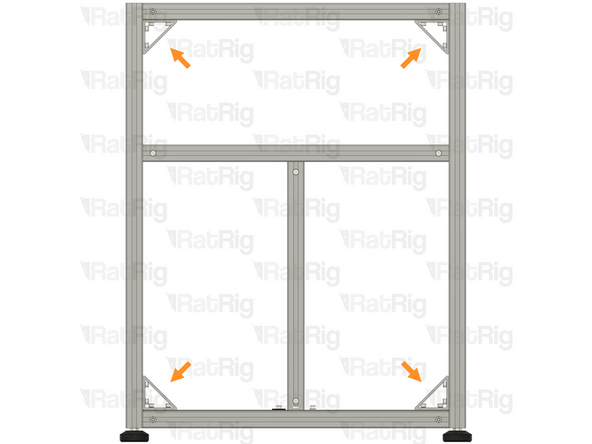

Make sure that the two frame side sub-assemblies match the provided image:

-

Left-hand side sub-assembly assembled in step 11 through to step 17

-

Right-hand side sub-assembly assembled in step 18 through step 23

-

The two sub-assemblies should be a mirror of each other

-

It is important to verify that the assemblies are correctly mirrored. Incorrect assembly will lead to significant issues during later steps

-

-

-

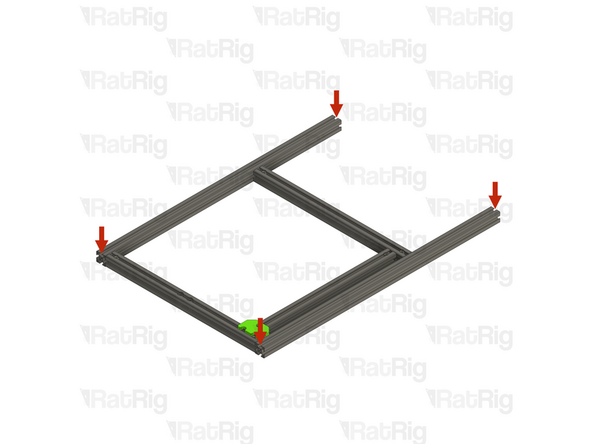

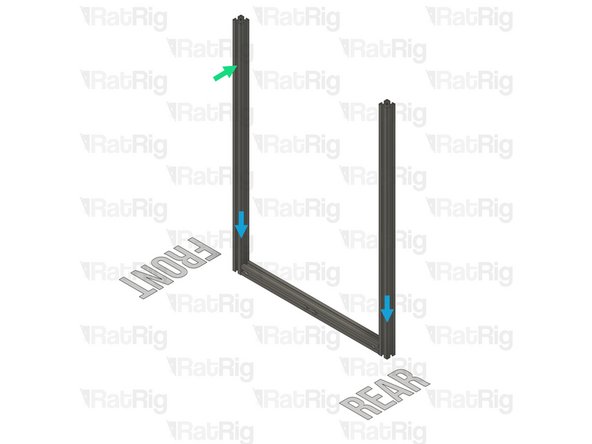

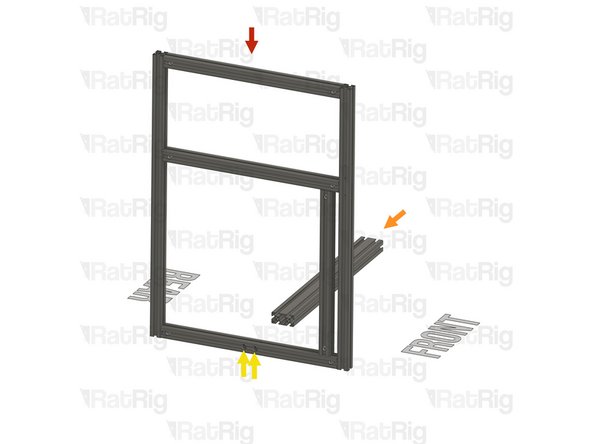

Left-hand side sub-assembly from step 17

-

T-Slot 3060 Milled Extrusion - 540mm from step 10

-

Align the holes in the 3060 extrusion with the M8 holes in the bottom extrusion of the left-hand side sub-assembly

-

2x M8x40 Cap Head Screw from step 10

-

Insert each M8x40 Cap Head Screw through the M8 holes in the bottom extrusion of the sub-assembly. Carefully begin to thread them into the end of the T-Slot 3060 extrusion before fully tightening them to secure the extrusions together

-

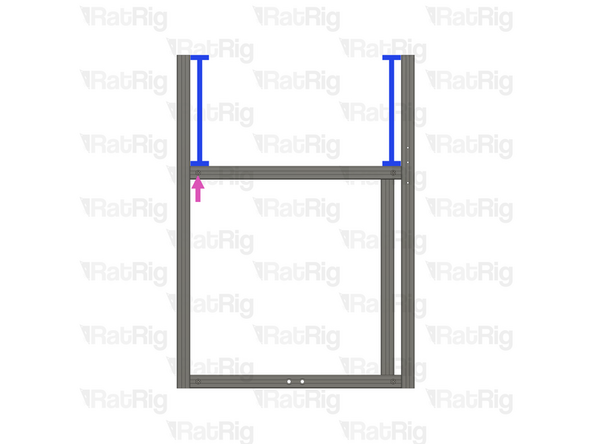

2x T-Slot 3030 Milled Extrusion - 540mm with Quick Connectors from step 9

-

Insert each extrusion into the side assembly. Make sure the Quick Connector T-Nut pins are aligned with the side extrusion slots and the Quick Connector Set Screws are facing outwards

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

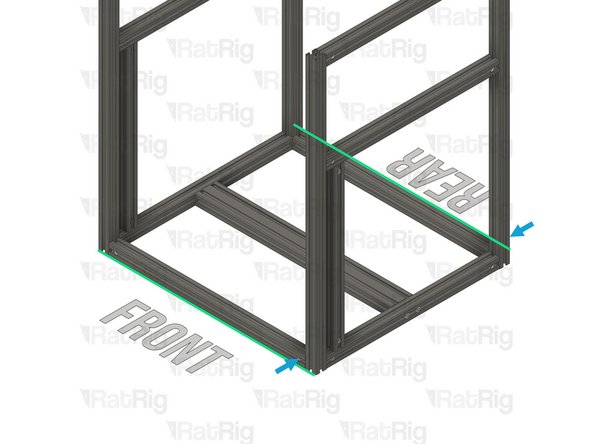

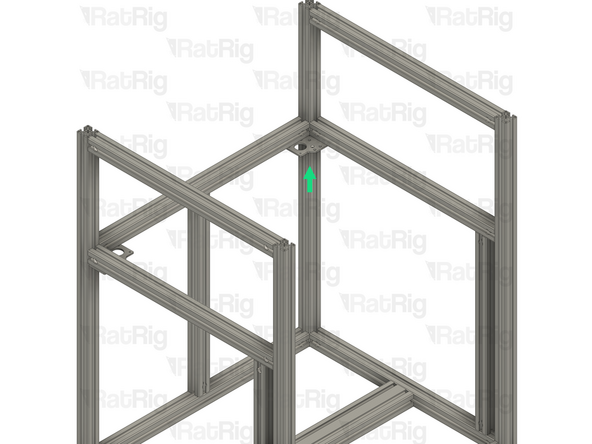

Place the assembly on a flat surface, this is crucial to ensure the extrusions are aligned and the frame is square

-

Make sure that the front extrusion is flush with the side assembly

-

Fully tighten the marked Set Screw on the front to secure the extrusion to the sub-assembly

-

Make sure that the rear extrusion is flush with the side assembly

-

Fully tighten the marked Set Screw on the rear to secure the extrusion to the sub-assembly

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

Make sure to support the frame assembly to ensure that it does not fall over

-

-

-

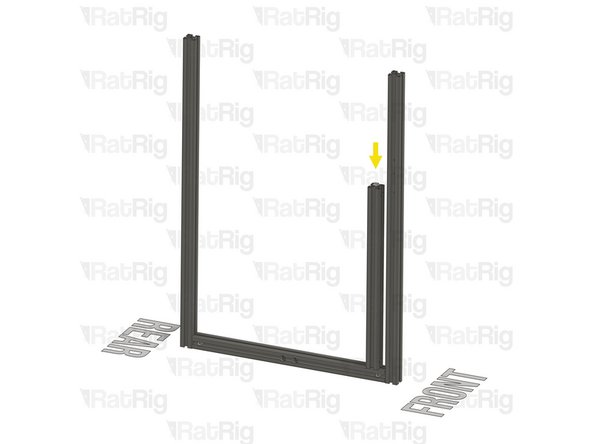

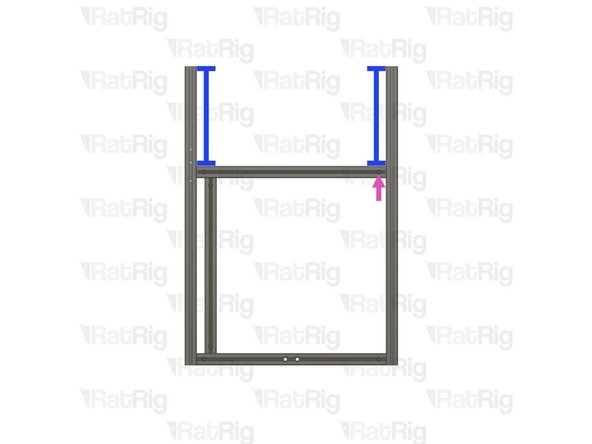

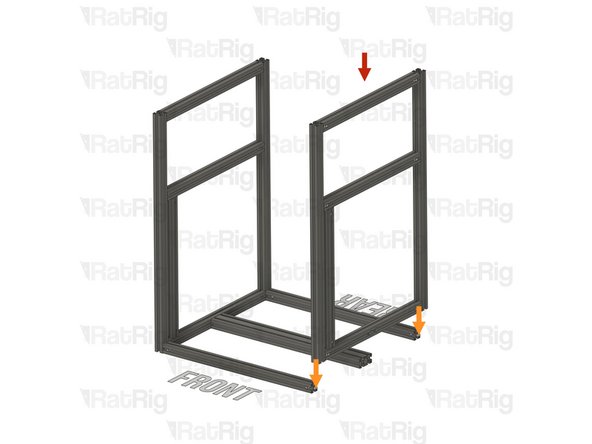

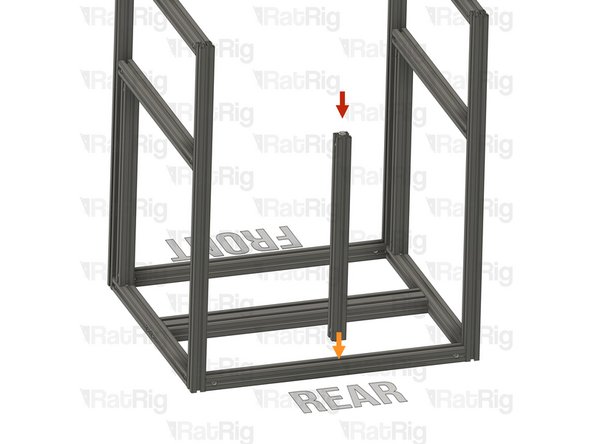

Right-hand side sub-assembly from step 23

-

Slide the right-hand side sub-assembly down onto the frame assembly. Make sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots

-

Be careful not to scratch the aluminium extrusions when assembling them

-

2x M8x40 Cap Head Screw from step 10

-

Insert each M8x40 Cap Head Screw through the M8 holes in the bottom extrusion of the sub-assembly. Carefully begin to thread them into the end of the T-Slot 3060 extrusion before fully tightening them to secure the extrusions together

-

Make sure that the front and rear extrusions are flush with the side sub-assembly

-

Fully tighten the marked Set Screws on the front and rear to secure the side sub-assembly to the rest of the frame

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

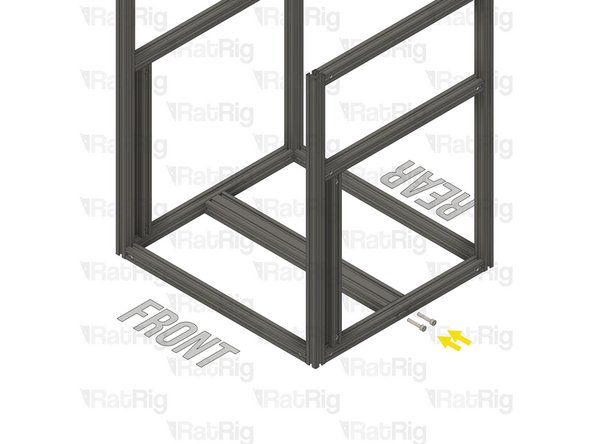

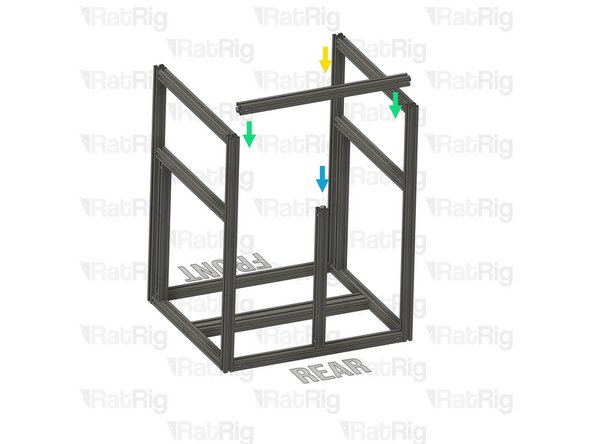

T-Slot 3030 Milled Extrusion - 440mm with Quick Connectors from step 9

-

Align the Quick Connector T-Nut Pin with the bottom extrusion slot and insert it

-

T-Slot 3030 Milled Extrusion - 540mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots and the Quick Connector Set Screws are facing outwards

-

Slide the extrusion downwards, making sure the Quick Connector T-Nut Pin on the 440mm extrusion fits inside the extrusion slot

-

Be careful not to scratch the aluminium extrusions when assembling them

-

-

-

Carefully rotate the marked extrusion 90 degrees so that the Quick Connector Set Screws face towards the rear as shown

-

Look into the extrusion slots and make sure that both the upper and lower Quick Connector T-Nut Pins have rotated correctly

-

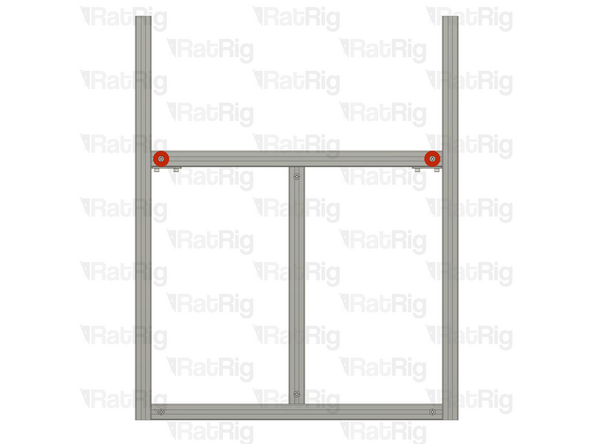

Install the Frame Jig onto the assembly as shown

-

Measure the marked gap on both sides, they should be equal and measure 255mm

-

V-Core 4.0 - 400: The gaps should measure 305mm

-

V-Core 4.0 - 500: The gaps should measure 355mm

-

Fully tighten the marked Set Screw to secure the extrusions together

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

Move the Frame Jig to the marked position

-

Make sure the Frame Jig is installed completely flush with the extrusion and that the bottom "tabs" are within the extrusion slot

-

Measure the marked gap on both sides, they should be equal and measure 255mm

-

V-Core 4.0 - 400: The gaps should measure 305mm

-

V-Core 4.0 - 500: The gaps should measure 355mm

-

Fully tighten the marked Set Screw to secure the extrusions together

-

Do not tighten either of the marked Set Screws at this point, they will be secured in a following step

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

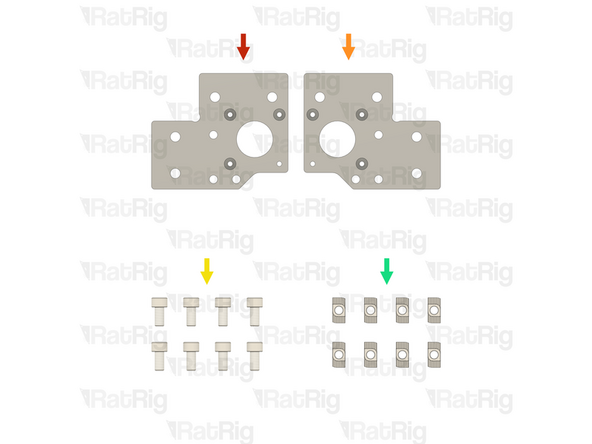

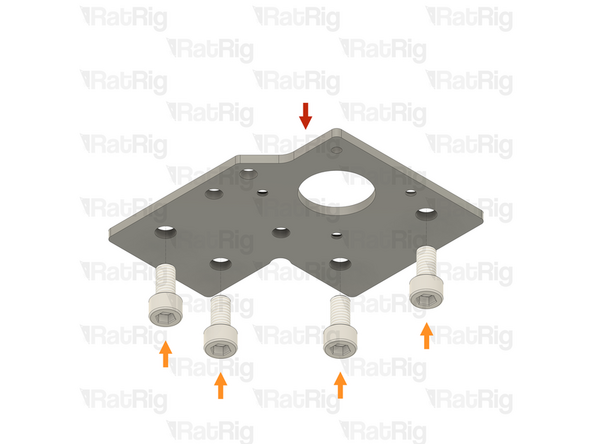

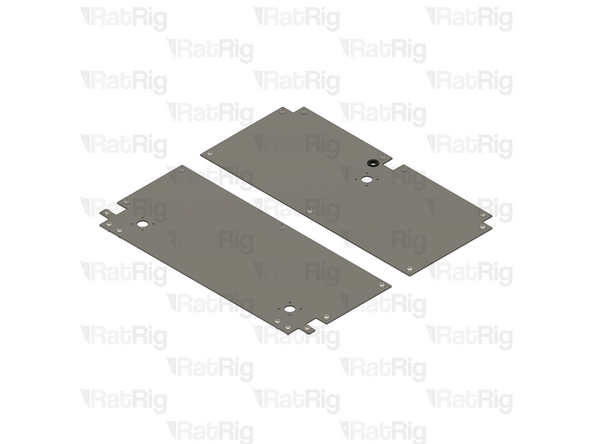

1x Rat Rig V-Core 4.0 - Motor Plate - Lower Left v1.0 (SKU: HW3606PC)

-

1x Rat Rig V-Core 4.0 - Motor Plate - Lower Right v1.0 (SKU: HW3607PC)

-

8x M6x12 Cap Head Screw (SKU: HW1836SC)

-

8x T-Nut Drop-in for 30 series - M6 (SKU: HW1361NC)

-

-

-

Rat Rig V-Core 4.0 - Motor Plate - Lower Left v1.0

-

4x M6x12 Cap Head Screw

-

Insert the M6x12 Cap Head Screws into the plate from the side without the countersunk holes

-

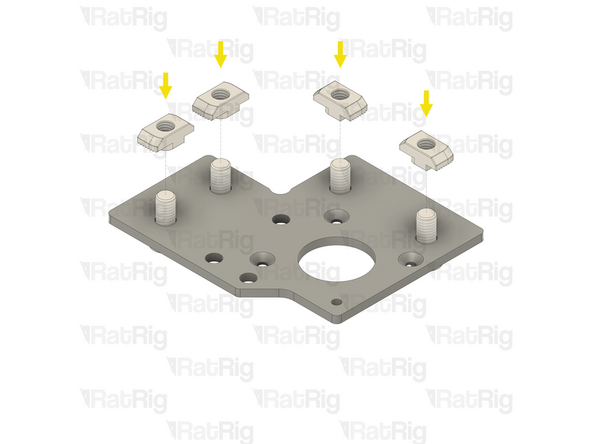

4x T-Nut Drop-in for 30 series - M6

-

Loosely thread a T-Nut onto each of the M6x12 Cap Head Screws. Do not tighten them at this point

-

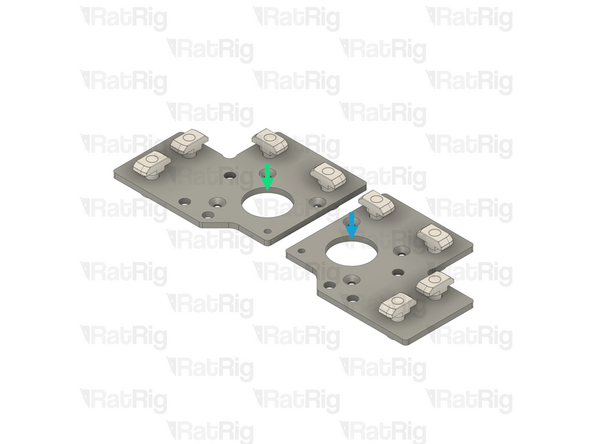

Repeat these instructions to assemble the lower right stepper motor plate

-

Completed lower left stepper motor plate

-

Completed lower right stepper motor plate

-

-

-

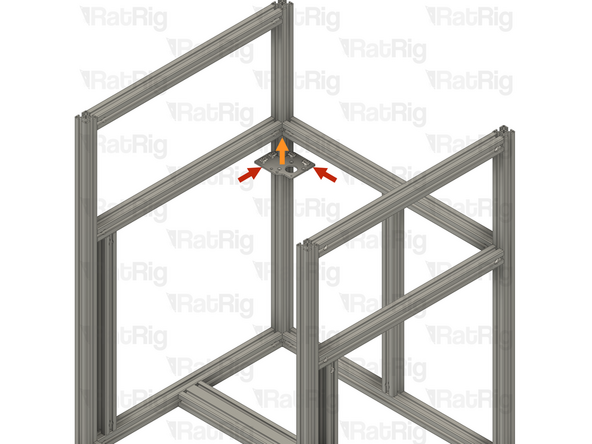

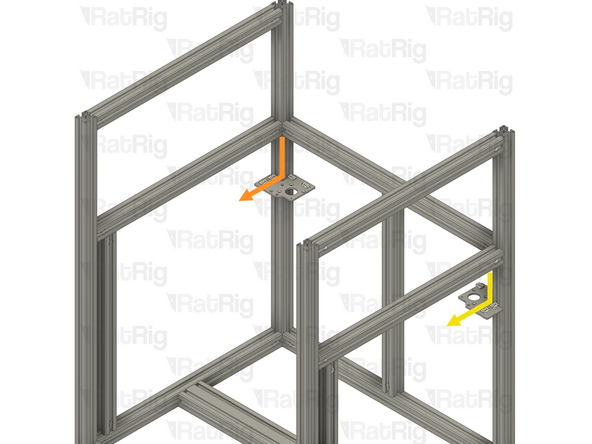

Align the lower left stepper motor plate assembly with the back left extrusion as shown

-

Make sure the plate is fully seated against the 3030 extrusion

-

Raise the plate upwards until it touches the extrusions above

-

Tighten the four M6x12 Cap Head Screws to secure the stepper motor plate to both extrusions. This will ensure the side and back extrusions are correctly aligned

-

Repeat the above instructions to align and install the lower right stepper motor plate assembly to the frame

-

-

-

Fully tighten the marked Set Screws to secure the rear extrusion to the frame

-

If the extrusion connection is loose after fully tightening the Set Screw, loosen the Set Screw and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

Loosen all four M6x12 Cap Head Screws on the lower left stepper motor plate, and remove it from the frame

-

Loosen all four M6x12 Cap Head Screws on the lower right stepper motor plate, and remove it from the frame

-

Set both stepper motor plates aside, they will be used later in the guide

-

-

-

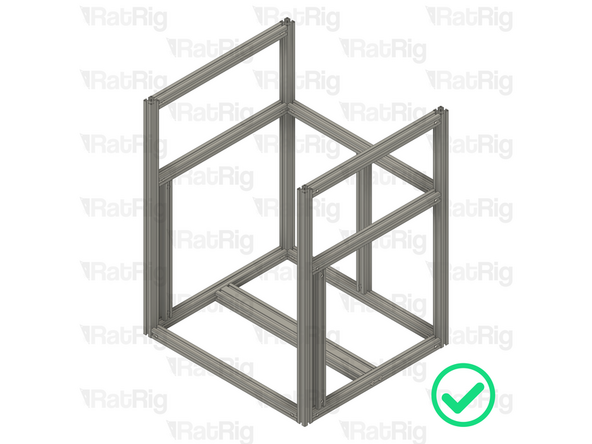

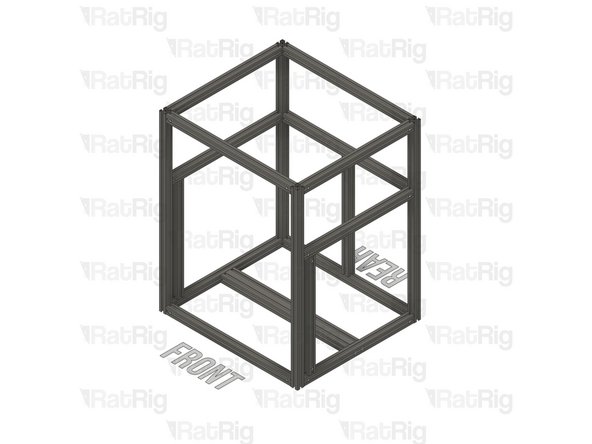

It is important to verify the frame assembly is correct at this point. Check the following:

-

The front extrusions are installed correctly with the three M3 holes at the top and facing towards the sides

-

The two M8x40 Cap Head Screws per side are fully tightened

-

All of the Quick Connector Set Screws are facing outwards and are fully tightened

-

-

-

T-Slot 3030 Milled Extrusion - 540mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots and the Quick Connector Set Screws are facing towards the rear

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

T-Slot 3030 Milled Extrusion - 540mm with Quick Connectors from step 9

-

Insert the extrusion into the side assemblies, making sure the Quick Connector T-Nut Pins are aligned with the side extrusion slots and the Quick Connector Set Screws are facing towards the front

-

Be careful not to scratch the aluminium extrusions when assembling them

-

Align the extrusions as shown - making sure the ends are flush

-

Refer to step 12 for instructions on how to correctly align the extrusions

-

Fully tighten both of the marked Set Screws to secure the extrusions together

-

If any of the extrusion connections are loose after fully tightening the Set Screws, loosen the Set Screw on the loose joint and check that the Quick Connector T-Nut Pin was properly positioned. The connection will not tighten if the "notch" on the pin is not aligned with the Set Screw

-

-

-

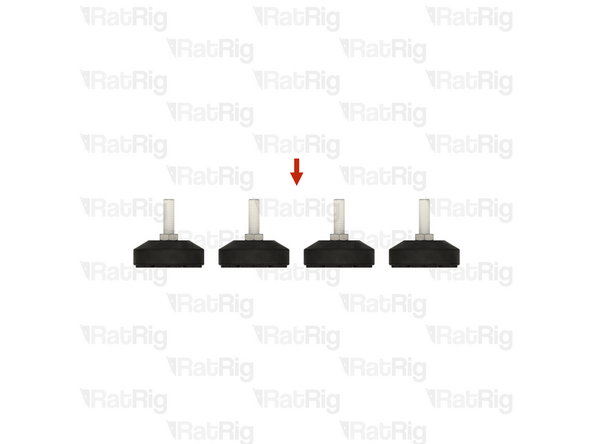

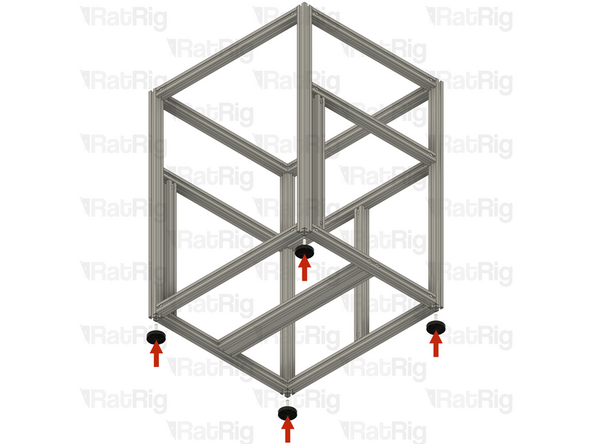

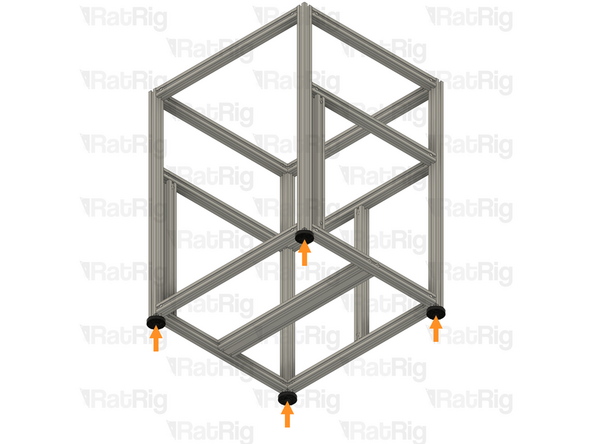

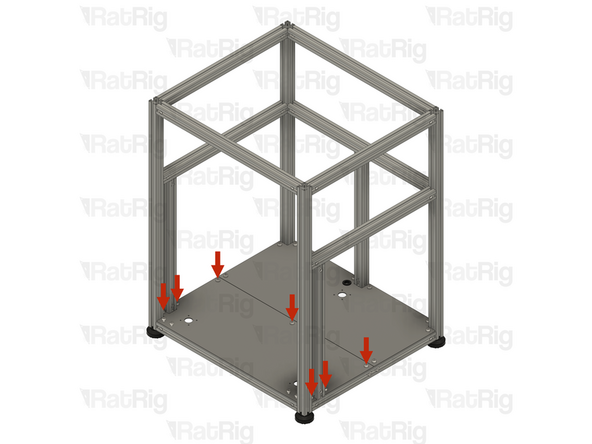

4x Leveling Feet for 3030 - M8x30mm

-

Carefully thread one foot into each of the four frame corner extrusions as shown

-

Adjust each foot so that the frame sits level and does not wobble

In case it helps. On my machine, the feet's screw threads weren't deep enough, and they weren't all the same depth.

And I didn't have a tap, but the advantage was that they were already mostly threaded, so I simply used the foot as a tap.

I'd did like a quarter turn more than what seemed to be the maximum, and then I'd go back about ten turns, before going back up and doing another quarter turn.

That way, I wouldn't force the foot too hard and the metal dust wouldn't condense.

And once every 4-5 round trips, I'd unscrew the foot completely, quick blow with an air blower and start again. Until I reached the end.

Took me a minute, but that way everything was as the same height.

-

-

-

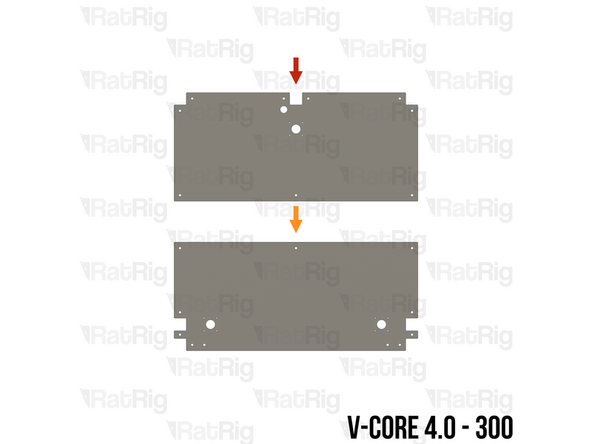

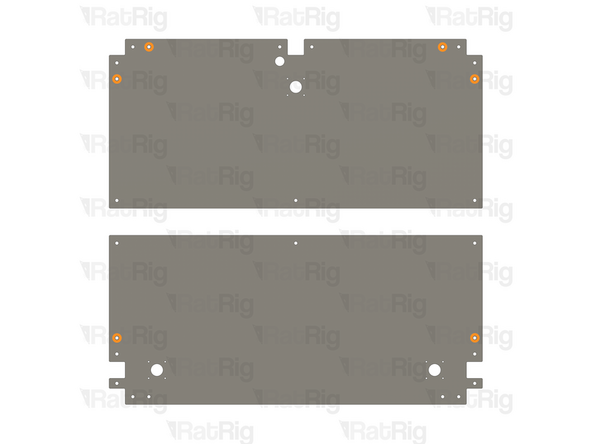

The SKUs for the V-Core 4.0 base plates vary depending on the size:

-

V-Core 4.0 - 300: Rat Rig V-Core 4.0 - Base Plate - 300 Rear v1.2 (SKU: HW3919PC)

-

V-Core 4.0 - 300: Rat Rig V-Core 4.0 - Base Plate - 300 Front v1.2 (SKU: HW3918PC)

-

V-Core 4.0 - 400: Rat Rig V-Core 4.0 - Base Plate - 400 Rear v1.2 (SKU: HW3921PC)

-

V-Core 4.0 - 400: Rat Rig V-Core 4.0 - Base Plate - 400 Front v1.2 (SKU: HW3920PC)

-

V-Core 4.0 - 500: Rat Rig V-Core 4.0 - Base Plate - 500 Rear v1.2 (SKU: HW3921PC)

-

V-Core 4.0 - 500: Rat Rig V-Core 4.0 - Base Plate - 500 Front v1.2 (SKU: HW3922PC)

-

-

-

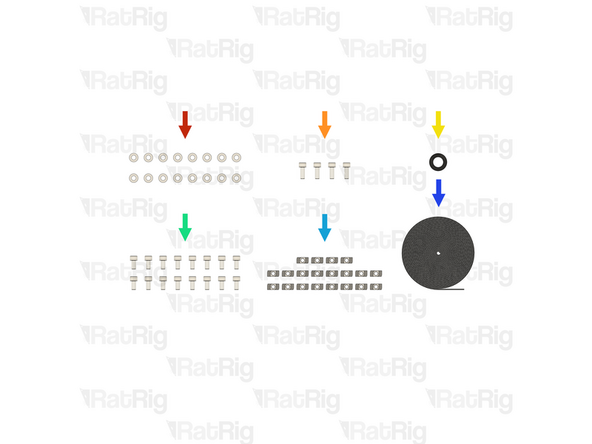

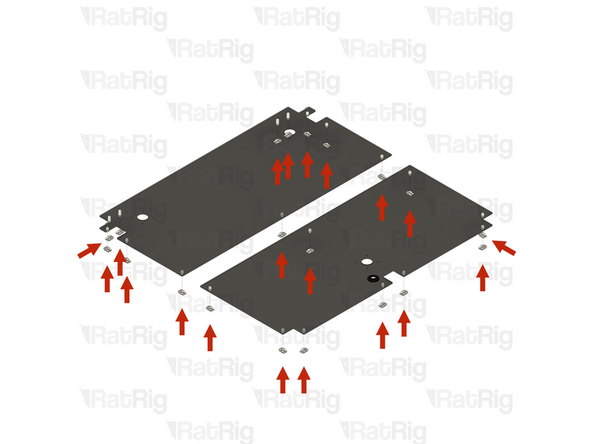

16x Washer Simple M6 - Black 12.9 Steel (SKU: HW2746NC)

-

4x M6x16 Cap Head Screw (SKU: HW2827SC)

-

1x Rubber Grommet - 18x14x3 (SKU: HW3783GC)

-

16x M6x12 Cap Head Screw (SKU: HW1836SC)

-

20x T-Nut - Drop In Type for 30 Series - M6 (SKU: HW1361NC)

-

22 Metres of Foam Strip - 1mm x 8mm - Adhesive 3M - EVA material (SKU: HW2943GC)

-

-

-

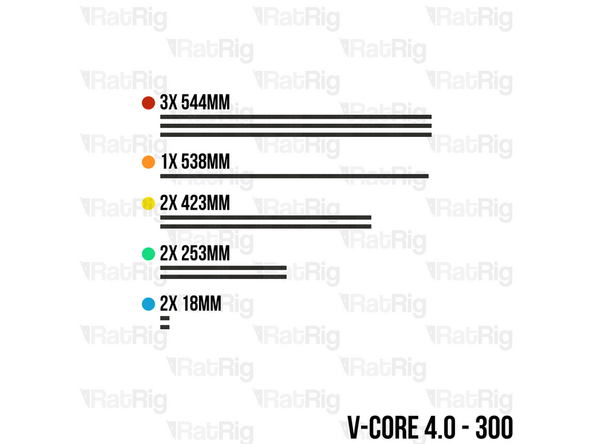

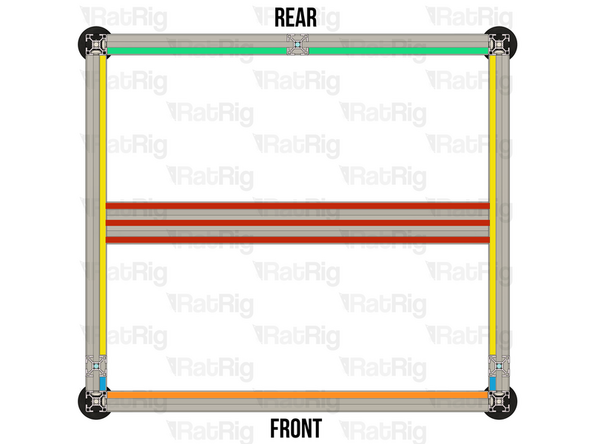

Using scissors, cut lengths of the foam strip based upon the size of the V-Core 4.0 being assembled:

-

3x 544mm (300) / 644mm (400) / 744mm (500)

-

1x 538mm (300) / 638mm (400) / 738mm (500)

-

2x 423mm (300) / 523mm (400) / 623mm (500)

-

2x 253mm (300) / 303mm (400) / 353mm (500)

-

2x 18mm (All sizes)

-

-

-

For each length of foam strip, carefully remove the backing paper which protects the adhesive and then apply it to the frame in the positions shown:

-

544mm (300) / 644mm (400) / 744mm (500)

-

538mm (300) / 638mm (400) / 738mm (500)

-

423mm (300) / 523mm (400) / 623mm (500)

-

253mm (300) / 303mm (400) / 353mm (500)

-

18mm (All sizes)

-

-

-

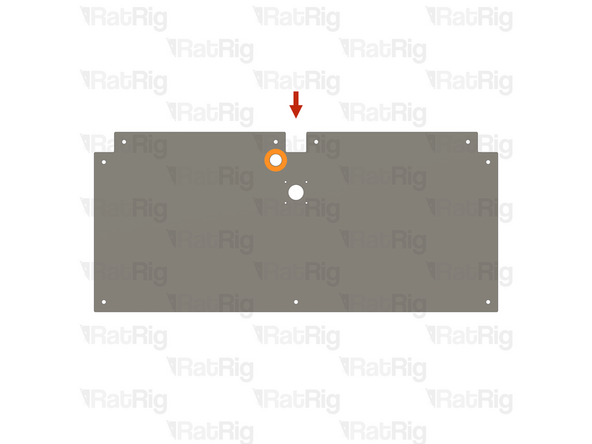

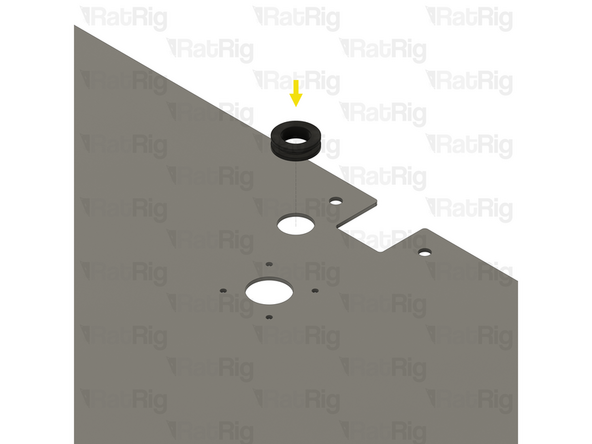

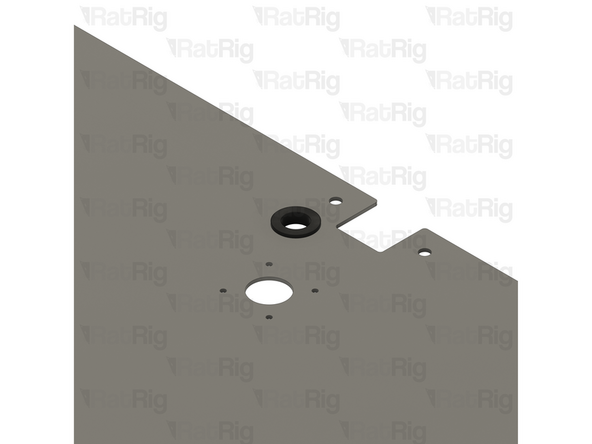

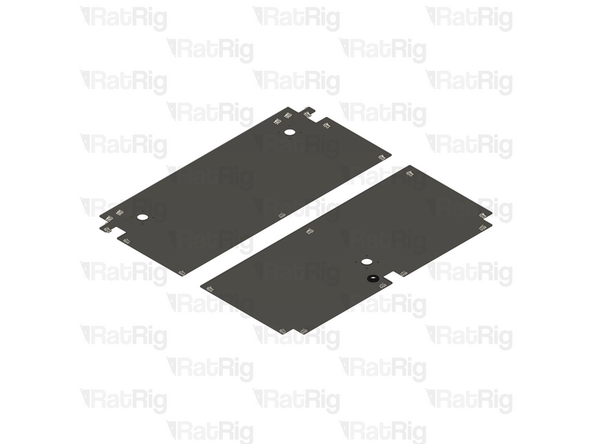

Rat Rig V-Core 4.0 - Base Plate - Rear

-

Locate the marked hole on the base plate

-

Rubber Grommet - 18x14x3

-

Install the Rubber Grommet into the marked hole. The grommet is flexible so it can be deformed to install it

-

-

-

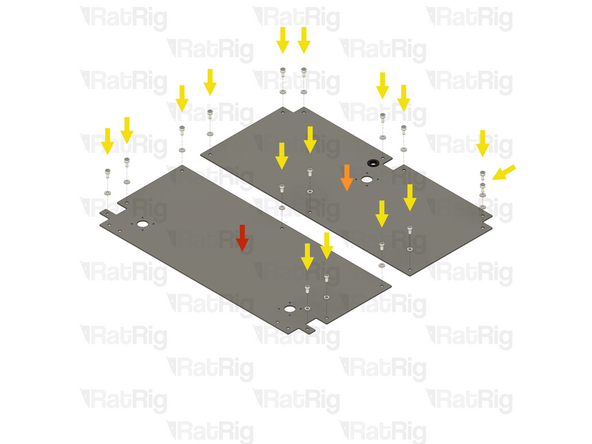

Rat Rig V-Core 4.0 - Base Plate - Rear

-

Make sure the rear base plate is oriented with the grommet offset to the left

-

Rat Rig V-Core 4.0 - Base Plate - Front

-

16x M6x12 Cap Head Screw

-

16x Washer Simple M6 - Black 12.9 Steel

-

Install an M6 washer onto each of the M6x12 Cap Head Screws and then insert the screw into each of the holes shown

-

4x M6x16 Cap Head Screw

-

Insert an M6x16 Cap Head Screw into each of the four holes along the front edge of the front base plate

-

-

-

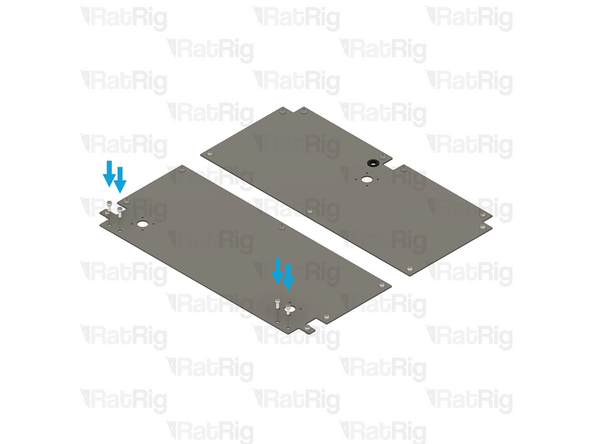

20x T-Nut Drop-in for 30 series - M6

-

Loosely thread a 3030 T-nut onto each of the sixteen M6x12 Cap Head Screws and onto each of the four M6x16 Cap Head Screws. Do not tighten any of them at this point

-

Please note: The base plates for both the V-Core 4.0 400 and V-Core 4.0 500 have six additional mounting holes which are not used in the default kit

-

These additional holes are provided to allow the optional installation of extra brackets for increased frame stiffness

-

-

-

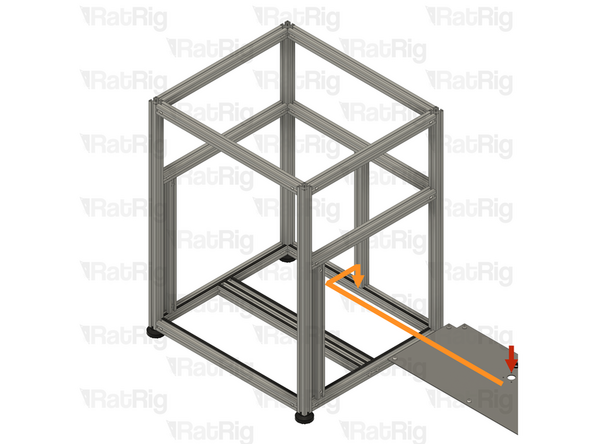

Rear Base Plate assembly from the previous step

-

Insert the Rear Base Plate into the side of the frame assembly, sliding it to the back, and then downwards to rest on the base of the frame assembly

-

Be careful not to scratch the aluminium extrusions when installing the Rear Base Plate

-

Make sure all of the T-Nuts are slotted into the extrusions

-

Secure the Rear Base Plate to the frame assembly by tightening all nine M6x12 screws

-

The ninth screw is obscured in the image

-

-

-

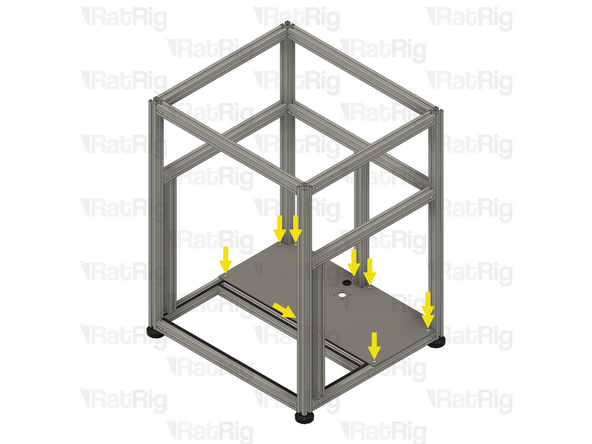

Front Base Plate assembly from step 46

-

Insert the Front Base Plate into the front of the frame assembly, at a 45-degree angle

-

Move the left-hand side of the Front Base Plate into position above the bottom left-hand side extrusions

-

Rotate the right-hand side of the Front Base Plate downwards until it sits flat within the frame assembly

-

Be careful not to scratch the aluminium extrusions when installing the Front Base Plate

-

Make sure all of the T-Nuts are slotted into the extrusions

-

-

-

Make sure that the Front Base Plate is fully seated in the base of the frame assembly

-

Secure the Front Base Plate to the frame assembly by tightening all seven M6x12 screws

-

Do not tighten the four M6x16 Cap Head Screws along the front edge at this point

-

-

-

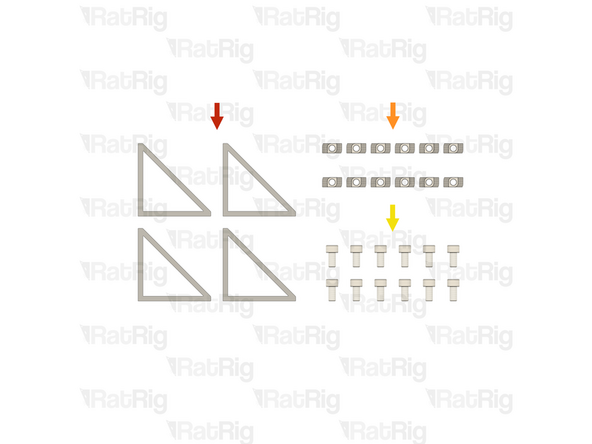

4x Bracket - Extruded 90º Corner for 30 series - 6030 Tall - Black (SKU: HW3162BC)

-

12x T-Nut - Drop In Type for 30 Series - M6 (SKU: HW1361NC)

-

12x M6x12 Cap Head Screw (SKU: HW1836SC)

-

-

-

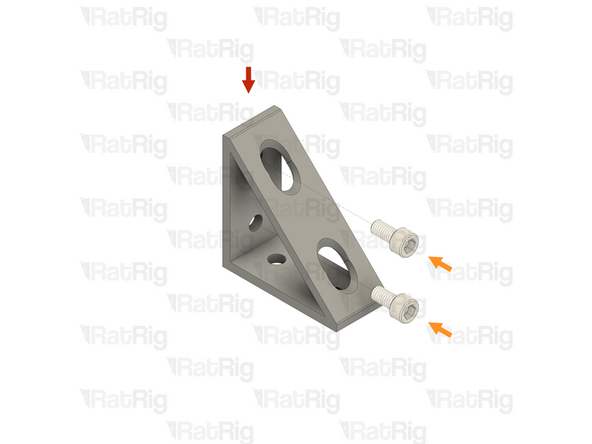

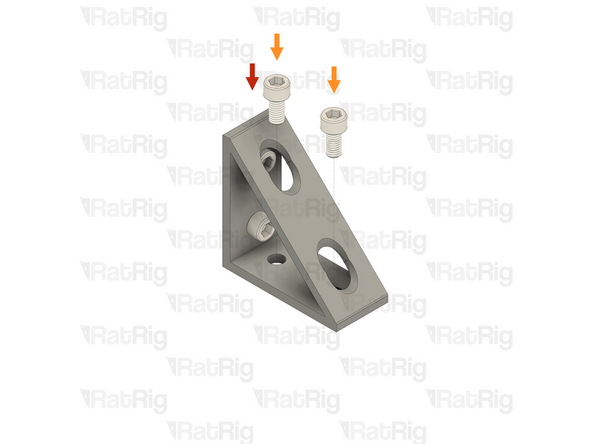

Bracket - Extruded 90º Corner for 30 series - 6030 Tall - Black

-

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the two holes on one side of the bracket as shown

-

2x T-Nut - Drop In Type for 30 Series - M6

-

Loosely thread a 3030 T-nut onto each of the two M6x12 Cap Head Screws. Do not tighten any of them at this point

-

Prepare four of these assemblies. Set two aside until step 53 and keep two for the next step

-

-

-

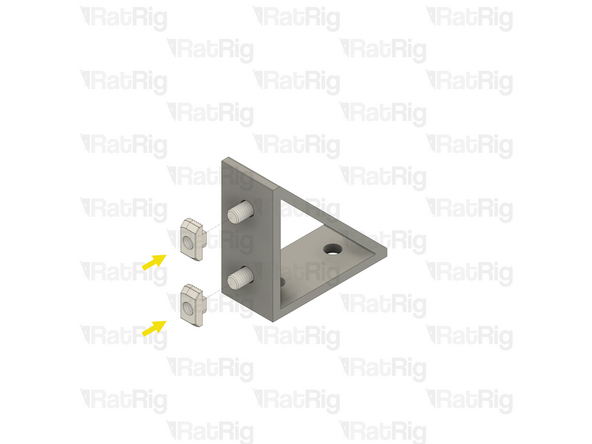

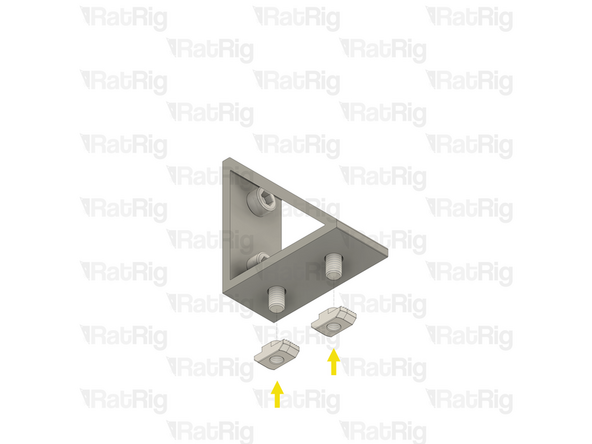

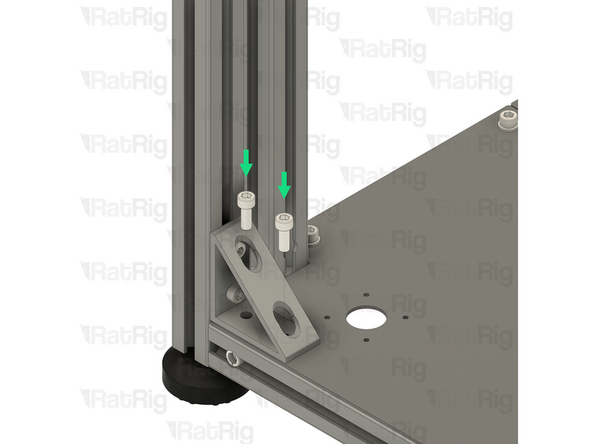

Lower frame bracket assemble from the previous step

-

2x M6x12 Cap Head Screw

-

Insert an M6x12 Cap Head Screw into each of the two holes on the remaining side of the bracket as shown

-

2x T-Nut - Drop In Type for 30 Series - M6

-

Loosely thread a 3030 T-nut onto each of the two M6x12 Cap Head Screws. Do not tighten any of them at this point

-

Prepare two of these assemblies and set them both aside until step 55

-

-

-

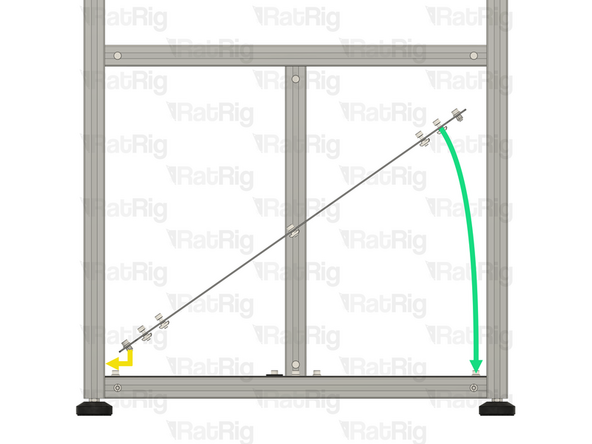

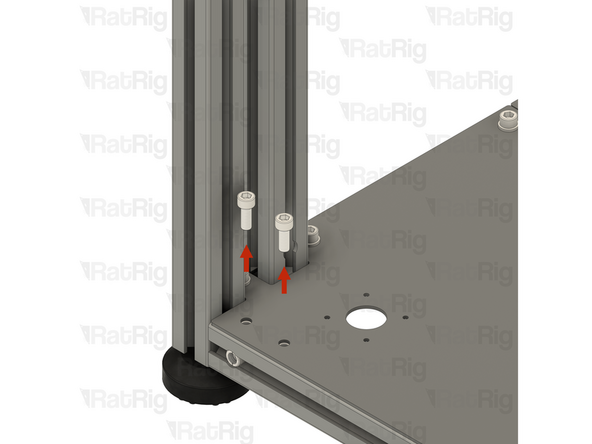

2x M6x16 Cap Head Screw

-

Carefully unscrew and remove both M6x16 Cap Head Screws, set them aside for a moment

-

It is important not to move the T-Nuts hidden under the Base Plate

-

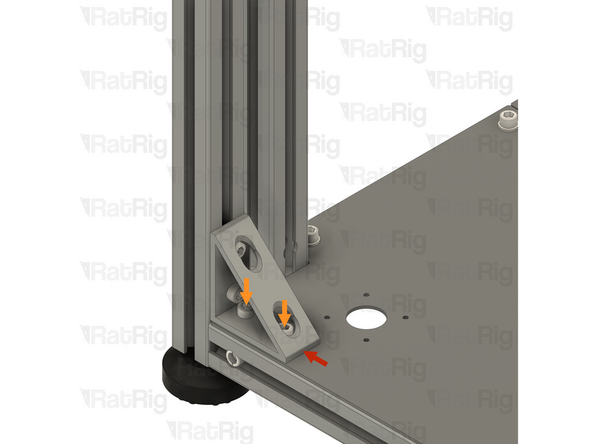

Lower frame bracket assembly from step 51

-

Position the lower frame bracket as shown. The bottom holes in the bracket should align with the holes in the Base Plate

-

Make sure both of the T-Nuts are slotted into the extrusion

-

Insert the two M6x16 Cap Head Screws into the lower frame bracket and loosely thread them back into the T-Nuts under the Base Plate

-

Do not tighten any of the M6x12 or M6x16 Cap Head Screws at this point

-

-

-

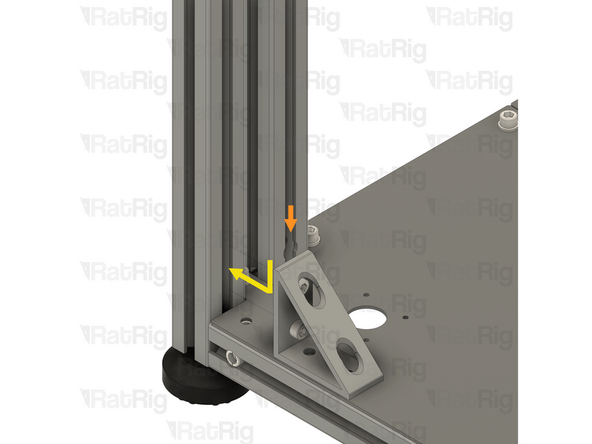

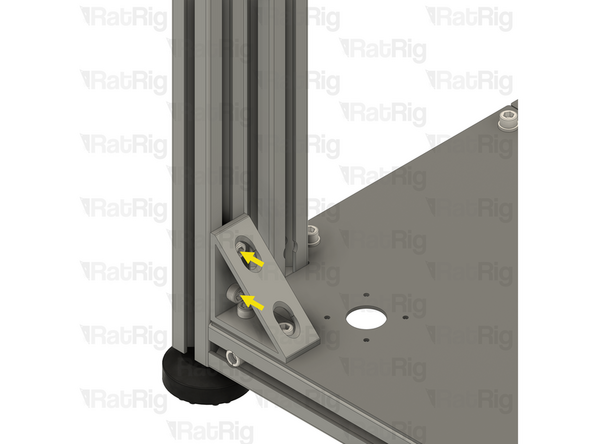

Press the lower frame bracket against the side 3030 extrusion

-

Fully tighten both of the M6x16 Cap Head Screws to secure the lower frame bracket to the Base Plate

-

Fully tighten both of the M6x12 Cap Head Screws to secure the lower frame bracket to the 3030 extrusion

-

Repeat both the previous step, and this step, to install the lower right frame bracket

-

-

-

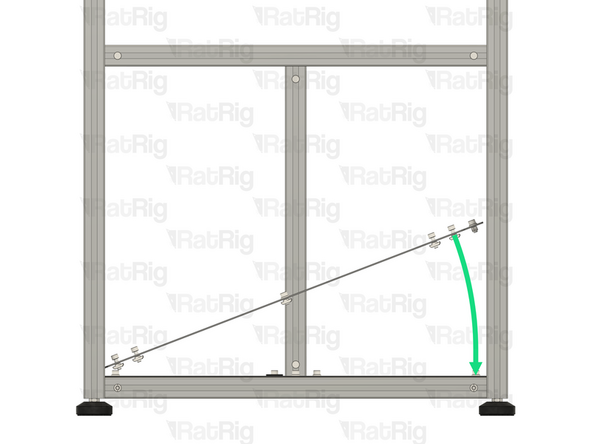

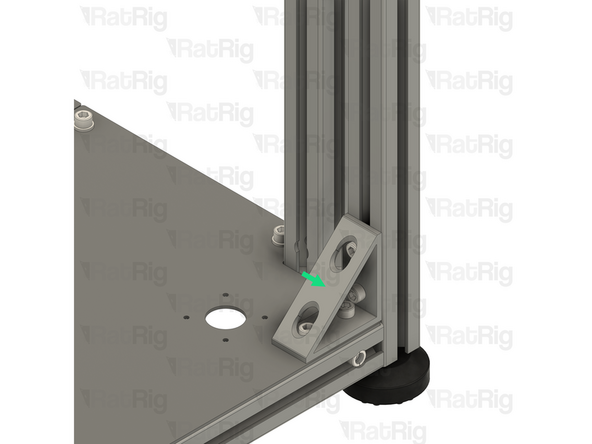

Upper frame bracket assembly from step 52

-

Position the upper frame bracket into the corner of the extrusions as shown

-

Make sure all of the T-Nuts are slotted into the extrusions

-

Press the upper frame bracket into the corner of the 3030 extrusions

-

Fully tighten all four of the M6x12 Cap Head Screws to secure the upper frame bracket to the frame

-

-

-

Repeat the previous step, to install the upper right frame bracket

-

Verify that all 4 frame brackets are correctly installed and that all Cap Head Screws are fully tightened

-

Cancel: I did not complete this guide.

51 other people completed this guide.